Jose Alegria - Fab Academy

Final

Project

Slide:

Video: Open directly

As the economy reactivated after the lockdown

enforced by worldwide authorities during the COVID-19 Pandemics, we started

learning about the different prevention measures that should be taken to avoid

contagion in public indoor areas.

For

example, the United States CDC has a page citing the following actions:

-

Get Vaccinated

-

Wear a mask

-

Stay 6 feet away from others

-

Avoid poorly ventilated spaces

-

Test to prevent spread.

-

Wash your hands often

-

Cover coughs an sneezes

-

Clean and disinfect

-

Monitor your health daily

-

Follow recommendations for

quarantine.

-

Follow recommendations for isolation.

-

Take precautions when you travel.

You can see a

description of each recommended step at: 2019-ncov Prevention

One

of the most common recommendations was to improve ventilation within the public

premises, this goal is easily achievable in Mexico City buildings because most

of them do not have a central heating, ventilation, and air conditioning

system.

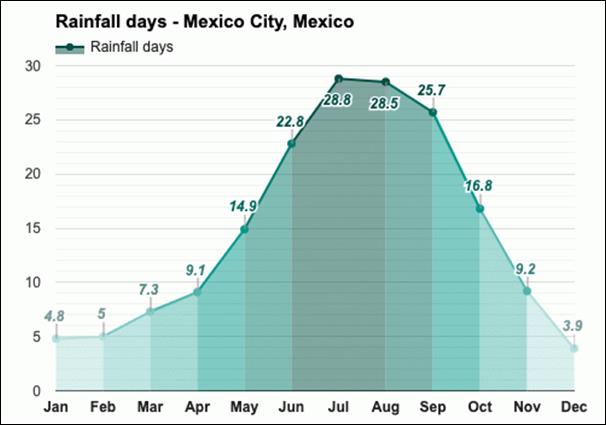

So,

the most effective action taken to reduce possible viral transmission was to

simply open the windows when a group of people gathered inside a building, but

nothing is as easy as it sounds, because in Mexico City we have a very steep

rainy season, averaging above 28 rainy days in July and August.

https://www.weather-atlas.com/en/mexico/mexico-city-weather-july#rainfall_days

Despite

a 93% chance of having a rainy day in July, most of the days are warm and the

rainfall will only be present after 5 pm and rain will stop before 9 pm (this

is an average and you should not trust your life to rain stopping early in the

night).

This

creates a logistic problem or an area of opportunity (whether you like being

optimistic or not), for most of the day windows will be open everywhere in our

buildings, but out of a sudden, there would be people rushing through the

entire university closing windows to avoid all the furniture getting soaked.

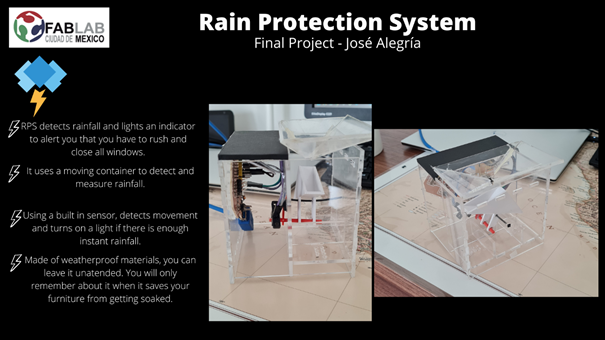

So,

I devised a way to automatically close the windows when it starts raining: Rain

Protection System (RPS).

A system comprised by two main parts

that work together:

-

Pluviometer:

o

Devised to measure rain intensity and

be able to decide if the instant rainfall is enough to send a signal to the

second part. The pluviometer relies on an electronic rain sensor because it is

intended to be able to differentiate between a light rain and a rain with

enough intensity to deploy the closing windows instructions.

-

Window closing:

o

Mechanism with the capability to open

or close a window, whether automatically or at will through a button.

Within Fabacademy:

-

MeteoFab: Alberto López (Fablab Barcelona)

2019

Super local

weather station comprising wind gauge, rain gauge, thermometer, and humidity

sensor. Works by collecting data and displaying information through an LCD

screen.

