MECHANICAL DESIGN

this two weeks assignements are:

- Design a machine (mechanism + actuation + automation), including the end effector, build the passive parts and operate it manually.

- Plan and make a machine. Document the group project and your individual contribution.

rotocasting machine

The Frame

This week we decide to work on a rotomoulding machine.

i was in charge of the frame part.

the frame.

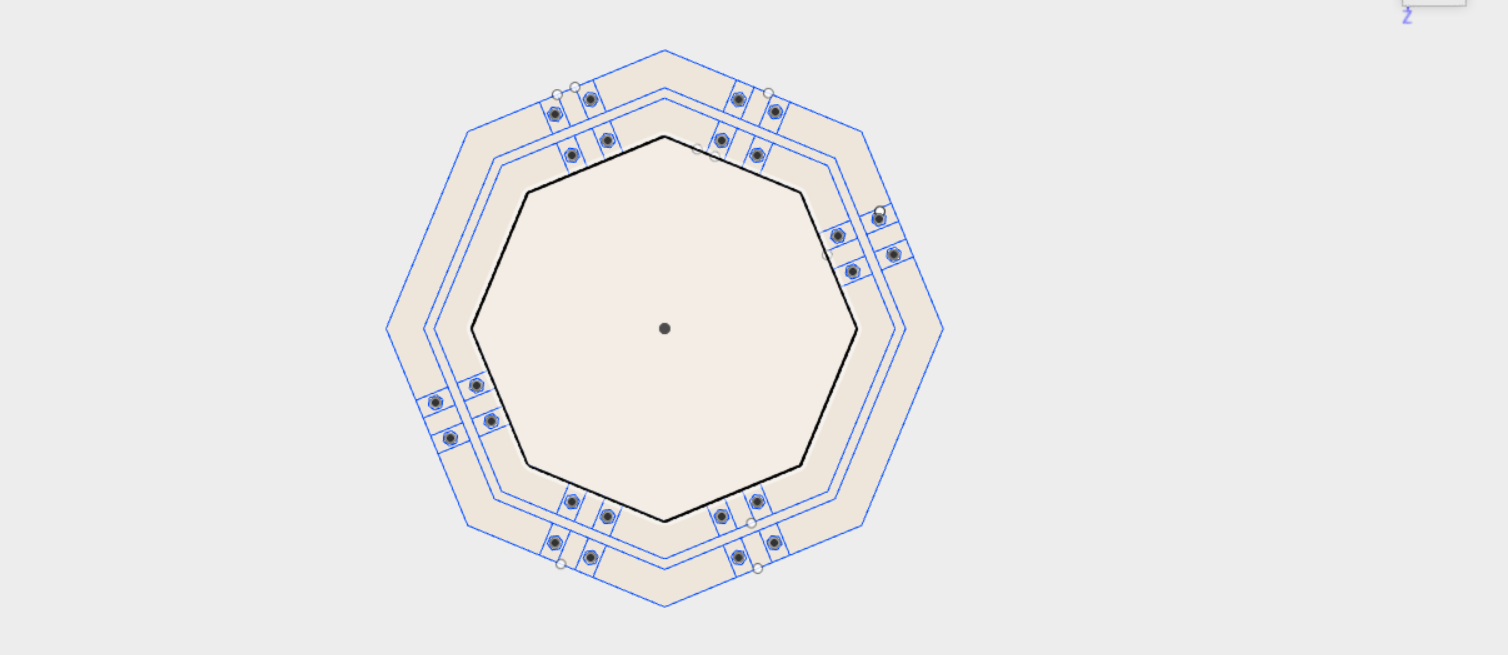

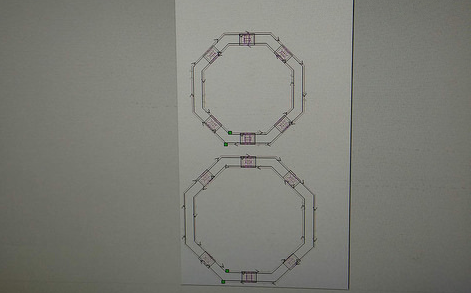

when we decide to work on the Rotocasting machine we decide to work on a octagon frame, the idea is to have one motor to control (them all) one axe, and an other one free, the idea it's to create a movement on the free axe I start to make my file on fusion. then i design some hole for integrate some 3D print piece for connecting the 2 frame together, and be able to connect it to the structure made by thierry Dasse

then i design some hole for integrate some 3D print piece for connecting the 2 frame together, and be able to connect it to the structure made by thierry Dasse

