week_03 computer-controlled cutting

Task

design and prototype a pressfit construction kit

File

download the rhino5 file

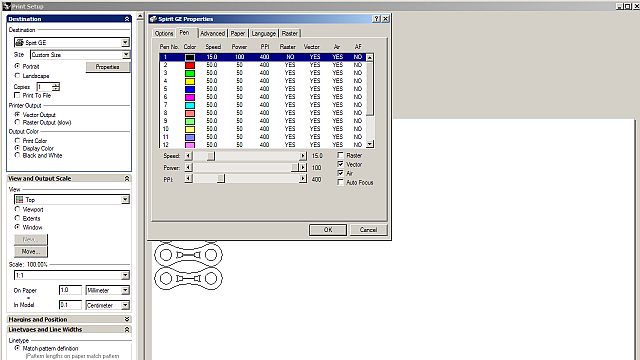

laser-cutting

machine: LaserPro | Spirit GE

max. material-size: 860 mm x 460 mm

location: Green FabLab Valldaura (BCN)

how to:

- draw a design, safe it as Rhino 4(!) version

- open it on the computer next to the lasercutter

- check the position of the drawing,

with new material it's best to place the top left corner to 0,0,0 coordinates

you will see a preview

- go to "print"

- make sure the printer is "Spirit GE"

- open "Properties"

- open "Pen"

- the settings are connected to the color of the lines, if you want to engrave and cut, make sure

you have two different layers with two different colors, one for engraving and one for cutting

- choose the settings: Speed, Power and PPI; for 3mm cardboard 5% Speed and 95% Power worked very well

without burning the material too much but cutting through nicely, the PPI was left on default; anyway it's best to do testruns because factors like humidity of the material,

age and cleanness of the lens etc. affect the result.

- click on "Print"

- go to the machine and place the material in the cutting area

-choose your file on the display by pushing F1 or F2, you will see the name of the file and the settings

- if you can't find the file check on the computer if it was sent, if the sending process on the screen doesn't proceed ask an instructor

- if everything is correct push "Start/Stop"

- the machine should start working

- if there are any issues, like burning material, push "Start/Stop" again, if the fire doesn't go out

open the lid and use an extinguisher to extinguish the fire, DON'T USE WATER!!

- close the lid and wait until the smoke is gone

Evolution

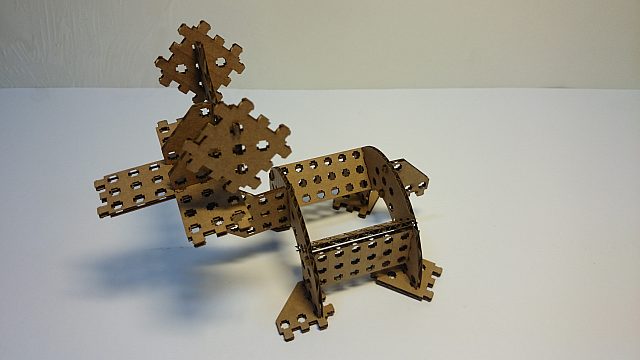

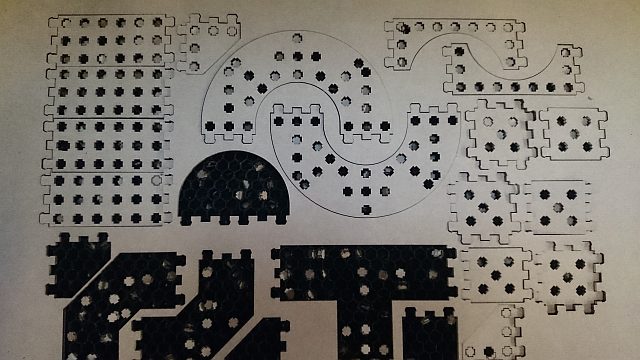

The inspiration came from the clips of a backpack. Considering the easy use of this device it can deal with a lot of tensile force. Nevertheless the idea of creating a new kind of toy was an intriguing thought, being fascinated by the impact of Lego, from kids rooms all the way up to scientific laboratories all over the world.

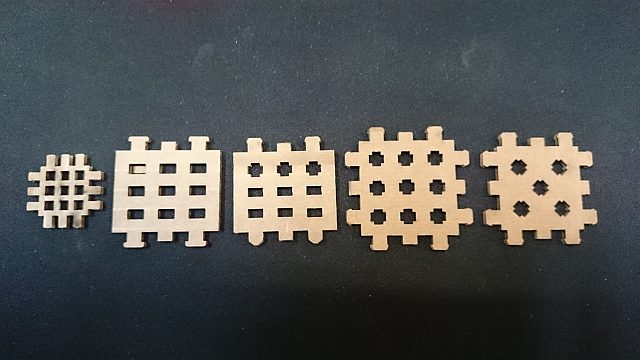

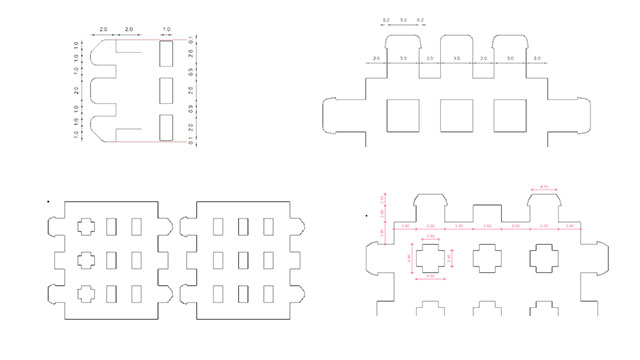

I started to play with the idea directly in Rhino, dismissing the first aproach right after finishing the drawing. The specifications of the cardboard were not known at the time but I kept developing the idea. With the second iteration I made a testcut and it turned out to be far too small to be practical and also too fragile.

For the laser-cutting I made two different layers, one for the holes which were cut first and one for the outlines. So the cardboard stayed in place and the distance between the laser and the material was kept constantly. This made the cutting more precise in the end.

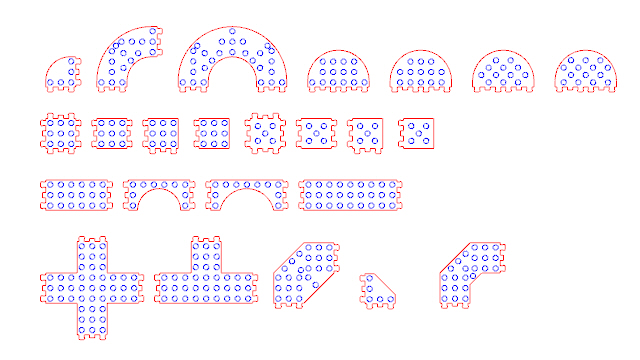

For the final prototype a set of different shapes makes it more fun to play with the kit.