This week I deside to make modular forniture, in order to configure it acording with your needs.

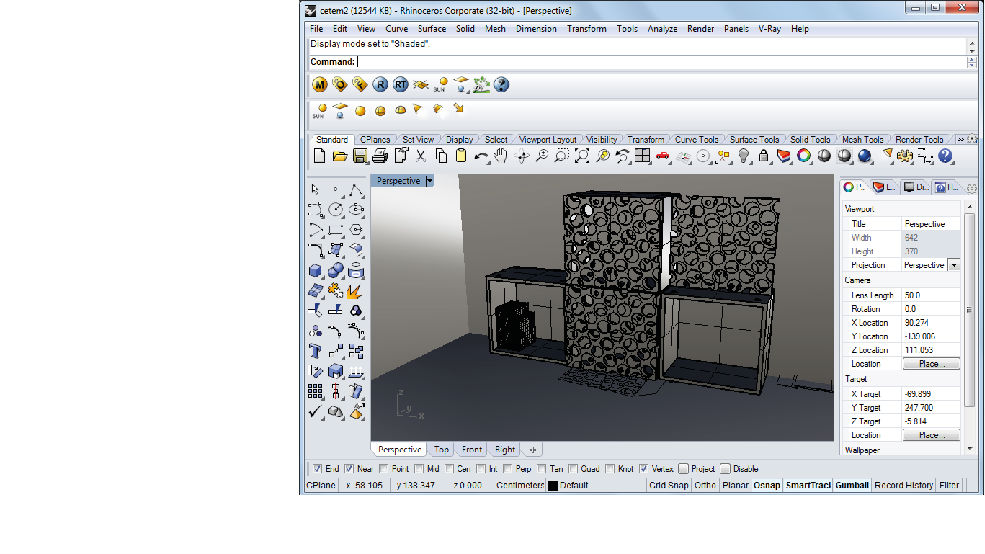

After making some drawings, I worked with Rhino to have a general perspective of the project.

Then I did a render of the model to show how this will work.

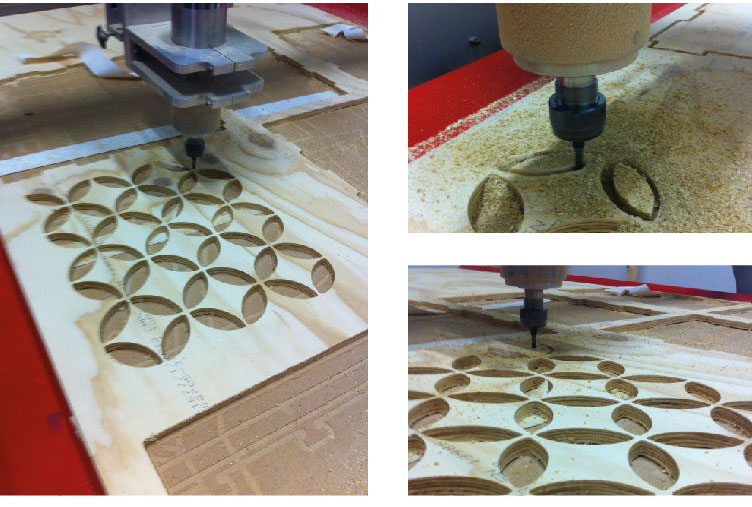

The idea is to build diferent modules with four specific functions, pot, lamp a little sit and a closet.

