Individual Assignment

For this assignment I will explain different aspects of my final project answering 10 questions related to the references, materials, processes, pricing, planning and evaluation.

13.1. Q1_What will it do?

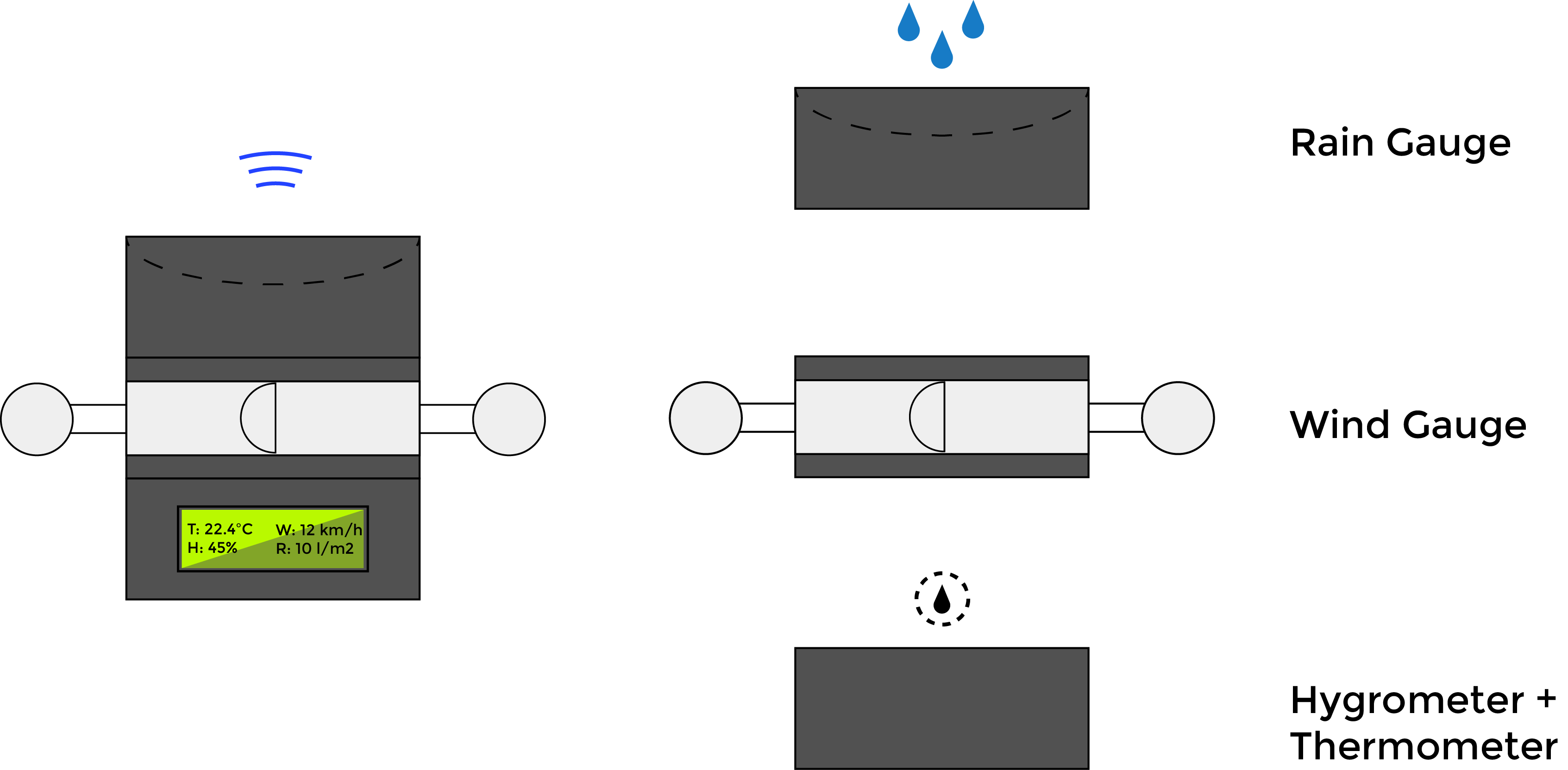

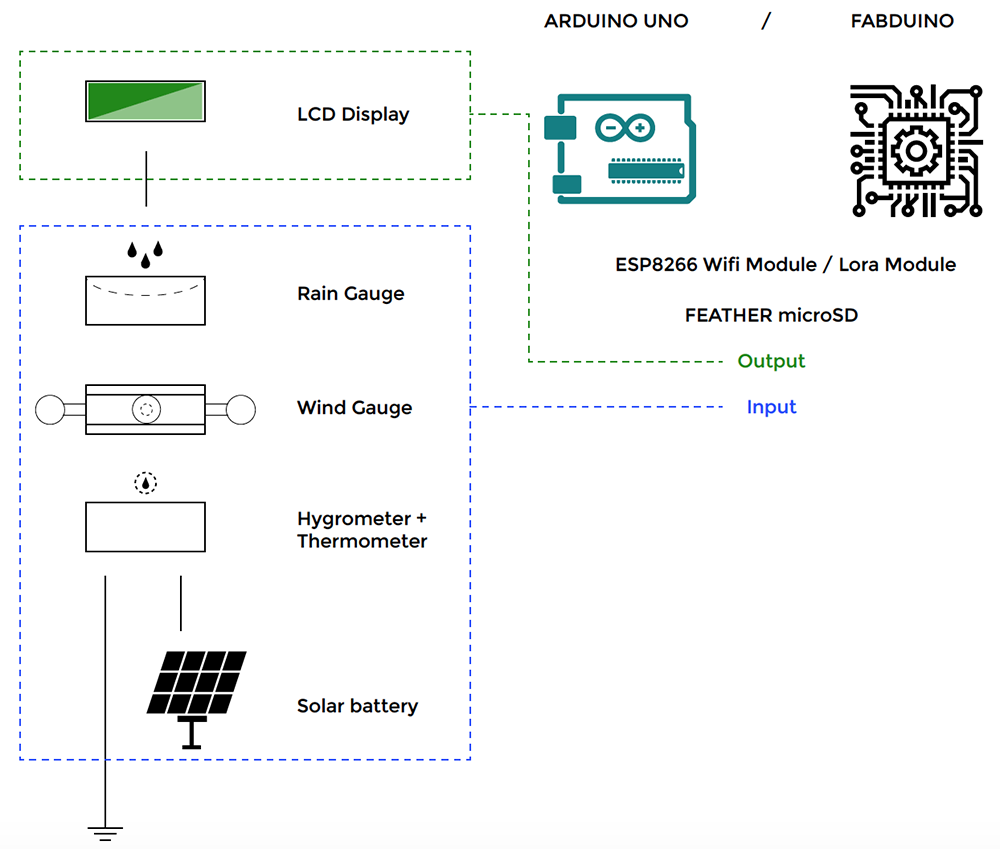

My final project will be based on a superlocal weather station for educational learning. Designed as a starter kit for environmental data collection, the device will gather realtime information from 4 different weather sensors: a wind gauge, a rain gauge, a thermometer and a humidity sensor.

The data collected by the system will be stored in a miniSD card, also displayed on a LCD screen, and hopefully, sent via a low-power wide-area network called LoRa. It can reach distances up to 10km in rates below 50kbps.

This kit is designed to be used in rural areas where there is a profound lack of realtime weather information not just average, or maximum and minimum rates

13.2. Q2_Who has done what beforehand?

There are two interesting projects that I took as referents in terms of the concept of the system, as well as the mechanical and software components they used.

