Small Flex Cube

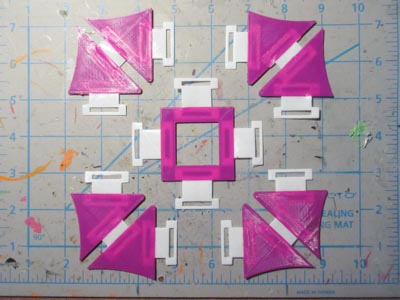

Final Result

Progressing from the previous experiment of embedding flexible prints into rigid ones, I wanted to try a smaller version of the cube to test it out, since this would be used for RDAS v0.3.

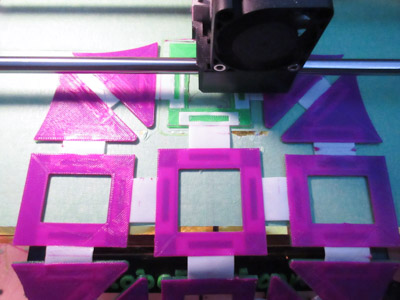

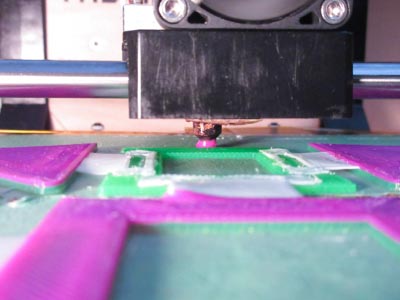

Here the printer is printing the top layer (purple) onto the last side piece that is linked together.

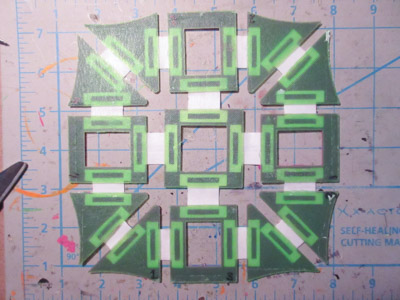

Flip side:

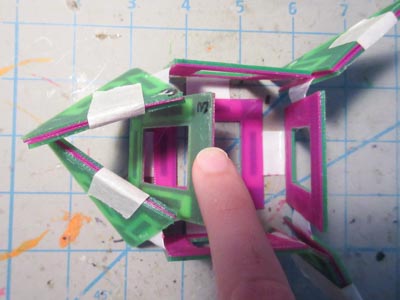

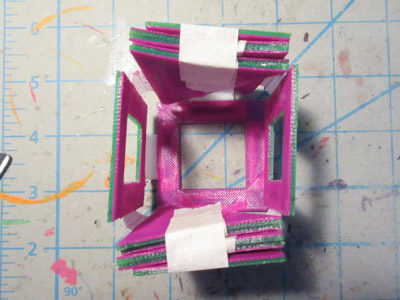

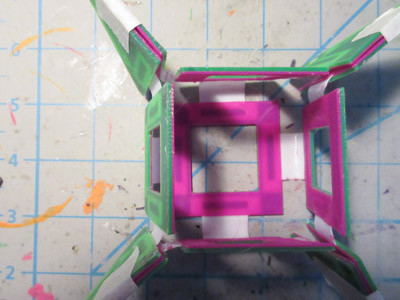

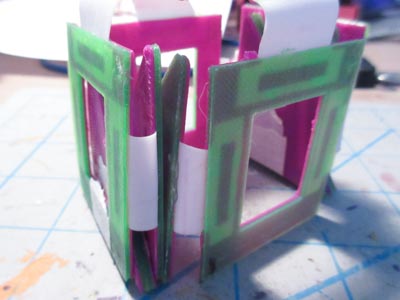

Folded up into a cube with tape holding it in place:

The panels are able to be folded up closely to eachother:

The sides angle outwards a bit. Maybe if the flex pieces from the base (center piece) were smaller, this would not be as noticable:

Making Of

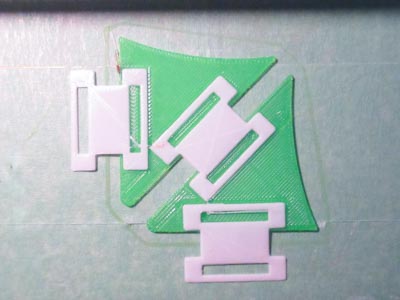

First piece that is printed, then the flexible pieces are attached onto it. Using hot glue to tack the pieces down:

