For this weeks assignment the fablab Kamp-Lintfort decided to build an robotic arm, which will move on 2 axis and will be completely 3d printed. I decided to concentrate on the grabbing system of the arm and also I designed one of the joints of the arm. For the whole documentation check our group assignments website

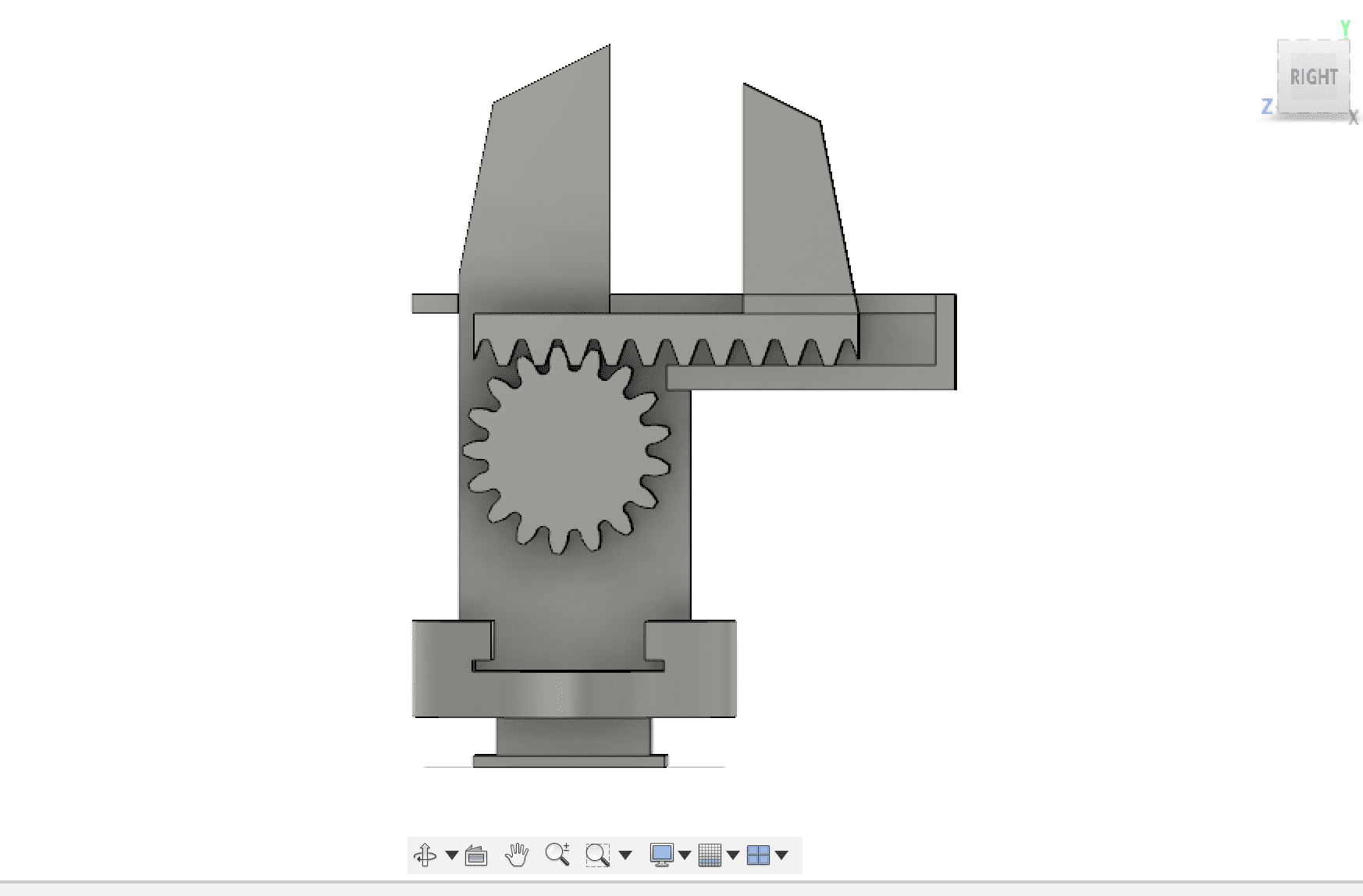

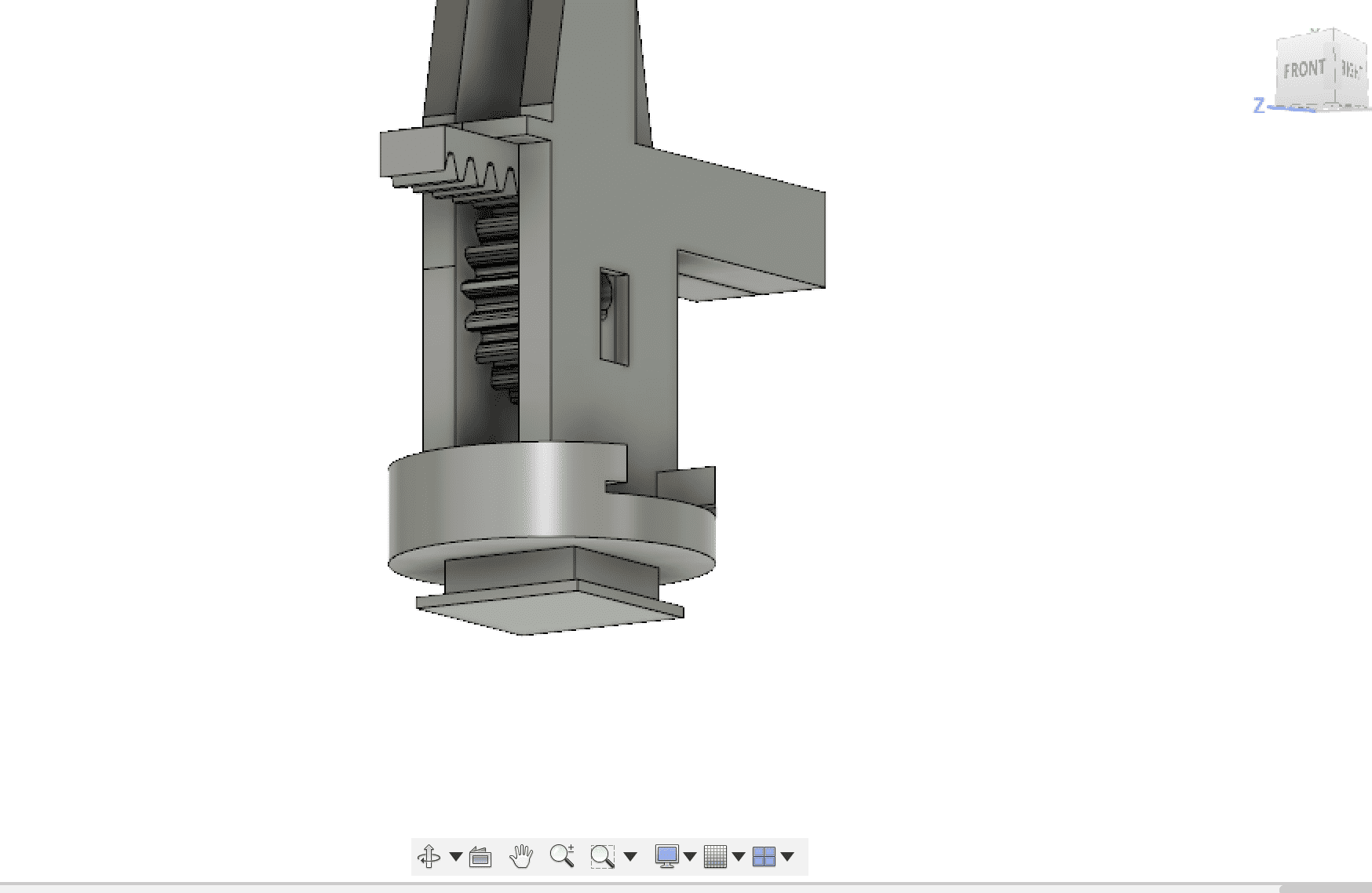

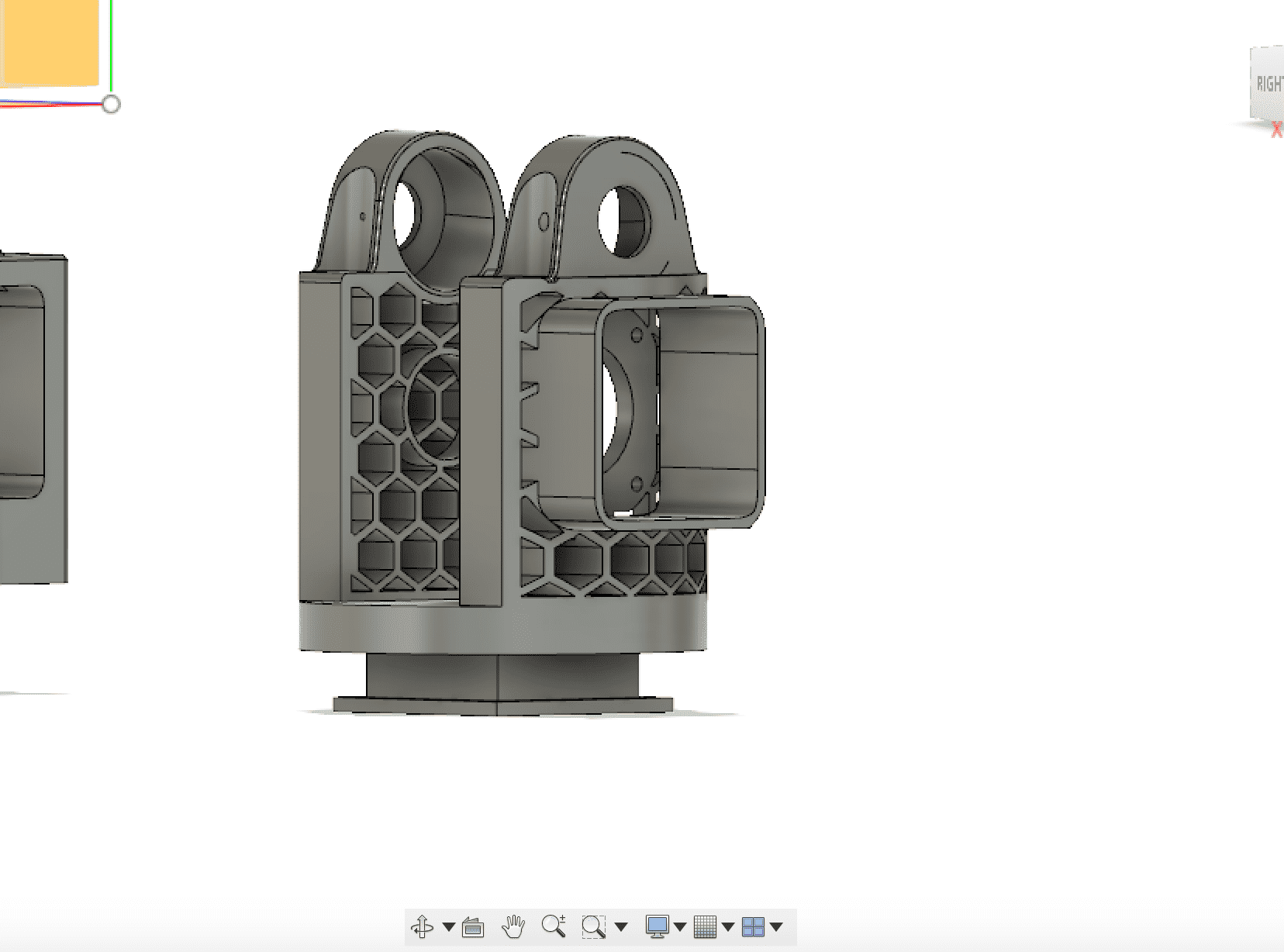

First of all I concrentrated on a grabbing system, I was looking for different ways to grab objects. After starting a few sketches, I decided to use a servo motor to move a gear that will move a linear gear to open and close.

