Objectives

The purpose of this week session was to complete a individual task and group task. This session was about Molding and Casting a 3D model.

Individual Task: Design a 3D model around a stock and use the tools in the FabLab to Cast the parts.

Group Task: Review the Material Safety Data Sheet (MSDS) for Molding and Casting Materials.

Individual Task: Design a 3D Model around a Stock and use the tools in The FabLab to Cast the Part!

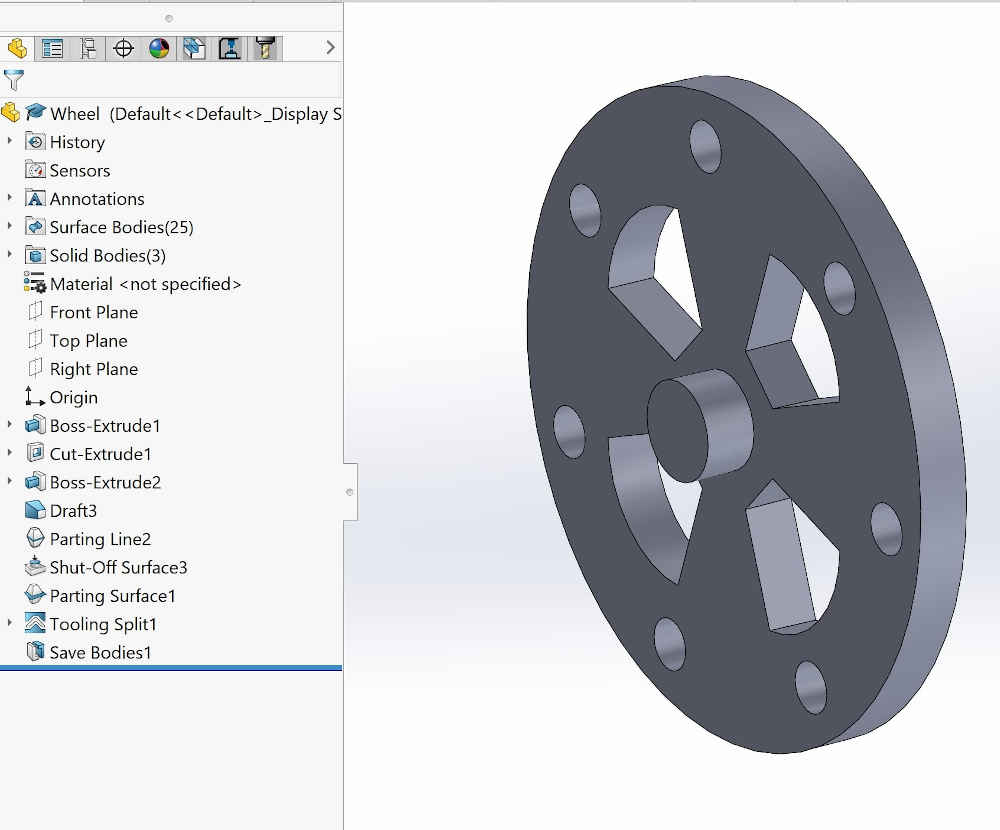

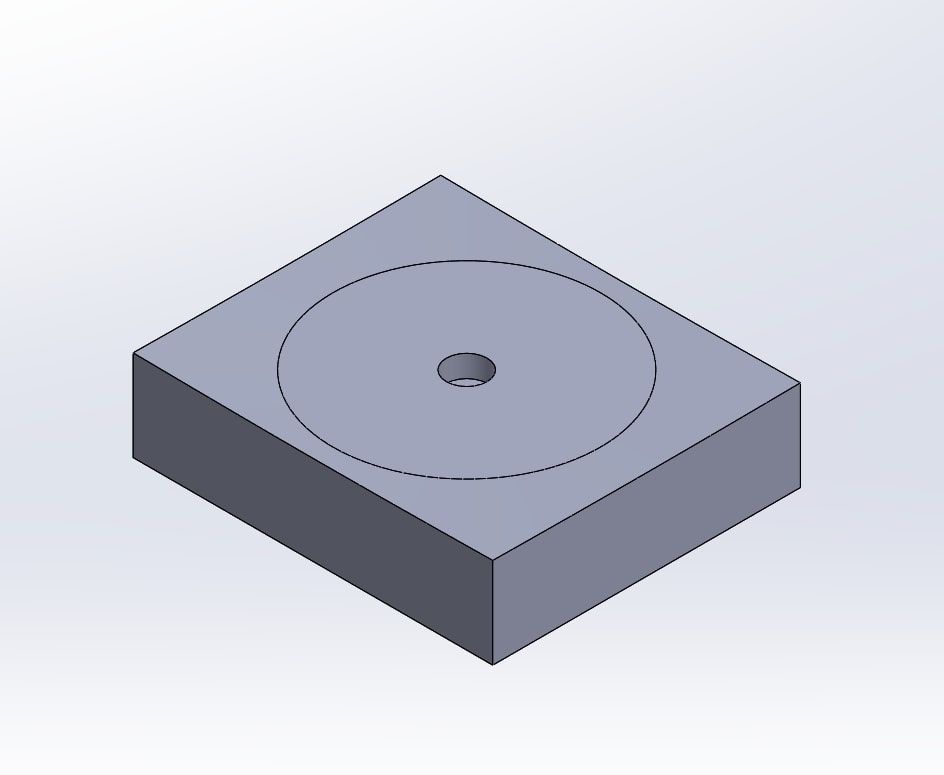

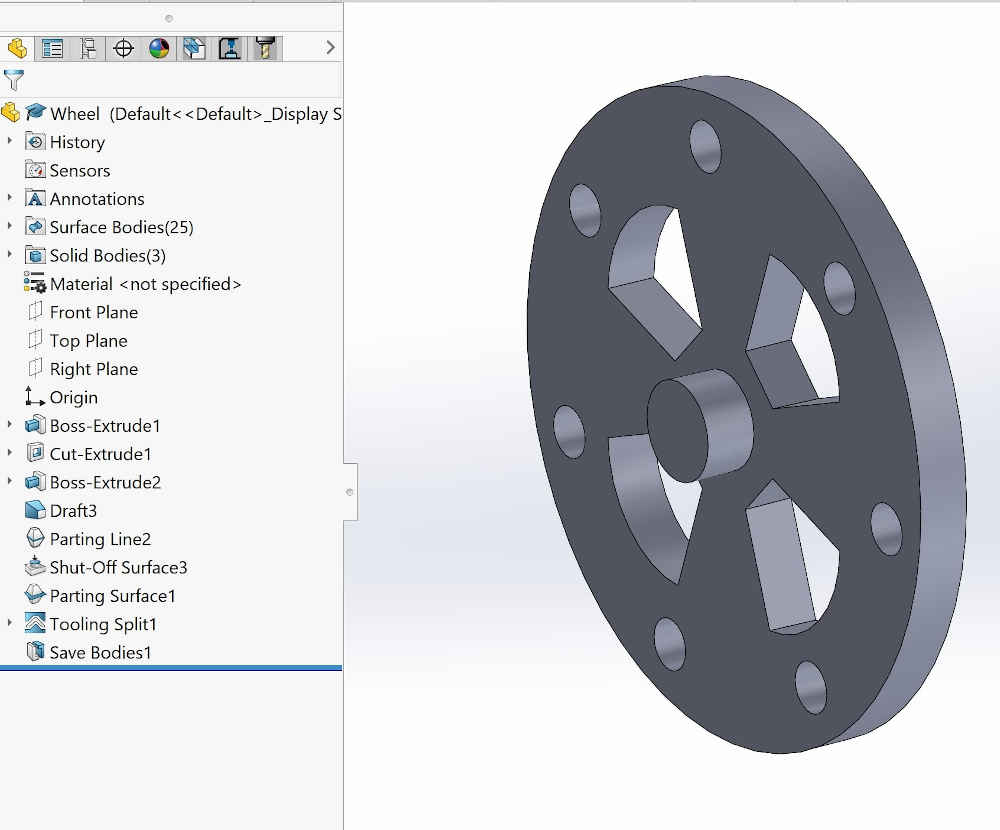

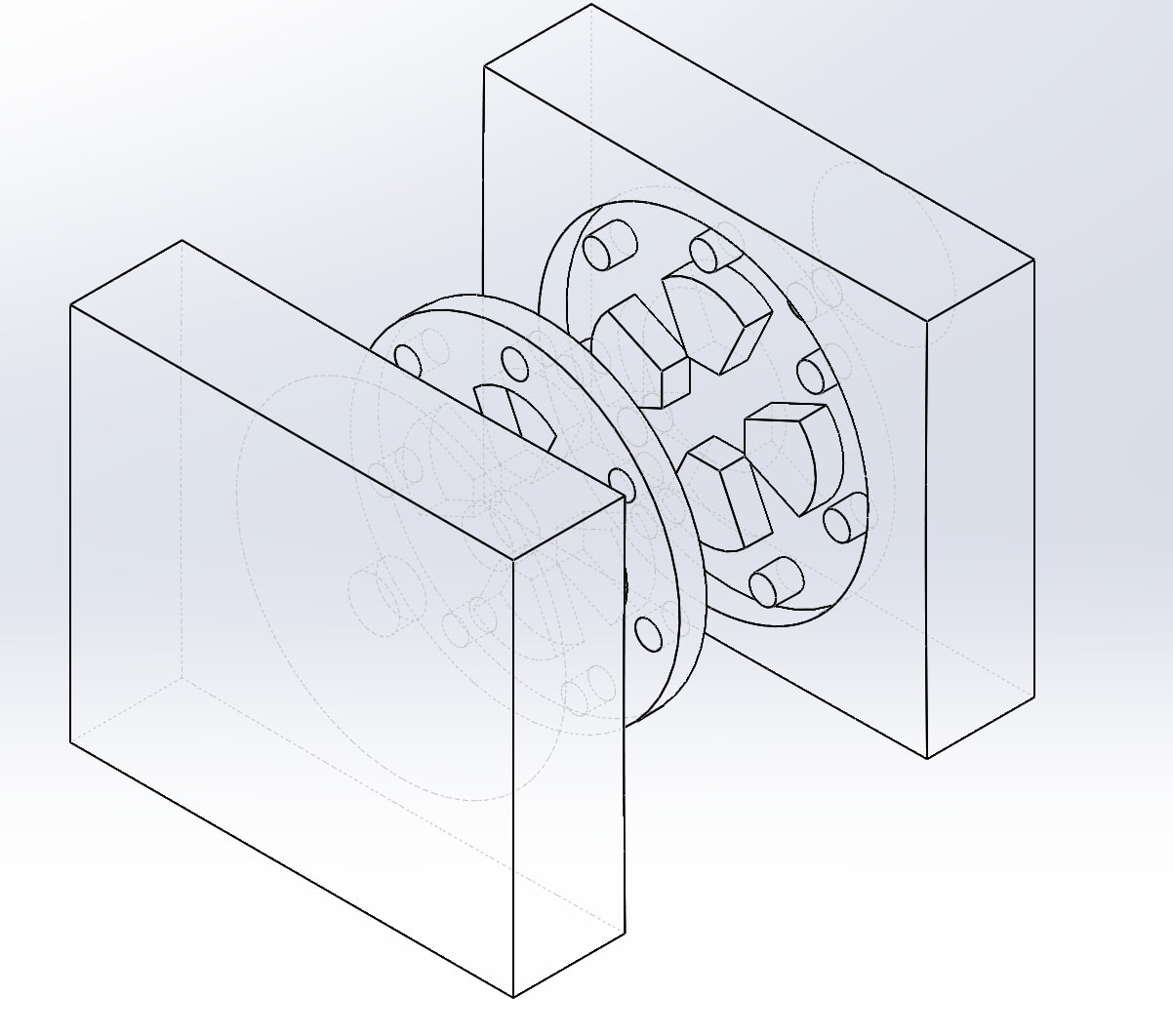

This task was began by digitizing the wheel in the SolidWorks software using the multiple features.