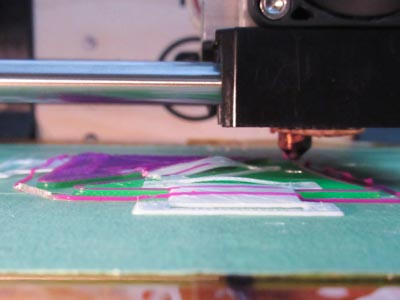

Here is the first layer of the top piece being printed over the flex link:

When finished:

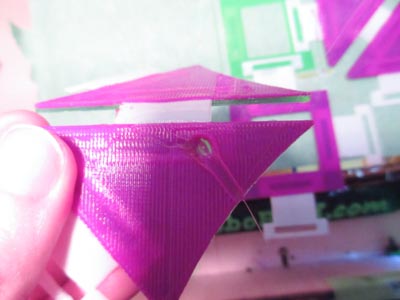

Here is a defect that was caused when trying to remove the print from the build platform:

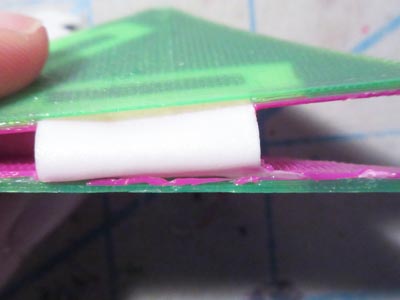

It's quite thin. It could be even thinner if I tried it at 0.1mm layer height rather than 0.3mm:

The next pieces printed are the panels, with the flex links added:

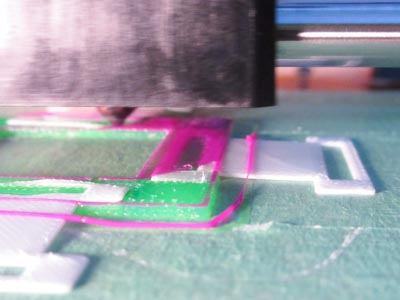

Ran into a problem here where the pieces were pushed out of their place from the nozzle:

Sometimes the flex links ended up buckling. Think it's caused by the space between the panels:

It still comes out OK, though you can see how some of the extruded filament rises over the flex link (a bit):

Bended view:

4.90mm, the width of the panels folded together:

Sometimes if folding the top pieces towards eachother, it won't be completely flat. Notice how the edges on the right side are not touching:

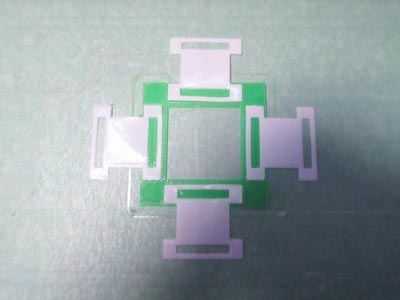

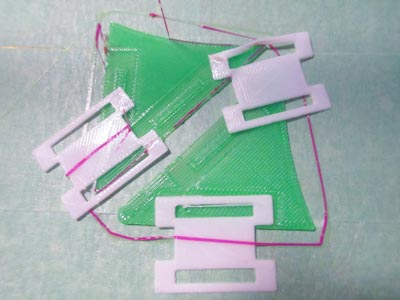

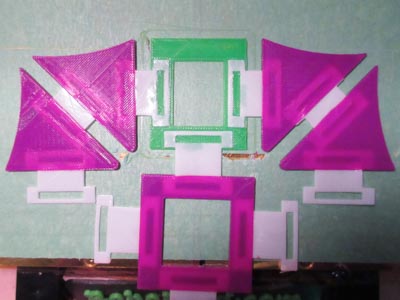

All of the pieces before starting to print the sides:

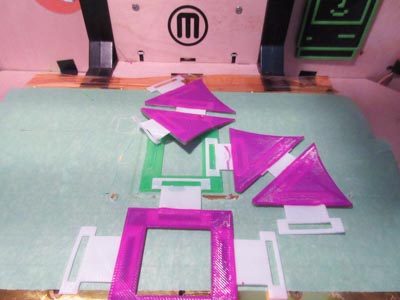

When the side piece is printed, two of the panel assemblies and the base are added to it:

Ran in to a problem here where the nozzle ran in to the panel piece and pushed it out of the way:

Melted a portion of the print:

How I worked around this was to pause the top piece print as it was printing the skirt, as it was out of the way. This would then let me load in the other pieces and attach the flex links.

One of the problems is that there was filament extruded while waiting, resulting in a 'blob' of plastic that was formed. It didn't interfere with the print though.

In the future want to make this better by adjusting the gcode to move the z axis down before moving the gantry across the platform to its starting position.

Side view of folded up:

It was interesting to see some of the movements that could be made from pressing on the different sides: