final project is coming

From Diary to Agenda

With this assignment I 'll have the opportunity to come back to my final project dairy purpose, where from now until the and of my Fab Academy ( that I hope will be that June) I'm going to app load my every_day_ Fab_Adventures.

How you will see in that page my final project has a complex genealogy . Coming from landscape design assessment tool going trow energy production integration until get to food production. Being just an architect It took me some times understand what kind of food production technology develop until I realized that the best way is start from what all productive landscape has in common and go on creating as much as possible a complete system.

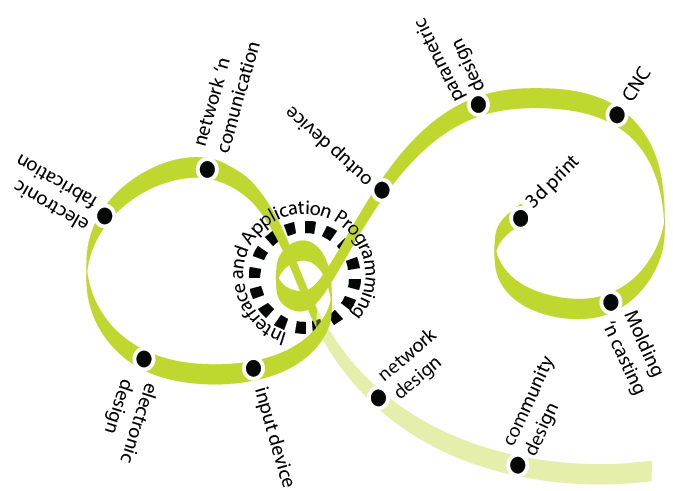

That first graphic is a retroactive project management trying to make order in my last years non-linear minds. The community project, is my back ground starting point and my final goal has well. The way to reach it is interface application .

WHAT WILL IT DO?

connecting people with the ground

Connecting people with their own territory by taking care of the common ground and at the same time of their own environment. I choose the food production as main tool of rebuild the connection between human and nature. It starts from private indoor food production as educational step to look for refill wasted urban area of new productive function. To do that it will start from a community interface of smart gardener sharing food production experience by sharing physical data collect by specific sensors ( light, temperature, humidity). Each new Smart Gardner will join the community by choosing by choosing the king of culture, indoor out door hydroponic, aquaponic, … or by choosing an area/territory and looking for person that at the same time wants to set up a new vegetable garden. As additional attractive I'd like to design a physical module of “experimental” aquaponic culture that help people to set up their first indoor/ rooftop vegetable garden.

WHO'S DONE THAT BEFOREHAND?

more than a classic an evergreen

- Open garden by COOKING HACK

- agua farm by backtotheroot

- 3D PONIC by 3dponics

- robert garita by fab academy 2014

WHAT MATERIAL AND COMPONENT WILL BE REQUIRED?

A fab kit a variable number of sensors some ground some water maybe some fire and at least a goldenfish …

MONITORING KIT and input devices

For the spiral development principle I ‘ll not afford all sensors necessary for a complete plant monitoring. I ‘ll concentrate in those sensors necessary in indoor aquaponic culture as well has in outdoor vertical agriculture. I will start with a light sensor to provide light lake in indoor agriculture. In case of vertical farming systems addicional temperature and humidity sensors it will be able to recognize a summer storm and to protect your plant as well as an extrem dry emergency.

LIGHT or WATER as out put devices

The watering system is the key of any agricultural system , but sometimes a direct responsive output mechanics could not be the best solution. In hydroponic and aquaponic system for example is the constant flow to determine the healthiness of roots and fishes more than quantity of water. On the other hand everybody had an vegetable garden knows how is dangerous for the culture watering plants in the warmer moment of the day. In that vision a humidity sensor could be useful just has a switch ( in case of to much water) of a sprinkle systems control by a clock or has an alarm to call the community of smart gardeners, this is still a community project after all. Has responsive output I will concentrate in lightning systems for indoor aquaponics systems. At least and if I will have enough time , I'd like to develop, some small mechanism to protect the plants as a micro green house system. For those responsive mechanism I will have to develop a network of sensors light sensor comparing data with one main humidity sensor and activating singles responds.