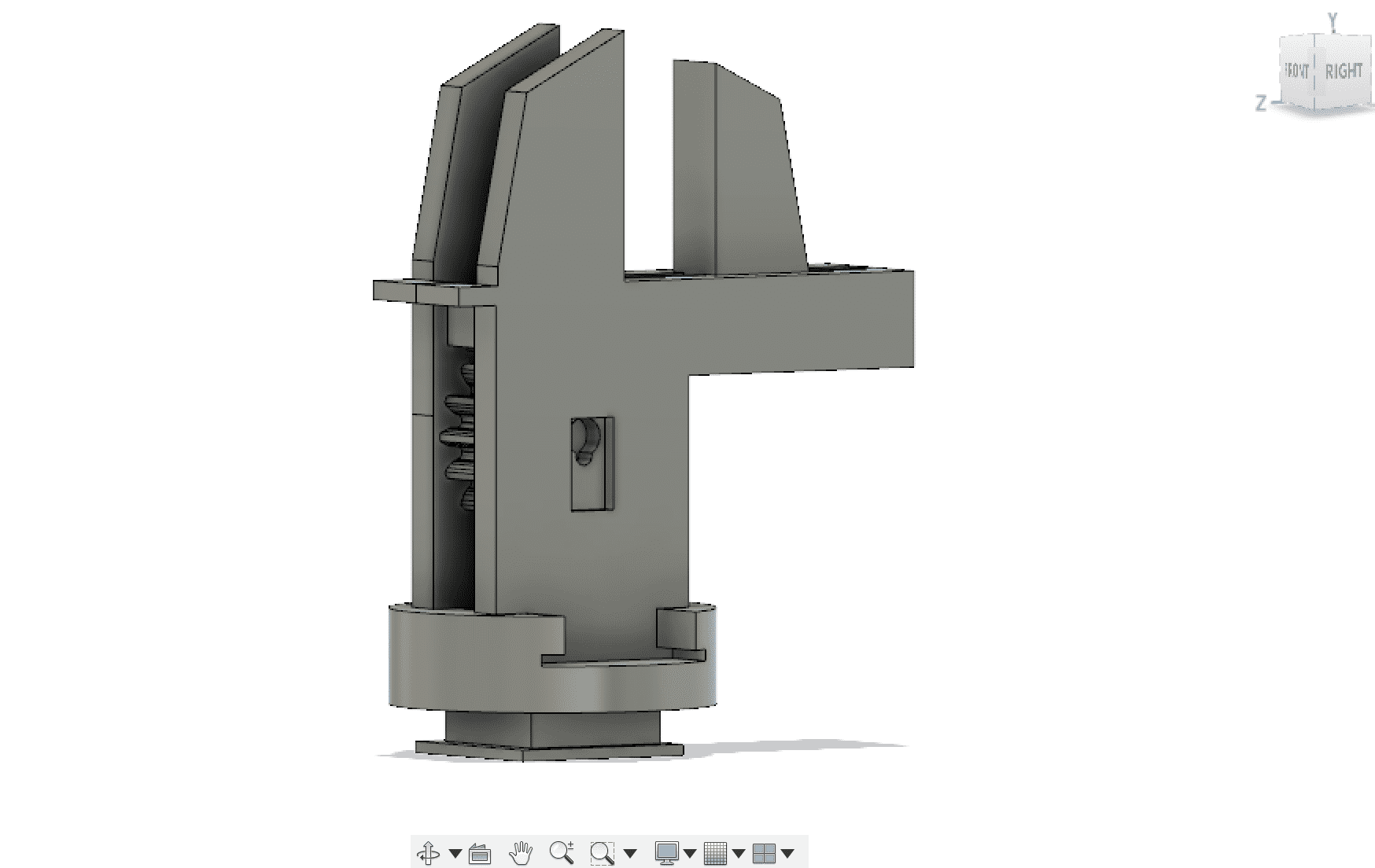

Then I created another wall to close the system and to hold it together. I dont want to use crews or glue, so I made a joint system so we were able to simply slide the last part in.

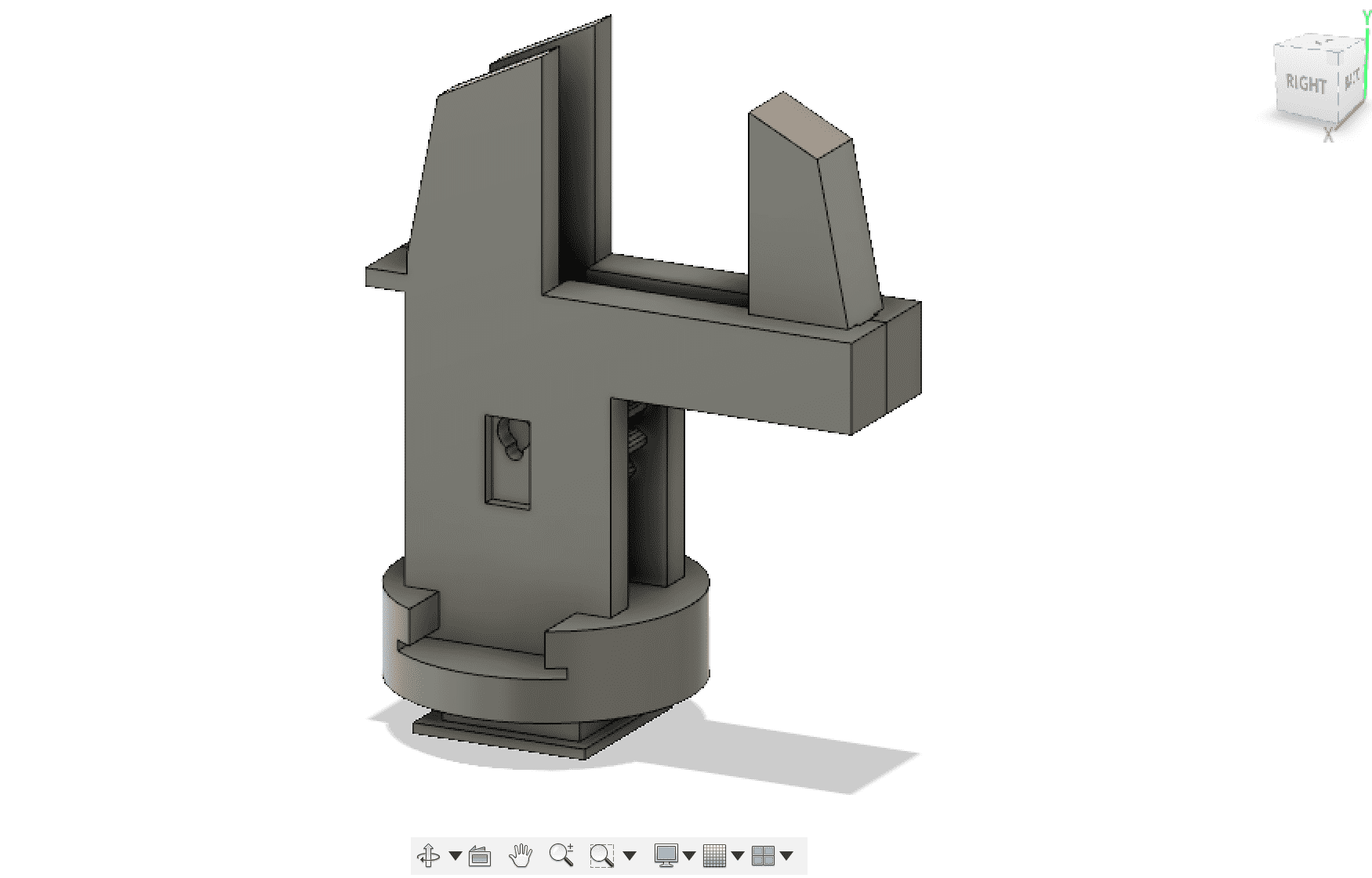

When completely open the hand will look like this.