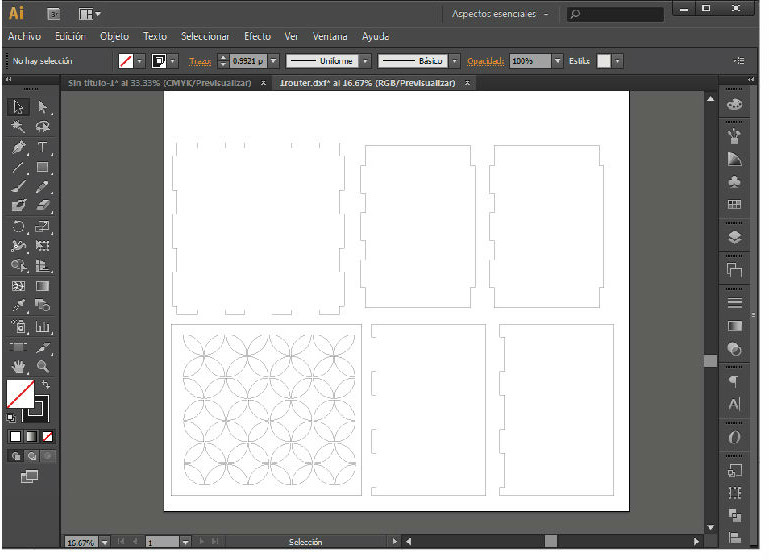

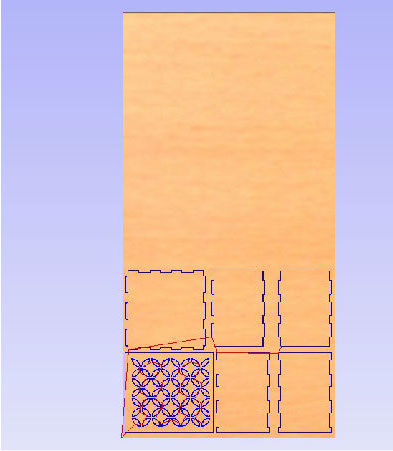

Drawing the parts in illustrator and organizing to save material.

Tip. If you work with illustrator always work with mm or in so when you exported to other software you wont lose the original dimentions

