- Solder the serial communication cable to the NET FAB plate and verify its operation.

- Prepare the electrical connectors for the different elements of the machine.

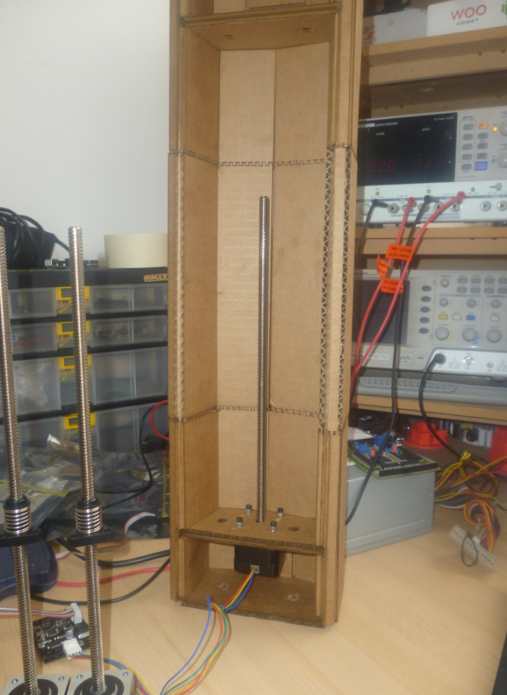

After that I belonged support in the task of assembling the machine parts and support my partner Nilton in performance tests of motor control cards.

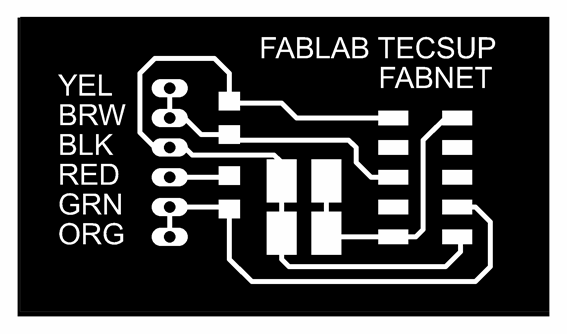

For the first part of the communication activities for FAB card NET was made , this was done on the machine MODEL . For it is as usual it was necessary to generate the image of the tracks and the cutting edge . It was used for a cutting tool of 1/64 and 1/32 inch for cutting the circuit board .

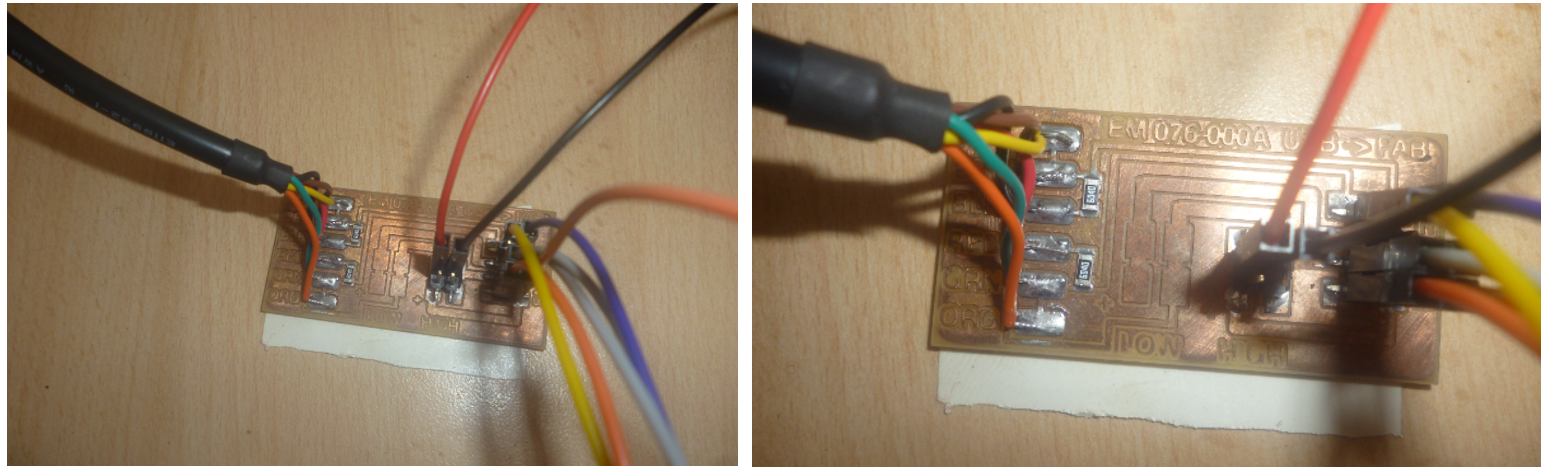

After it was necessary to weld the serial communication cable in the FAB NET card only for this color order he was followed. To verify the operation of the card was necessary to connect the motors, this was done with my partner Nilton.

Once verified the various connectors that were necessary for connecting other elements, such as prepared motors, etc.

Thereafter support activities in other activities with my colleagues , which was supported in the assembly of the mechanical structure , and support in checking run of cards for engines working together was made.