Jose Alegria - Fab Academy

Electronics

Design

Assignment

wHAT iS THE ASSIGNMENT ABOUT?

Redraw one of the echo hello-world

boards or something equivalent, add (at least) a button and LED (with

current-limiting resistor) or equivalent input and output, check the design

rules, make it, test it. Optionally, simulate its operation.

GROUP ASSIGNMENT:

Use

the test equipment in your lab to observe the operation of a microcontroller

circuit board.

What did I learn:

-

The most important part of electronics

production is electronics design.

-

There are a few options to make the

design, this is the simplest part. Once you get used to design in the chosen

software the process is straightforward.

-

The difficult part is to connect all

the pins, ports, and pads correctly and getting to know the function of each

one of those.

1st Step. Getting

a design

For this

assignment we are not making a board from scratch. So, I used the board that

Adrian Torres (Leon, 2020) uses as a SAMDINO,

to have a starting point and proceed with the modifications needed.

This is the

board I will be modifying:

2nd Step.

Modifying the board

To modify the

board, I used the Eagle module embedded within Fusion 360. I made a list of the

components needed according to the first board, and then added the components

needed to install two sets of button and LED. The first one using the

microprocessors internal resistor and a second one using an external resistor.

|

Description |

Part |

Value |

Device |

Package |

Qty. |

|

Capacitor 1 micro F |

C1 |

1uF |

CAP_UNPOLARIZEDFAB |

C1206FAB |

2 |

|

Regulator 3.3 V |

IC1 |

VR_REGULATOR-SOT23SOT23 |

SOT23 |

1 |

|

|

Regulator 5 V |

LM2940 |

VR_REGULATOR_SOT223 |

VR_REGULATOR_SOT223 |

SOT223 |

1 |

|

Resistor 100 K |

R1 |

100 K |

RES-US1206FAB |

R1206FAB |

1 |

|

Resistor 0 |

R2 |

0 |

R1206FAB |

R1206FAB |

2 |

|

Resistor 1 K |

R3 |

1K |

R1206FAB |

R1206FAB |

2 |

|

Resistor (US Symbol) |

R7 |

10K |

R1206FAB |

R1206FAB |

1 |

|

Button 6 mm |

S1 |

6MM_SWITCH6MM_SWITCH |

6MM_SWITCH |

2 |

|

|

LED |

U$2 |

LEDFAB1206 |

LEDFAB1206 |

LED1206FAB |

2 |

|

Programming Pin 2x2 |

U$1 |

PINHD-2X2-SMD |

PINHD-2X2-SMD |

2X02SMD |

1 |

|

Microprocessor |

U1 |

ATSAMD11C14A-SSUT |

ATSAMD11C14A-SSUT |

SOIC14_SL_MCH |

1 |

|

USB Connectors |

X1 |

CONN_USBPCB |

CONN_USBPCB |

USB-A-PCB |

1 |

I changed

some of the component’s footprints to the ones in the Fabacademy Library to get

bigger footprints that are easier to fix to.

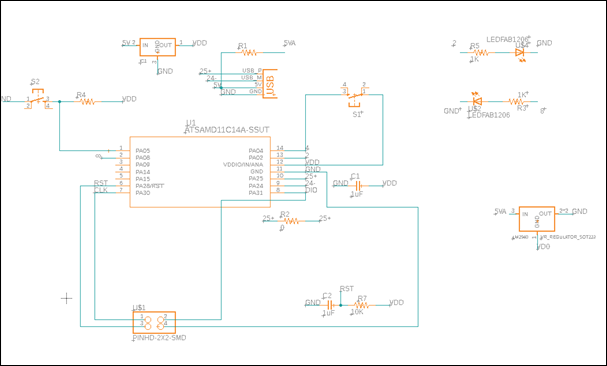

Then, the

next step was to create a board schematic with all the connections needed for

the board to work.

This is the

result:

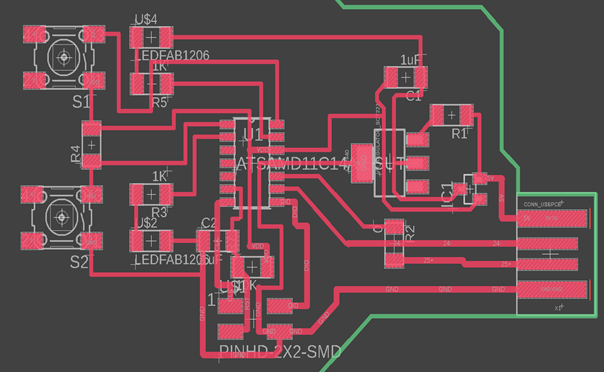

At last, I

had to locate all components in the PCB Board and make the routes needed to

connect them.