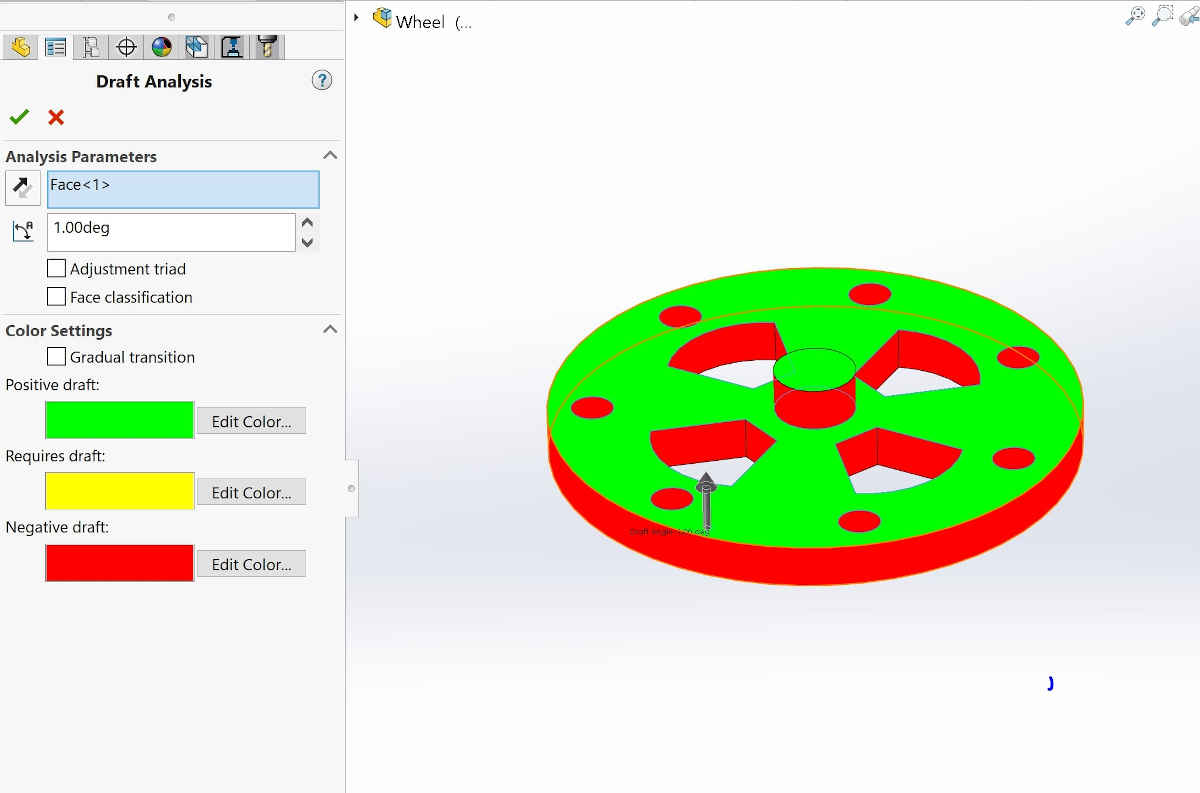

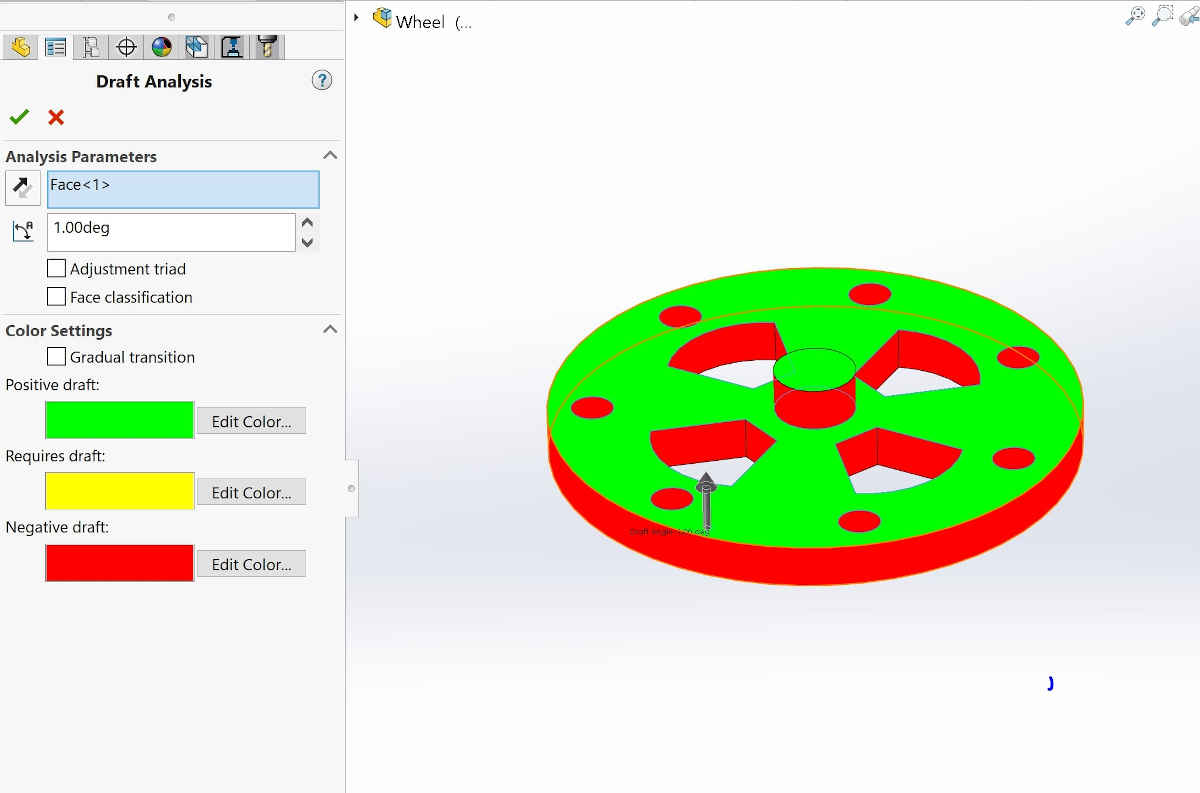

Then the 3D model of the wheel was subjected to Draft Analysis prior to molding process in order to determine the angles and surface that needs to be fixed before the molding process.

