Wildcard Week

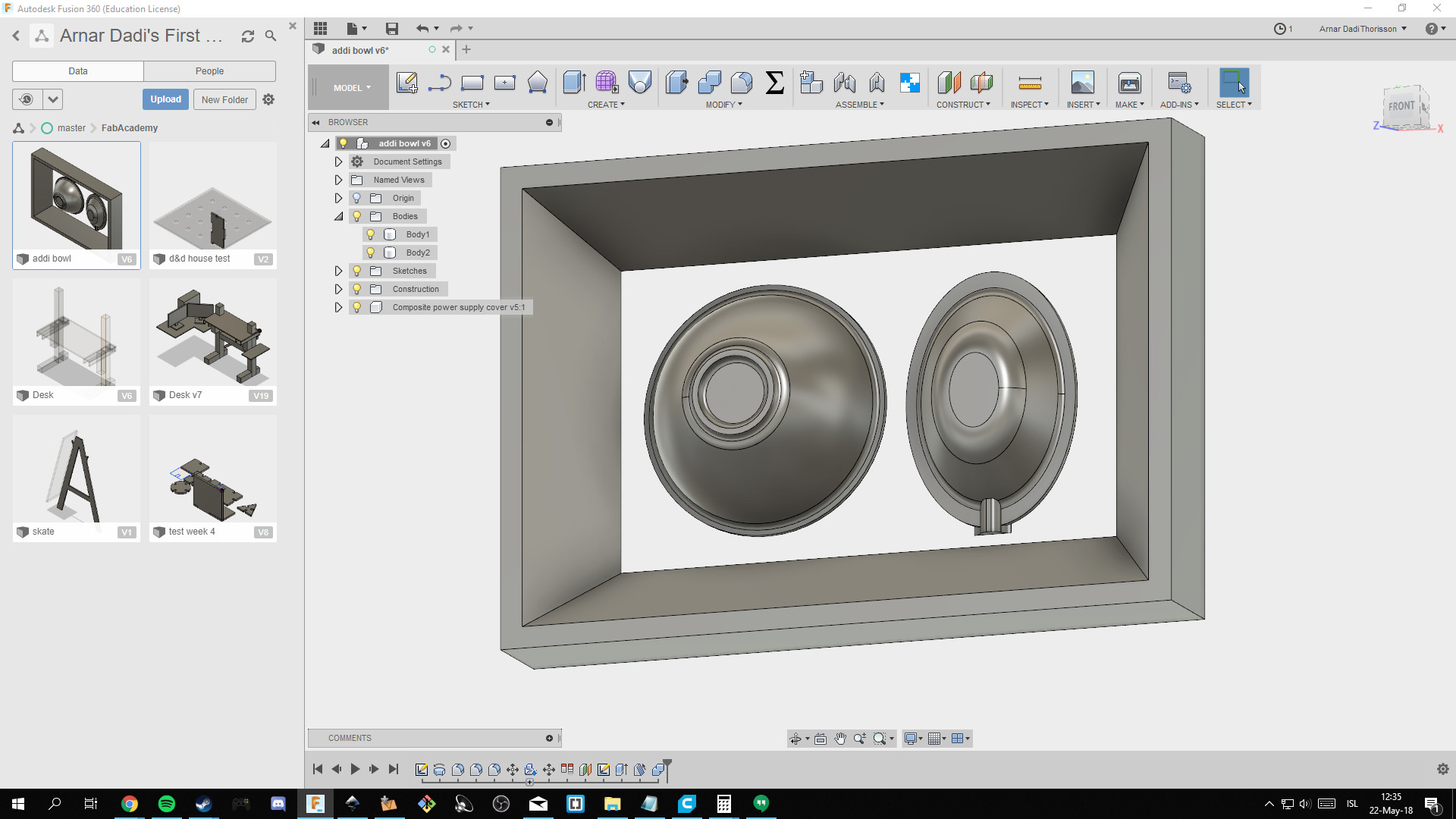

This week was wildcard we and we decided to use composites. We used epoxy to and block of foam that was milled out with the Shopbot. Me and

Svanur

used Fusion 360 to make our parts and joined the files together and used the cam to make the toolpaths.

