Week 10 (Applications and Implications)

Week 10

The box will have inside different kinds of CNC bits and clamps for the first spiral. With the help of a dashboard anyone can select a specific bit by diameter (1/4’’ or 1/8’’) or clamps. Then the box will open the specific drawer that stores the needed item.

A CNC router has a big learning curve. As a remote student it took me a lot of time of research to understand enough to finally play with my CNC in a safe manner. Bits have a lot of variable that places them in a different category, some of those variables are: shank diameter, tool diameter, cutting height, rotation, feeds and speeds, number of flutes, etc.. A person with this knowledge should arranges the box to ensure that people with less experience can locate the proper tool. This can be really helpful for new students and remote students like me. In advances spirals an instructor could potentially use a remote interface to select the toll that the student needs to use based on the needed job.

I’ve seen people make different types of arrangers like vending machines or big furniture’s that move. Most of them store food, power tools or fasteners. Specifically made for a CNC I haven’t seen one. Probably because a lot of labs have CNCs with automatic tool changer or easy access to something similar.

Well, the biggest challenge will be designing the whole structure using the 2 machines I own (3D printer and CNC) using the material I have available in Honduras. Most of the structure will be designed in favor of my CNC. I’ll be able to make it faster and safer taking to account that I have to consider the spontaneous blackout that are happening in Honduras due to the electricity crisis the country is facing. I’ll also make my own PCB’s and a basic user interface.

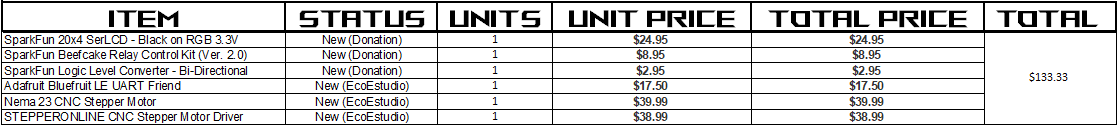

Donation and EcoStudio.

I need to know: the amount of vibration generated by the movement of the mechanism, build deadweight of stracture, and if the motor is capable of moving the mechanism (torque)

The lifter need to be capable of lifting me (I weigh 220 pounds) with no problem and control general movement with my phone.