Wildcard Week: Open your imagination!

In this assignment we are supposed to try something new, something that we have never tried or studied in Fab Academy. During Fab Academy we used different technology that you can always find in Fab Lab. However, in this assignment we are suppose to either use a technology that we did not use during the past 6 months, or maybe try something completely new in every single way. Therefore, I decided to do Soft Robotics as my wildcard week assignment.

Molds Designs

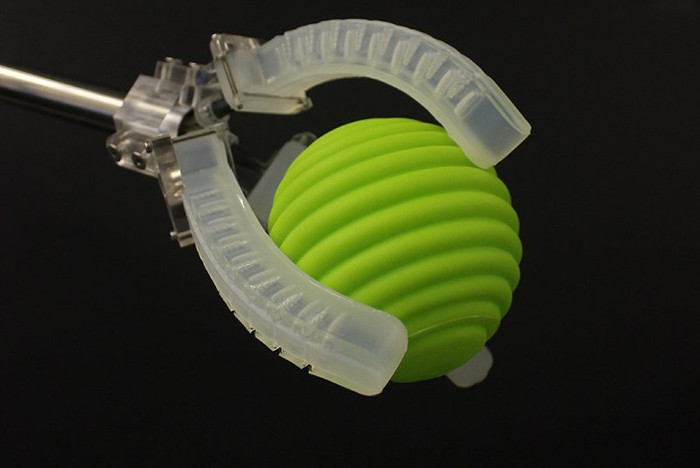

Soft robotics are structures created with flexible, body-friendly materials, usually controlled by air, that attempt to simulate the subtlety of the body's movements. In this assigment I am planning to design and cast a mold for robotic hand, using soft robotics techniques.

Earlier this year our lab hosted a workshop in soft robotics developed and delivered by Mrs. Adriana Cabrera one of Fabriacademy global faculty. In the workshop she expalined how to design and fabricate soft robotics using two differnt technologies (vinyl cutting, and molding and casting) you can read more about the delivered workshop here. For me I decided to design my soft robotic mold and then 3D printing it using differnt material, and finally cast my molds.

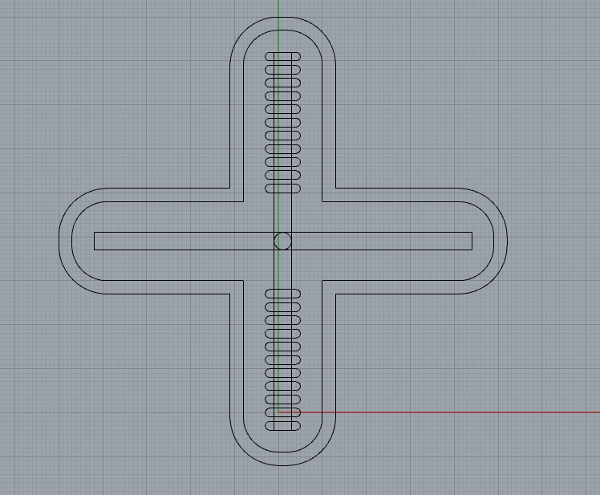

I used Rhino to create my mold design, I followed the same designs instructions Adriana explained to us specially for the one related to air chambers and how they should be designed to allow air to flow inside the object withoud dameging it. The designs steps are the following:

I also designed one plane mold using the outlines of my orginal mold, since it is required to cover my orginal mold with one layer to cover the air chambers. Here is the final results for the mold design:

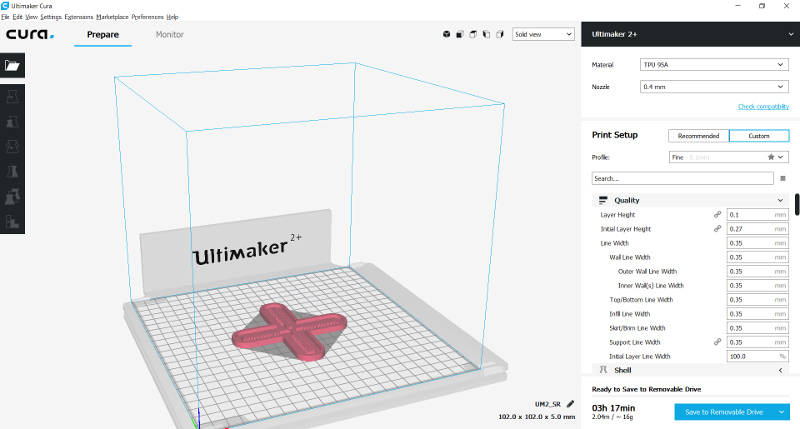

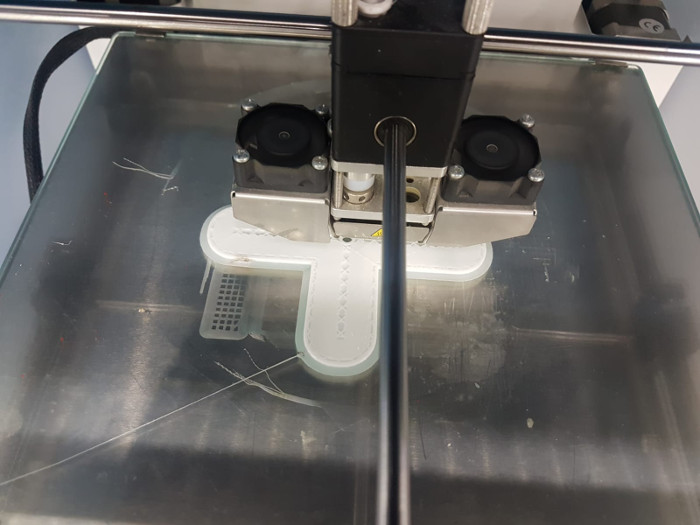

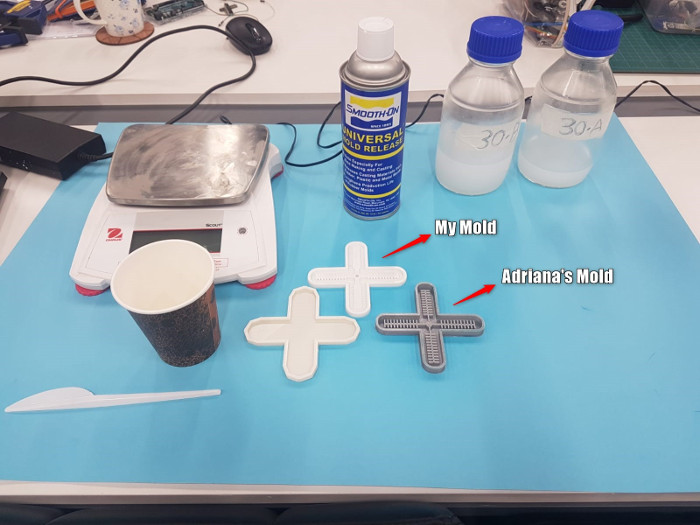

After I finish from designing my mold, I print it using Ultimaker 2+ 3D printer. During Adriana's workshop she provided us with a ready made 3D printed mold for soft robotics, and the material she used to print this mold was PLA. Therefore, I decided to use TPU which is elastic material to print my mold, however I sticked with PLA for the plane mold.

For the printing setups, I used 0.1 layer hight, with 20% infill density, without support, and I used brim as the build plate adhesion. After that I started the printing process and it took around 4 hours for the mold with the air champers, and 2 hours for the plane mold to finish.

And by this I finished the desiging and the fabrication of the molds I am using for creating the soft robotic, and it is time to start the casting process.

Molds Casting

The casting process is divided into two main stages; the first stage is to cast the mold with the air chambers, and the second stage is to re-cast the results from the first stage with the plain mold to cover the air chambers.

To do the this I used the Ecoflex™ 00-30 which is a platinum-catalyzed silicones that are versatile and easy to use. The mixing ratio of the Ecoflex rubber is 1A:1B ratio by weight or volume and it can be cured at room temperature.

I arranged everything to start the casting. To test the process I casted my molds and Adriana's mold to see their behaviour when pumping air inside them.

Then I mixed the material and poured it in both molds.

