PROCESS

You can see our progess in our FabLab page or here.

My personal contribution

This was the plan:

In my case I helped to understand how one part of the python program worked:

In my case I helped to understand how one part of the python program worked:

# Two stage example Virtual Machine file

# moves get set in Main

# usb port needs to be set in initInterfaces

# Nadya Peek Dec 2014

#------IMPORTS-------

from gestalt import nodes

from gestalt import interfaces

from gestalt import machines

from gestalt import functions

from gestalt.machines import elements

from gestalt.machines import kinematics

from gestalt.machines import state

from gestalt.utilities import notice

from gestalt.publish import rpc #remote procedure call dispatcher

import time

import io

#------VIRTUAL MACHINE------

class virtualMachine(machines.virtualMachine):

def initInterfaces(self):

if self.providedInterface: self.fabnet = self.providedInterface

#providedInterface is defined in the virtualMachine class.

else: self.fabnet = interfaces.gestaltInterface('FABNET',

interfaces.serialInterface(baudRate = 115200, interfaceType = 'ftdi',

portName = '/dev/ttyUSB0'))

def initControllers(self):

self.xAxisNode = nodes.networkedGestaltNode('X Axis', self.fabnet,

filename = '086-005a.py', persistence = self.persistence)

self.yAxisNode = nodes.networkedGestaltNode('Y Axis', self.fabnet,

filename = '086-005a.py', persistence = self.persistence)

self.xyNode = nodes.compoundNode(self.xAxisNode, self.yAxisNode)

def initCoordinates(self):

self.position = state.coordinate(['mm', 'mm'])

def initKinematics(self):

self.xAxis = elements.elementChain.forward([elements.microstep.forward(4),

elements.stepper.forward(1.8), elements.leadscrew.forward(8),

elements.invert.forward(True)])

self.yAxis = elements.elementChain.forward([elements.microstep.forward(4),

elements.stepper.forward(1.8), elements.leadscrew.forward(8),

elements.invert.forward(False)])

self.stageKinematics = kinematics.direct(2) #direct drive on all axes

def initFunctions(self):

self.move = functions.move(virtualMachine = self,

virtualNode = self.xyNode, axes = [self.xAxis, self.yAxis],

kinematics = self.stageKinematics, machinePosition = self.position,

planner = 'null')

self.jog = functions.jog(self.move) #an incremental wrapper

for the move function

pass

def initLast(self):

#self.machineControl.setMotorCurrents(aCurrent = 0.8,

bCurrent = 0.8, cCurrent = 0.8)

#self.xNode.setVelocityRequest(0) #clear velocity on nodes.

Eventually this will be put in the motion planner on initialization

to match state.

pass

def publish(self):

#self.publisher.addNodes(self.machineControl)

pass

def getPosition(self):

return {'position':self.position.future()}

def setPosition(self, position = [None]):

self.position.future.set(position)

def setSpindleSpeed(self, speedFraction):

#self.machineControl.pwmRequest(speedFraction)

pass

#------IF RUN DIRECTLY FROM TERMINAL------

if __name__ == '__main__':

# The persistence file remembers the node you set. It'll generate the

first time you run the

# file. If you are hooking up a new node, delete the previous persistence file.

stages = virtualMachine(persistenceFile = "test.vmp")

# You can load a new program onto the nodes if you are so inclined.

This is currently set to

# the path to the 086-005 repository on Nadya's machine.

#stages.xyNode.loadProgram('../../../086-005/086-005a.hex')

# This is a widget for setting the potentiometer to set the motor

current limit on the nodes.

# The A4982 has max 2A of current, running the widget will

interactively help you set.

#stages.xyNode.setMotorCurrent(0.7)

# This is for how fast the

stages.xyNode.setVelocityRequest(8)

# Some random moves to test with

moves = [[10,10],[20,20],[10,10],[0,0]]

# Henry Sanchez: I helped to understand these numbers were milimeters.

# Move!

for move in moves:

stages.move(move, 0)

status = stages.xAxisNode.spinStatusRequest()

# This checks to see if the move is done.

while status['stepsRemaining'] > 0:

time.sleep(0.001)

status = stages.xAxisNode.spinStatusRequest()