To

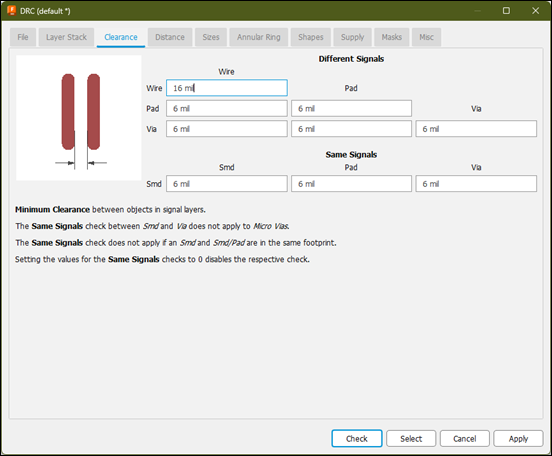

make the new routes I followed a few design rules such as:

1.

Minimum wire width: 24 mil (made this

way to avoid wire breaking up)

2.

Clearance: 16 mil (this is the tool

diameter)

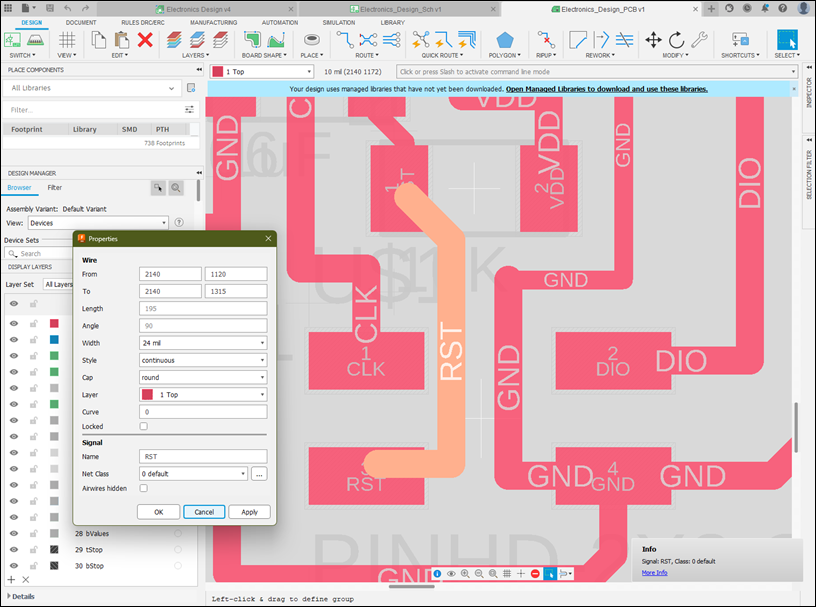

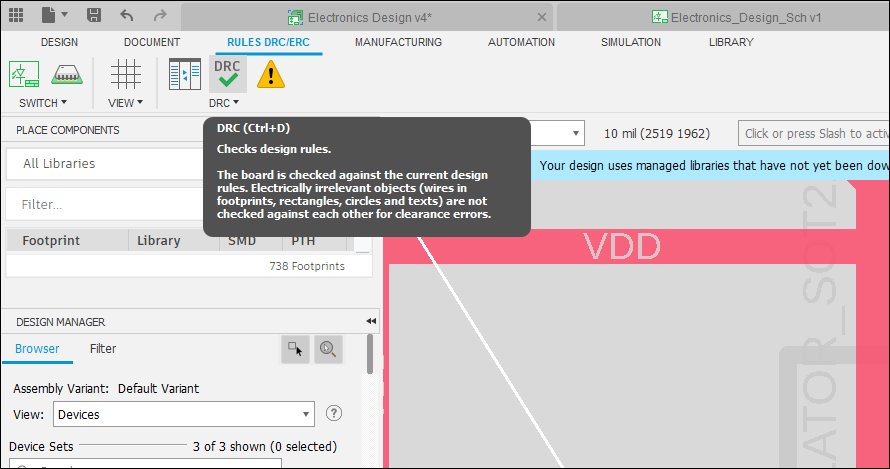

This

design rules that I followed by myself had to be set into the program in a

toolbox called DRC, to get there you should go to the upper bar, select the DRC

/ ERC tab, and click in the DRC button (or press Alt + F4).

There

you can set the different rules which will be followed as a preset when you

design, although they can be overrun if needed for your design. Due to this

possibility, you can make mistakes that will lead to certain design flaws

within your board: wires being too thin, small clearances that difficult the

wielding of components or wires being too close to the board limits.

