Jose Alegria - Fab Academy

Electronics

Production

Assignment

wHAT iS THE ASSIGNMENT ABOUT?

Make an in-circuit programmer that

includes a microcontroller by milling and stuffing the PCB, test it to verify

that it works.

GROUP ASSIGNMENT:

What did I learn:

·

We had a few issues with the

characterization and tried different ways to link the files we were trying to

mill and cut and the machine. Once we solved them, our process was easier.

·

The different ways had different ways

to achieve the same parameters, you must have a correct comprehension of the

meaning of each of the settings and only then you will be able to use a machine

that works in a different environment.

·

The most important settings are

speed, tool diameter and cut depth.

1st Step.

Introduction to electronics

As we are going to make an electronic

board for the first time, we should get familiar with the names for the

different materials and equipment we are going to be using:

Materials:

-

Copper board: Here in Fablab Mexico City, we are using two kinds of copper

boards, both work similarly but are made of different

materials. The first one is a single sided glass epoxy board covered with a

copper sheet that is conductive, and the second one replaces the glass epoxy

with phenolic paper (also known as bakelite). We are

using them indistinctly and the main difference will be the resistance when

milling. We have various sizes, but the most common one is 4X4” (10 mm X 10

mm). If you need to mill a smaller size board, it is recommended to previously

cut the board to work with a smaller area (this is different from the cutting

we are going to do further ahead with the machine).

-

Welding: The basic material used to

get the electronic materials attached to the board, there is not too much to

worry about it.

-

Resistors: They limit the amount of

current going through the conductors, therefore protecting other components.

-

LED: We will be using them to signal

us if something is working or not, mostly they are optional. You must identify

the cathode because they will not work if installed incorrectly; usually in the

schematics it is marked with dots or thicker lines, within the LED it could be

marked with a green or black line.

-

Capacitor: They are used to store

energy and their measures are expressed in Farads (F).

-

Header: Pins used to plug the board

to any other component for programming or transmitting information.

Equipment

-

PCB Cutting and milling machines.

-

Welding equipment.

-

Voltimeter.

2nd Step. Getting

a design

To make an electronic board we have

two main paths to follow:

-

Find someone within the Fabacademy

universe who has made the same thing we want to do and use their board

schematics

-

Find someone who has made something

that kind of does what we have to do and make the

appropriate modifications to get it where we want.

Either way we

must get two or three images (we are using png files)

to get the following:

-

Traces

-

Holes drill

-

Outline

Here, we will

be using the following images to make our programmer board:

-

Outline:

-

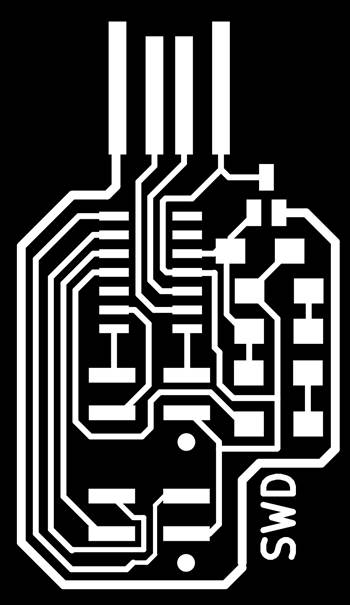

Traces:

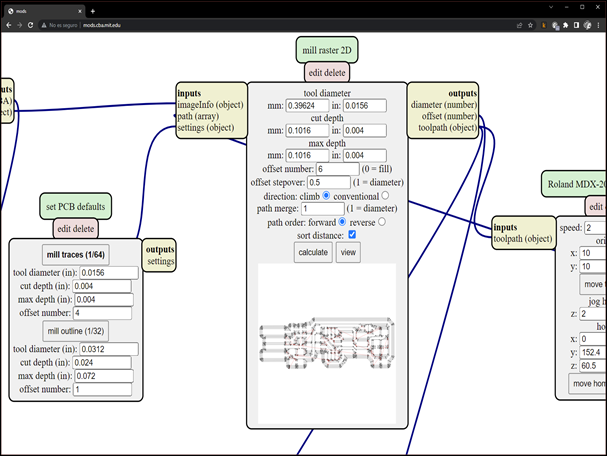

3rd step. Cutting

This step is, perhaps, the most

time-consuming of the entire process. We will mill and cut using our Roland

Modella MX-20 and the appropriate Mods Program to create a file from our png image and send it to the machine. For more information,

please refer to the group assignment page.