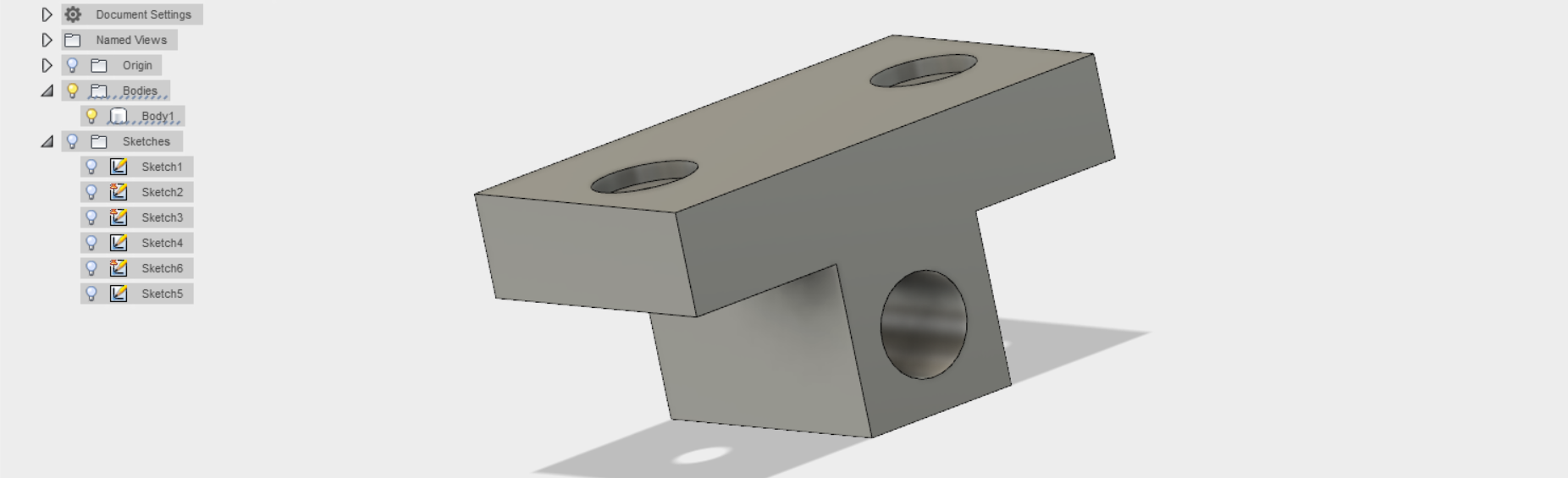

The connector.

When we finish to design the Frame, i need to create someway to connect them together, to the structure. This connector is made for being 3Dprinted, with a hole of 6mm for adding a 6mm alluminium Rods of 20mm lengh.

This connector is made for being 3Dprinted, with a hole of 6mm for adding a 6mm alluminium Rods of 20mm lengh.

After that is was time to 3D print the piece and laser cut the frame for make a first test.

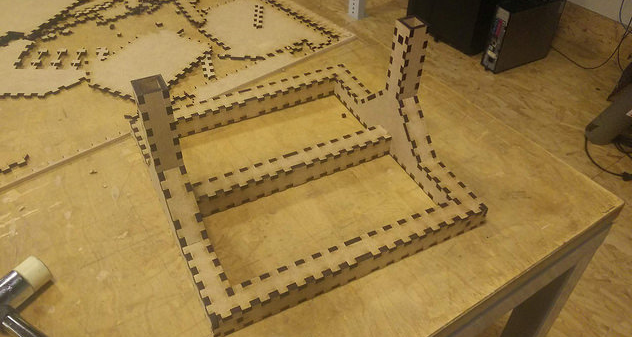

i decide to cut the frame on the laser cutter,we where at the @carrefour Numerique. where they have a Trotec 300 bigger than our Speedy 100

After that is was time to 3D print the piece and laser cut the frame for make a first test.

i decide to cut the frame on the laser cutter,we where at the @carrefour Numerique. where they have a Trotec 300 bigger than our Speedy 100 so for cutting it, i decide to cut it, in 3 part and glue them together.

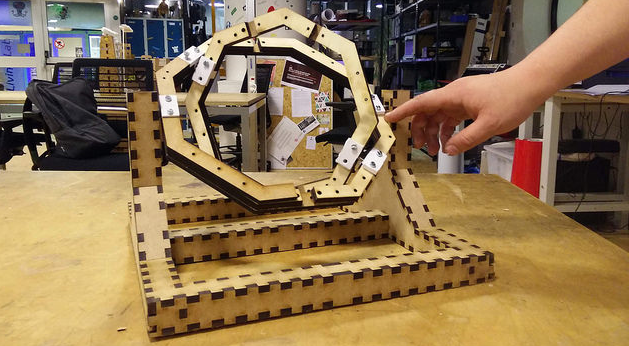

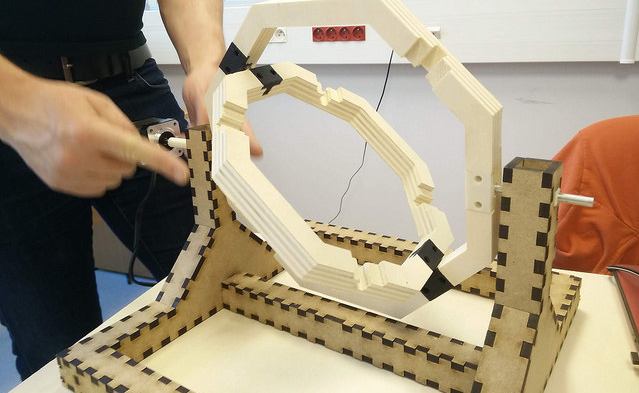

When it was done, we installed the frame into the structure. of thierry and look how the Chaotic movement worked.

When it was done, we installed the frame into the structure. of thierry and look how the Chaotic movement worked.

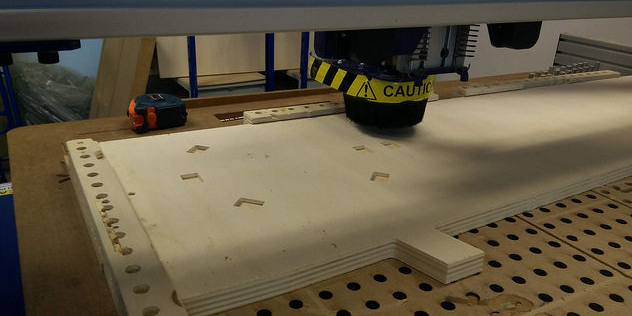

Milling the Frame

After few day's we came back to the university and prepare the file for the shopbot with Vcarve and mill it with a

and mill it with a

- 6mm diameter down-cut

- 40mm/Sec

- 7000RPM

install it into the structure with the 3D printed piece.

install it into the structure with the 3D printed piece. ET VOILA!

--

--

file of the week.

here you'll find the file of the week

For downloading

right click and save as