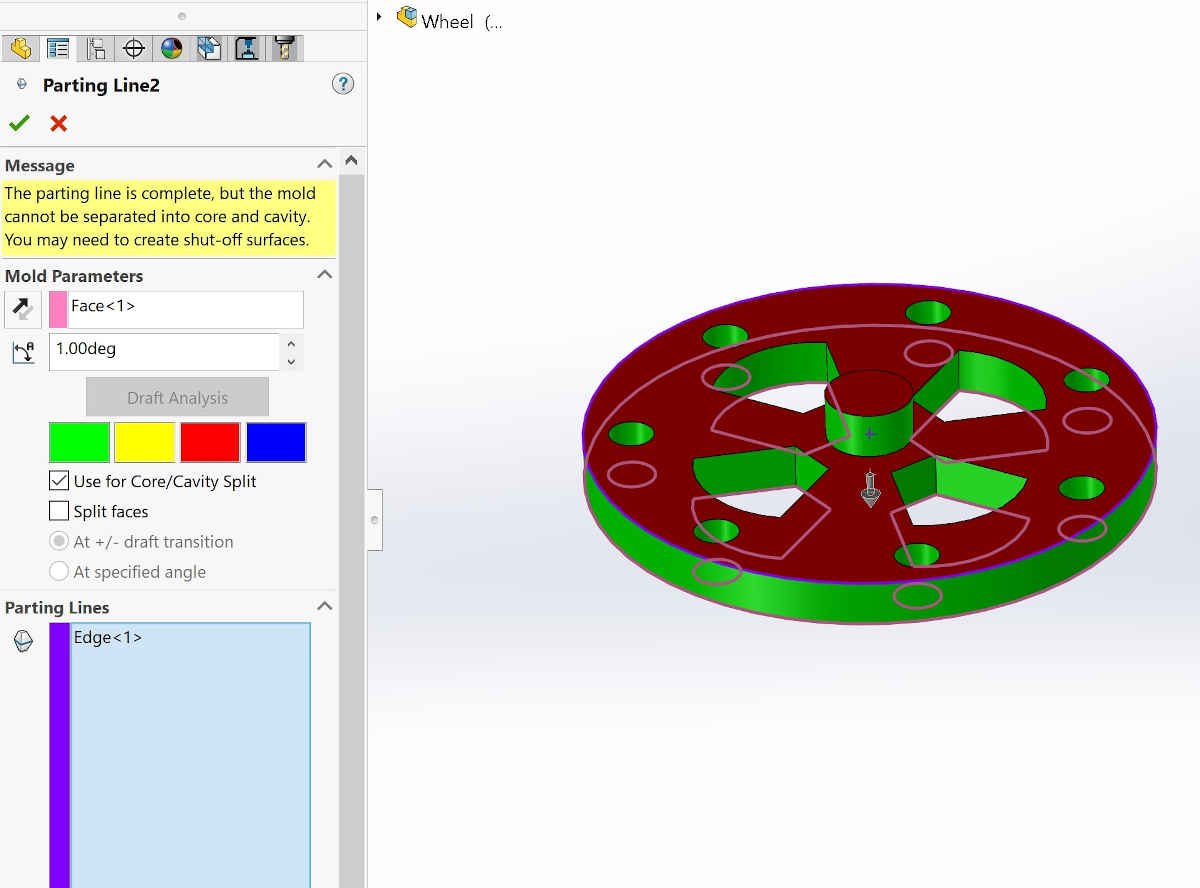

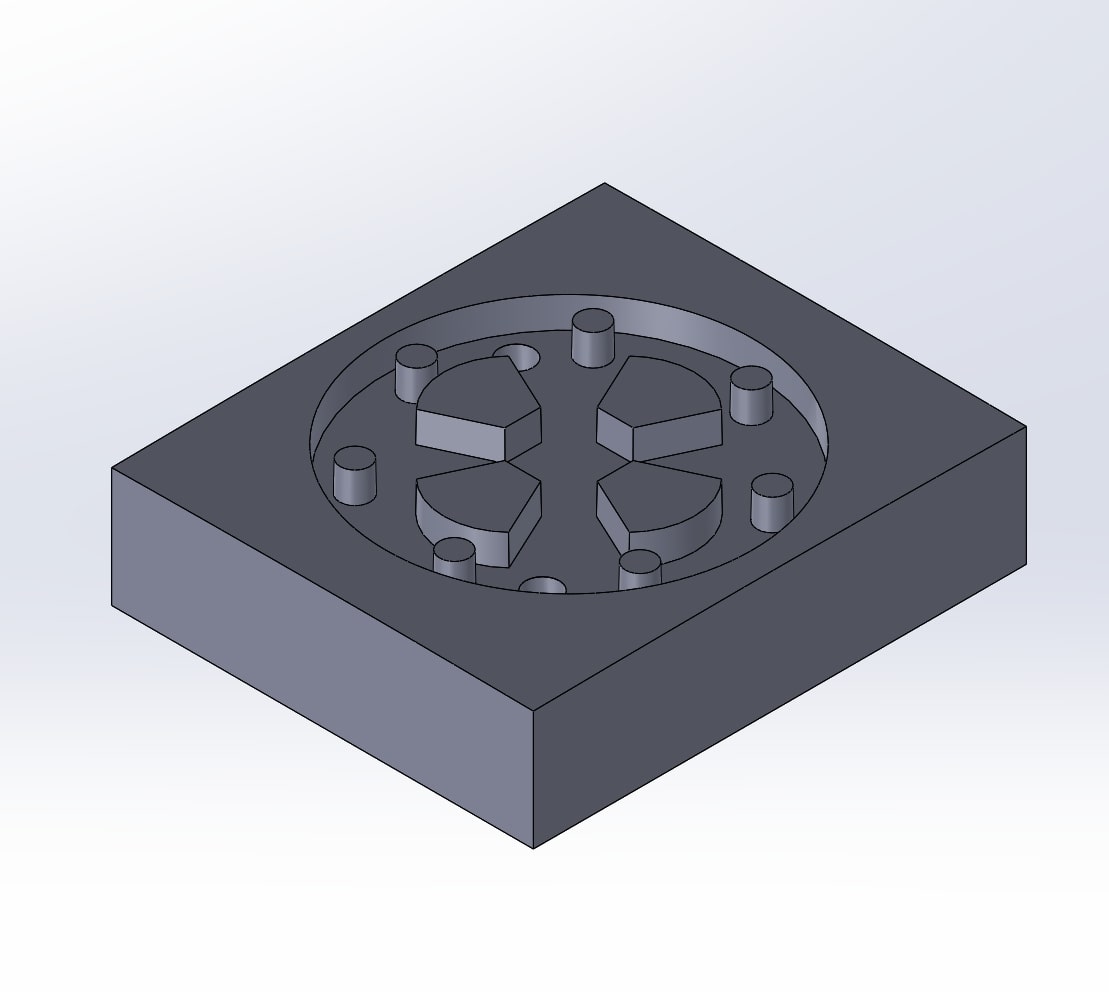

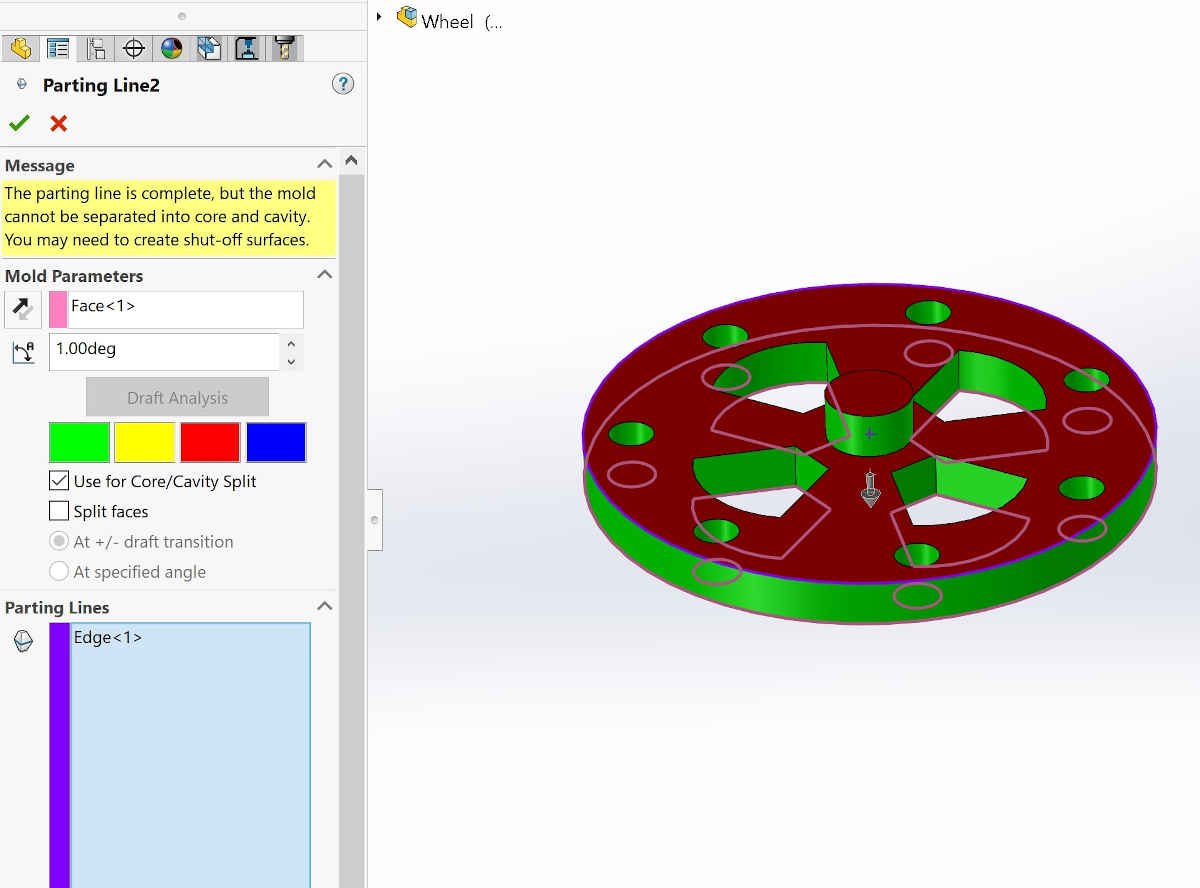

This was followed by defining the parting line for the model where it can be be split in two halves during molding process.