-

Window Opener: Bergþóra Ólöf

Björgvinsdóttir (Fablab Vestmannaeyjar)

2018

Device

with air quality sensors that, when reaching preset parameters, would open a

window.

Outside Fabacademy:

There are several commercial options, using different types of actuators

with prices ranging from 400 USD to 1 000 USD per window, these are part of

whole home automatization systems. They are not available in every country (i. e. in Mexico), though.

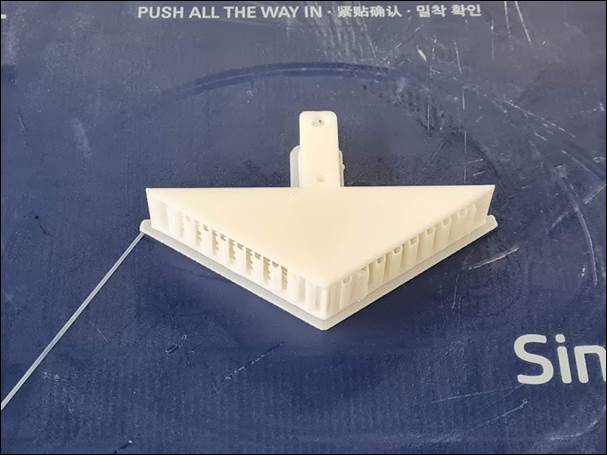

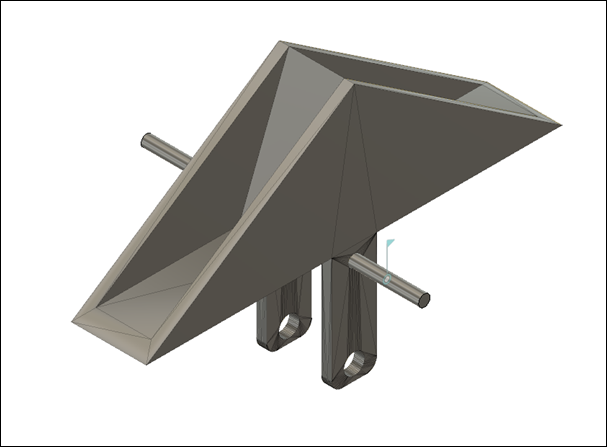

Pluviometer Moving Parts

-

Pluviometer bucket:

o

Process: 3D Printing

o

Material: ABS

o

Description: The moving parts of the

pluviometer were designed to be 3D printed; these were separated into 3

different pieces that work together. A bucket that works by collecting water in

one of its two sides and when there is enough water to make a movement it

simply lets it run and starts collecting water in the other side. A Pin that

crosses the middle wall to ensure the movement is detected outside the area

which will be receiving water and, therefore, will have excessive humidity for

the electronics to work safely. Both, the bucket, and the crossing pin, were

made of ABS through 3D printing in a WOX 3D Printer. I chose ABS over PLA so

that the material would be able to endure being outside into direct sunlight.

-

Main support pin:

o

Process: 3D Printing

o

Material: Resin

o

Description: The central pin is only

there to allow the rest of the system to have free rotational movement, I tried

to use ABS as with the other parts, but the 3D Printer resolution would not let

me have the smoothness needed for the water be able to move the bucket, so I

changed the material and printed it with an Stratasys Objet

Resin Printer. This, while pricier, allowed the system to work correctly.

-

Second pin:

o

Process: 3D Printing

o

Material: ABS

o

Description: The second pin is

designed to allow the movement transmission into the dry case of the

pluviometer. Consists of a pin that crosses the middle wall and a second part

that allows it to be held by the main pin and promotes the water to fall below

the electronics boards being attached to the dry case.