Here are the parameters I used for my

own board for milling:

-

Tool Diameter: 0.0156 in

-

Cut depth: 0.004 in

-

Max depth: 0.004 in

-

Offset number: 6 (used this to create

a cleaner area to work with even though it needs more time to be done)

-

Speed: 2 mm/s

And these are

the parameters I used to cut:

-

Tool Diameter: 0.0625 in

-

Cut depth: 0.024 in

-

Max depth: 0.072 in (made in 3 steps)

-

Speed: 3 mm/s

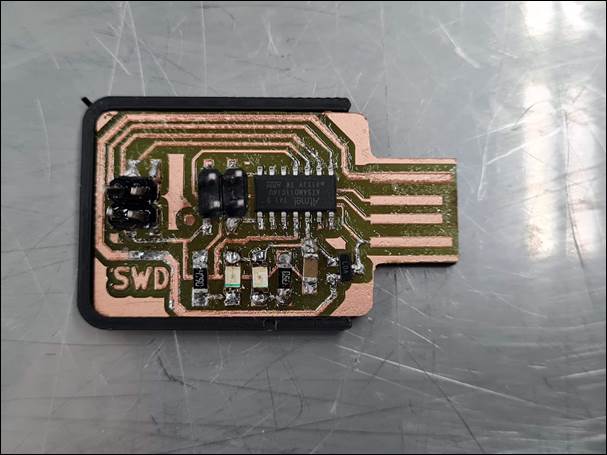

4th step. welding

and fixing all the components

Welding was the most difficult task

to accomplish, that is because it requires a manual ability and to get some

practice before doing it well.

Here are some recommendations that we

followed during this process:

-

There are two ways to work, starting

with the microprocessor to have plenty of space to work with, or leaving it

towards the end because to avoid excessive heat to damage it. Either way will

work, I started with the microprocessor and had difficulties with the headers

(I have not found a perfect way to weld).

-

LEDs and Regulators have a correct

position, you have to be aware of where the cathode is

and work accordingly.

-

The other components are easier to fix

because there are not heat related risks or space related issues.

Once you finish

fixing all the components you should check for discontinuities with the voltimeter, that will help you find any mistakes done and

correct them before proceeding to board programming.

5th step.

Programming the device

For this stage I

had to create a programmer board used exclusively for programming my different

boards I was going to use for the different assignments. This was also created

from Adrian Torres SAMDINO

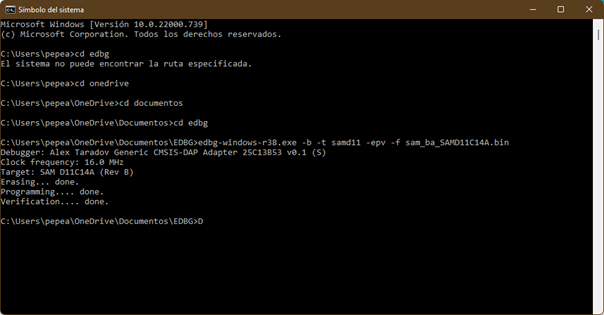

page, and programmed with EDBG as follows (Windows):

- Download EDBG

software to the PC in any folder, it is in: https://github.com/ataradov/edbg

- Download EDBG Free

Dap Bootloader file and save it in the EDBG folder.

- Open Terminal.

- Go to EDBG

Folder.

- Type the next

command: << edbg-windows-r38.exe -b -t samd11 -epv -f

free_dap_d11c_mini.bin >>.

- If everything

is plugged in correctly and working your board is now a free dap programmer.

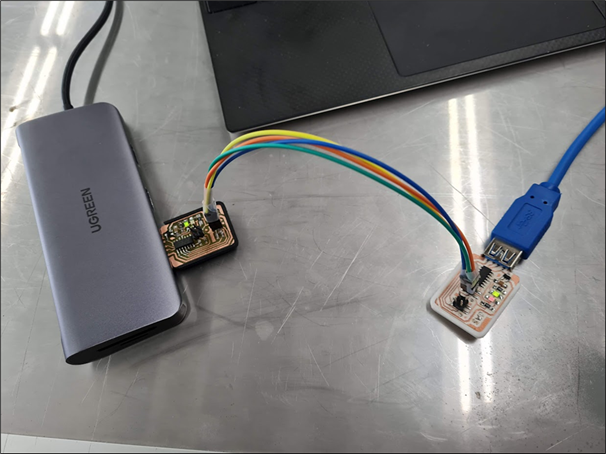

This is a

picture of the SWD programmer being plugged to be programmed:

As

you can see, the best way to plug the connectors between the programmer and a

board is by signaling somehow where the GND pin is. The programmer board has

two sets of pins, one is designed to get the board programmed and a second one

to program different boards. For that part you should have the correct

bootloader file, for my board is the sam_ba_SAMD11C14A.bin file, which should

be stored in the same folder we are working on and then use the same command to

call it: << edbg-windows-r38.exe -b -t samd11 -epv

-f sam_ba_SAMD11C14A.bin >>.

Once the programmer is ready, you can

use it to program any other board:

In

this video we can see how you have to plug the

connectors to program a new board:

Conclussions

This assignment importance was to get

used to what we were going to be doing for a few weeks. I got to learn the

different components and what are they for. And most important, the principles

and basics of electronic boards where I should get my design ready as soon as I

can, because there are too many mistakes I could make in the process, so if I

do not have enough time to repeat the processes, I am going to be having more

problems than I should, during the next weeks.

Nueval

Checklist

ü

Linked to the group assignment page.

ü

Documented how you made (mill, stuff,

solder) the board.

ü

Documented that your board is

functional.

ü

Explained any problems and how you

fixed them.

ü

Included a hero shot of your board.

2022