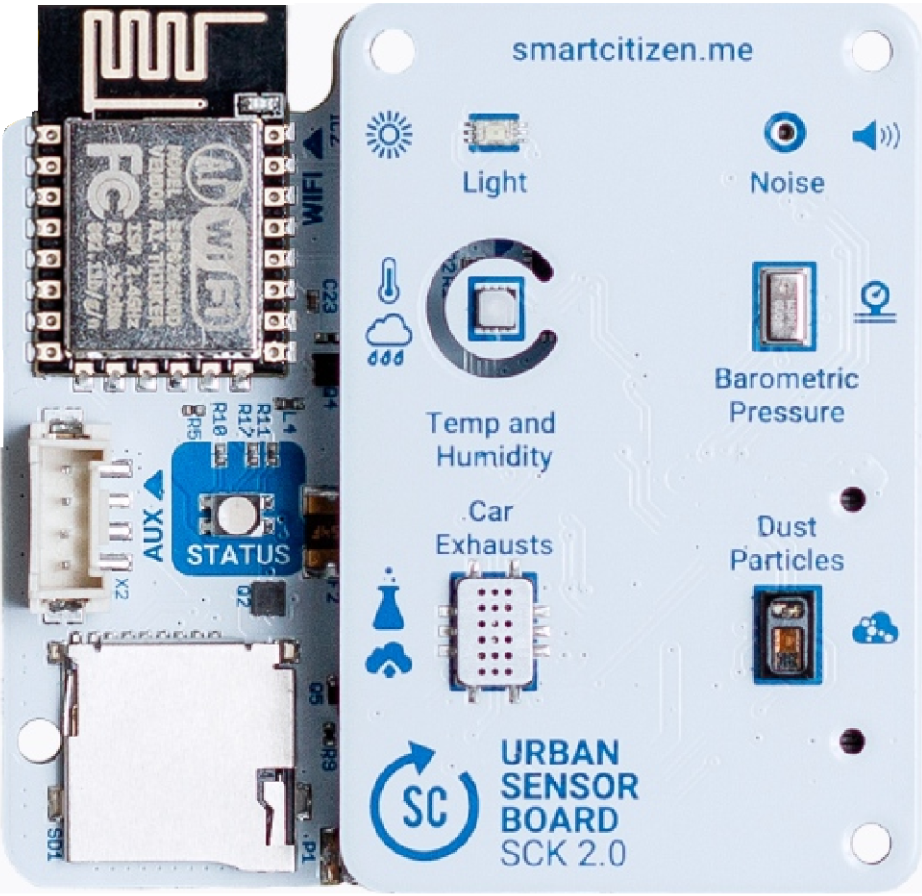

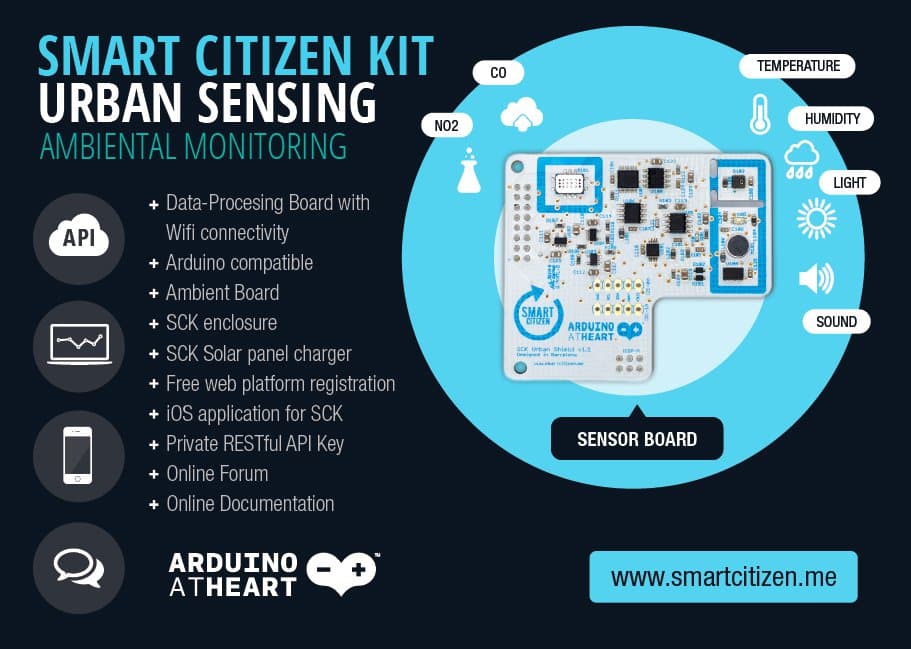

The first one is Smart Citizen. A project that was developed in Barcelona FabLab:

This device is used to capture, analyze and share data from urban environments within an open source development community. The technology used is based on arduino and the information is available to public on their own Smart Citizen platform.

The different sensors included on the device can be seen on the picture below.

The main difference between the concept of my project and the one from Smart Citizen, is the context of use that defines the system. The Smart Citizen device is set mainly for urban areas that need to detect not just pollution but also noise rates; whereas my system is focused on rural areas, specially the ones facing windy and rainy conditions. That is why the sensor gauges as well as the production process will surely change.

