Computer-Controlled Cutting

Assignment

design, make, and document a press-fit construction kit

check out the assignment guidelines at academy.cba.mit.edu

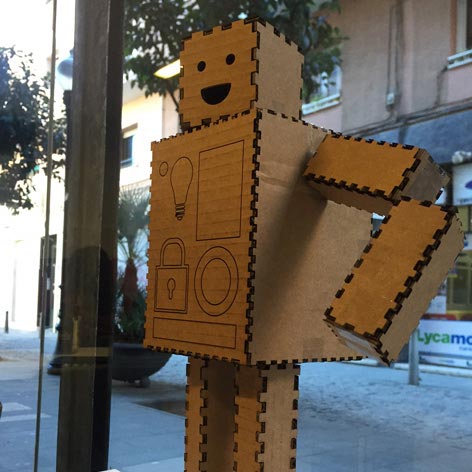

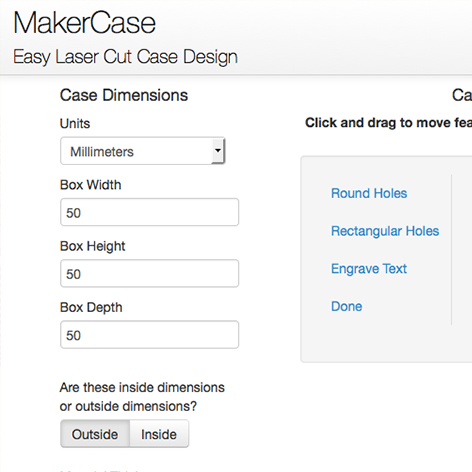

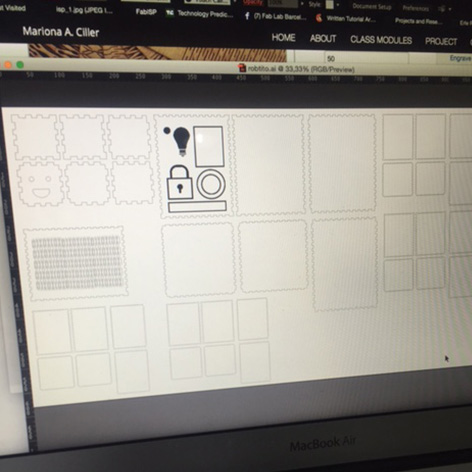

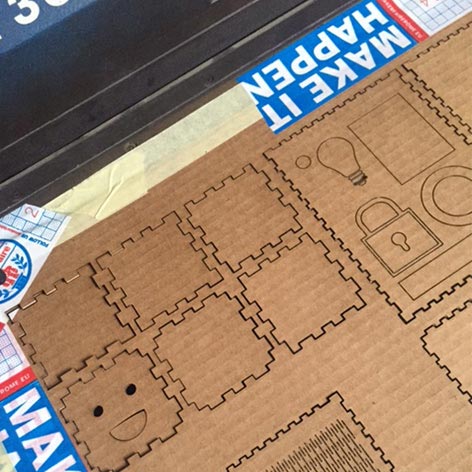

This module will be perfect to prototype Robtito's body, head, legs & knew using cardboard as a learning experience to use tin can in the near future. For the body & head I will use MakerCase & for the legs, arms & neck I will use the parametric kerf curved flexed wood. I created the head, body, legs & arms with MakerCase which exported an .svg that I opened with Illustrator to be able to prepare the file in an artboard of 80cm by 50cm to fit in the Epilog Laser Cutter. Once the files for the head, body, legs & arms are combined all snug in the artboard & separated by red for cut & blue for engraving we can proceed to export the file as a dxf file format to be able to prepare it further in Rhino for the laser cutter.

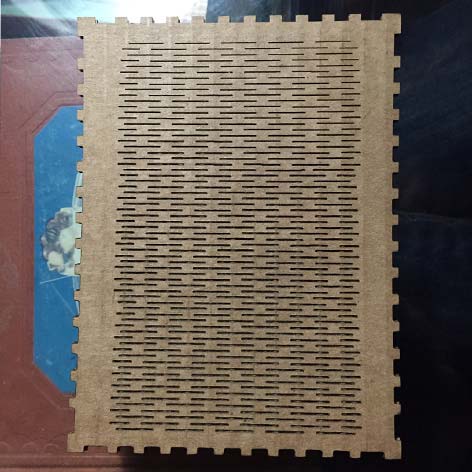

To make the arms, legs & neck I tried laser cutting parametric kerf to create flexible cardboard. It did not work so well due to the power settings I choose & the material. Since the robot will be bamboo I will ty again to see if it could work.

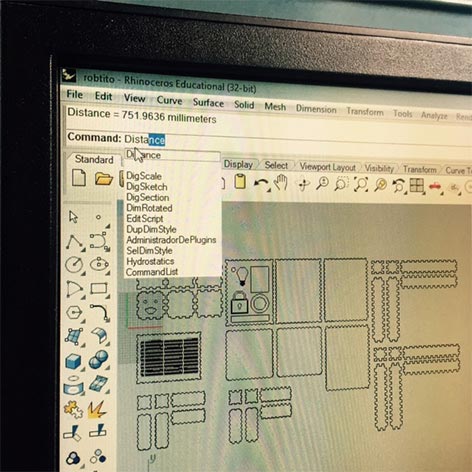

After importing the dfx into Rhino & checked the distance (width & height) to make sure everything fits on the laser cutter. The humidity in Barcelona made the cardboard a little bent so it had to be glued with tape to the laser cutter borders in order to flatten it & make sure that the cut would not be less deep & therefore not but the whole cardboard. I proceed to send the file to the machine, checking the fab lab barcelona wiki to see the settings for Cardboard Corrugated (5mm/2 layers) / Carton Corrugado with CUT: Speed: 55% & Power: 45% / ENGRAVE: Speed: 90% & Power: 10%. It was super helpful!

These are the 3dm & dxf files prepared for the laser cutter:

The robot in a box idea emerges from the need for mobility & storage.