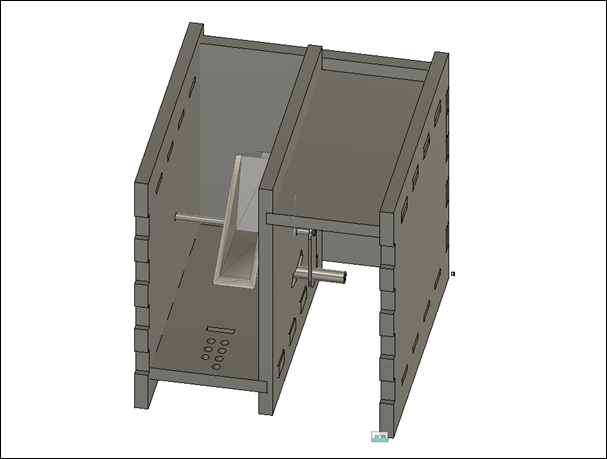

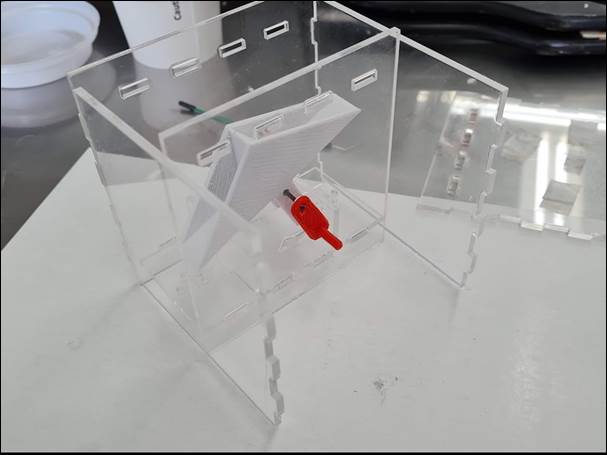

Pluviometer Case

-

Case:

o

Process: Laser cutting

o

Material: 3 mm Transparent Acrylic

o

Description: The pluviometer case was

made as a press fit box of transparent 3 mm acrylic; the design had several

stages to allow all the different components to be set without the need for

extra supports. It consisted of two separated compartments: The first one, an

open-ended area, is intended to contain the pluviometer bucket (the one I 3-D

printed) and receive the rain water, so it has to be able to let the water flow

through a series of holes drilled into the bottom piece, in theory water will

only be entering the case through the bucket, but I have to be prepared in case

the water flows outside the bucket, so everything into this compartment should

be made with any waterproof material. This leads us to the second compartment,

an enclosed area where the electronics are and that should not get any water

into it (we must remember that the entire ensemble, by design, must be outside

into the rain). This was easy except for one part: There should be a connection

between the dry and wet compartments of the pluviometer. I solved it by adding

a second pin (the first one is only intended to support the bucket in its place

and allow it to rotate in only one axis), the function of this second pin is to

translate the movement between both compartments, it is designed so that if any

water should cross on it, the water would fall before getting close to the

electronics boards (they will be over this height).

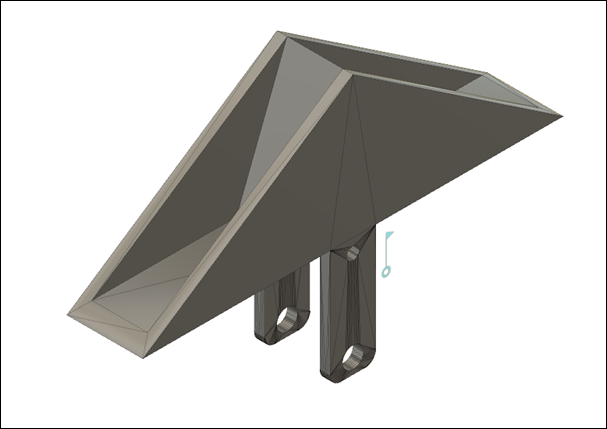

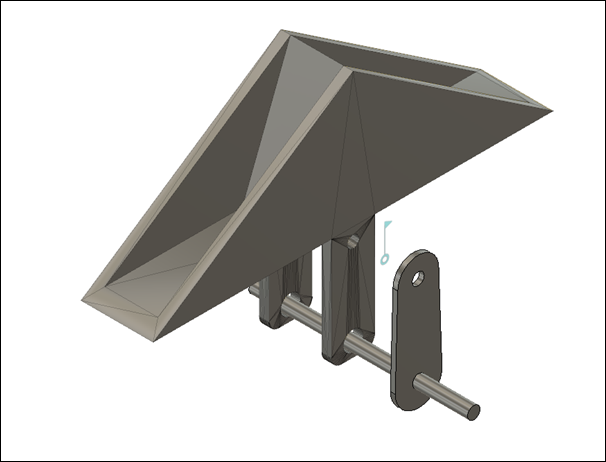

Motor and moving mechanism (Future Development)