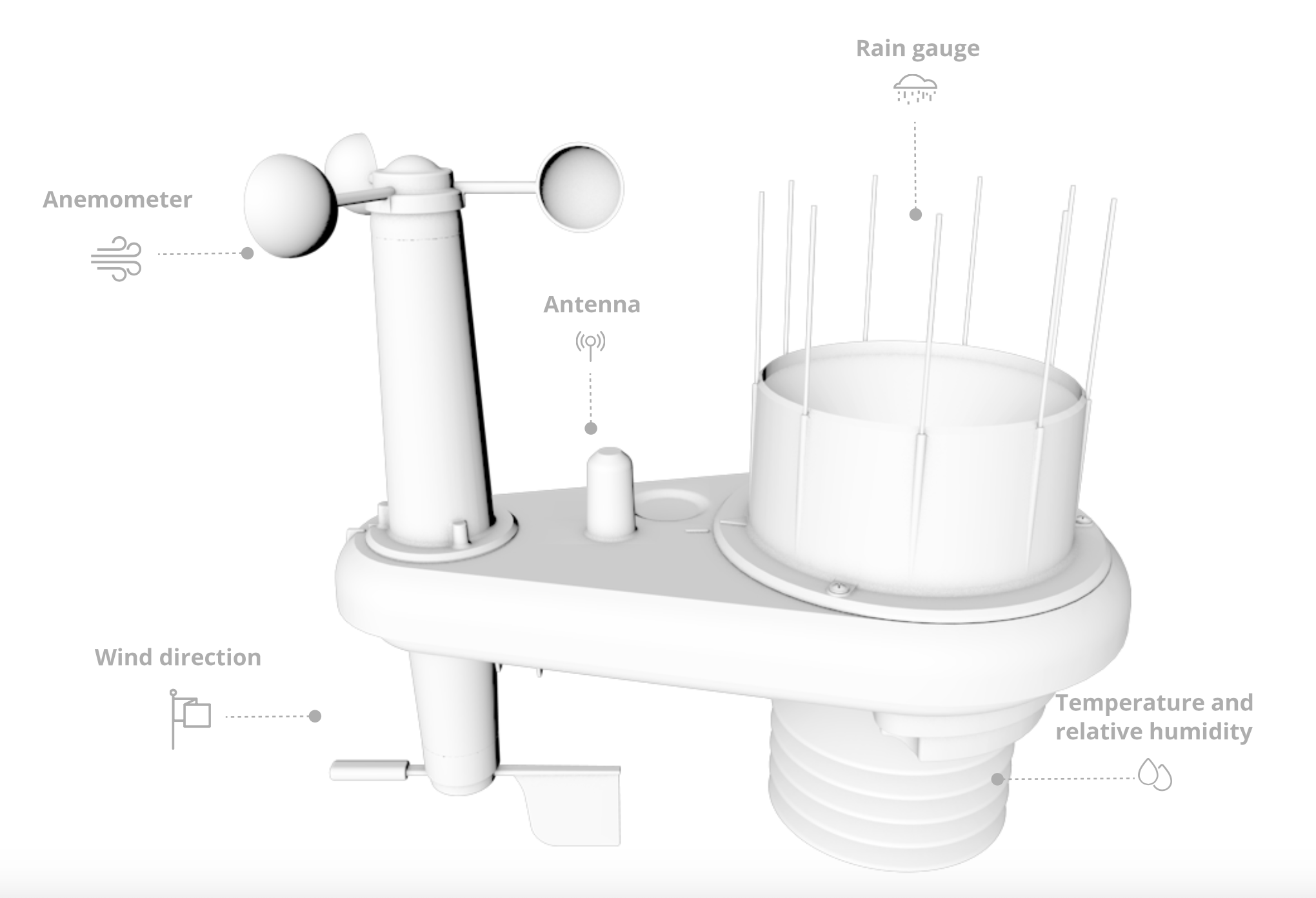

The second referent I found useful for my project is another open source project from Brazil called Pluvi.on.

This system is similar to the Smart Citizen project as a climate monitoring system, but the production focus is meant to be projected widespread and adaptable to new redesigns and new open source systems.

The original device has similar climate measurement tools that I need such as the wind gauge and the rain gauge. On the following image, we can see the new redesign of the device, more compact and reliably produced.

13.3. Q3_What will you design?

On one side I will design all the electronic board I may need, similar to the Fabduino board, with an ATMega328p microcontroller, and modular shield boards for the sensors: DHT22 (temperature and humidity), the wind gauge system components (DC motor vs magnet + hall sensor), rain gauge; and also I2C for LCD display, miniSD card, and ESP8266 wifi module.

