Fab Academy 2015

Fab Academy

How to Make Almost Anything...

How to Make Almost Anything...

At the beginning of my project, the LED display was not the most important, but as the project has progressed it has been taking more and more importance in the end, this part will contain all the control electronics, the main support of the aquarium.

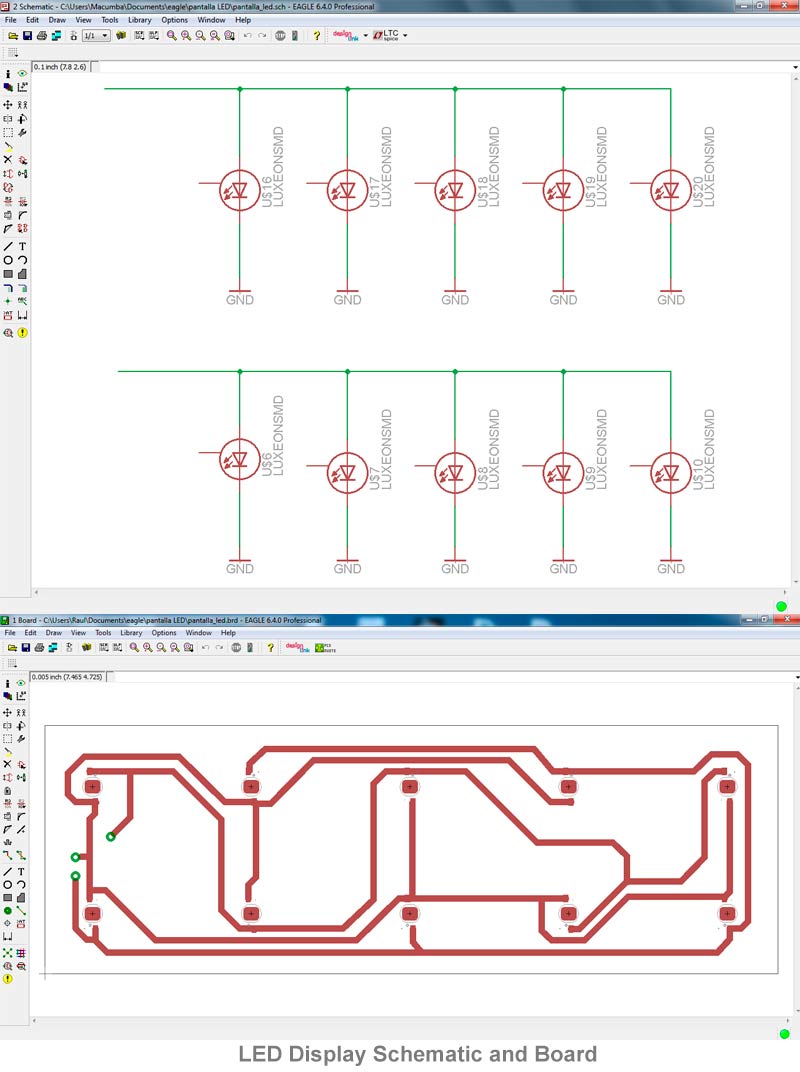

LED display panel is composed of 20 LEDs 1 Watt of power each, these LEDs generate lots of heat, which are mounted on a metallized surface.