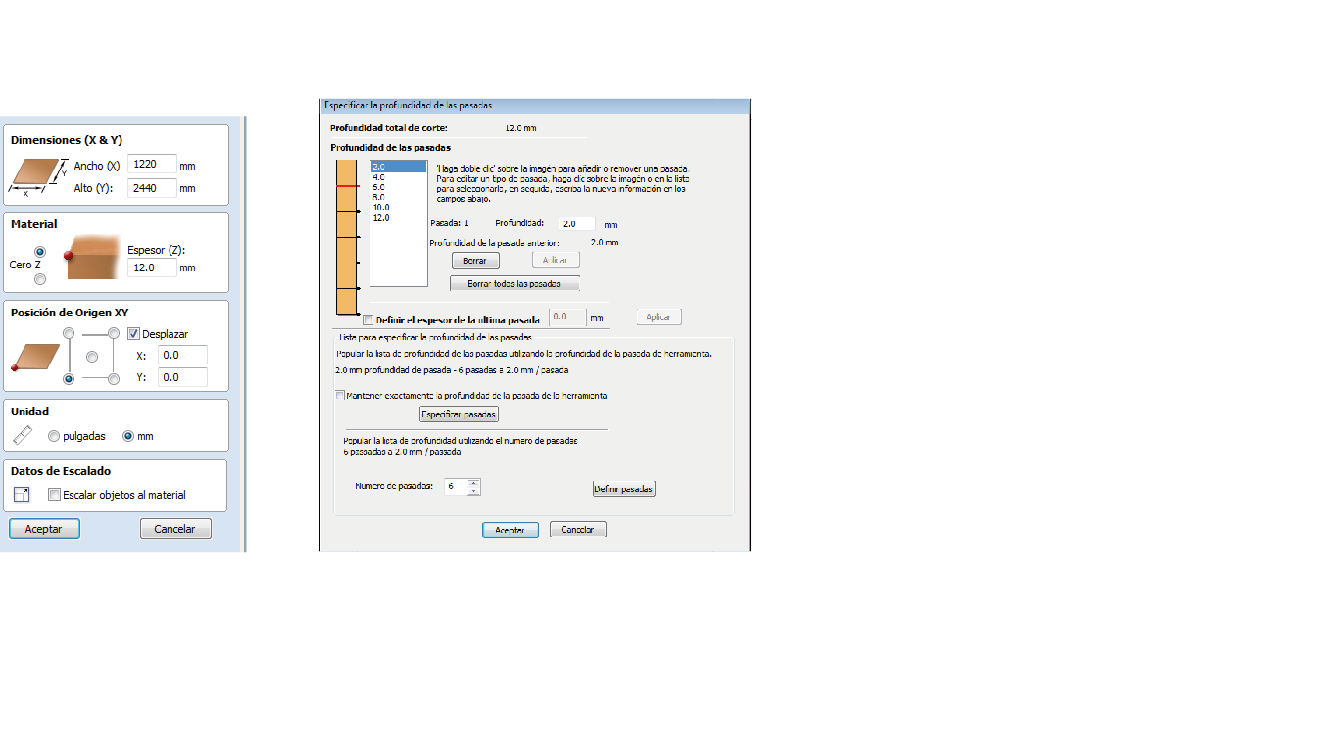

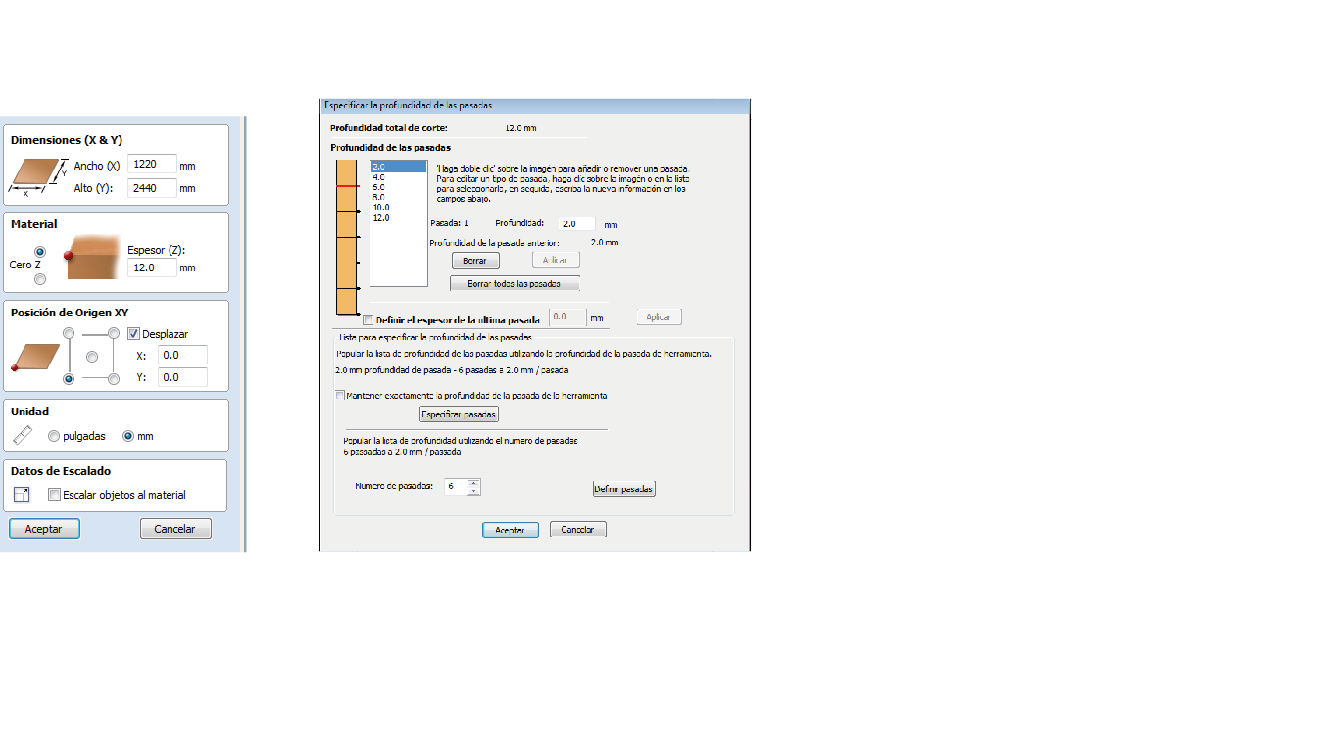

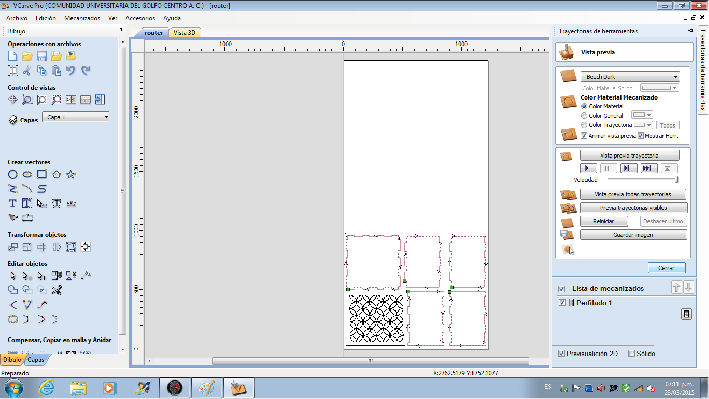

Exporting the file to VCarve

This program is very easy to use. First you have to open your dxf file and to configure your material sizes, in my case I worked with triplay so I change the dimension to 1220 mm x 2440 mm and 12mm.

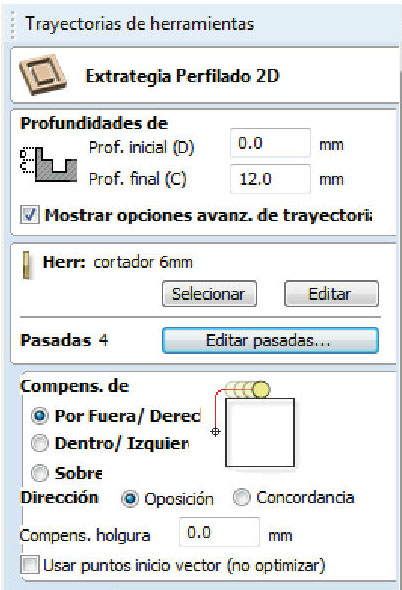

When your material dimmentions are correct you need to choose the right tool to work with and the number of times the tool will run the path and how many mm will go through in each stage.