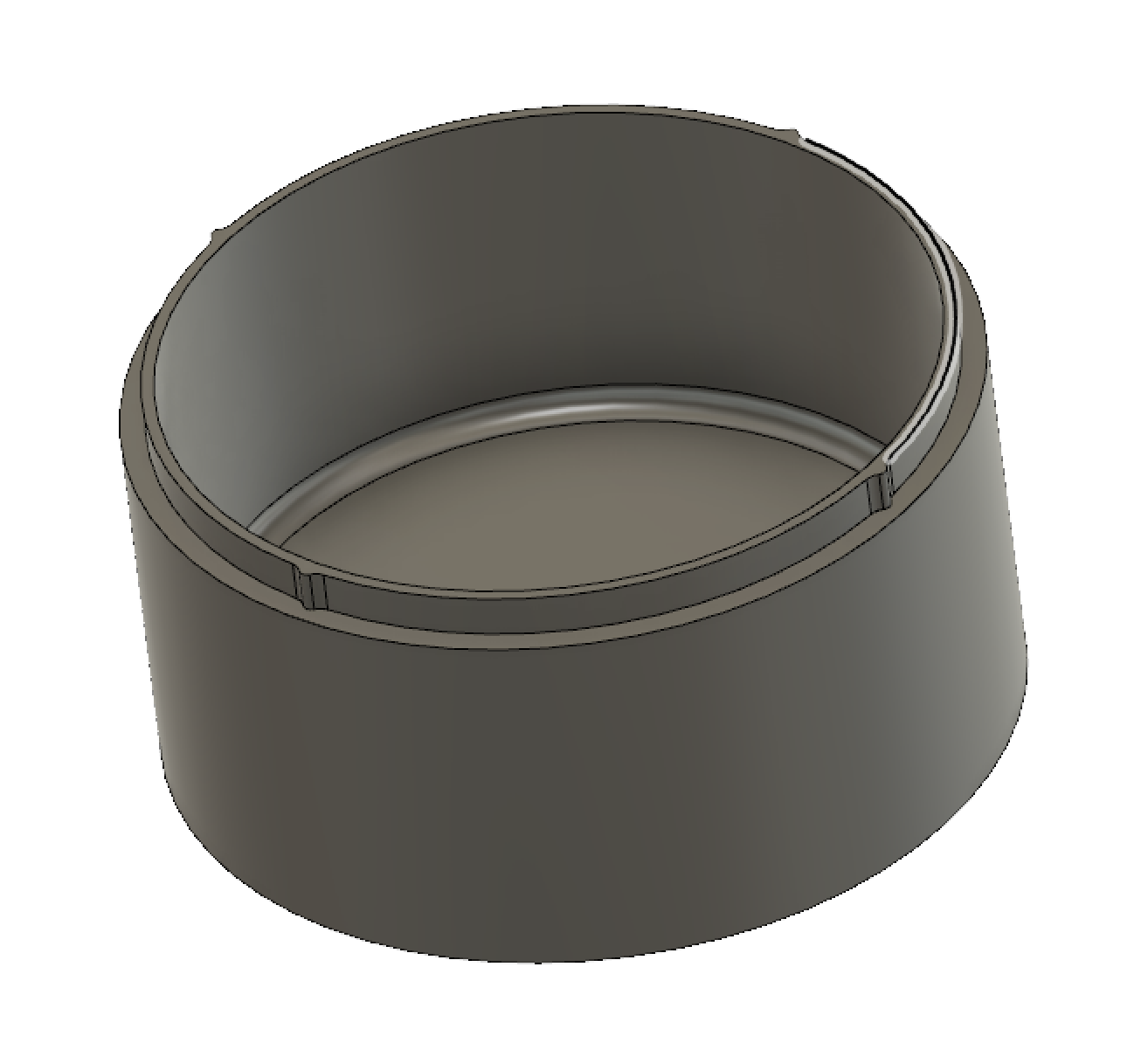

I will also design the container that will enclose all the components. This case should be made of recycled materials such as plastic bottles and trash.

Furthermore, all the sensor gauge hardware elements for the anemometer and the pluviometer, should also be produced and even any extra gadget that may add an extra value to the system and make it adjustable to different positions.

