08 - Molding, Casting and Composites

WWII Soldier Composite Mold from Existing Object

I used Flexwax to create a composite wax mold from a old glass liquor bottle my grandmother gave me. I heated up the wax, then brushed it onto the glass. After I had built up a sizable layer, I wrapped cheesecloth around the wax to strengthen the mold. I then reapplied another layer of wax. I repeated this process twice.

After the composite mold hardened, I cut it open down the side and removed the glass bottle. I then took a coat hanger and bent it into a stand so I could pour the Hydrostone into the mold. After the mold was poured, I cut open the wax mold (again) to remove the final Hydrostone cast.

Tools Relief - Attempt 2 - Success!

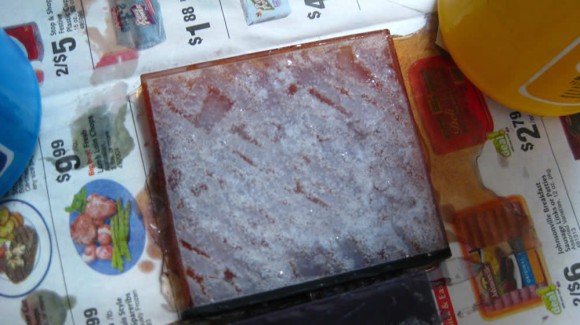

I re-milled my tools relief mold, correcting the problems inherent in the design of the first cast. I made the border around the tools relief wider and deeper in order to have a rim to hold the poured material before creating the final cast. In order to conserve wax (it is $29.00 a bar), I melted down used wax and shavings from previous molds. The info from McMaster-Carr website state " Softening point is 222° to 244° F." I melted the wax down in my oven at a temperature of 300 ° F. There was some sediment / impurities that worked their way into the wax, but they sunk to the bottom and did not affect the mold.

Machinable Wax

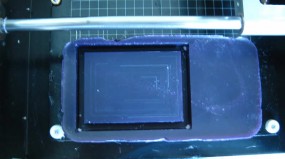

Poured Rubber Mold

Curing the Rubber Mold with a Lamp

Finished Urethane Mold - Much Better!

Measuring and Pouring the Smooth Cast Plastic and Hydrostone

Measuring and Pouring the Smooth Cast Plastic and Hydrostone

Plastic Tools Relief Cast

Hydrastone Tools Relief Cast

Hydrastone Tools Relief Cast

Tools Relief - Attempt 1 - Failure

I milled a mold out of wax and then cast it in Smooth Cast 305. The border around the mold did not mill out on all sides as deeply as I planned. I did not use enough soap as a mold release and the plastic I cast in the urethane mold stuck to the mold and I destroyed it as I tried to pull it out.