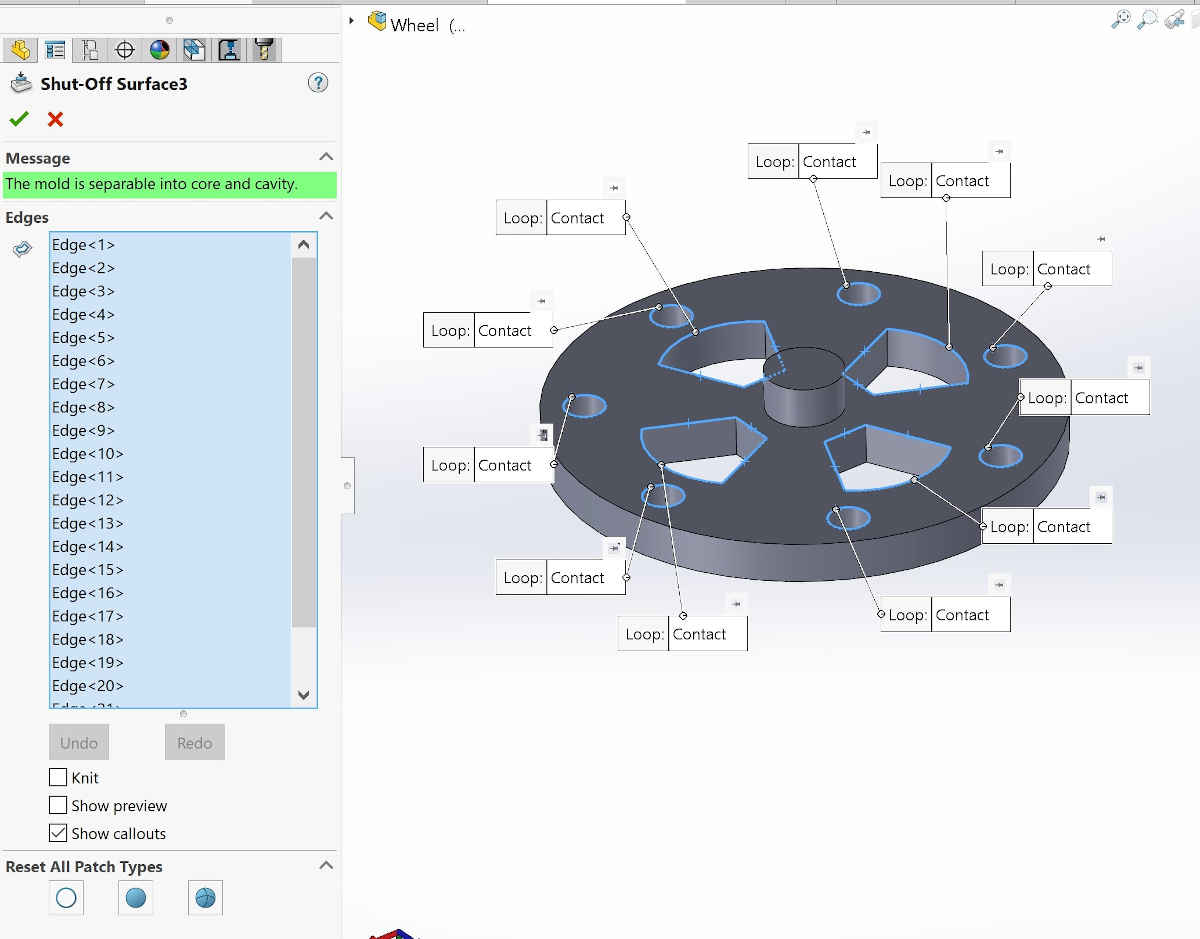

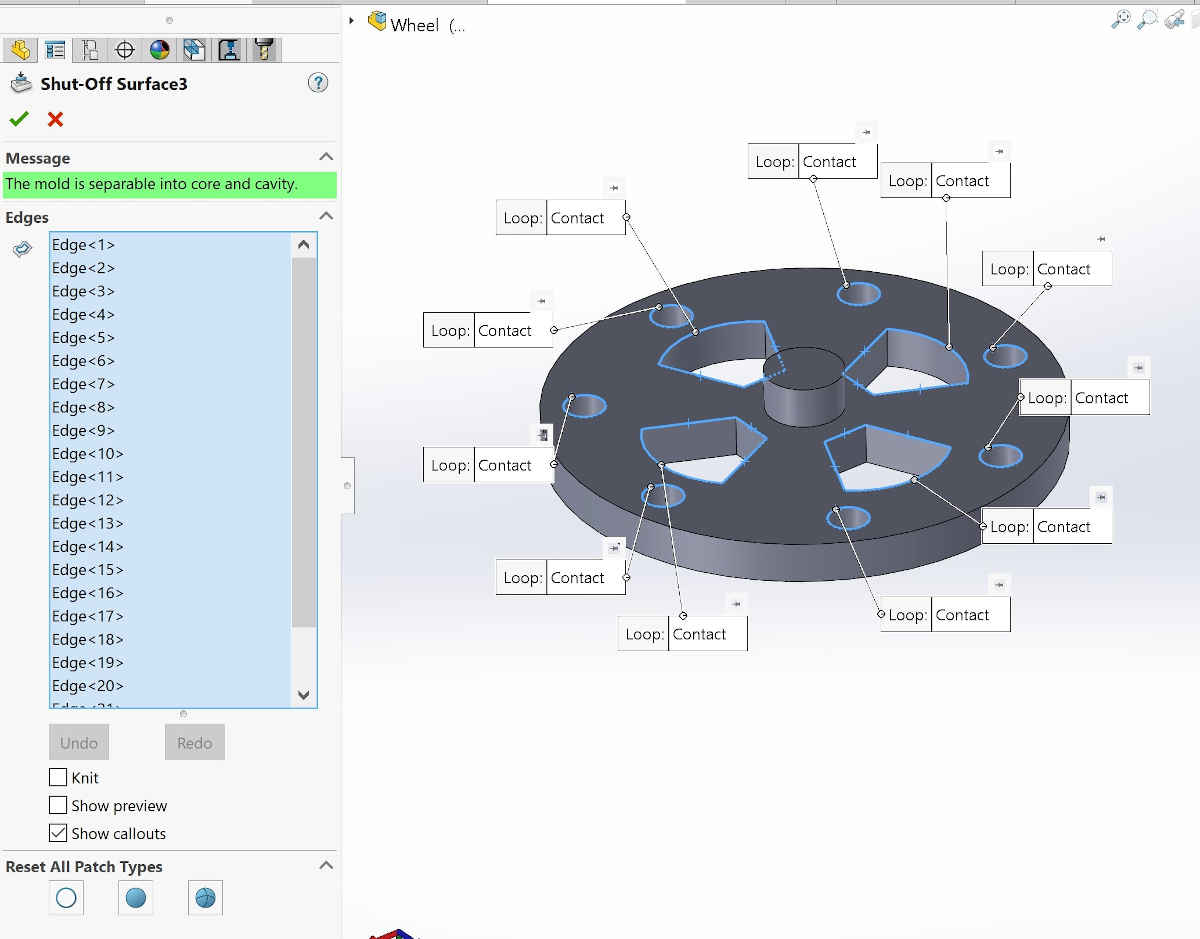

Then the empty cavities on the wheel were filled in order to create a mold using the Shutoff Surface feature.

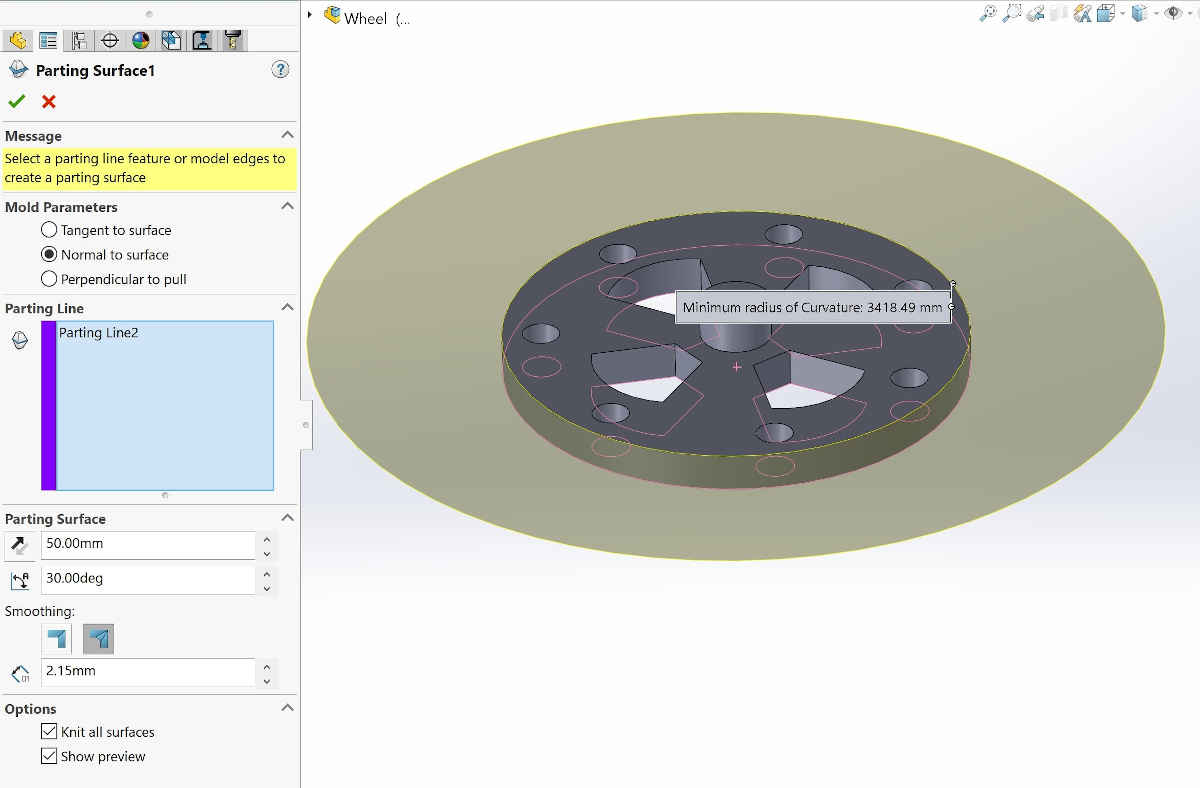

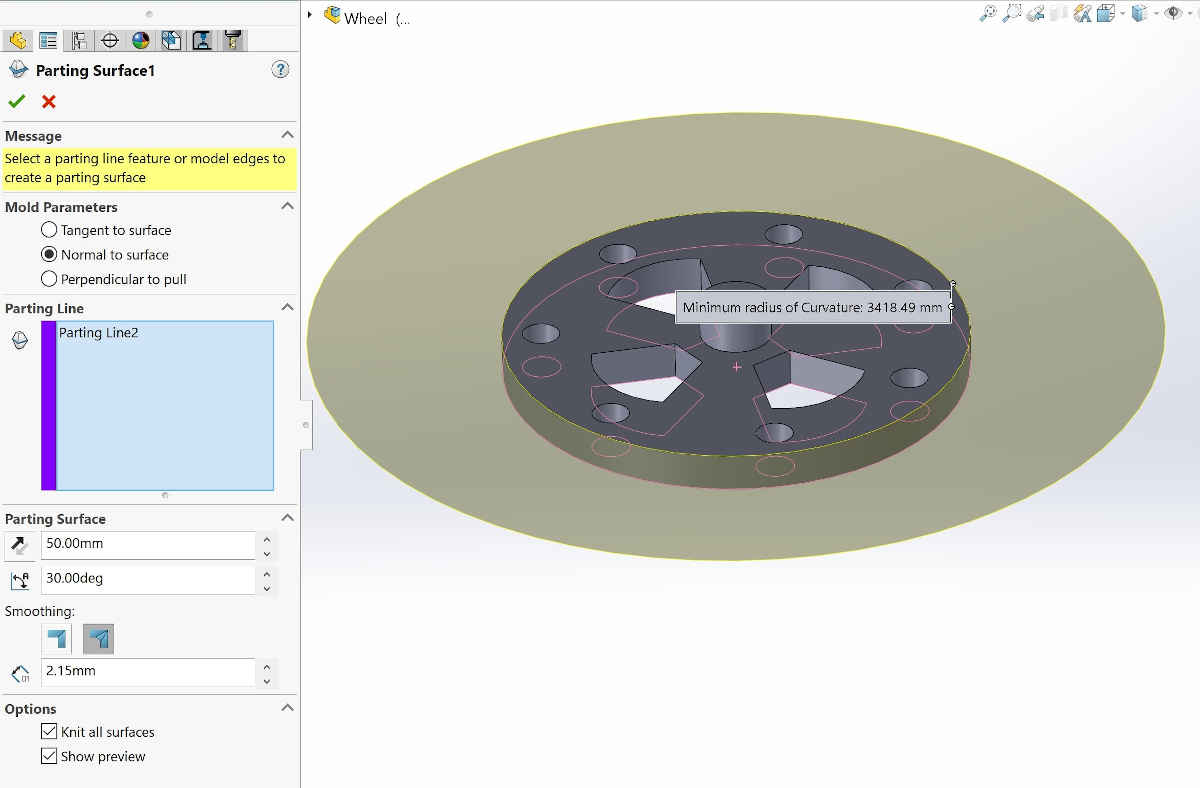

Then the parting surface was created where the parting line was defined in order to split the model into two halves.