-

Rack and Pinion:

o

Process: Laser cutting

o

Material: 5 mm Transparent Acrylic

o

Description: The rack-and-pinion

system was chosen over other options made to transform the rotating movement

generated by a motor into a linear movement needed to move a window (at least,

this kind of window), because it is simple to use and takes a good advantage of

the amount of torque produced by the step motor. The main requirement that I

had while choosing the material was that it may be attached to the outside side

of the window and must be waterproof (although it is not going to be the case

in every window configuration I had to be prepared if that was the situation).

So, I chose to use 5 mm acrylic and let it accomplish another requirement, it

is going to be visible so, it must look nice with any material the window could

be made of. The rack-and-pinion design was chosen as a straight gear, over a

helical gear, to ensure all the torque is applied into the pinion. The

pluviometer case was made as a press fit box of transparent 3 mm acrylic; the

design had several stages.

-

Step Motor:

o

Process: None

o

Material:

o

Description: I used a step motor to move

the window because it allowed me to define a certain movement range, counting

from one of the sides, and avoid having to add a switch in each side of the

window, reducing the need of wiring through large distances.

Electronics

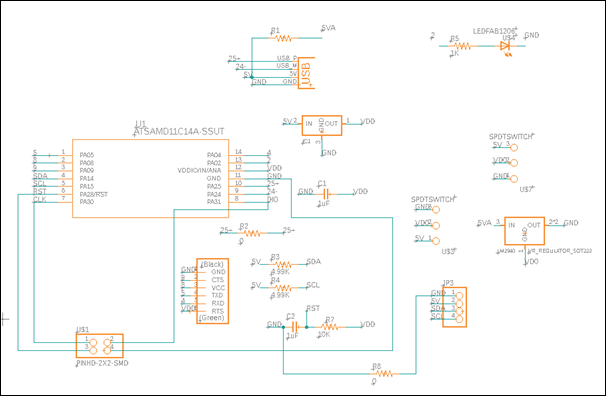

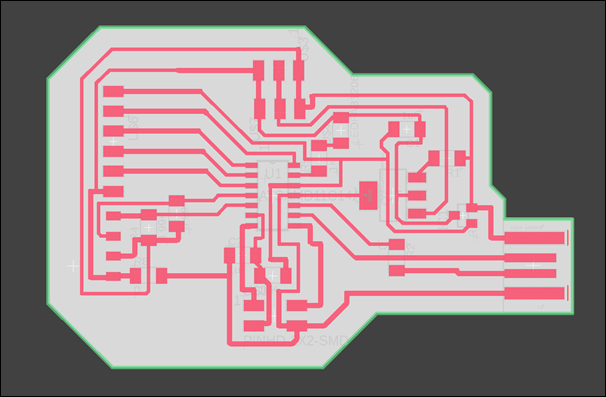

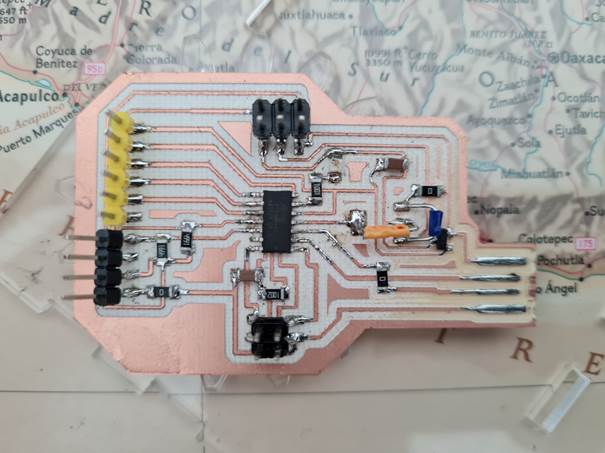

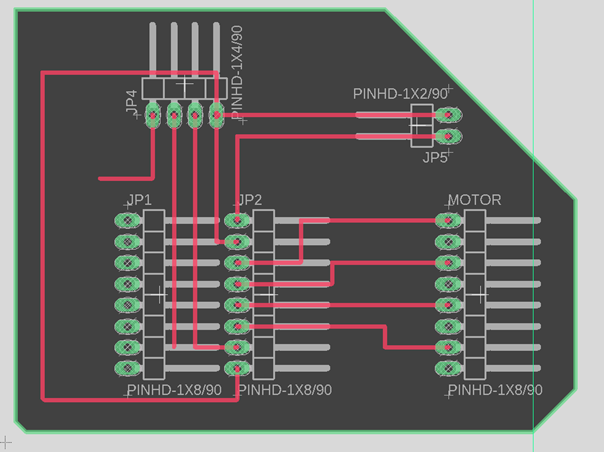

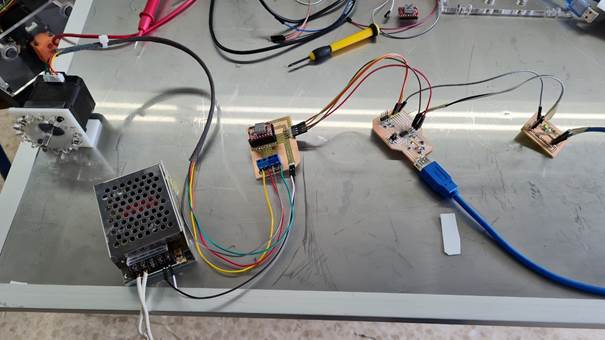

-

Main board:

o

Process: One sided Milling

o

Material: Single sided copper PCB

Circuit Board

o

Description: The electronics work by

having one main board (i. e. where the microprocessor

sits) and two auxiliary boards just made to allow the sensor and the motor to

be plugged into. This configuration allowed me to make a smaller main board

that will be prepared for future additions because it only has to have one

extra port if I want to add another sensor or anything else to the system. The

boards functions will be explained in the electronics design section. The

milling process was chaotic at first but as we tested different methods to send

our board designs to the Modella MDX-20 Machine we have in our fablab, things

started to work out easier. I used the characterization for the machine I

explained in my Electronics Productions assignment.

-

Secondary board (Motor PCB) (Future

Development)

o

Process: Perforated PCB Milling

o

Material: Single sided copper PCB

Circuit Board

o

Description: The PCB for the motor

was designed as a perforated board to allow for a stronger board because we

were testing many different configurations and the pins were starting to fail

because of the excessive manipulation.

The system

works by detecting the motion of the bucket within the pluviometer, processing

it as a signal, and once stating that rain is falling, sending a signal to the

motor to start a closing window procedure.

Individual

component operation is as follows:

Pluviometer moving parts

-

Description: The rain falls into the

pluviometer bucket, thus adding an extra weight that when filling the recipient

is enough to rotate the bucket letting the water flow downstream into the

pluviometer case and discarding the water, this movement changes the position

of the bucket and sets the second recipient into the water dripping line,

filling it with water until the weight produces a second rotation movement that

discards again the water and sets the first recipient in the water receiving

position. Each movement is transported to the dry case with the help of the

second pin, moving the pin inside and outside the sensor range and letting the

sensor to be able to detect each change of the bucket position.

Pluviometer case

-

Description: It has a cover that

leads water to fall into a specific area, ensuring the water collected into a

measurable area falls directly into the bucket, this could let us to calculate

the rain intensity for in a standardized unit (i.e. mm/h or in/h). After the

water has been discarded the configuration of the holes drilled in the bottom

of the case will allow the water to leave the case and avoid water accumulation

inside the system.

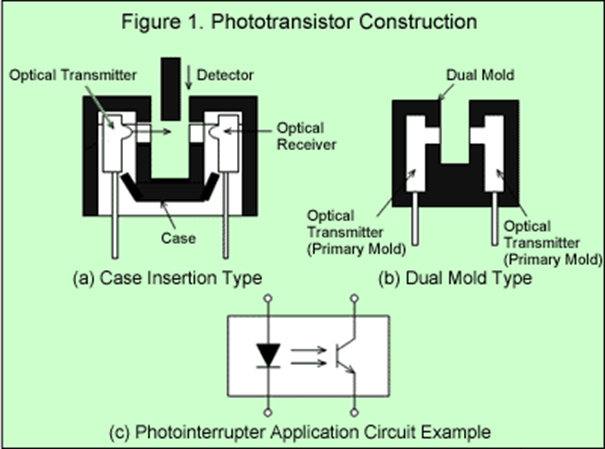

Electronics

-

Description: The electronics were

designed to operate with two different processes. The first one is the rain

detection, which is provided by a photointerrupter.

This device works by detecting the movement of the second pin by sensing if it

is closing its circuit. When the bucket position changes, it sends (or not) a

signal to the main board which then determines if that movement is being

frequently enough to consider (by user set parameters) that it is raining with

enough intensity to deploy the other processes. The first process is to light a

LED to allow me to know that the movements are being frequently enough.

Simultaneously, it sends a signal to the motor to start operating, and that

movement will close the window. The board is divided into three different

parts:

o

Main board:

§

Processor: SAMD11c14

§

Power input: 5V, GND

§

Input: None

§

Output: Red LED

§

Signal Inputs: Photointerrupter

board signal.

§

Signal Output: Motor board signal.

§

Notes: This is a modified board based

on Adrian Torres SAMDINO Board: https://fabacademy.org/2020/labs/leon/students/adrian-torres/samdino.html

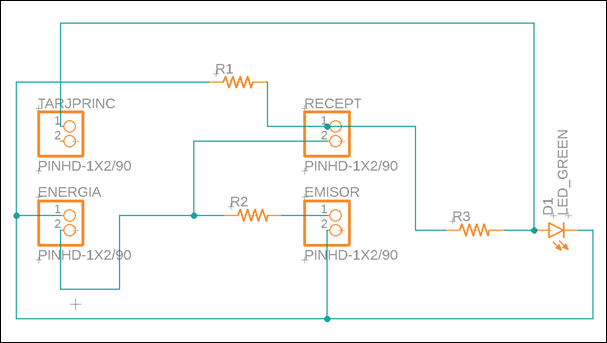

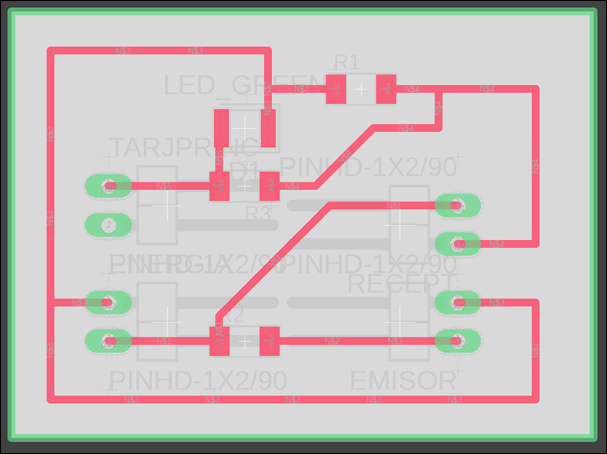

o

2nd board (Photointerrupter board):

§

Processor: none

§

Power input: 5V, GND

§

Input: Photointerrupter

§

Output: Green LED (shows if

interrupter is closed or open)

§

Signal Inputs: None

§

Signal Output: Photointerrupter

board signal (to the main board)

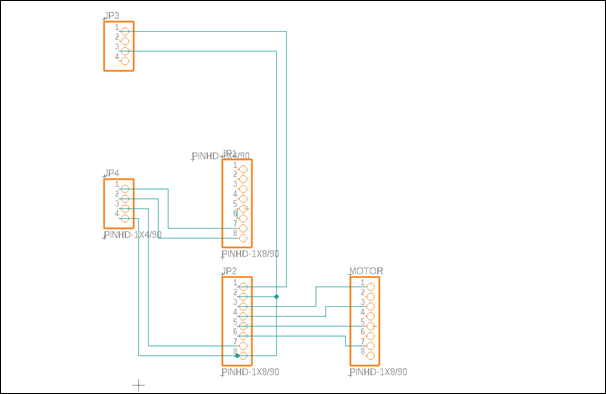

o

3rd board (Motor board)

(Future Development):

§

Processor: Motor Driver model: Pololu a4988

§

Power input: 5V, GND (from main board);

24V, GND (From External Power Source)

§

Input: None

§

Output: None

§

Signal Inputs: Motor board signal

(from the main board)

§

Signal Output: Motor board signal (to

the motor)

Motor and moving mechanism (Future Development)

-

Description: Once the motor receives

a signal, the motor starts working to move the window to its closed position.