13.4. Q4_What materials and components will be required?

In this case, the device can be devided in two parts: the mechanics and the electronics.

Mechanics:

- Main case: folded acrylic, 3d printed/casted joints

- Paddle wheel: PLA 3d printed

- Anemometer axis: bearing 5mm, M5 screw-washer-nut, magnet

- Stevenson screen (DHT22 shelter): PLA 3d printed

- Rain gauge: PLA 3d printed, metal axis 30x3mm

Electronics:

- Arduino / Fabduino board:

milled PCB

ATMega 328P

LED 1206

reset switch 6mm

20 MHz resonator

499 ohms res

10 uF cap

FTDI pins

8 pin headers

- Shield1 (rain gauge + temperature + humidity sensors):

milled PCB

Hall sensor

DHT22 sensor

(x2) 10 kohms res

4 pin headers

- Shield2 (wind gauge):

milled PCB

Hall sensor

4 pin headers

- Shield3 (communication shield):

LCD 16x2 display + I2C interface

Bluetooth LE 4.2 HC-08 module

10 kohms res

1 uF cap

3.3V-0.3A regulator

FTDI pins

4 pin headers

- 5V 500mA power source

13.5. Q5_Where will they come from?

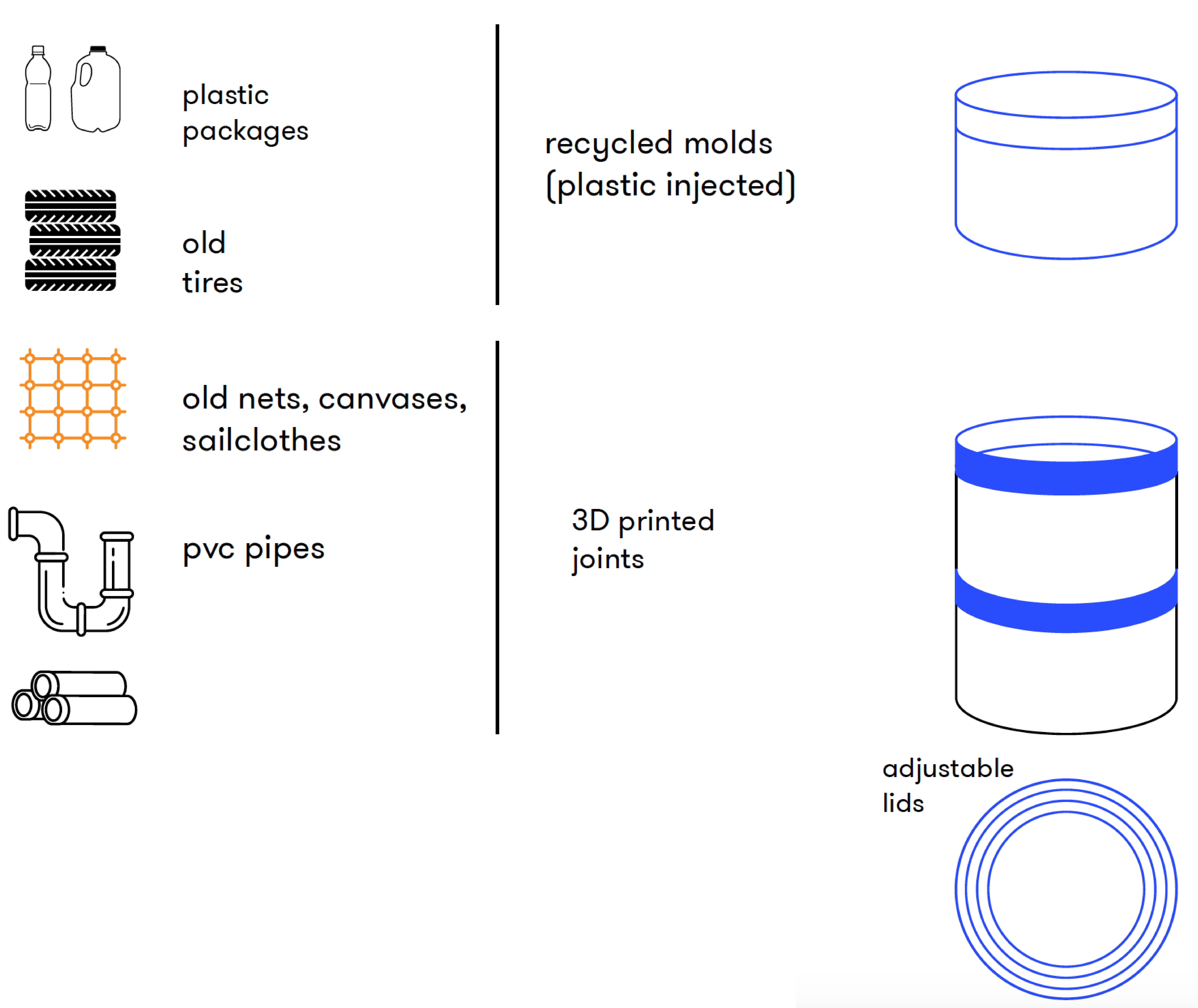

The idea is to take advantage from most of reliable and useful material from OS platforms, natural resources and recycling processes or waste, to build part of the hardware system.

Here are some referents I took that could be part of the source of my materials:

- Precious plastic

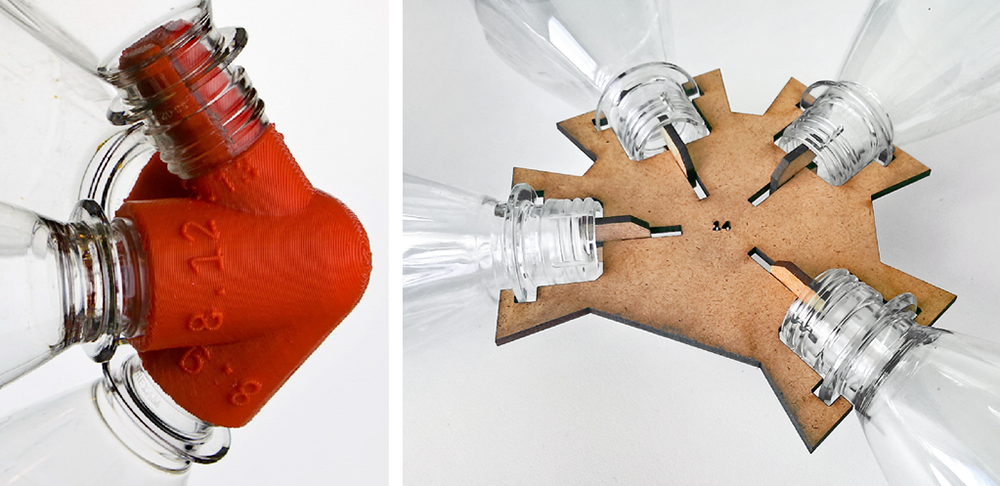

- TrussFab from Hasso-Platte-Institut

13.6. Q6_How much will it cost?

All the components used in the project should be obtained and produced in any FabLab or makerspace with some basic tools for electronics production, 3d printing, 3d milling and workshop tools. In this case the maximum budget should be the electronic components, not over 25 euros.

In case the user chooses to use Arduino based technology, the price could rise up to 50 euros.