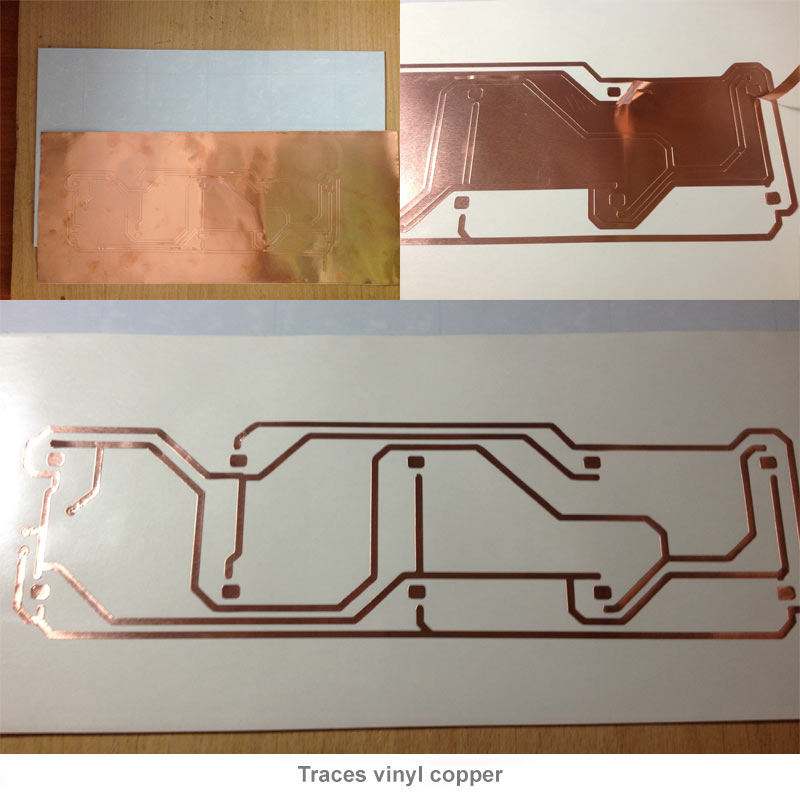

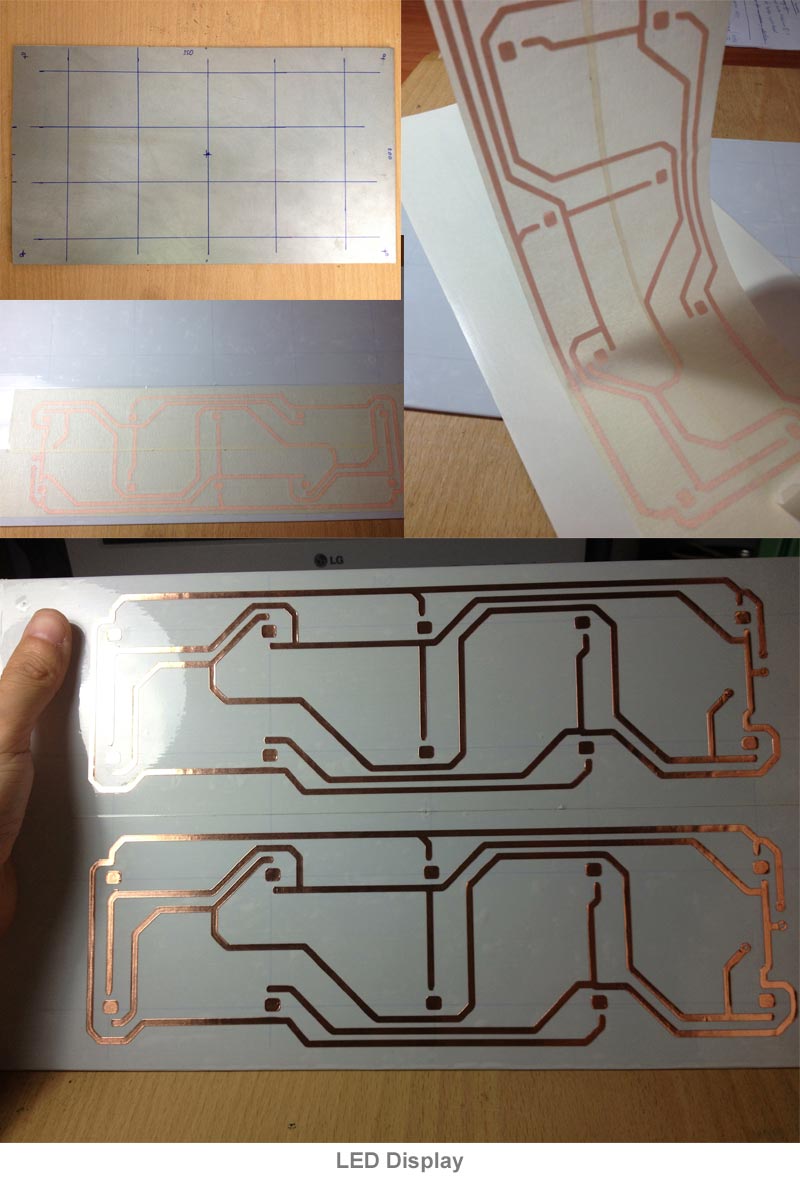

Due to the size of the LED display it was not possible to make a normal circuit, so I decided to make the circuit with copper vinyl.

Once the design on "eagle" I went to cut the copper using the cutting plotter the cutting plotter configuration is the same as for normal vinyl, you just have to give a little more pressure to cut 190gr/cm.

Once cut and peeled vinyl should pass to the metal surface to help dissipate heat, I used 1.2mm steel sheet which have cut to size and drilling to put spacers. To transfer the vinyl I used masking tape. Another very important detail is to isolate the steel plate of the copper I have done this with a special vinyl that resists high temperatures.

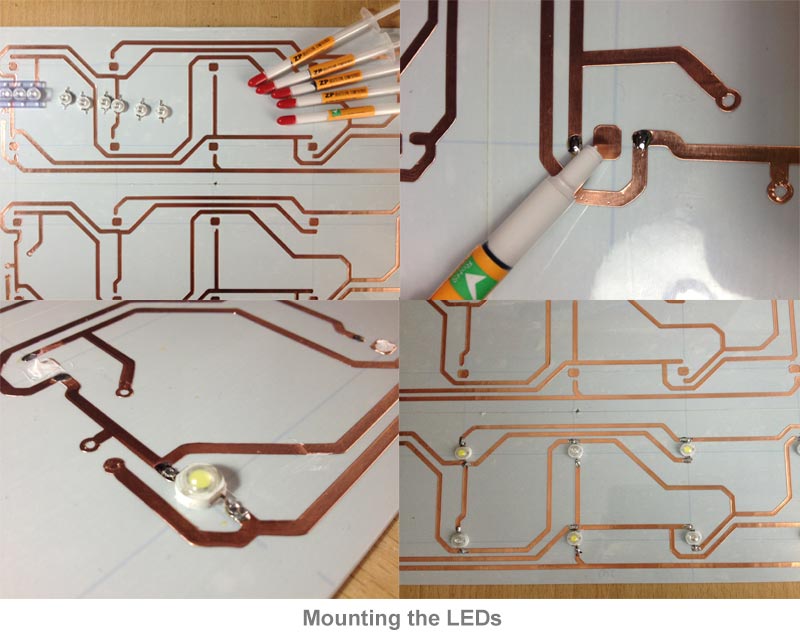

The next step is to fix the LEDs to the board, this requires a welder powerful enough because steel will dissipate heat and becomes difficult to weld, I will also use thermal paste on the basis of the LEDs to ensure that heat dissipation is correct.

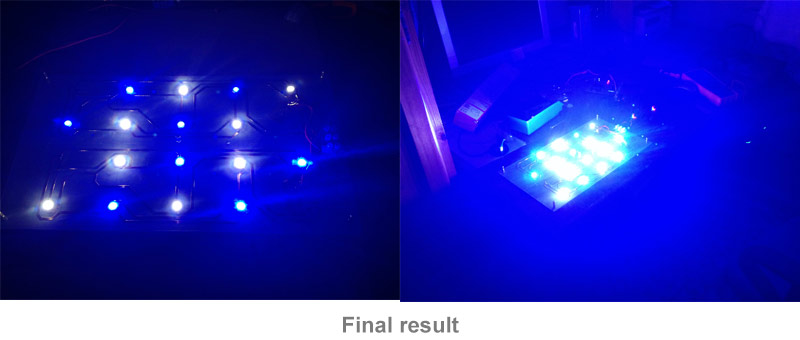

This is the final result once the LEDs are fed through current limiter, as you can see I used white and blue LEDs. The power of the LEDs is adjustable through the current limiter, LEDs in the image are about a quarter of the total power. I think I've spent whith the power...