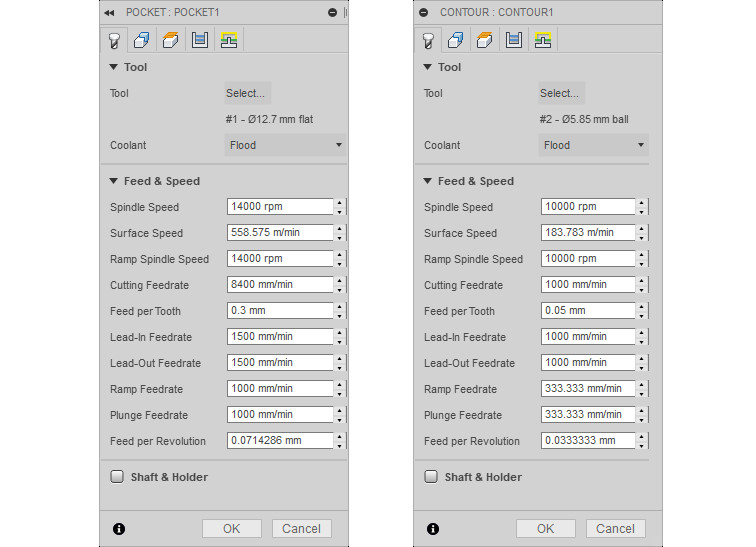

I made the toolpath go deep so it would go fewer steps down so we would save time because the foam is soft and used 2 flute straight bit for roughing and a ball-nose for the finishing toolpath.

I made the toolpath go deep so it would go fewer steps down so we would save time because the foam is soft and used 2 flute straight bit for roughing and a ball-nose for the finishing toolpath.

