The Making of the Time to Make Things Clock

The Making of the Time to Make Things Clock

By Jessica Nelson 2015

Champaign Urbana Community Fab Lab

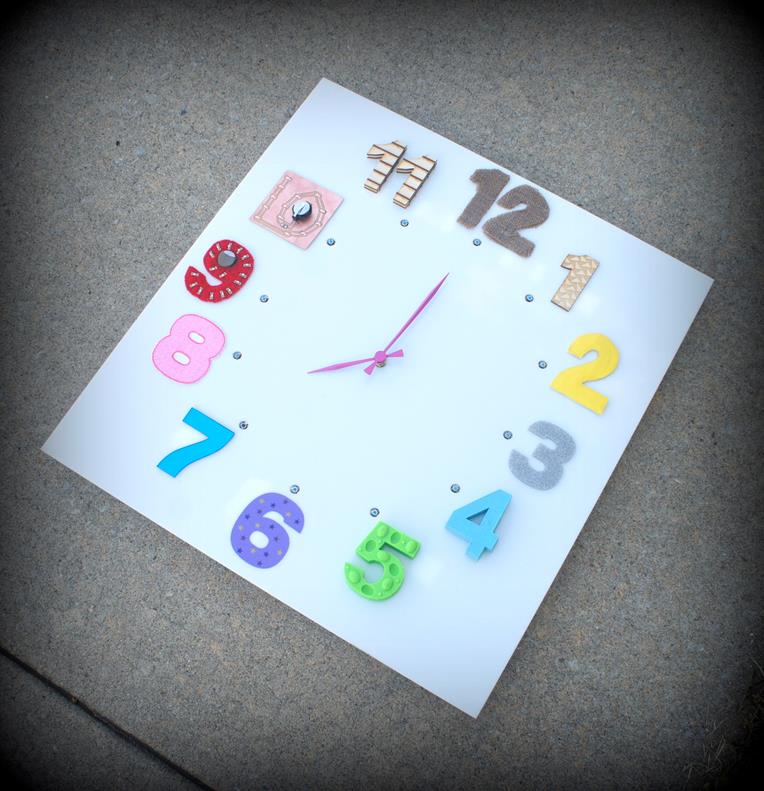

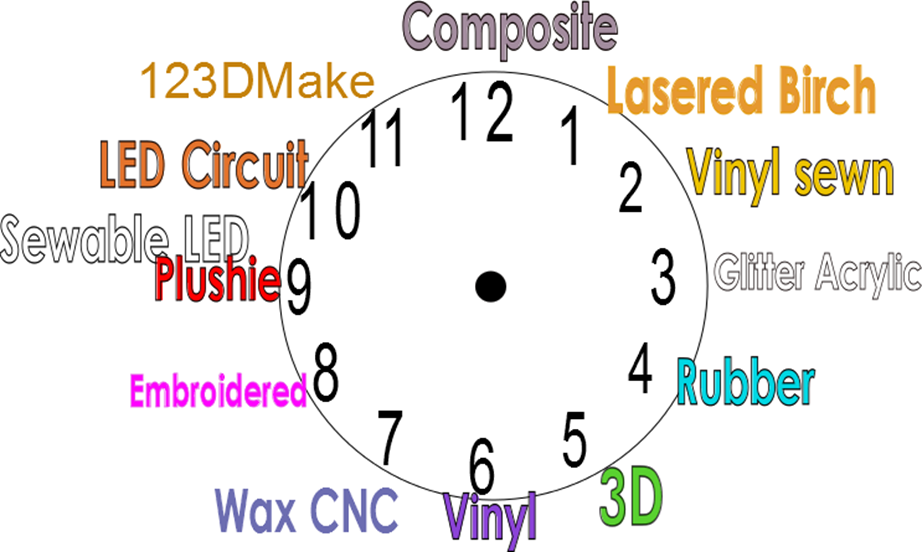

When I first came to our Fab Lab, I

always thought it would be neat to have a clock made using all the fancy machines.

Once I learned how to use them, I was inspired and motivated to make my idea

come to life! To begin, I sketched out a rough draft on paper. Then, I made a

digital document of my plan. I tried to include everything I had learned in Fab

Academy, with a few of my own personal maker touches. Each number would have a

button that when pressed, would launch a website with a tutorial or info on  how the

number was made!

how the

number was made!

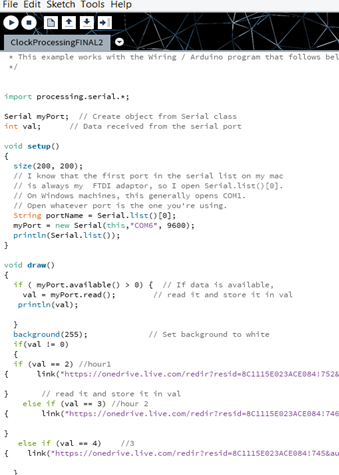

Arduino Code & Processing

Arduino Code & Processing

Code

Code

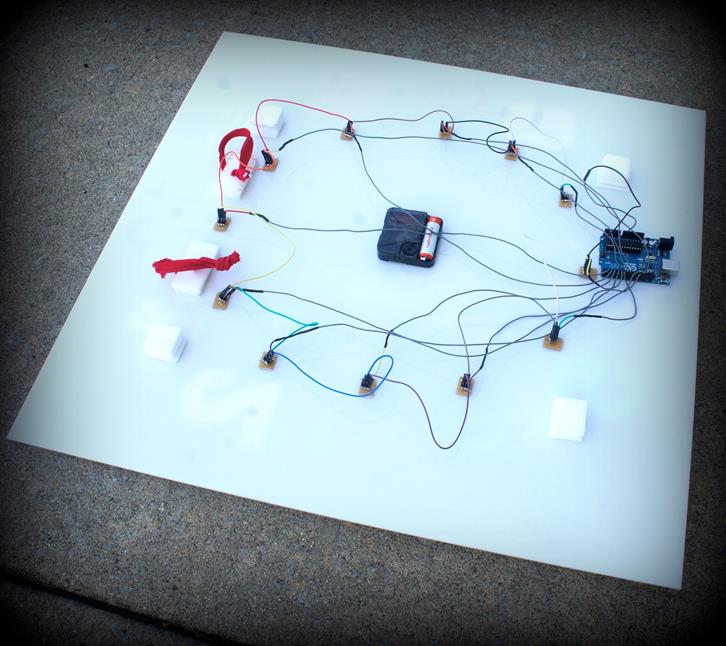

The

coding part was tricky. Once I had my Arduino code, I put together a processing

code using examples. The hardest part was figuring out how to have the Processing

program stop opening multiple web pages after a button was pressed. Another

hurdle was to have the Arduino continue listening for a button pressed after

one was pushed! Once I had finally figured it out (“else if” was very useful) I

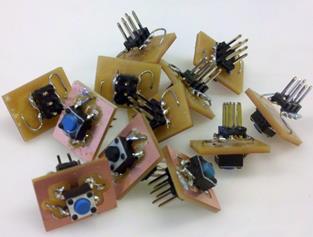

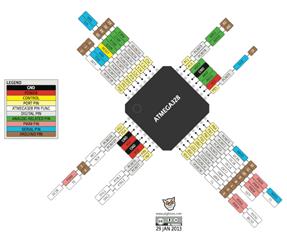

was ready for the next step, preparing my board! I designed my board in EAGLE

cad. I decided to use an ATMEGA328 for the multiple inputs. I had planned for

the buttons to be connected via headers and wires to my board. Here is my schematic. It

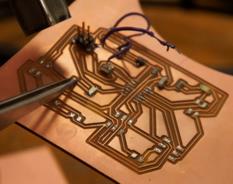

was not without difficulty that my board was milled and populated. My first one

had traces going to the wrong place. My second had issues with the traces

falling off because of their daintiness. My third and final attempt was

correctly done, however I was unable to burn the bootloader. My instructor

suggested that I use an Arduino instead, but to make sure to include my work on

the ATMEGA328. My second attempt at creating a microcontroller that incorporates

an output and input device was easier when I switched to using an ATTiny44. The

only difference is that there are two buttons, instead of 12. This is the schematic. This is the software serial programmed to the ATTiny44.

I used example sketches and helpful forums from the internet. The processing was

trickier, main difference between my processing sketch for Arduino and

processing for Attiny 44 were that I had to use println(Serial.list()); in my

setup instead of println(val);.

In the time I had to make my idea come to  life,

using an Arduino was a lot simpler.

life,

using an Arduino was a lot simpler.

(Below are images of the web page that pops up. Since they

are images the highlighted links won’t work. To view the links easier, please

see the processing sketch above.)

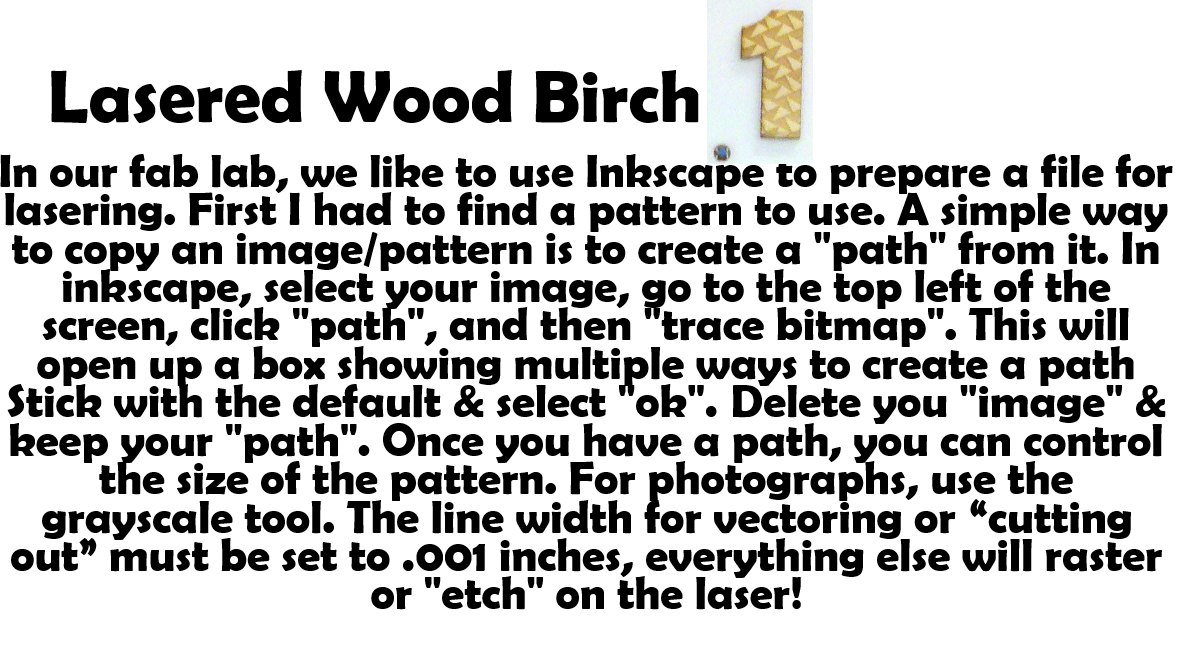

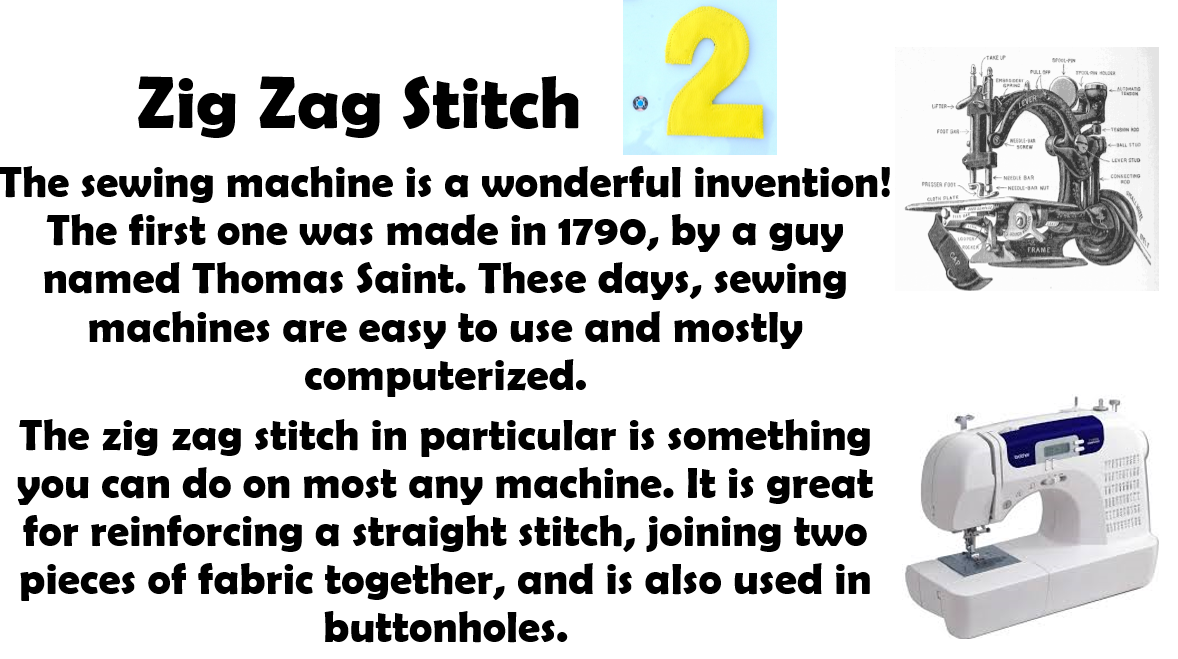

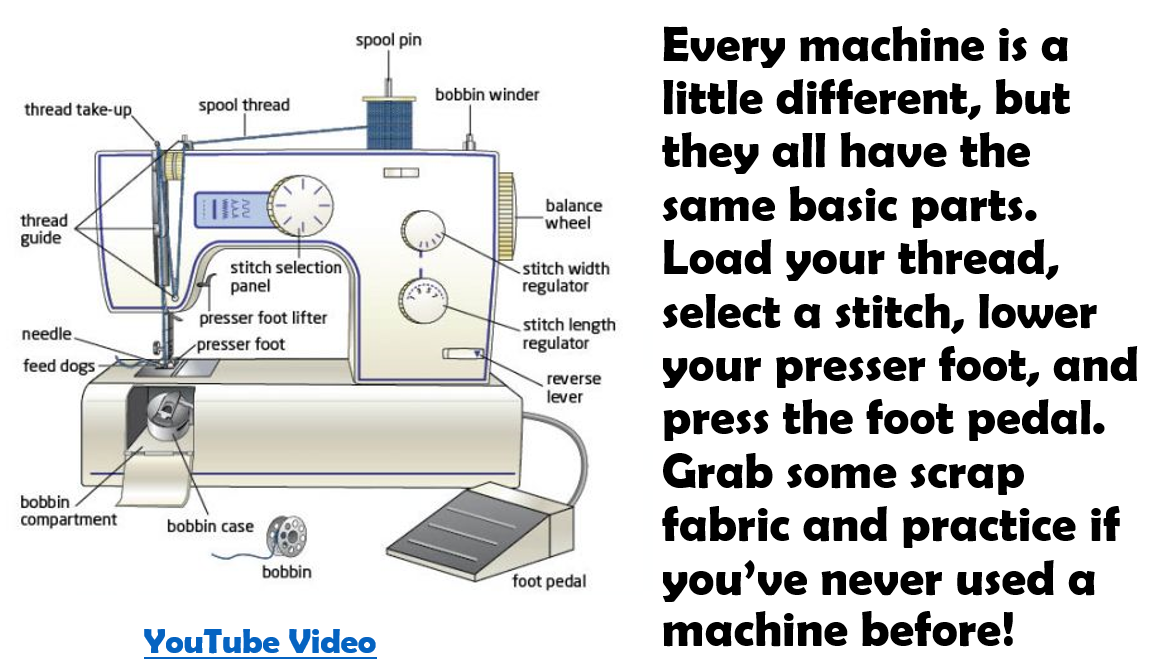

Cut File for 1/8” birch plywood-epilogue laser =$2(time on laser, scrap wood)