Tip: The tool need to go through the half of the tools size, in this case I worked with a 6mm tool so it will run in distances of 3mm

Then you need to indicate wich way the tool will go throgh the path, there are some opcions: out of the line, inside the shape or above the line.

I choose going inside for the shapes on the front part of the module and out side the lines for the parts that define the shape of the module

Once you choose the way the tool will go through, you can visualise it to be sure its the right way.

When you are sure its the way you want save the fale in txt format

Files:

VCarve

txt file

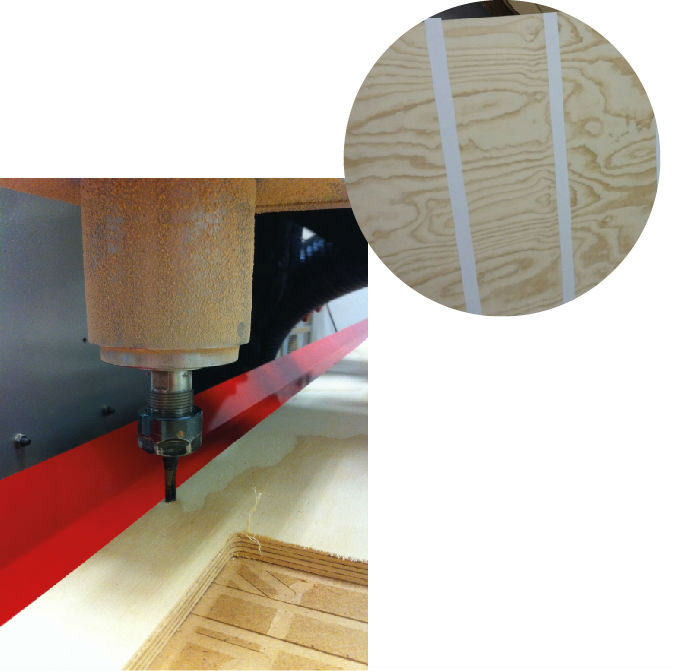

Preparing the material with tape.

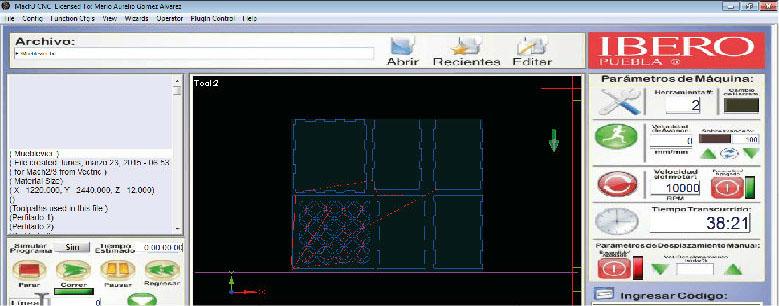

Setting the origin of the tool

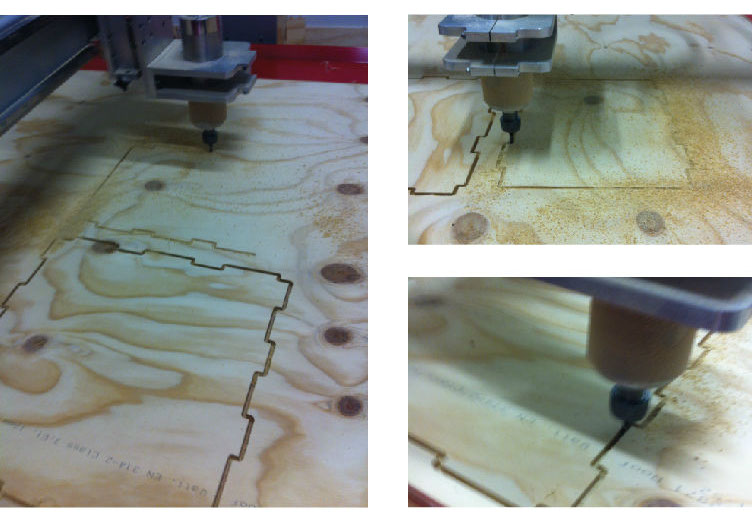

Cutting:

Assembling it:

After cutting the first module I had to make some changes in the sedign to assemble it better. I re-sized the grooves and errased some of them.

Final result