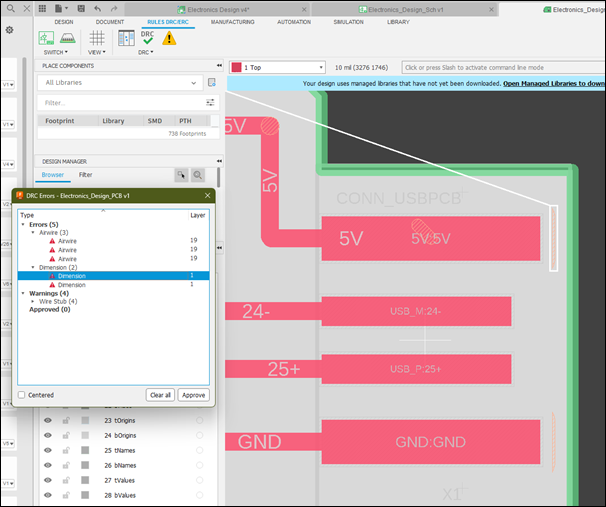

So,

if you want to know beforehand if you have made this mistakes, there is an

Error check button that will display the problems within your design, then you

can decide whether or not they are allowable.

For

example, in my design there were some design errors displayed when using this

feature, there were a couple of wires too close to the board limit, but once I

checked them out, they were the USB connector pads and it was part of the

design I needed, so I disregarded them.

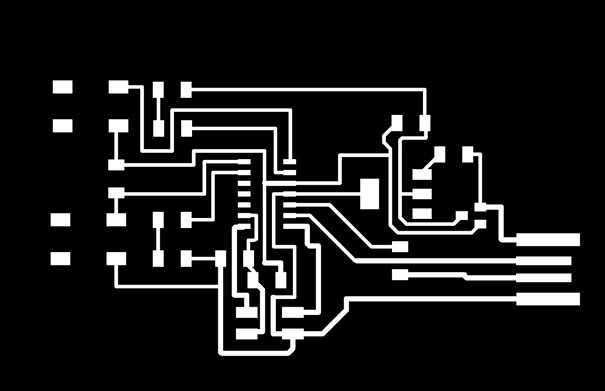

Finally,

exporting them to png files that will be readable by

the Mods Program:

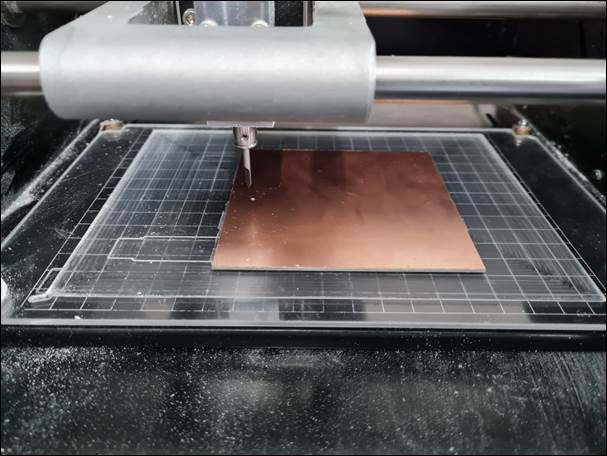

3rd step.

Electronics production

To send the milling and cutting files

to the machine we used a different method than the one used during the group

assignment. Now, the computer was directly sending the file to the machine from

mods, and we did not used the processor program. The parameters where the same

that we were using before.

Here are the parameters I used for

milling:

-

Tool Diameter: 0.0156 in

-

Cut depth: 0.004 in

-

Max depth: 0.004 in

-

Offset number: 6 (used this to create

a cleaner area to work with even though it needs more time to be done)

-

Speed: 2 mm/s

And these are

the parameters I used to cut:

-

Tool Diameter: 0.0625 in

-

Cut depth: 0.024 in

-

Max depth: 0.072 in (made in 3 steps)

-

Speed: 3 mm/s

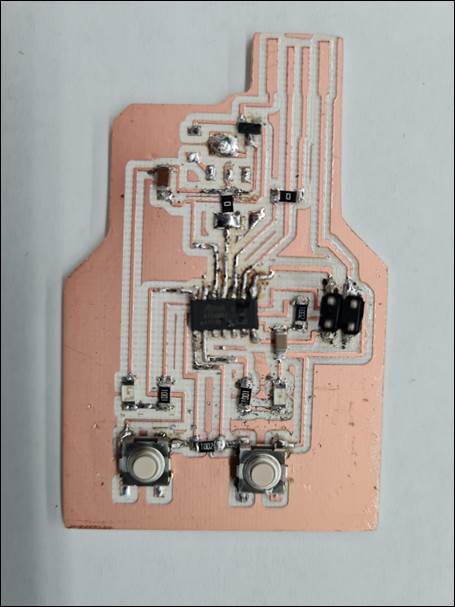

Finally, after a few tries, getting

the work done correctly. Next step is to fix the components and set up the

board for programming. This is how it looked like after fixing everything in

place.

4th step.

Programming

For this stage I had to create a programmer board used exclusively for

programming my different boards I was going to use for the different

assignments. This was also created from Adrian Torres SAMDINO

page, and programmed with EDBG as follows (Windows):

-

Download EDBG software to the PC in

any folder, it is in: https://github.com/ataradov/edbg

-

Download EDBG Free

Dap Bootloader file and save it in the EDBG folder.

-

Open Terminal.

-

Go to EDBG Folder.

-

Type the next command: <<

edbg-windows-r38.exe -b -t samd11 -epv -f

free_dap_d11c_mini.bin >>.

-

If everything is plugged in correctly

and working your board is now a free dap programmer.

This works to

only to create a programmer board. Next, I had to program my new board. For

that we need to download a bin file for a SAMD11C14A

from Mattairtech page. Save it to the EDGB Folder,

open Terminal and go to EDBG Folder. Type the following command: <<

edbg-windows-r38.exe -b -t samd11 -epv -f

sam_ba_SAMD11C14A.bin >>.

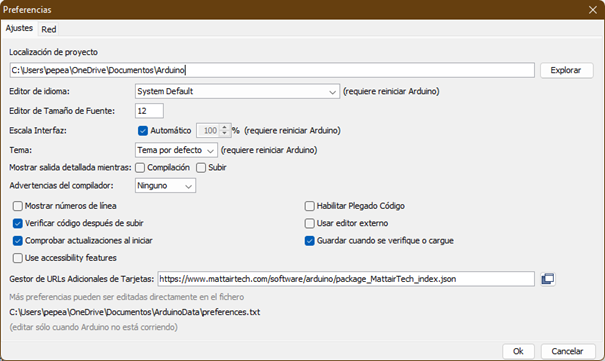

Now we should

download the Arduino IDE and change a few parameters to let it control our

board:

-

Open Arduino IDE.

-

Open Preferences

-

Open Additional Boards Manager URLs

and type: << https://www.mattairtech.com/software/arduino/package_MattairTech_index.json

>>

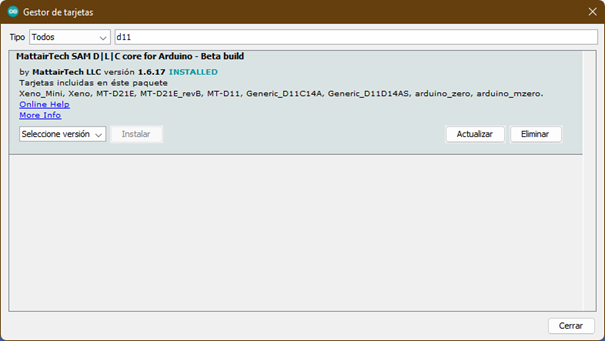

-

Go to Tools - Board Manager and install the Generic

D11 board Manager:

After this, you will be

able to use your board as an Arduino Board for programming purposes.

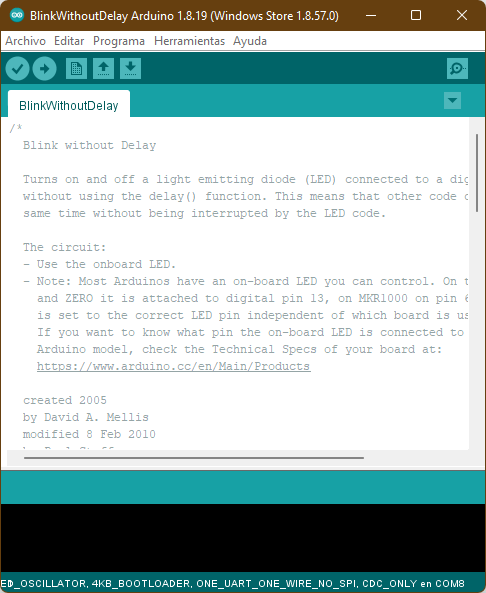

To test the board I

uploaded a << BlinkWithoutDelay >>

program that I found within the Arduino precharged

files.

Conclussions

This assignment importance was to

learn how to modify the existing schematics to take advantage of the work that

already has been done within the FabAcademy universe.

We must have an understanding of what do we need and how this components work

to be able to modify them.

Original

Files

1. Original

Files (f3z, brd, sch, png)

Nueval

Checklist

-

Linked to the group assignment page.

-

Documented what you have learned in

electronics design.

-

Explained problems and how you fixed

them.

-

Included original design files.

-

Included a hero shot of your board.

-

Loaded a program and tested if your

board works.

2022