13.7. Q7_What parts and system will be made?

The next diagram shows the two options I explained on the previous question. In both cases, the scheme of components and functions are the same.

In the following image, there is a system's example of implementation or studycase of the starter kit.

13.8. Q8_What processes will be used?

The fabrication processes used for the case, joints and hardware production should be made by 3D printing, molding and laser cutting.

For the electronics production, I will use PCB milling, components soldering, programming and debugging.

The rest of the project will include software programming, and network and interface design.

13.9. Q9_Design a weekly plan

The components I am using for th:

april

- w12: electronics design (input sensors, display data, sending data)

- w13: electronics design (sensors hardware + testing)

may

- w14: networking and communication (wifi ESP32/ESP8266 modules, and NFC2401/HC12 networks)

- w15: molding boxes

- w16: interface and output (testings)

- w17: hardware modelling (testing sensors, all system)

june

- w18: kit design

- w19: kit testing

13.10 Q10_What questions need to be answered?

These are some questions that should be answered along the process and to get further implementations in the future:

- Is the system giving reliable data?

- Is the system completely autonomous?

- Is the program working in real time?

- Is it easily exportable and scalable to other cases?

- Can we predict the weather from the data we got from the station?

- Can we read info from different spots? How it may change the system?

13.11. Q11_How will it be evaluated?

All the system should be tested and compared to other marketed tools' results. Also the devices should be tested in different conditions and locations.