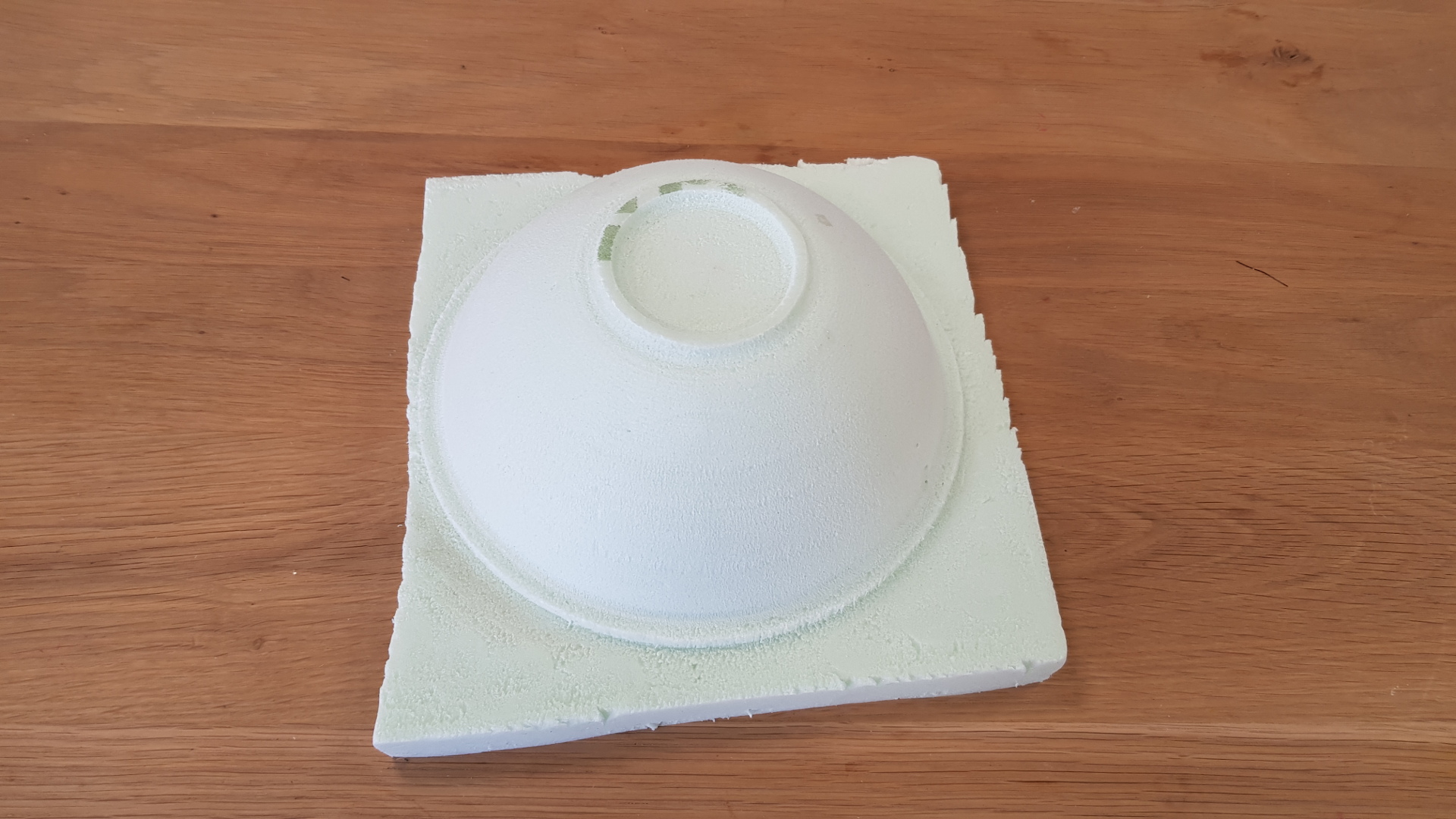

The material after the rough mill.

The material after the rough mill.

It came out really smooth but I was really picky and sanded it a little bit.

We put a clear film around the object so the resin wouldn't stick to it.

We put a clear film around the object so the resin wouldn't stick to it.

We used burlap as the material to cover the things.

Then we prepped the clear-film that was going on the top of the resin by poking it with the torture device so the excess resin can get out of the film and seep into the cotton.

The main purpose of the cotton is used to distribute the air flow around the cast.

Then we prepared the burlap by cutting it so it would fold nicely.

Removed unnecessary material.

Removed unnecessary material.

Put the resin into the material. The

Super Sap 100 Epoxy resin

was used (here you can find the safety data sheet). Part A Epoxy and part B is the hardener. (Picture borrowed from

Sigridur Helga Hauksdottir

because I forgot to take A picture of the resin when I was doing the composites).

Put the resin into the material. The

Super Sap 100 Epoxy resin

was used (here you can find the safety data sheet). Part A Epoxy and part B is the hardener. (Picture borrowed from

Sigridur Helga Hauksdottir

because I forgot to take A picture of the resin when I was doing the composites).

Safety is very important when working with epoxy in general. Under the supervision of my instructor we covered the table with aluminum to keep the resin from permanently attatched to the table. We wore gloves and an apron to protect our skin. When the epoxy is mixed it becomes really hot and if it comes into contact with your skin it's possible to get a 1st degree burn. Ventilation is important since the epoxy gives out fumes that can make you faint. However this epoxy is a gentle kind so keeping an open window is sufficient.

I layered it so the first layer would be flat and in the middle was 2 different techniques, on one half flat and I had it so it was crossed to strengthen it and the other scraps (small pieces), on the top another flat piece.

I layered it so the first layer would be flat and in the middle was 2 different techniques, on one half flat and I had it so it was crossed to strengthen it and the other scraps (small pieces), on the top another flat piece.

Then we put it in the vacuum bag.

Then we put it in the vacuum bag.

Befor we opened the resin bottle, we did check the bag on holes to make sure it was airtight.

When we checked the compisites the next morning the bag loosened up a little bit, but the end result was rather nice. At one spot it didn't fold together where I had made a cutout, so next time I should be more aware to make larger overlaps. I also noticed that the different techiques of layering the fabric didn't seem to matter in this end resault.

It can also double as a straw hat.

It can also double as a straw hat.

Fusion file

Fusion file

Shopbot mill rough file

Shopbot mill finish file