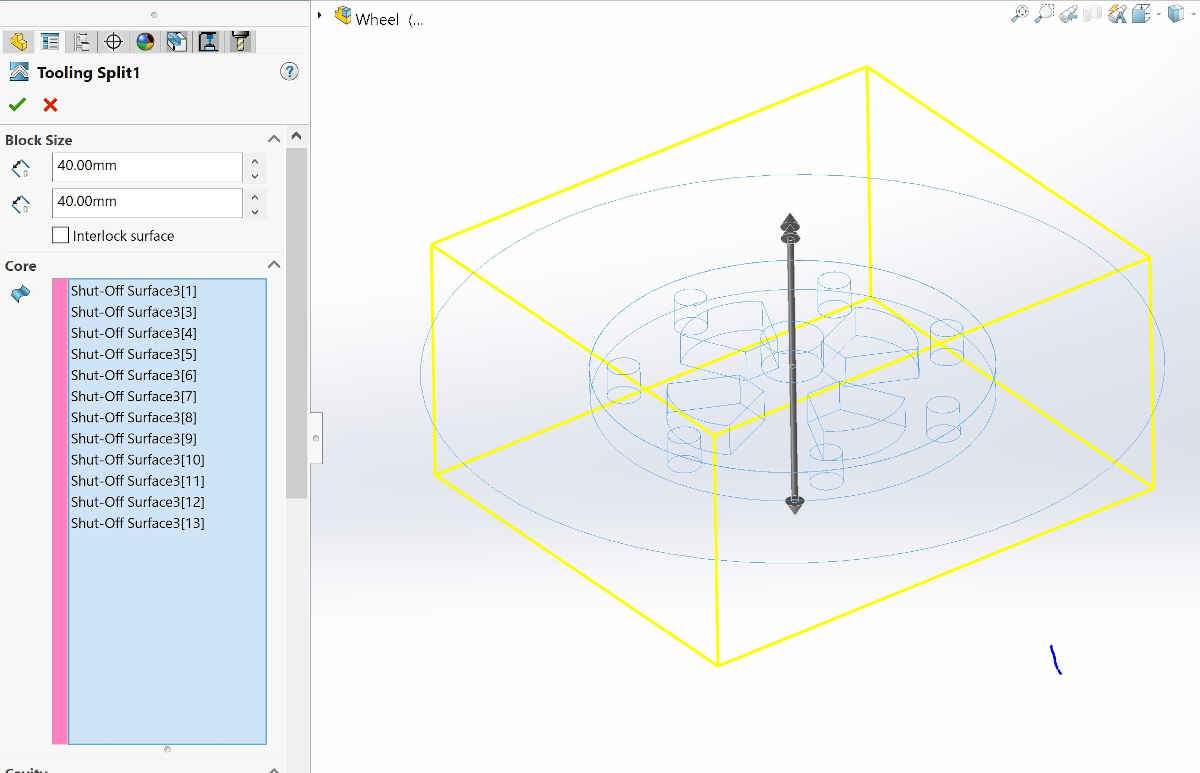

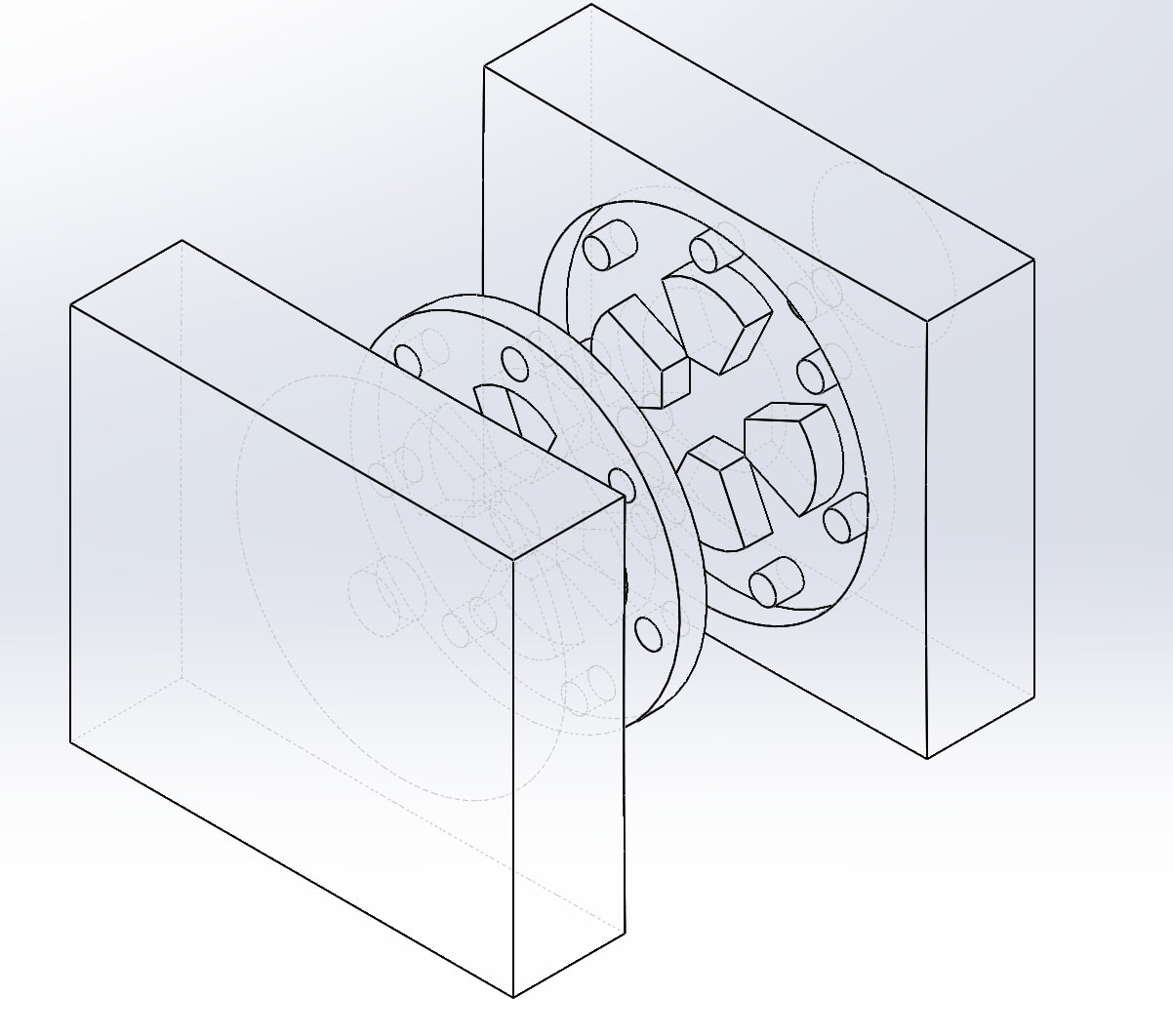

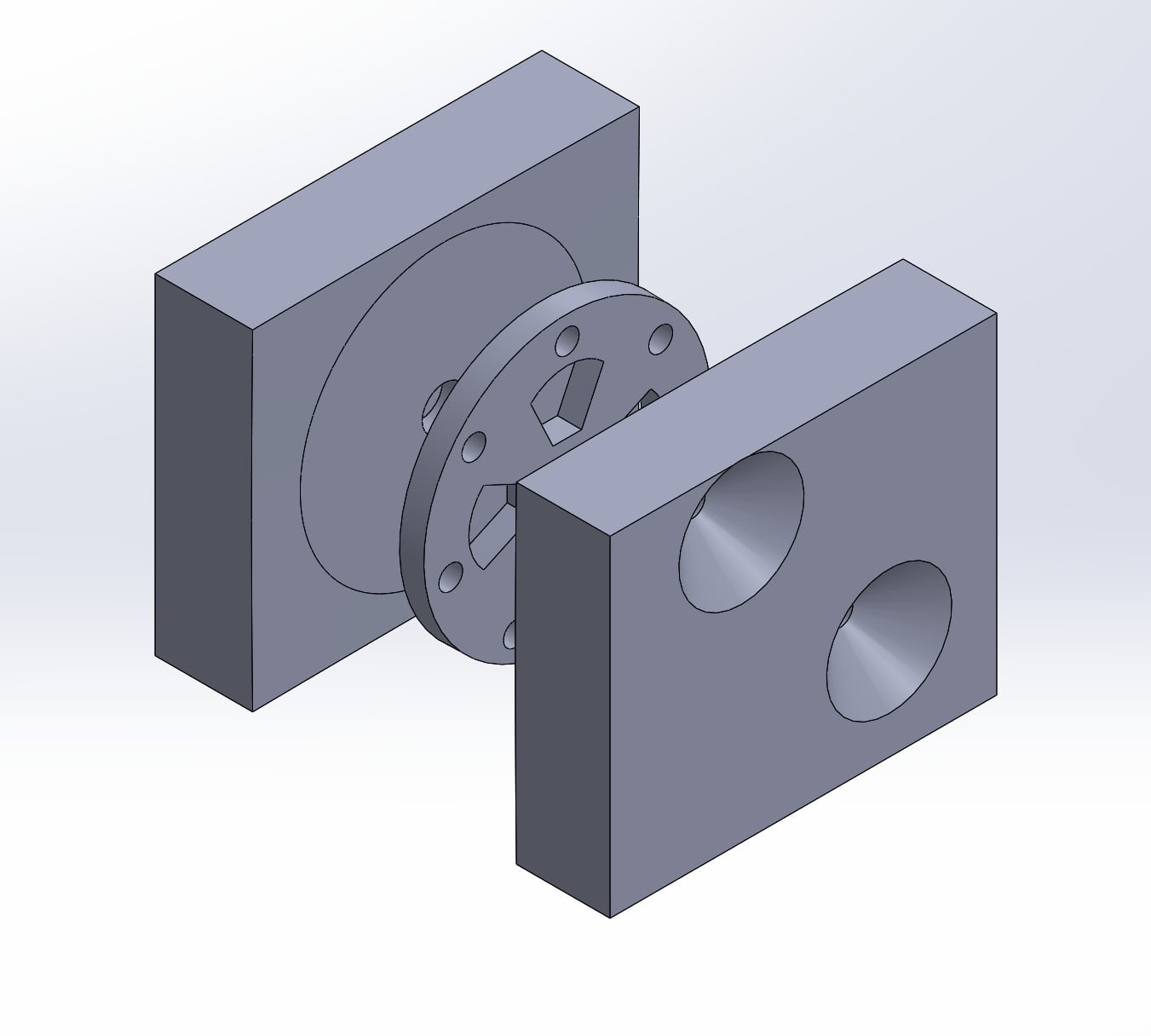

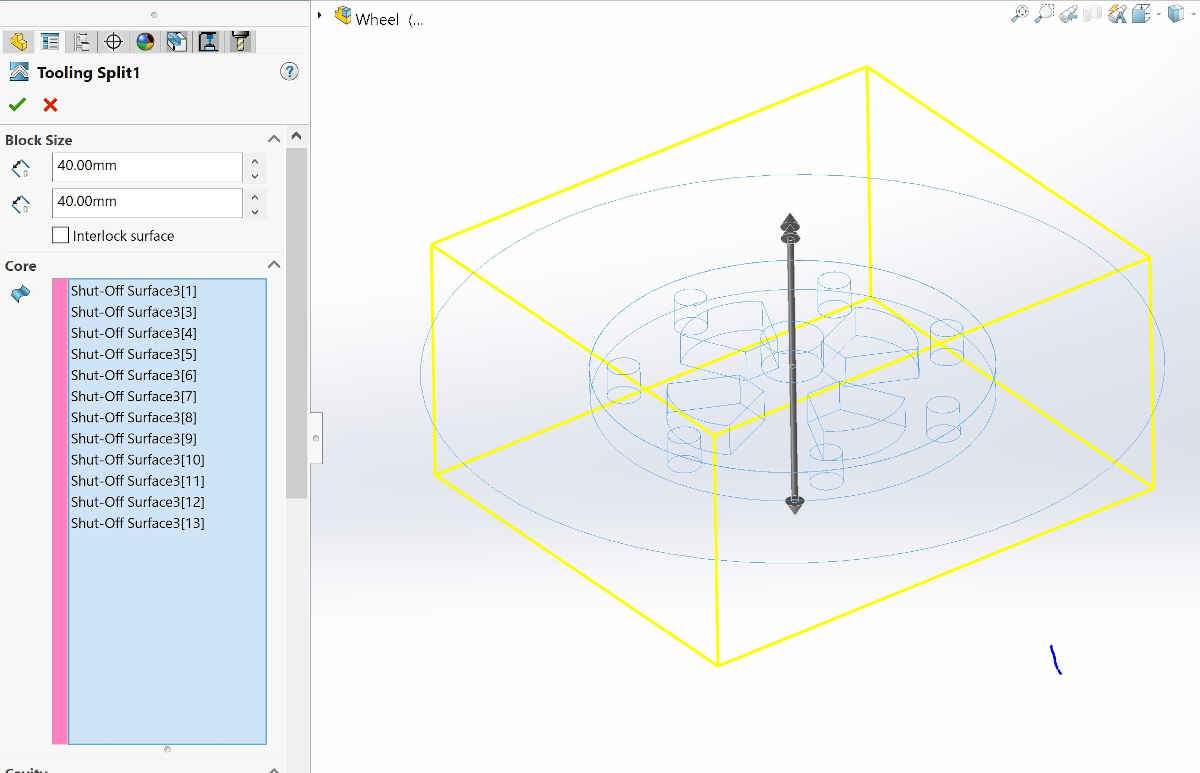

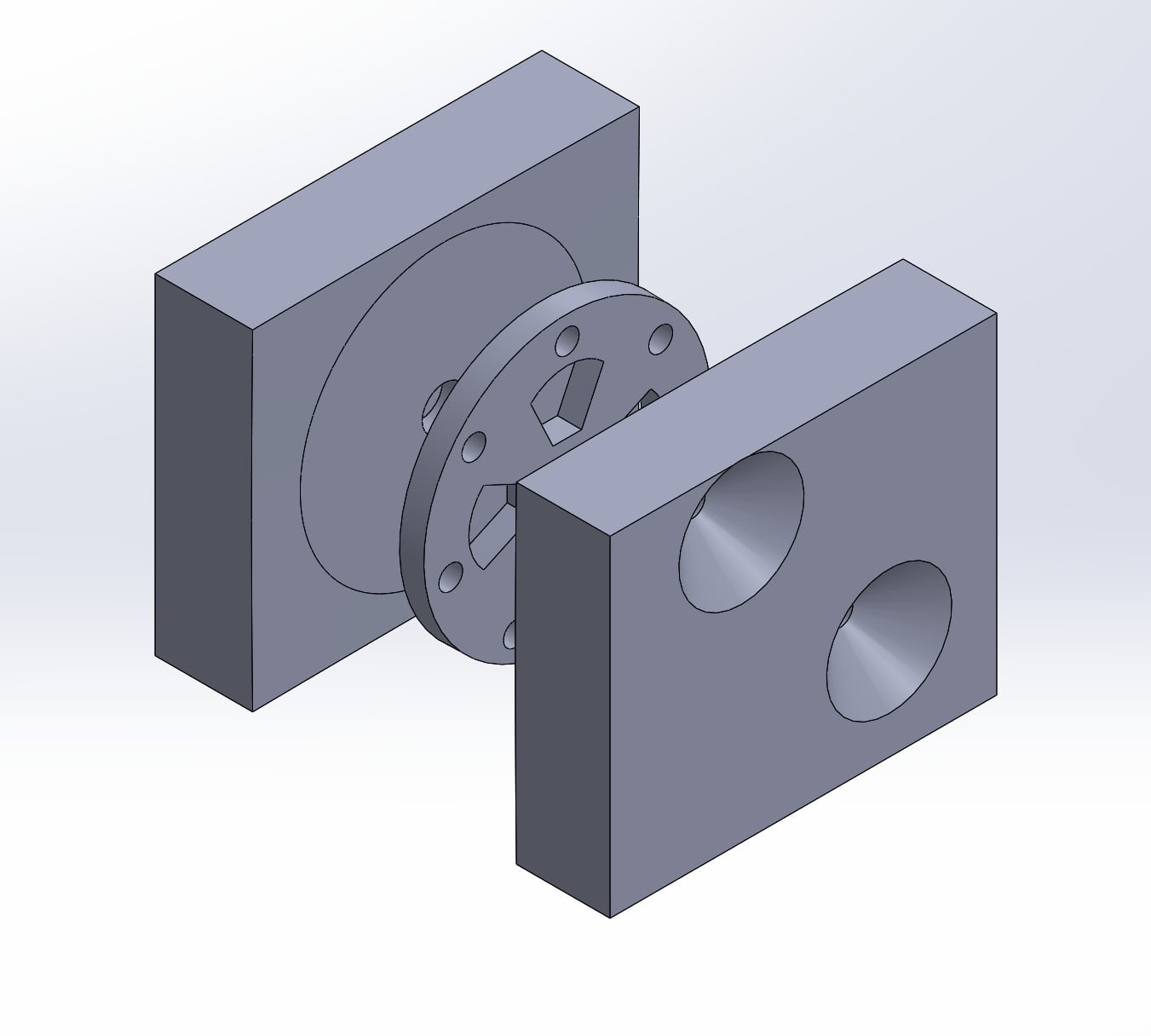

Finally, the mold dimensions for the 3D model was defined using the Tooling Split feature.

\

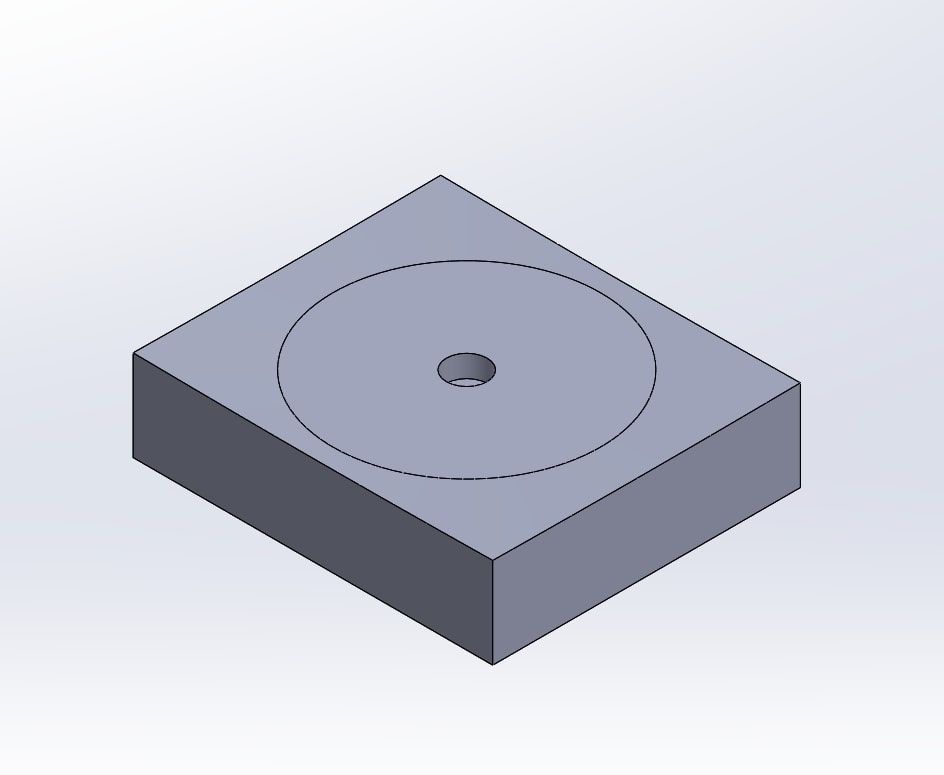

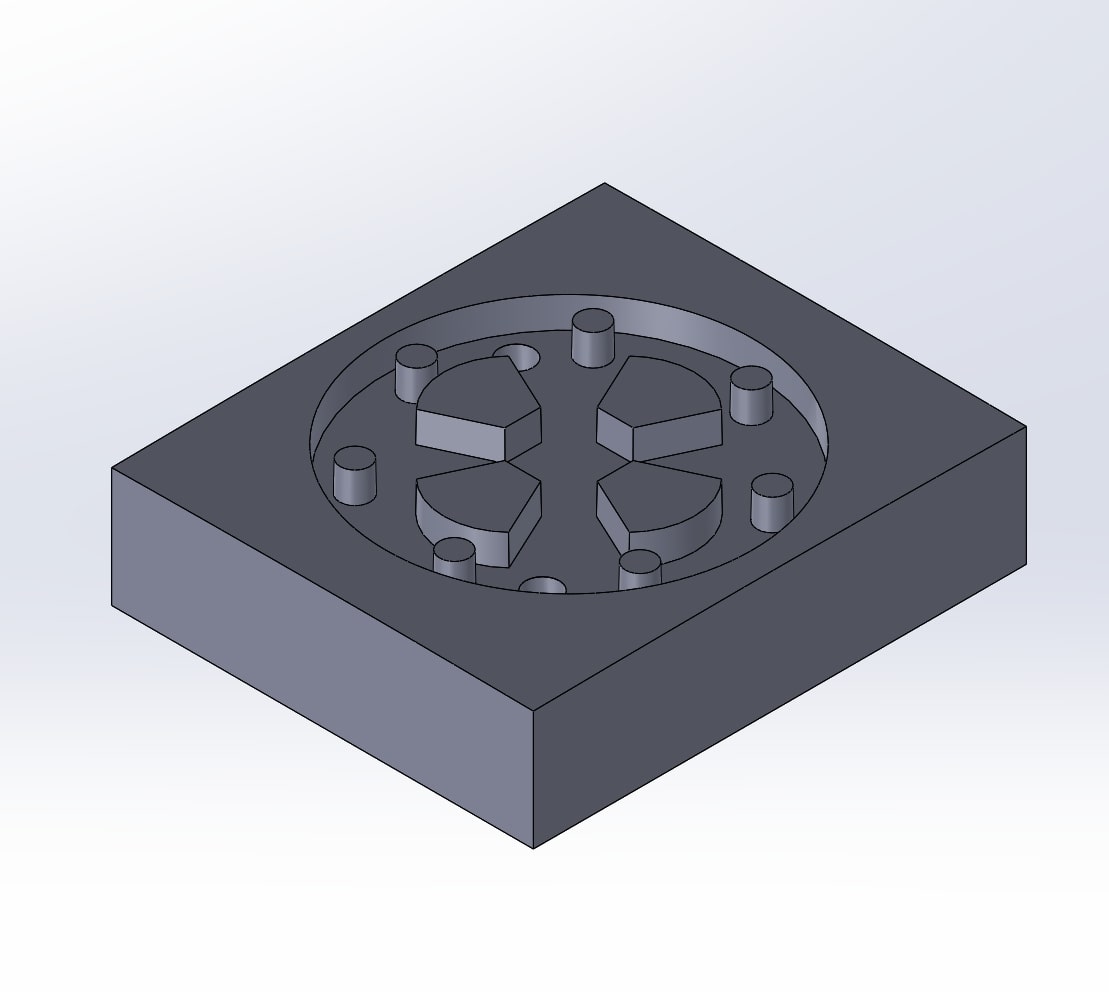

This resulted in splitting the mold in two equal halves at the partling line.

As seen in the last image, two external holes were created for pouring the material and air vent during the molding process using the Hole Wizard feature prior to Tooling Split feature.

Note: The individual task was limited to only digitization of the molding process in the CAD software as the material was not avialable in the FabLab due to COVID-19 outbreak.

\

Group Task: Review the Material Safety Data Sheet (MSDS) for Molding and Casting Materials!

This task was about reviewing the MSDS of the molding material from the online source (https://www.smooth-on.com/products/oomoo-25/) in order to review about OOMOO -25 molding material. The website is one of the leading supplier for molding and casting.