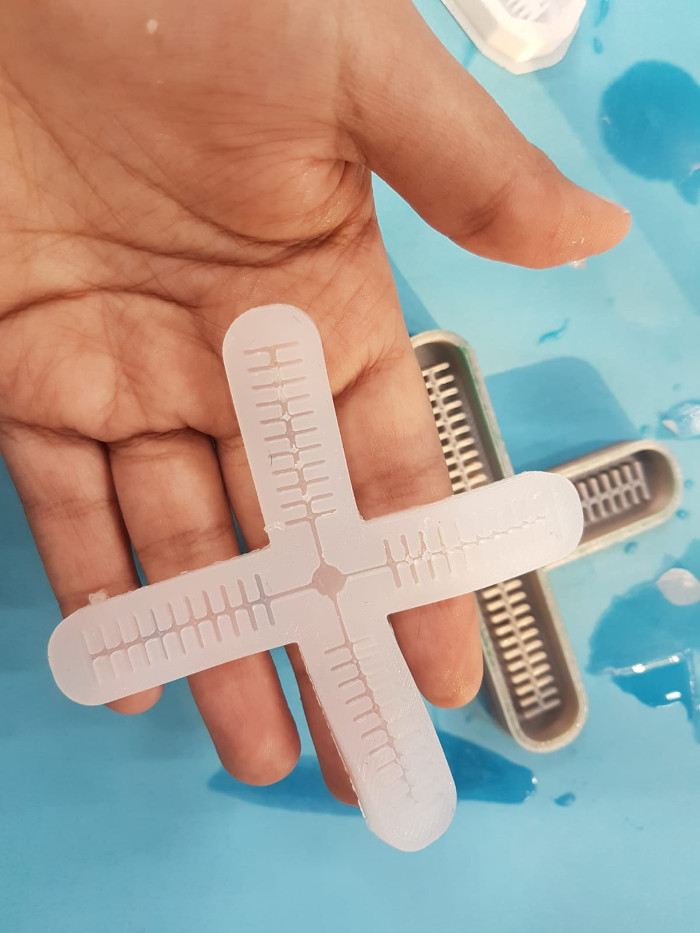

After 24 hours I removed the casting material, and here is the results of both mold:

You can clearly see a big differences between my molds results and Adriana's mold results. My mold has more air chambers in each arm however they are narrowed and the line across them is wider. however, in Adriana's she has less air chambers in each arm but they are wider and the line across them is narrowed compared to mine.I am not sure if it would affect a lot the behaviour when air is pumped inside them, but the only way to know is by testing both of them.

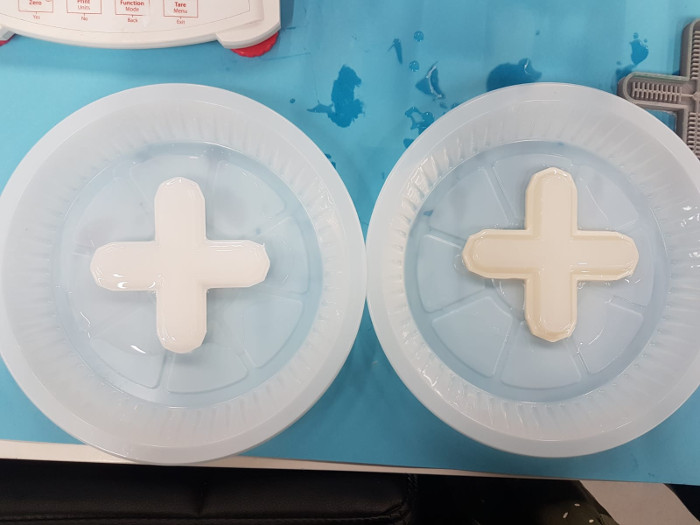

Then After I finish the first stage of casting the molds with air chambers, it is not time to start with second stage, which is casting again the mold upside down using the plane mold fabricated to cover up the air chambers of the first mold. I followed the same process of the first stage, and I poured the mix as the following:

Finally here is the results of casting both molds (mine and Adriana's) and the only thing left to do now is to pour air inside them and check their behaviours.

Soft Robotic Samples

The final results of soft robotics were satisfying which made do extra two molds as well!!