Objectives

The purpose of this week session was to complete a individual task and group task. This session was about using the CNC Router machine in the FabLab for fabricating a large-scale project.

Individual Task: Design and and Fabricate a Large-scale project using CNC router machine.

Group Task: Test a turnout and toolpath of a CNC Router machine at the FabLab.

Individual Task: Design and Fabricate a Wooden Reclining Chair!

3D Modelling of reclinging chair in SolidWorks Software

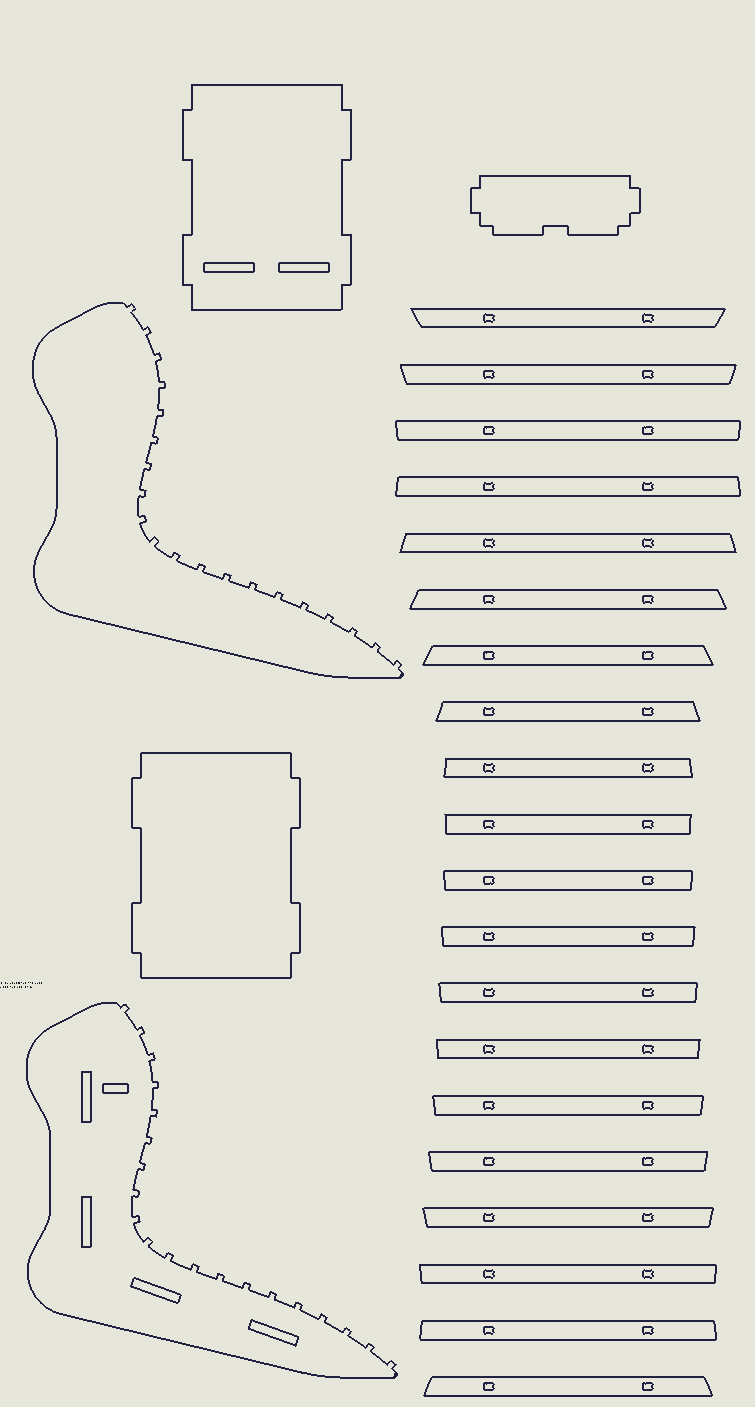

This task was divided into two subsections i.e. Digitization and Fabrication. In digitization phase, the 3D model of the reclining chair was created in the SolidWork software using multiple features.

Then the 3D model of reclining chair was converted into .DXF file format in order for the CNC router machine to read the file.

Fabricating the 3D model of Reclining Chair in CNC Router Machine

The ShopBot CNC Router machine would be used for fabricating the reclining chair using the MDF Wood. The ShopBot CNC machine in the FabLab is fully capable of fabricating 3D model and the following is the discription about the machine.

Model: PRSapha 96-48.

Movement and Cut Area: 2.49m X 1.27m X 0.2m.

FootPrint: 3.05m X 2.01m X 1.70m

Step Resolution: 0.0127mm

After digitizing the 3D model in the SolidWorks software, the .DXF file of the model was imported into the CNC Router machine VCarve software for calibration. The following are the steps that for setting the machine for fabrication.

Intially, the MDF wood of thickness 18mm was placed on the cutting surface and secured by drilling the screw bolts on four corners to prevent it from moving during operation.

Then the cutting bit was selected and changed onto the machine spindle and for our project, the bit size was selected to be 12mm based on the smallest dimension of the reclining chair.

This task was divided into two subsections i.e. Digitization and Fabrication. In digitization phase, the 3D model of the reclining chair was created in the SolidWork software using multiple features.

Fabricating the 3D model of Reclining Chair in CNC Router Machine

After digitizing the 3D model in the SolidWorks software, the .DXF file of the model was imported into the CNC Router machine VCarve software for calibration. The following are the steps that for setting the machine for fabrication.

Group Task: Test a turnout and toolpath of a CNC Router machine at the FabLab!

This task was to test the working mechanism of the CNC Router machine by testing its toolpath, speed and homing the coordinates. However, due to the recent outbreak of the COVID-19 Virus that resulted in closure of the FabLab. The following is the list of tasks that was completed in this task.

The internal angels of the workpiece cannot have have sharp edges due to the diameter of the cutting tool thereby creating a fillet edge. This problem can be resolved if we cut the internal angles of the workpiece in the form of "dog bone" or with small indentions.

The calibration of the Z axis for the CNC Router machine was also done using a metal plate in to determine the Z-axis height from the workpiece.