Principles and Practices: Project ideation week!

In this assigment we should decide what we want to do as a project. Neil Gershenfeld the fab academy director, shared with us during the online session examples of what we can do for our projects, and showed us the pass years alumnas's projects.

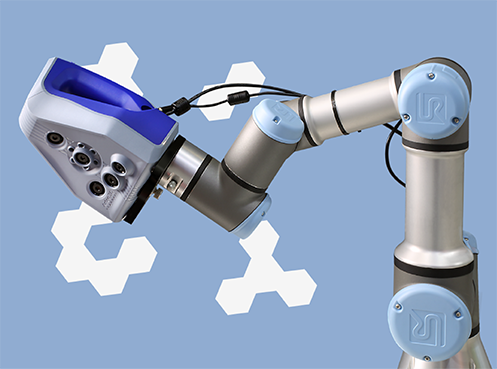

For me I decided to do A 3D scanning set for the handheld 3D scanner. A robotic arm will be attached to a circular field to control the rotation of the 3D scanner around the object automatically using a remote control. The objective of this project is to help patients with limb loss to scan their limbs and fabricate for them an artifical limb that has similar characteristics to their old limb. The objectives of this project are:

1. Portobal 3D scannin set.

2. Scan syrian refugees body's limbs.

3. Digital fabricate artificial limbs.

4. Cheap Option to Buy form the market.

In order to achieve these objectives different design goals were setted. These desingns goals will help me in fabricating my project in a very work oriented way. The projects design goals:

1. Design and fabricate tripod arm, and holder, to hold the 3D scanner.

2. Design and fabricate a circular rail for the 3D scanner to travel around the 3D object.

3. Design and fabricate a table or box to hold the 3D scanning set.

4. Control the system automatically using a mobile app.

5. Work on making the entire system portable.

There is a huge chance that not all designs goals might be achieved during Fab Academy. However, I will work in the future to achieve all project objectives and goals.

Project Ideation

The ideation process started by thinking of different ways to fabricate the main idea, which is a 3D scanner rotating around the object. The main idea came from the fact that you cannot rotate body's limb 360 degree, and because there will be no accurate and high resolution results if the 3D scanner was rotating in arbitrary way around the body limb.

Therefore, and based on the problem disscussed, I came out with three different way of how the 3D scanner can rotate around the body limb. Some of these ideas were already available in the market, and I just add few adjustments to them, and otheres can be consider completely new for now, since I could not find a similars ideas in market.

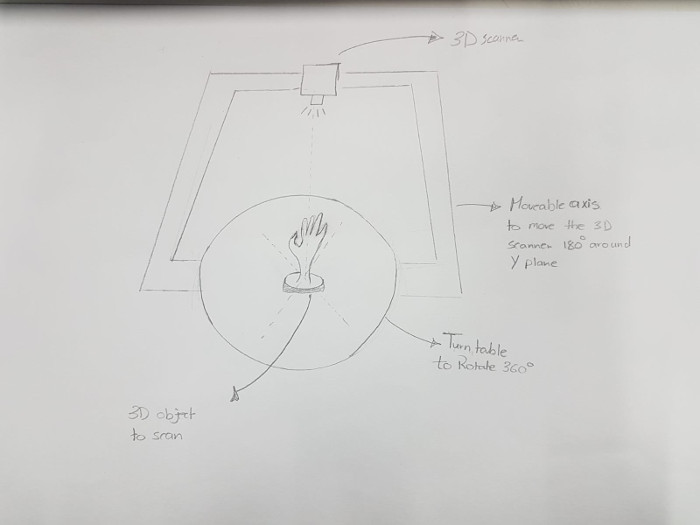

1. 3D scanner that rotate 180 degree around the body limb.

The idea of this approach is for the scanner to rotate around the object through the y-plane, the scanner will rotate 180 degree around the object, to collect the scans from different directions.

When I was looking for this option I found out that there is similar idea in one of the korean company. The brand called Raptor3DX Scanner - Proprietary SSS Technology. The proprietary technology enables platform stage to avoid swinging movement during scanning, and will reduce clamping or fixation of scan parts before scanning. This idea consider to be one of the innovative ideas, however, I don't think that I will do this idea since it is already available in the market.

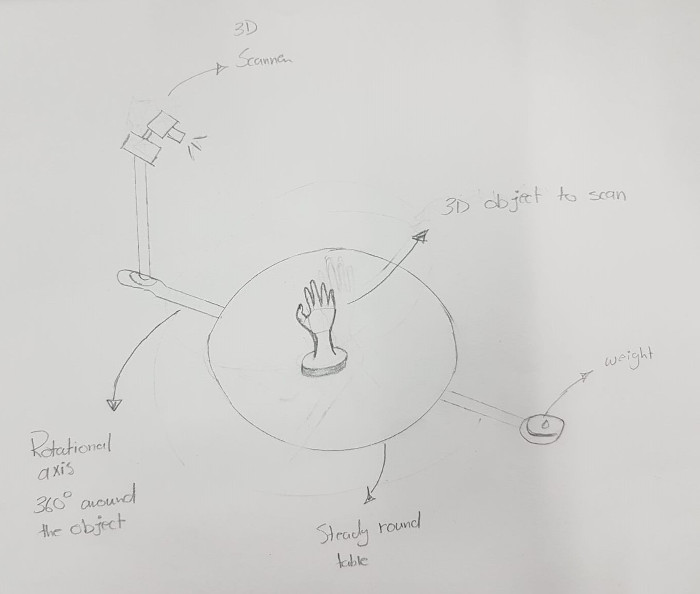

2. 3D scanner rotate 360 degree around the body limb.

The main concept behind this idea is that the scanner will rotate 360 degree around the object using a rotational axis attached on the bottom of the table.

The scanner will be adjusted on a fix axis, and the only moving part will be the rotational axis. Also there will be a weight to control the balance of the whole system. This mechanism usually used to capture the slow motions cuts in movies, and when I was reading about it I found out that I can even use it as scanning option. However, the only drawback about this option is that I cannot adjust the angle of the scanner automatically, which actually might be a great help to get an accurate results.

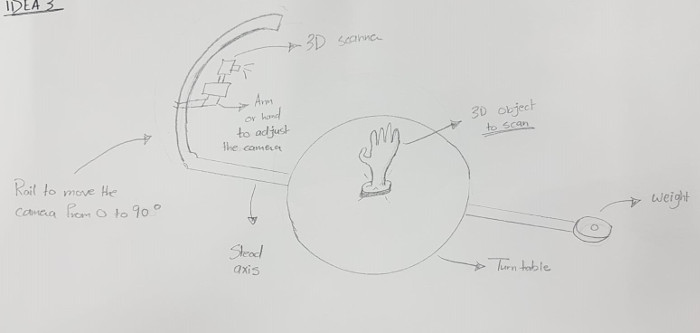

3. A two axes 3D scanning system.

The concept behind this idea or mechanism is similar to option number 2. However, the only difference here is that there is a rail for the 3D scanner to travel through up and down to change the scanning angel.

Initailay, I am more convinced with this option, it mostly has all the features required to design and fabricate this project. However, I am still open for modifications if required in the future while developing the project.