The distance is determined by the number of steps done by the motor. The speed

of the motor and direction of the rotation will be preset by the user.

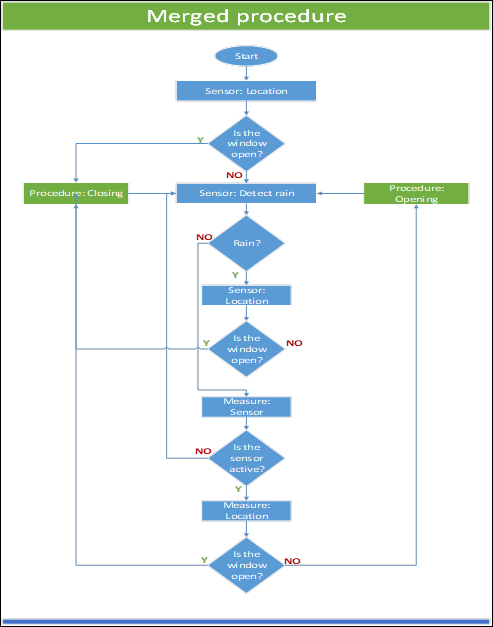

Process to be programmed:

-

Check for the position of the bucket

through the photointerrupter.

-

Count the time between the changes.

-

Determine if it is raining by

counting 10 minutes between the movements.

-

If the movement is repeated in the

set time, send the signal to LED.

Settings:

-

Initial state: No rain.

-

Rain started: When there are two

movements within a 15 second interval.

-

Rain ended: When the time between

movements is over a minute.

-

Rain: Anytime between rain started

and rain ended.

-

When rain is happening: Turn on the

Red LED and send 1 time the signal to the motor.

-

When rain stops: Turn off the RED LED

and send 1 time the signal of reverse movement to the motor.

Code:

const int ledPin1 = 2;

const int buttonPin = 4;

int pos = 0;

int lluvia

= 0;

int pos_guardada = 0;

int cambio

= 0;

int tiempo_lluvia = 10000;

int tiempo_altolluvia = 20000;

int t1 = 0;

int t2 = 0;

void setup() {

pinMode(ledPin1,

OUTPUT);

pinMode(buttonPin, INPUT);

}

void loop() {

pos = digitalRead(buttonPin);

if (pos != pos_guardada)

{

pos_guardada

= pos;

cambio++;

Serial.print("Número

de cambios: ");

Serial.println(cambio);

t1 = millis();

}

if (millis()-t1>tiempo_lluvia) {

cambio = 0;

}

if

(cambio>2) {

lluvia = 1;

t2 = millis();

}

else {

lluvia = 0;

}

if

(lluvia==1) { digitalWrite(ledPin1, HIGH);

}

else { digitalWrite(ledPin1,

LOW);

}

delay(1000);

}

Main Board

|

Part |

Device |

Description |

Value |

Qty |

Price |

USD |

|

1 |

Capacitor |

|

1uF |

2 |

0.77 |

1.54 |

|

2 |

Regulador |

IC REG LINEAR

5V 500MA TO252-3 |

5V |

1 |

0.60 |

0.60 |

|

3 |

PINHD-1X04_2.54-SMD-90° |

PIN HEADER |

|

1 |

0.17 |

0.17 |

|

4 |

Regulador |

IC REG LINEAR

3.3V 1A TO252-3 |

3.3V |

1 |

2.03 |

2.03 |

|

5 |

Resistor |

Resistor |

0 |

3 |

0.26 |

0.78 |

|

6 |

Resistor |

Resistor |

4.99K |

2 |

0.26 |

0.52 |

|

7 |

Resistor |

Resistor |

1K |

1 |

0.26 |

0.26 |

|

8 |

Resistor |

Resistor |

10K |

1 |

0.26 |

0.26 |

|

9 |

Microprocessor |

ATSAMD11C14A |

|

1 |

1.78 |

1.78 |

|

10 |

LED |

LED |

|

1 |

0.05 |

0.05 |

|

11 |

Placa 10x6 |

Copper Clad

PCB Laminate Circuit Board, Single Side, 4 x 2.7 inch |

|

1 |

0.69 |

0.69 |

|

Total |

|

|

|

|

|

8.68 |

Secondary Board (Motor)