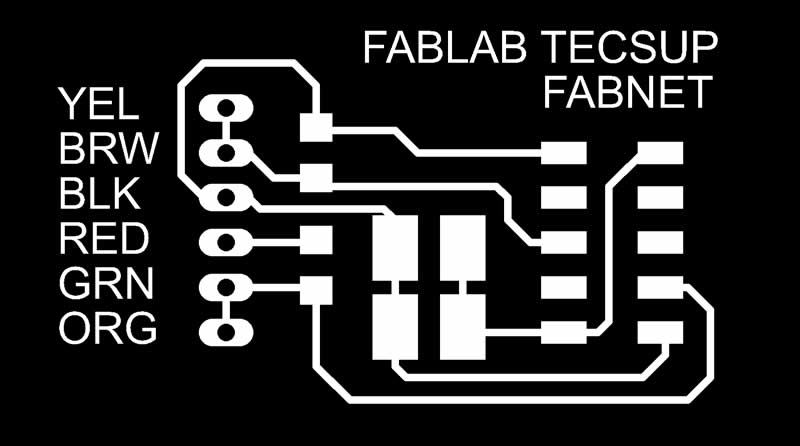

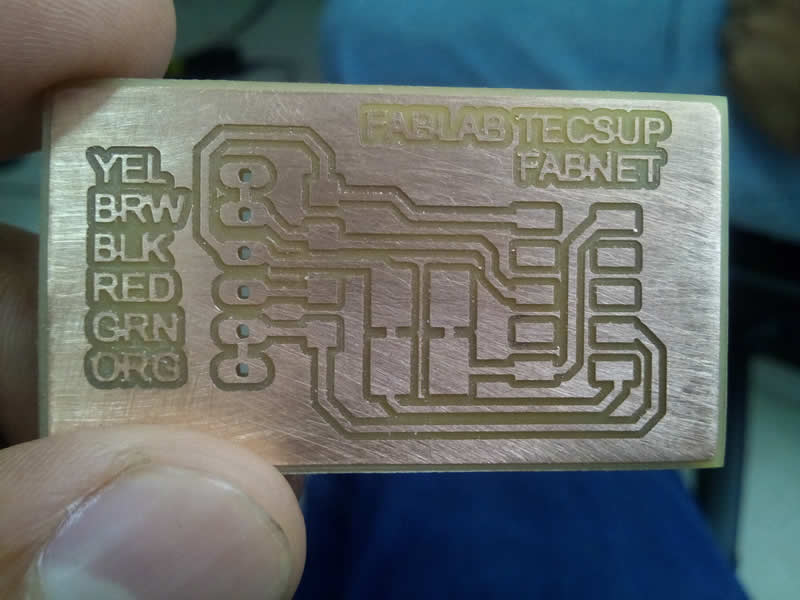

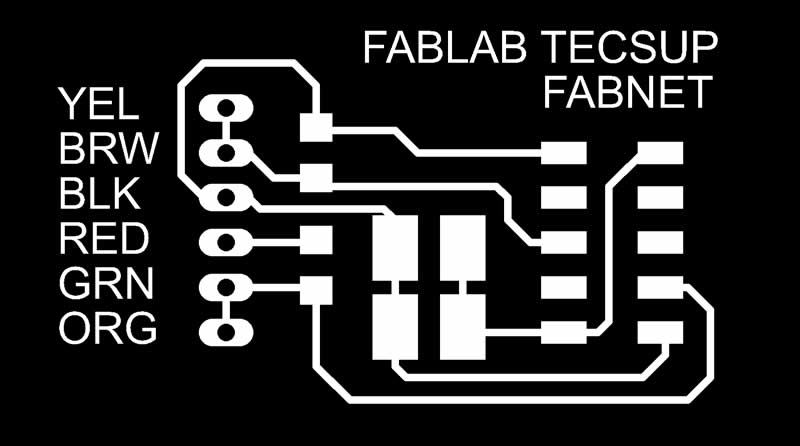

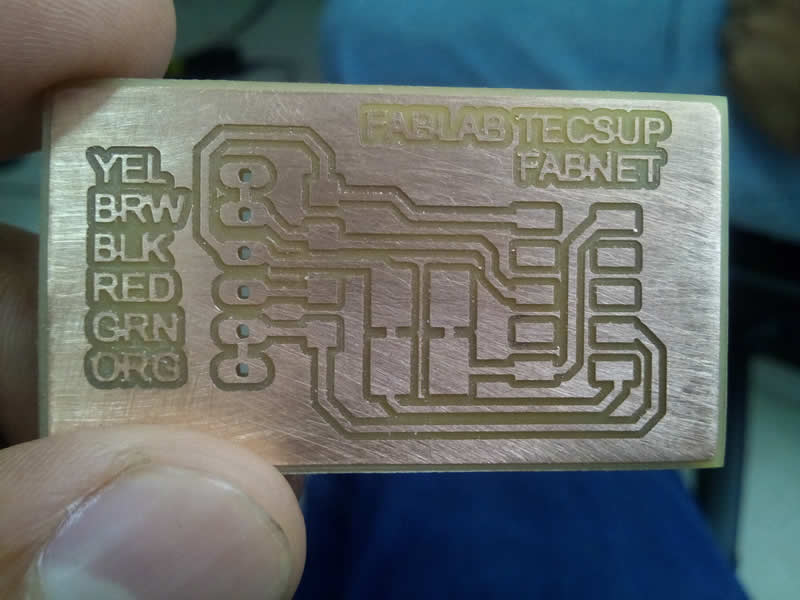

Designing a New FABNET

With my classmate Edgar Chacca try to desing a new FABNET.

We needed to improve the FAB NET pcb to make the easiest and direct connections.

This is our re-design.

We milled it using MODELA

We milled it using MODELA

You can know more about it in my ELETRONIC PRODUCTION web.

But finally we did not use it because one of our friends (Bas Withagen) told us that we needed to do power traces thicker because it will pull more the 1 Amp of current.

But finally we did not use it because one of our friends (Bas Withagen) told us that we needed to do power traces thicker because it will pull more the 1 Amp of current.

In my case I helped to understand how one part of the python program worked:

In my case I helped to understand how one part of the python program worked: