Jose Alegria - Fab Academy

Wildcard

Week

Assignment

wHAT iS THE ASSIGNMENT ABOUT?

Design and

produce something with a digital fabrication process (incorporating

computer-aided design and manufacturing) not covered in another assignment,

documenting the requirements that your assignment meets, and including

everything necessary to reproduce it.

1st Step: Defining

the wildcard week process.

When I asked

for different production methods for Molding and Casting, I was told there was

one method we do not use while doing the assignment: Thermoforming. In our

Fablab we were trying to make as extensive as possible every Group Assignment,

so I was proposed to make a thermoforming procedure for molding, the problem

was that to make that possible we had to overcome a couple of issues arising

from the digital process of fabrication (3D Printing) of the first positive

mold, the thermoforming requires to heat the product to make it soft, and this

is not compatible with the materials we used for the 3D printers. So, I left

this work for a later assignment and here we are.

2nd Step: Setting

up the parameters.

Thermoforming

process requires the fabrication of a positive mold for which I decided to use

3D Printing. Due to the physical properties of the materials we can use for 3D

printing in our lab, I settled with ABS (the material we had with the highest

melting temperature). Then, I have to make a

negative mold using the thermoforming procedure, for this I will be using a

HIPS sheet to be used with our smallest thermoforming machine. Once this is

done, we can cast anything with our mold. For this assignment, I tried casting

with plaster.

So,

this is the list of materials I will be using:

-

Positive: ABS 3D Printing (Datasheet)

-

Negative: Thermoforming in High Impact

Polystyrene (HIPS) (Datasheet)

-

Casting: Plaster

3rd Step: Making

the positive mold.

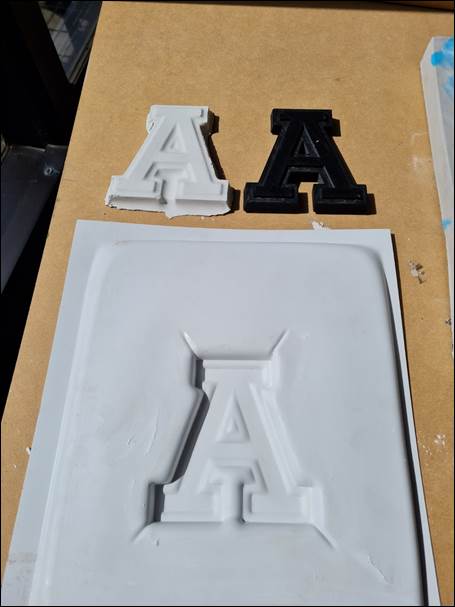

For

this I used a design that was made by my coworkers using the Anahuac University

Logo. This was made with ABS in our Sindoh 3D Wox Printer. The procedure is explained in the 06 - 3D Printing and Scanning

Assignment.

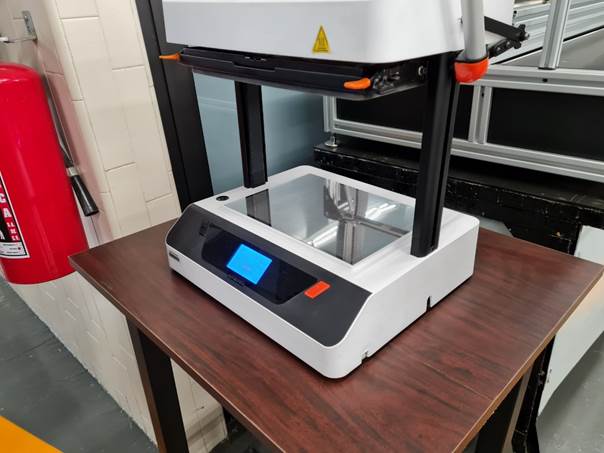

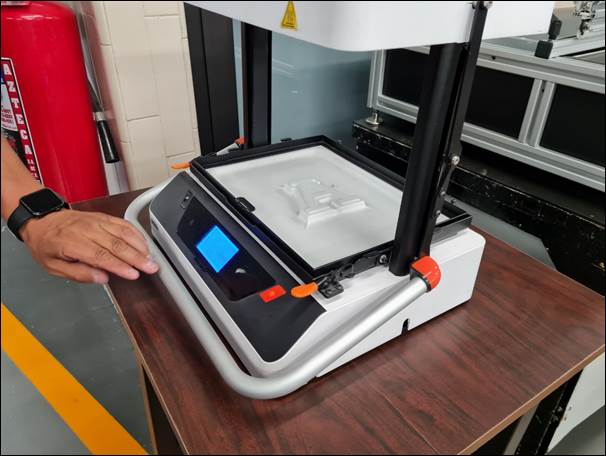

4th Step: Making

the negative mold

This is the main step of the assignment. Once I

3D printed the positive mold, I started the process to create the negative mold

by thermoforming. This is the procedure followed:

-

Put the positive mold into the

thermoforming machine.

-

Fix the HIPs sheet into the upper

compartment of the machine.

-

Set the temperature for the

thermoforming process above the HIPs melting temperature and below the ABS

deforming temperature. The default temperature for HIPS was 160°C, but with

this temperature the ABS would have melted, so I used a slightly lower

temperature of 120°C and did not keep the HIPS sheet longer than strictly

necessary.

-

Start the machine to begin the

heating process.

-

Press the vacuum button to start the

vacuum motor.

-

Move the upper compartment down just

to be set above the positive mold and slowly keep moving it down.

-

Finish the procedure by releasing the

HIPs sheet once it cooled down.

5th Step: Casting.

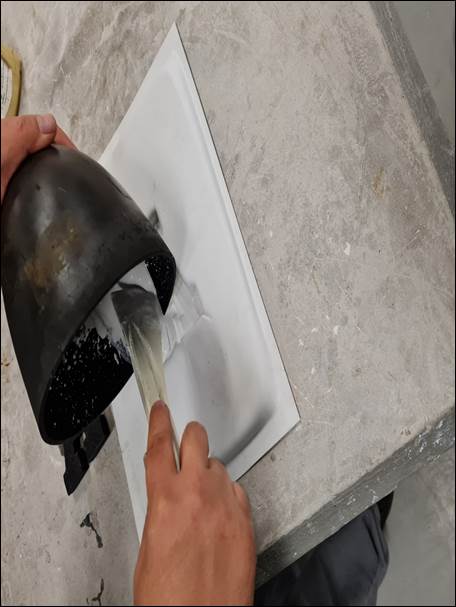

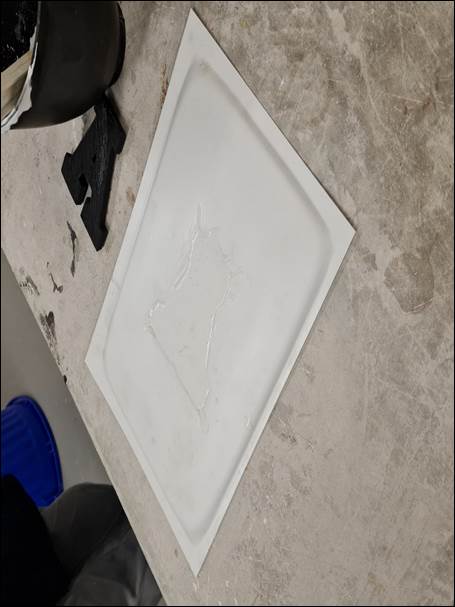

Having

already a negative mold, I continued to the casting step of the assignment by

mixing plaster with water. The process is pretty straightforward

and I am posting here a few photographs.

Conclussions

This assignment showed us that there

are many ways to make a mold and cast anything into it. I tried to incorporate

as many as possible digital fabrication processes, and as you could see, the

human interaction was kept to a minimum. Maybe, there could be some way to mix

and cast the plaster with a digital procedure. If so, that would be our next

step to try and use.

Original

Files

1.

STL

File

Nueval

Checklist

-

Documented how you made your creation

-

Described problems and how you fixed

them.

-

Included your design files and hero

shot of the result.

2022