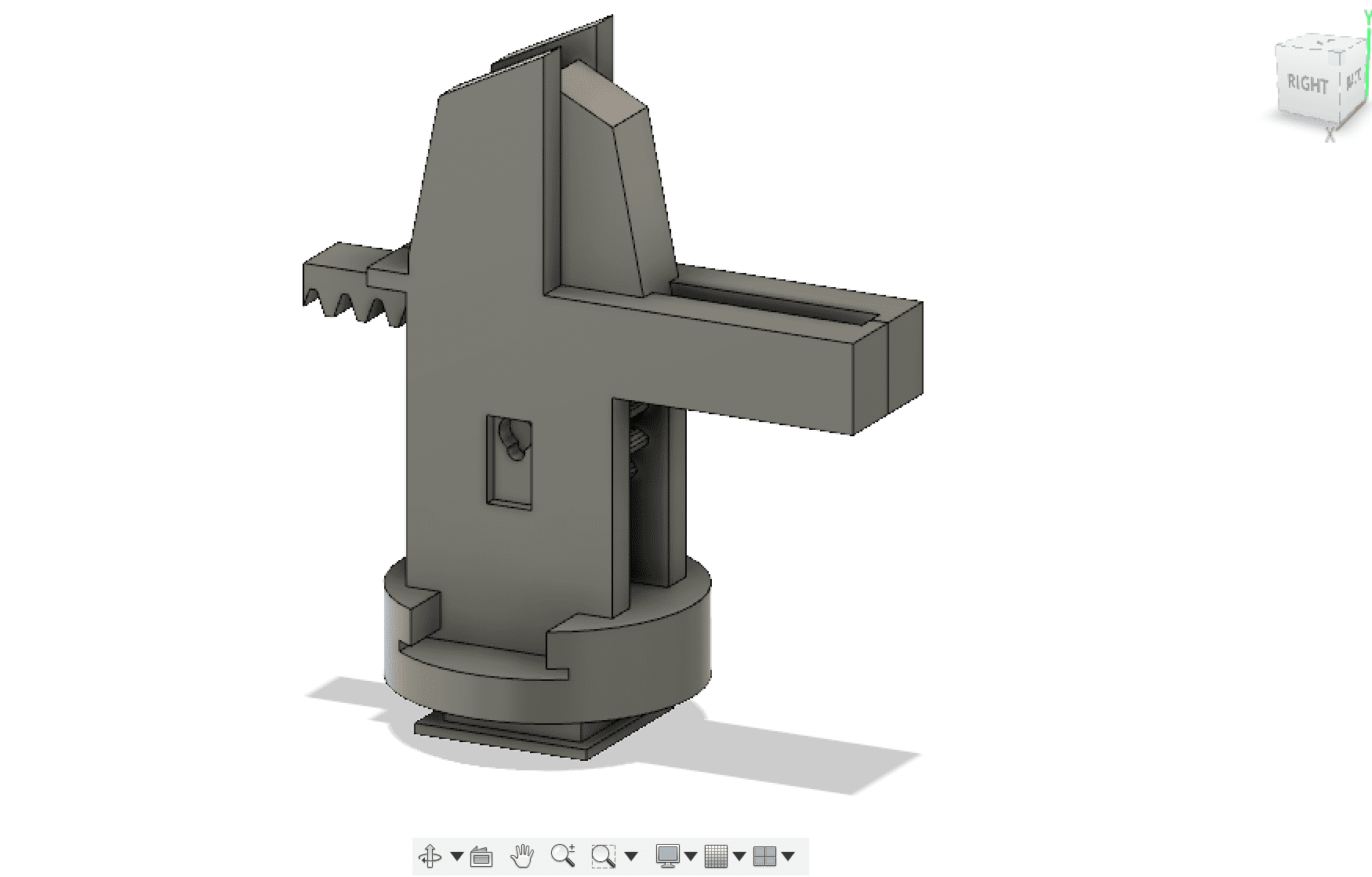

When closed it will look like this

To make it attachable to the rest of the arm I created a joint in the bottom so I was able to slide it onto the rest of the arm.

