13. Applications and Implications

Propose a final project masterpiece that integrates the range of units covered,

answering:

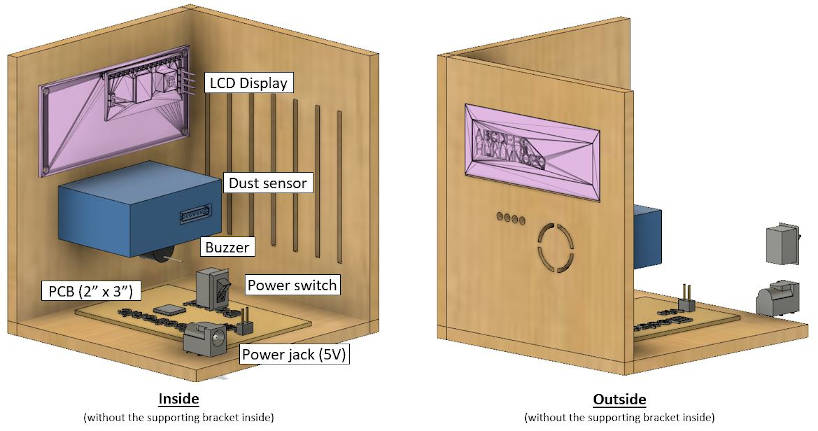

My final project is a dust sensor which will measure the amount of airborne dust particulate matter in my Project Lab (which is a carpentry workshop that I manage) and in-turn display the reading onto the LCD display screen. It will display PM10 and PM2.5 readings.

PM10 is particulate matter 10 micrometers or less in diameter. PM10 is generally described inhalable coarse particles.

PM2.5 is particulate matter 2.5 micrometers or less in diameter. PM2.5 is generally described as fine particles.

In addition, if the reading of PM2.5 exceed a pre-defined limit, the buzzer of the dust sensor will sound.

1) M 2.5 Sensor running from an Arduino Uno Rev 3 board :

http://fab.cba.mit.edu/classes/863.16/section.EECS/people/Jain/articles/2016-12/final-project-planning.html

2) Arduino Tutorial : A dust sensor running from an Arduino Fio board :

http://arduinodev.woofex.net/2012/12/01/standalone-sharp-dust-sensor/

3) A PM 2.5 Sensor connected to a Particle Photon :

https://www.hackster.io/edwios/air-quality-monitor-3f422f

I will design :

1) The PCB or electronic board to take in reading form the dust sensor module and output to a LCD display module and a buzzer (if unhealthy limit is reach).

2) A 3D-print support frame to hold the electronics comonenets together. 3D Print is a form of additive manufacturing which give me more flexibility in my design, to design to the shape and size I want.

3) A 3mm thick wooden/acrylic plastic enclosure box. Using laser cutting, a form of subtractive manufacturing.

First impression in 3D of my final project without the 3D print support frame (not design yet yet)

| No. | Part No. | Part Description | Qty | Price (USD) |

Total (USD) |

Remarks | Input device |

|---|---|---|---|---|---|---|

| 1. | PMS5003 | PM2.5 Air particle/dust sensor, laser inside, digital output module | 1 | 13.30 | 13.30 | AliExpress | Output device |

| 2. | LCD Screen 1602 | LCD Display Module (2 rows x 16 lines) 1602 5V Blue Blacklight | 1 | 1.32 | 1.32 | AliExpress |

| 3. | IIC/I2C adaptor | IIC/I2C adaptor for LCD 1602 display module | 1 | 0.88 | 0.88 | AliExpress |

| 4. | 433-1028-ND | Buzzers Transducer, Externally Driven Magnetic 5V 50mA 2.4kHz 87dB @ 5V, 10cm Through Hole PC Pins | 1 | 0.59 | 0.59 | DigiKey | Electronic Board |

| 5. | ATMEGA328P-AU-ND | ATMEGA 328P MCU 8BIT 32KB FLASH 32TQFP | 1 | 2.27 | 2.27 | Digikey |

| 6. | 535-9362-6-ND | 16MHz Ceramic Resonator Built in Capacitor 22pF | 1 | 0.44 | 0.44 | Digikey |

| 7. | 1276-1075-6-ND | CAP CER 10µF 25V X5R +10% 1206- | 1 | 0.24 | 0.24 | Digikey |

| 8. | 399-4674-1-ND | CAP CER 0.1µF ±10% 250V X7R 1206 | 1 | 0.48 | 0.48 | Digikey |

| 9. | 311-10.0KFRCT-ND | RES SMD 10K Ohm1% 1/4W 1206 | 1 | 0.11 | 0.11 | Digikey |

| 10. | 311-1.00KFRCT-ND | RES SMD 1 kOhm ±1% 1/4W 1206 | 1 | 0.11 | 0.11 | Digikey |

| 11. | SW262CT-ND | Switch Tactile 1206 SMD | 1 | 1.17 | 1.17 | Digikey |

| 12. | 160-1167-1-ND | LED Red Clear 1206 SMD | 1 | 0.41 | 0.41 | Digikey |

| 13. | 609-5161-1-ND | ISP Header Surface Mount 6 position 0.100" (2.54mm) | 1 | 0.91 | 0.91 | Digikey |