|

Part |

Device |

Description |

Value |

Qty |

Price |

USD |

|

1 |

Stepper Motor Driver |

Pololu A4988 |

|

1 |

4.45 |

4.45 |

|

2 |

Pin Header |

PIN HEADER |

5V |

1 |

0.60 |

0.60 |

|

3 |

Placa 10x6 |

Copper Clad

PCB Laminate Circuit Board, Single Side, 4 x 2.7 inch |

|

1 |

0.69 |

0.69 |

|

Total |

|

|

|

|

|

5.74 |

Secondary Board (Sensor)

|

Part |

Device |

Description |

Value |

Qty |

Price |

USD |

|

1 |

Optointerruptor |

ITR8102 |

|

1 |

0.75 |

0.75 |

|

2 |

Resistor |

Resistor |

499 |

2 |

0.26 |

0.52 |

|

3 |

Resistor |

Resistor |

4.99K |

1 |

0.26 |

0.26 |

|

4 |

Placa 10x6 |

Copper Clad

PCB Laminate Circuit Board, Single Side, 4 x 2.7 inch |

|

1 |

0.69 |

0.69 |

|

Total |

|

|

|

|

|

2.22 |

Pluviometer Case

|

Part |

Device |

Description |

Value |

Qty |

Price |

USD |

|

1 |

Acrylic Case |

Acrylic Sheet

81.3x111.8 cm 3 mm |

|

0.12 |

30.91 |

3.71 |

|

2 |

Bucket |

ABS 3D Printer

Filament |

|

14.2 |

0.05 |

0.74 |

|

3 |

Main Pin |

ABS 3D Printer

Filament |

|

1.1 |

0.05 |

0.06 |

|

4 |

Secondary Pin |

ABS 3D Printer

Filament |

|

1.4 |

0.05 |

0.07 |

|

Total |

|

|

|

|

|

4.58 |

Motor base and window actuator (Future Development)

|

Part |

Device |

Description |

Value |

Qty |

Price |

USD |

|

1 |

Motor |

NEMA 23 Step Motor |

|

1 |

24.22 |

24.22 |

|

2 |

Motor Base |

ABS 3D Printer

Filament |

|

11.3 |

0.05 |

0.59 |

|

3 |

Acrylic Rack and Pinion |

Acrylic Sheet

81.3x111.8 cm 3 mm |

|

0.1 |

30.91 |

3.09 |

|

Total |

|

|

|

|

|

27.91 |

Pluviometer:

-

Laser cutting for a press fit case was

difficult, at first the case was weak and moving it from one place to another

was a real problem. After a few modifications and revisions of the laser

cutting characterization and the kerf measures, it fitted correctly and that

problem disappeared.

-

3D printing the pins that support the

bucket had challenges. The printer resolution was too big, and the pins were

not working as intended because they were not perfectly round. The main pin,

which would allow free movement of the bucket was changed to a resin 3D printer

and the problem was solved.

-

When milling the electronics boards,

I had a few issues with the design, mostly because the pads were separating

from the board when I manipulated the header pins (which by the way were the

most difficult part when welding). I solved it by changing the design, trying

to make the lines as straight as possible and avoiding 45 degrees connections

with the pads.

Window actuator:

-

For a future development, I decided

to add an automatic window closing system, there is already a lot of

information about this in my page. I started working into it, but I am

currently having issues with calculating the torque needed to move an actual

window and finding a step motor that would do the job. I will be working in

this development through the next months to ensure that the system works as

intended before presenting it as a formal addition to my project.

Laser Cutting Design:

-

Laser cutting case (Autocad)

Electronics Design:

-

Main board schematics (Eagle)

-

Secondary board schematics

(Eagle)

Programming code:

3D Printing files:

Fusion 360 Design (All files can be downloaded

individually above)

-

Pluviometer (Fusion 360 design)