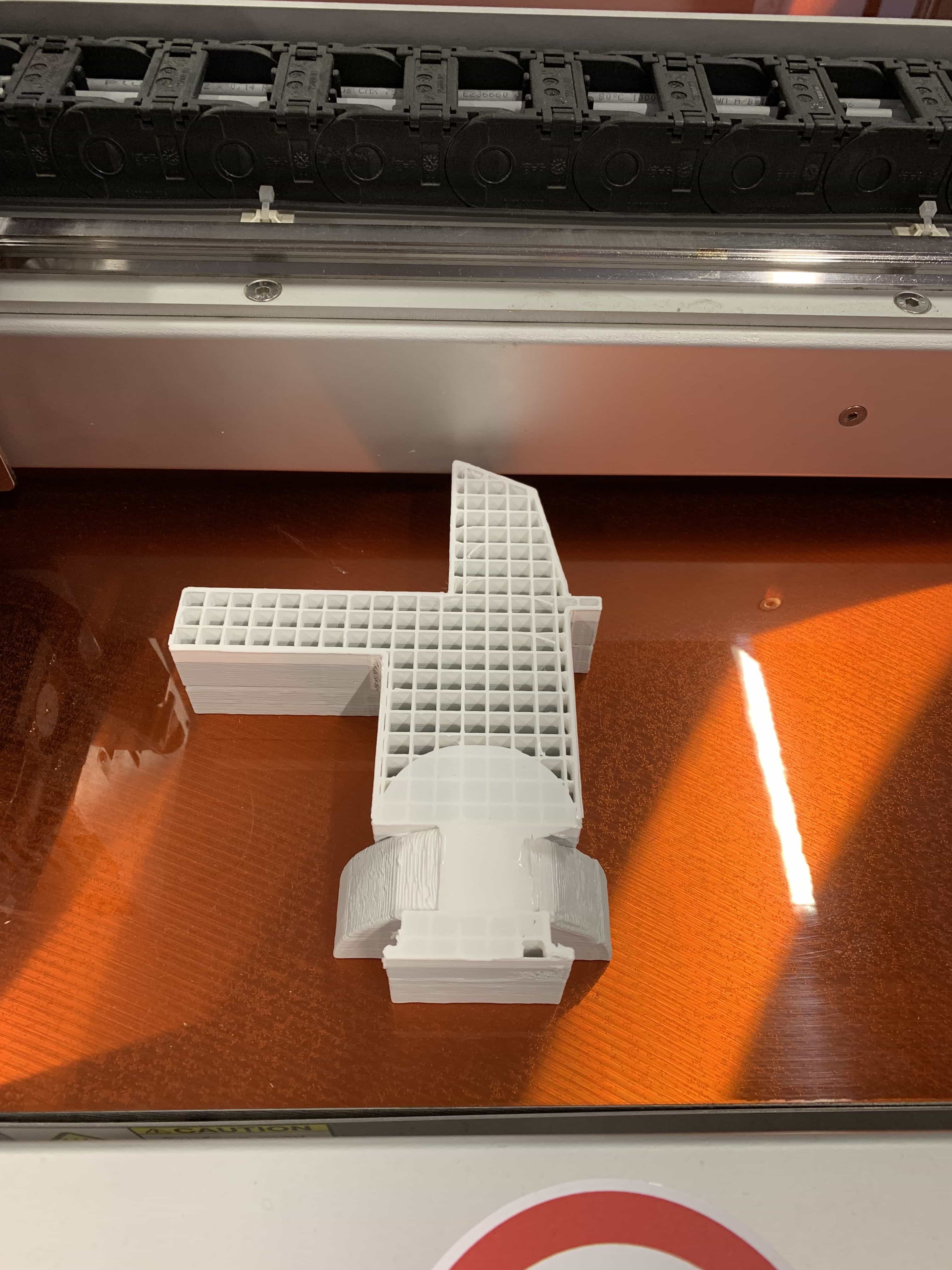

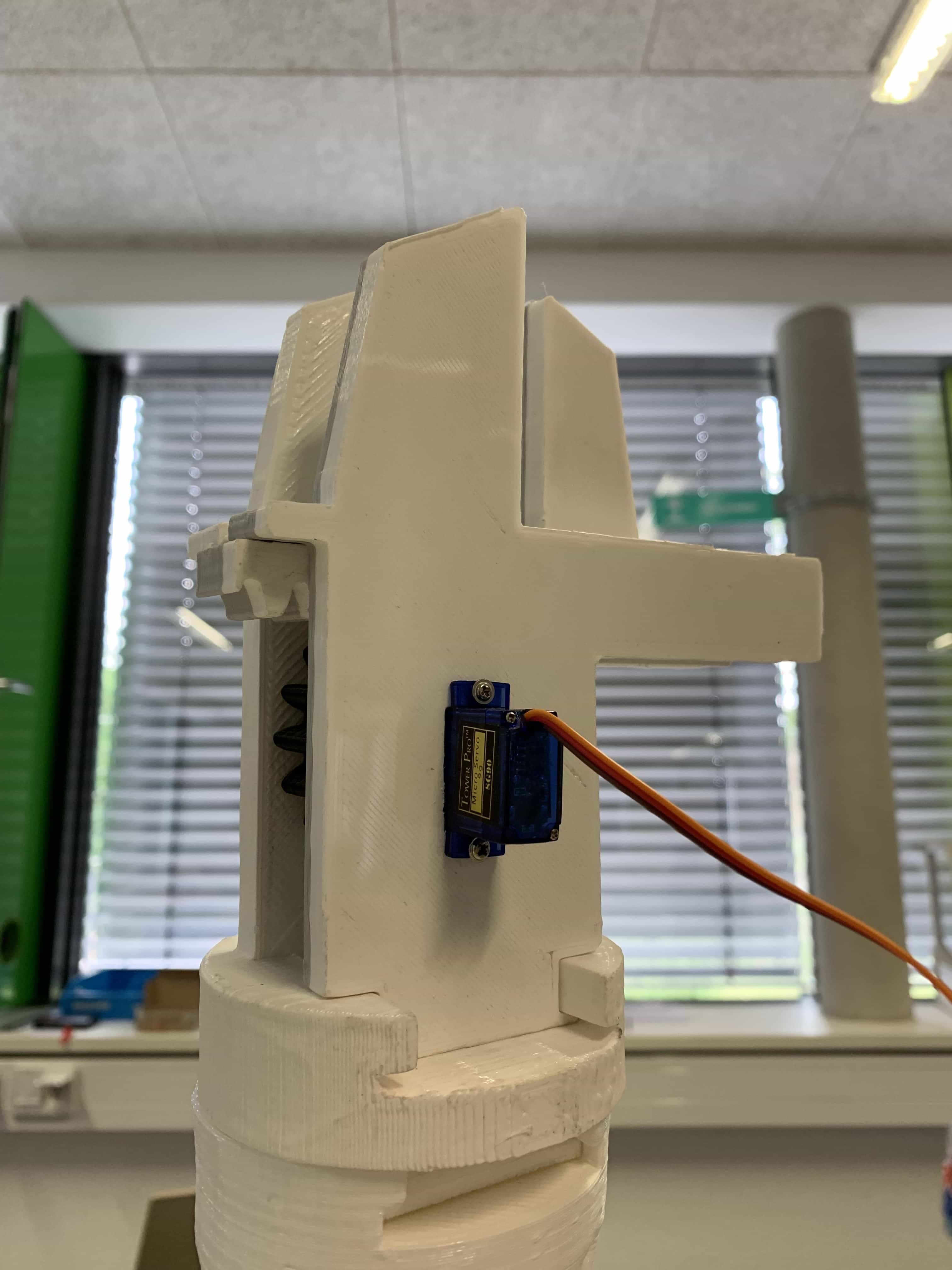

I started printing all the parts using a BigRep 3d printer for bigger objects.

It took me about 8 hours to print every part, but at the end the outcome was like I have expect and calculated it.