MODULE DESIGN

I will start to makeing 3 modules, one for fish one for food plant and one for biomass/other_use_plants. Each one of those will be a 3d printed brick in clay and recycled plastic elements.

WHERE WILL THEY COME FROM?

Once upon a time there was a FabLab placed in a fabulouse hood...

All the material involved in modules production will come as much as possible from the collserola natural park that surround the green fab lab. Soil and water for clay , wood fibers, straws, and some plastic bouttle recicled by our luch break if extra water resistance will be required. On th other hand I can't really verify where are coming from our electronics components at the moment but I will investigate that.

HOW MUCH DOES IT COAST?

speaking about money or CO2...

I estimate a 10 € spent in electronic production one for one fab kit and 10 € for each extra sensor +LED module in network. The commercial water pump cost 50€ (just one needed for entire system). Remaining material as clay and wood will kindly sponsored by our wonderful natural environment. In a LCA point of view It could be interesting understand the co2 equivalent production of 3d clay printing by robots, but this is another chapter in that story...

WHAT PARTS AND SYSTEMS WILL BE MADE?

From spiral development to clover and node...

The project will be based in 3 main brunches:

1)A modular system for vertical gardening adaptable for hydroponic and aquaponic systems, modular as well for column systems than walls systems for landscape integration. Design to be made with local material compatible with traditionalist techniques.

2)A modular electronic device that with different conformation will be useful to monitor the mail stages of installing a garden . Starter kit to choose the better place or plants to install. A gardening kit to control the watering system and the help kit that storing he environmental data along the working life of the watering system will be a system of the bug of plants healthiness.

The first 2 brunches joins in the interfaces node from where starts the third brunch:

3) the networking an community project that will be developed in the future.

WHAT PROCESSES WILL BE USED?

or maybe interchange them

As shows in the graphic below here been involved all the processes of electronic design and production. Starting from a fab-kit board I'm designing and producing several breakout board for sensor's input input ( DHT11 sensor , light resistor, ultrasonic proximity sensor ) and 2 for out put ( CD motor pump control and SD card for data storage).

Depending from timing my plan is to apply all the weekly assignment exercises that I developed around light sensor and led to create a bus network of board independently controlling and supplying the specific requirement of light of each plant.

The structural module, had been design for robotic3d print clay, but at the same time I'm trying to find those parameter to make that design compatible with other traditional technique, making molds with CNC and casting clay.

WHAT TASKS NEED TO BE COMPLETED?

designed almost evething

Almost everything had been design but apart the light sensors network everything need to be made.

I'm still waiting to test the geometry that I design with the robot, that is not available in the Green Fab Lab at the moment.

The R -do[L]ino fab kit is design and need to be tested with the program that I'm developing using an Arduino-Uno board. I need to find the right in face for the data feedback and to create a mobile app to control the system status.

WHAT QUESTION NEED TO BE ANSWERED?

Look for some limits

Understand limits of a programming: time response, sketch dimension.

Understand how the light's power supply will grow proportionally with the number of modules (plants).

Find the better interface language ( processing, python?).

WHAT IS THE SCHEDULE?

first design, prototyping, programing and testing it,than restart

Depending from machines availability the schedules will follow the time line shows in the graphic. The 2 main brunches at the same time starting from input and output design to finish with 3d printing and interface ( and community design if possible ).

HOW WILL IT BE AVALUATED?

from me?

I will evaluate it has much as possible basing in 3 priciples : be effective (working not workin) , low energy requirement ( can it save more energy?) and local production frindly ( can it be replicate in another part of the word with loal materials?)

To follow the evolution of my final project back in the time read how it started in the Project Management and how it finish in the Green Bricks Diaries.