No digital file, cut by hand & ruler: Vinyl Leather-sewing

machine=$2 (materials)

Cut File for

Glitter Acrylic-Epilog Laser=$5.50(material & laser time)

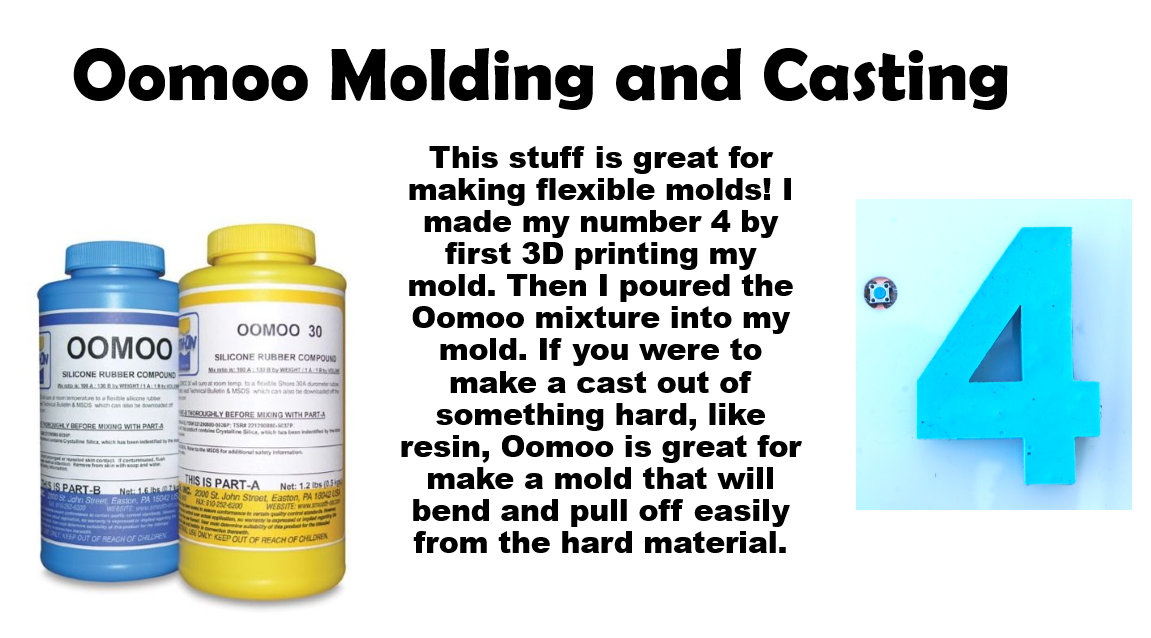

3D Mold File for

Flexible Oodoo-molding material=$15(filament & oodoo)

3D File for 3D

Print Hips-Up mini printer=$3.55(filament)

Silhouette File for Vinyl Sticker-Silhouette=free (from

scrap vinyl)

Laser File for

Mirrored Acrylic-Epilog Laser=$5.50(material & laser time)

Embroidery File for

Embroidered Patch-embroidery machine=$2(thread & machine use)

No

digital file, cut & sewn by hand: Soft Circuit Felt-hand sewing=$17.85(LEDs,

conductive thread, battery, & conductive pocket)

Schematic for PCB

Circuit-Roland Modela=$6(PCB, LED, battery holder,

battery)

Laser File for

123DMake-Laser=$1(laser time, scrap wood)

No

digital file for Resin Burlap-Composite=$2(donated burlap, 1/4cup resin)

There

are several ways to go about creating a clock mechanism. I am very interested

in creating a “Genesis

Clock” created by Clayton Boyer. If I were to build my own mechanism, I

would start by using this. Having a done a bit of research, I might also try a great

CAD file I discovered, with plastic as the main material. I am also curious

about this 3D

printed clock file as well. I had no idea there were so many ways to build

clocks! I might also give this digital

LED clock a try as well when I have the time! Total cost of the clock was

$100.40. If you were to make your own, this price would not be definite!

![]()

Time to Make Things

Clock by Jessica

Nelson is licensed under a Creative Commons Attribution

4.0 International License.

Video Presentation of Final

Project