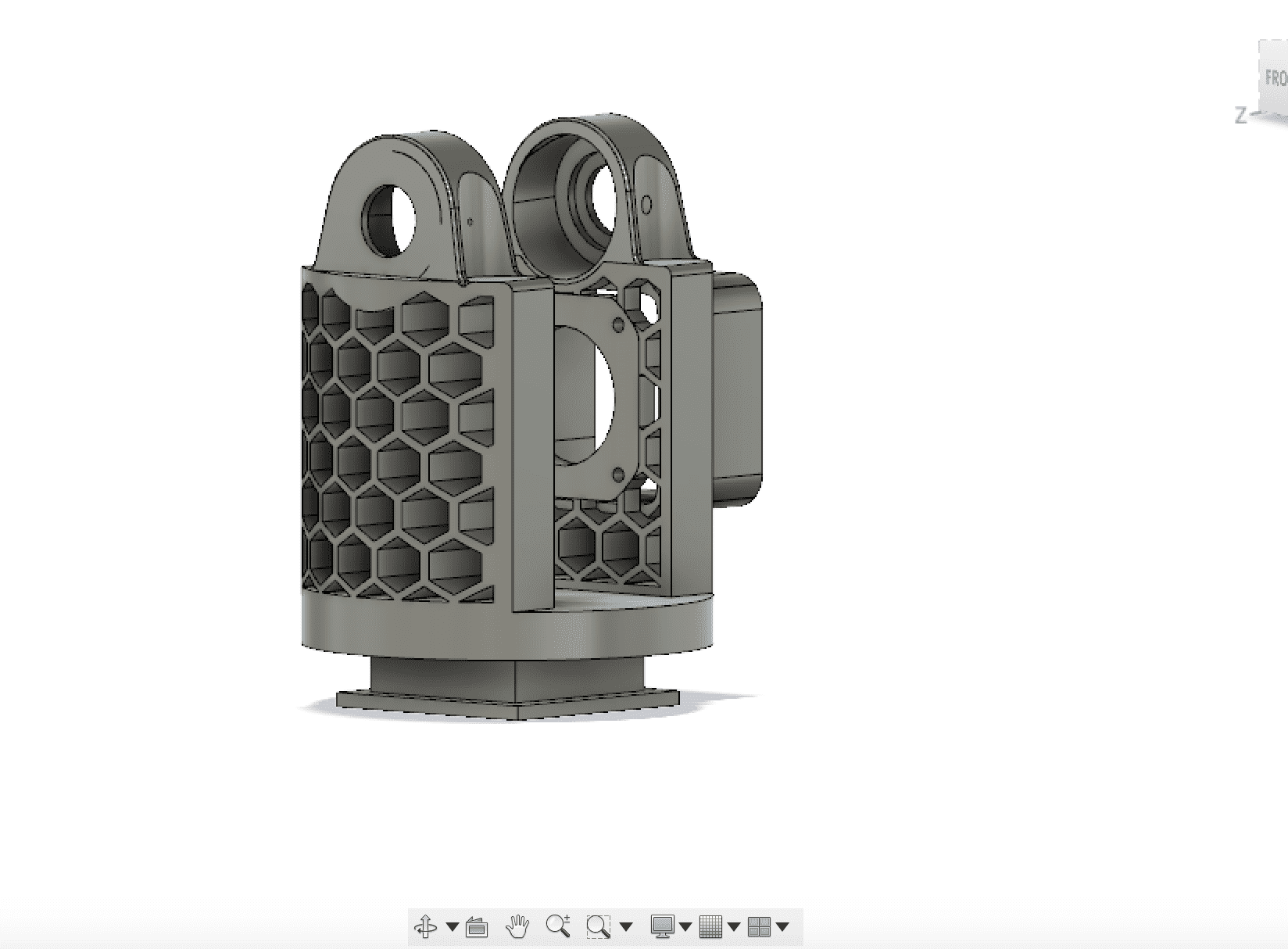

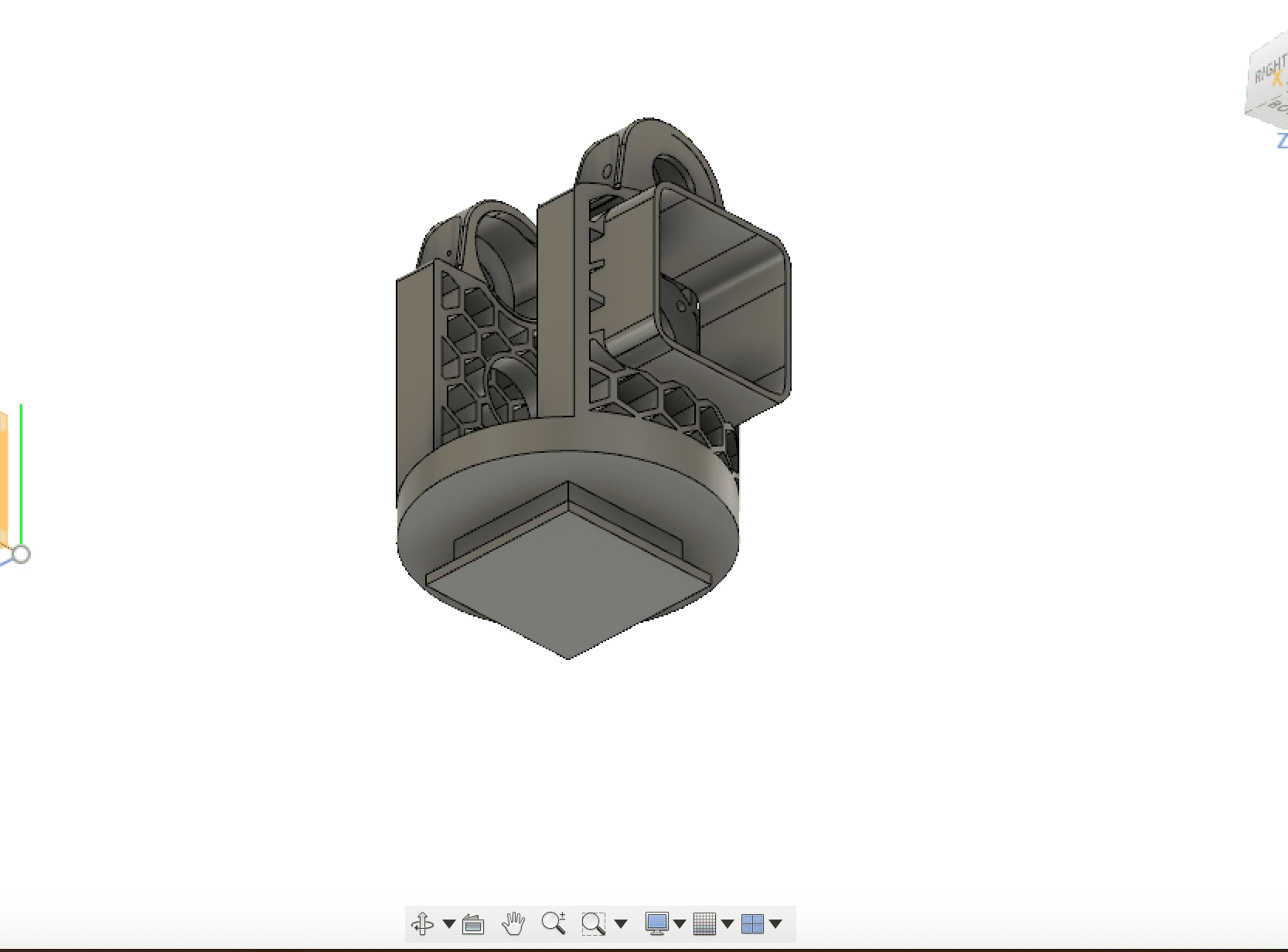

CONNECTION PIECE

The second part I created for the robotic arm, is a link piece for two parts of the arm. Also it had to hold a stepper motor to turn the part that is attached on top of it. Since we wanted the arm to be lighter so it will move easier I decided to use a honeycomb pattern to save some weight.

On the other side I made a hole into the pattern to stick the stepper motor in.

and finally I created a joint so that my part can be connected to the rest of the arm.

The fact that our team always used the same measurments for the joints made the arm very modular. We are able to shorten the arm or make it longer. We were also able to place the parts where we wanted to. We tested the arm and every part of it is working very well.