| 14. | S1011EC-40-ND | Connector Header Through Hole 40 position 0.100" (2.54mm) | 1 | 0.72 | 0.72 | Digikey |

| 15. | TOL-14974-ND | FR1 Copper clad board single sided 2.00"L x 3.00"W stock for PCB Fabrication | 1 | 1.38 | 1.38 | Digikey | Pin header connectors (female) for PMS 5003 sensor |

| 16. | VENSTPOW | 2.54mm Single row Dupont Connector Plastic Shell Plug Jumper Wire Cable Pin Header female | 8 | 0.16 | 0.16 | AliExpress | Wiring cables |

| 17. | ROBOTLINKING | Jumper Wire Female to Female, Dupont Line 10cm length | 9 | 0.86 | 7.74 | AliExpress | Power source |

| 18. | LJH-186 | AC/DC 100-240V Universal Power Adaptor Output 5V 0.5A (2.1mm dia) EU plug 5.5 mm x 2.1 mm | 1 | 1.71 | 1.71 | AliExpress |

| 19. | DC-050 | DC Power Jack Socket Connector DC005 5.5x2.1mm | 1 | 1.26 | 1.26 | AliExpress | Wooden Enclosure Box |

| 20. | 434-295 | Clear Acrylic Sheet, 500mm x 300mm x 3mm | 1 | 12.39 | 12.39 | Might be using recycled material from Fab Lab | Miscellanous : mounting fixture/support |

| 21. | PLA filament for 3D Printer, Innofil, 2.85mm, 750gram, silver color | 1 | 30.35 | - | Obtain from Fab Lab | |

| 22. | Small screws | 6 | 0.05 | - | Obtain from Fab Lab | |

| Total | 46.42 | |||||

Note :

Digital fabrication tools/machine require :

| Dust Sensor Module |

|---|

|

|

Brand : Plantower Model No. : PMS5003 |

| Datasheet |

| This sensor uses laser scattering to radiate suspending particles in the air, then collects scattering light to obtain the curve of scattering light change with time. |

| Price : USD 13.30 |

| More info on aqicn.org website |

| LCD Display Module | Buzzer |

|---|---|

|

|

|

Brand : LANDZO Model No. : 1602 |

Brand : Soberton Inc. Model No. : 433-1028-ND |

|

- LCD Display Module 1206A (1602A) Datasheet 1 - LCD Display Module 1206A (1602A) Datasheet 2 |

Datasheet |

| This blue screen LCD Display Module display 2-lines X 16-characters. Viewing area size: 64.5mm x 16mm. | Buzzers Transducer, Externally Driven Magnetic 5V 50mA 2.4kHz 87dB @ 5V, 10cm Through Hole PC Pins |

| Price : USD 1.32 | Price : USD 0.59 |

|

More info on Digikey |

More info on Digikey |

Most of the electronic components can be found in the SP Fab Lab like buzzer, LCD display module, copper claded FR1 material for PCB milling. PLA filament for 3D printing is provided by the Fab Lab. Estimated PLA material require to be less than 8m.

For the specialise PM2.5 dust sensor module and other electronic components which are not in the Fab Lab inventory, will need to be purchased from online shop.

For the 3mm thick plywood or acrylic sheet used to fabricate the enclosure box, it will be purchase from local art and craft shop.

Electronic board - made

Enclosure box - made

Support frame to hold the Dust Sensor, LCD display module, etc - made

2D/3D Design - Autodesk Fusion 360 software

PCB Designing - Autodesk EAGLE software

PCB fabrication process - StepCraft 420 PCB milling machine

Stuffing of components - Soldering station, soldering wire and soldering tool

Additive manufacturing process -

3D Printer

Subtractive manufacturing process -

Laser cutter

Testing and troubleshooting of electronics : - Digital multimeter

1. How can I fit the various electronic components inside the enclosure?

2. How the various electronic components going to be connected together?

3. Is there a way to have a neat cable run inside the enclosure? A cable mamagement tube/tray?

4. Will the dust sensor work accurately as advertised?

5. Will the enclosure box be stable and not filmsy or easily broken?

6. Where will the source of power coming from?

7. How long does the dust sensor last in normal office environment? or in a dusty environment? Dust is inevitably produced in the Project Lab. If the workshop environment is very dusty, how long will the dust sensor last? I would need to be able to remove the dust sensor for cleaning, or replace the dust sensor if needed.

1) Successfully design and fabricate the enclosure box. Enclosure box should not be shaky and flimsy

2) Successfully design and fabricate the support frame

3) Support frame is able to securely hold the various componenets together

4) Successfully design and fabricate the electronic board (PCB milling, soldering the components)

5) The fabricated electronic board is able to integrate with the LCD display module, the buzzer, the 5V power jack and power switch. Connection and programming

6) LCD Display module is able to display PM2.5/ PM10 reading

7) Buzzer is able to sound if a pre-defined unhealthy PM2.5/PM10 limit is reach or exceeded

In view that a standard USB 2.0 port power output is around 500mA. I will use a 100-220 AC to 5V DC 500mA power adaptor as my main source of power supply.

I hope to have some form of logging, therefore I intend to integrate a storage device into the project somewhere in the future. It will be ideal to take an average reading over 1 hour or a few hours duration, therefore might need to log the data down.