About me

Final project -

development

Final project

Weekly projects

Wk 9 Moulding and

Casting (Mar 25)

Assignment:

• Design a 3D mold,

machine it, and cast parts from it.

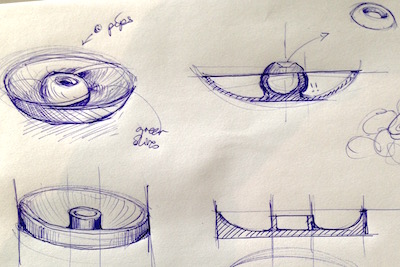

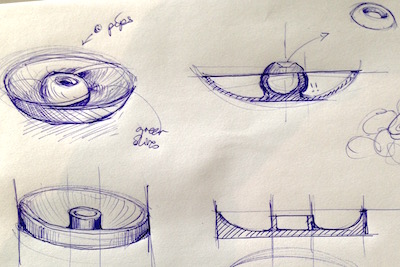

Design

I

decided to design, mould and cast a

shallow dish which could be used to serve

olives, incorporating an out of sight

stone disposal pocket. My original design

was quite curved across several planes,

including a spherical form which created

an overhang challenge which would require

a complex multii-part mould.

Therefore, as a first mould and cast

project I decided to simplified the

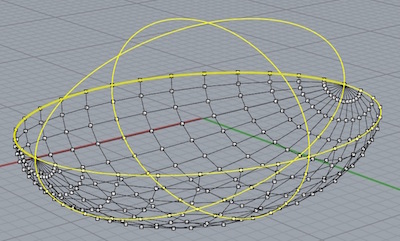

design. I tool the opportunity again to

explore CAD in Rhino and SolidWorks.

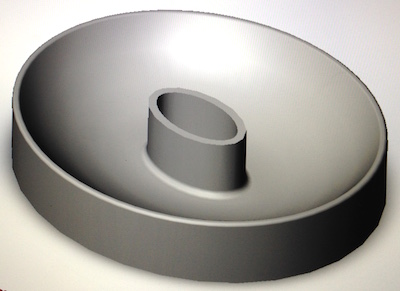

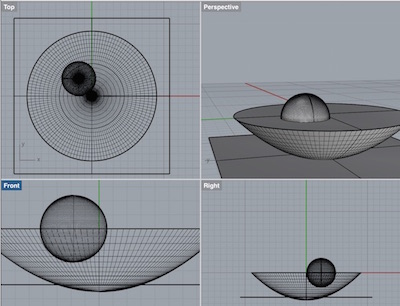

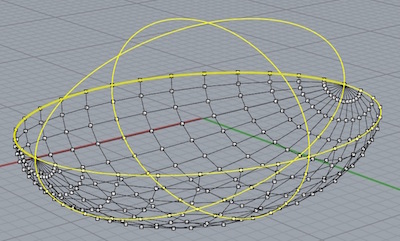

For my first attempt, I simplified the

design to have vertical walls on outside

(preserving the spherical base interior,

but removing the spherical overhang of the

form in the middle of the dish):

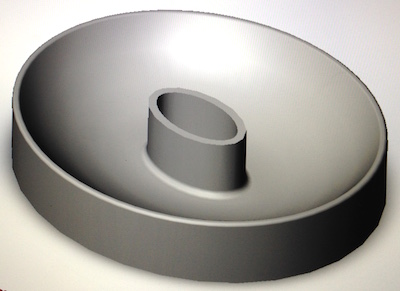

Despite having been a

significant learning curve

for me to get to grips

with Solidworks, I did

appreciate all the

dimensioning flexibility

its parametric design

tools enabled along the

way. The design and

modelling process has

given me an in-road into

Solidworks.

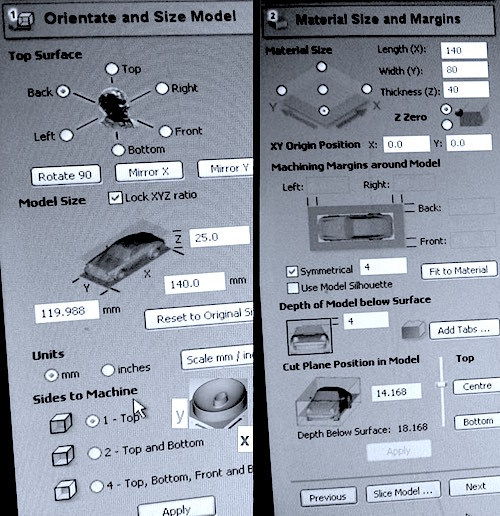

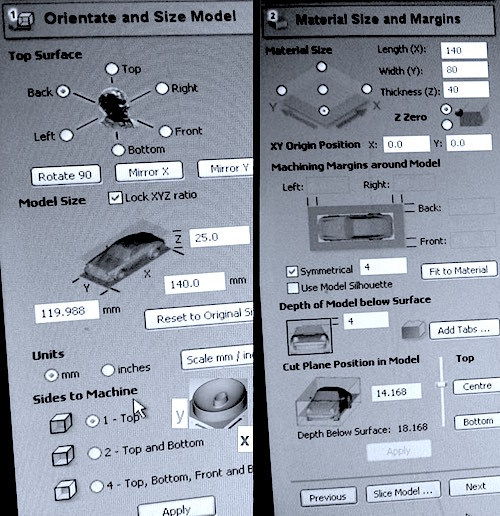

The model was saved as an

.STL (file size: 478kb),

ready to be opened in

Partworks, which is the

interface to the Shopbot

CNC machine.

Preparing the

materials

for making the form

Machinable

wax was remelted

in cake tins in

the oven at around

220˚C.

This

took around 45

minutes.

I

think its

worth making

sure that all

the wax has

completely

melted throughout,

otherwise I

suspect weaknesses

develop

in the

material which

can show up

during milling

stresses.

Also,

impurities

may cause

some unpredictable

results as

well as

imperfect

surfaces. Once

melted, the

wax has to be

allowed to

cool down.

I cooled

the

block outside (temp

approx

12˚C), which

I deemed to be not

too cold

but perhaps this

was

too

sudden?

I

filed down the rasied

edges around the block

(consequence of

heating and shrinking

from edge as it cooled

down)

so that I

had

a flatter,

more stable

surface with

which to screw

down onto a mobile

base for

securing to

the sacrificial

bed

of the Shopbot.

Setting up

the shopbot

and toolpaths

to mill

the form

Previews

of rough and

finishing

toolpaths

milling:

The

image below

demonstrates

both

the work of

the rough (stepped

mill path -

using

flat

end mill),

next to the

finishing path

using the

ball-nosed

mill finishing

path (crossing

at 45 degrees).

Also

visible is

the fracture

which caused a

piece of

the inner

ellipsical wall

to break away.

I

had also

selected the

'extra passes'

option, but as

it milled, I

could not

detect any improvement

in surface

smoothness or

finish

- perhaps

the stepover

setting needed

to be

decreased, so

as not to

create a

'micro-ribbing'

in the surfce.

As

this was

taking

extra time

with no

apparent gain,

I

decided to

abort the completion

of the extra

passes

toolpath.

I

used multi purpose

plaster to

fill the

fracture:

Measuring the

volume of the

form to estimate

quantities

required:

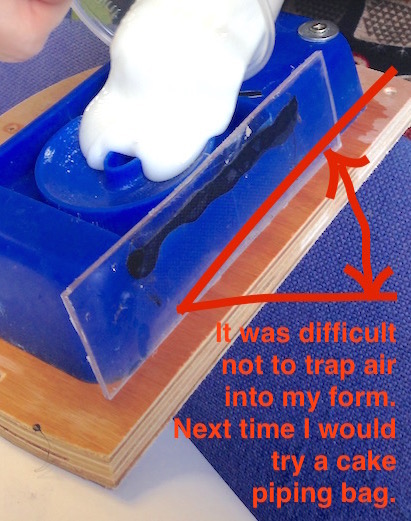

Prepartion

of Liquid

Silicone

Rubber to make

mould:

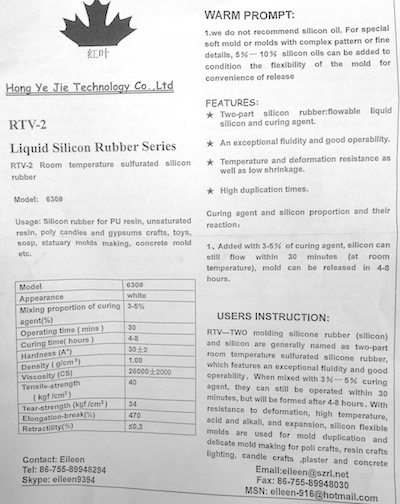

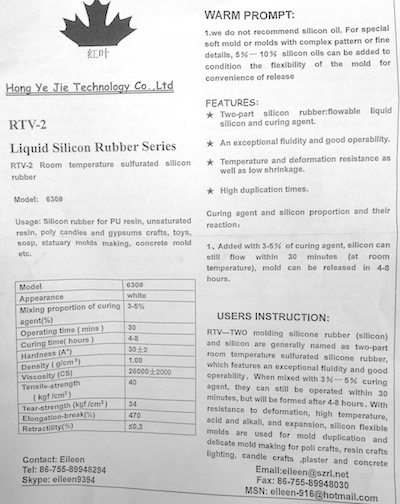

Instructions:

Methods

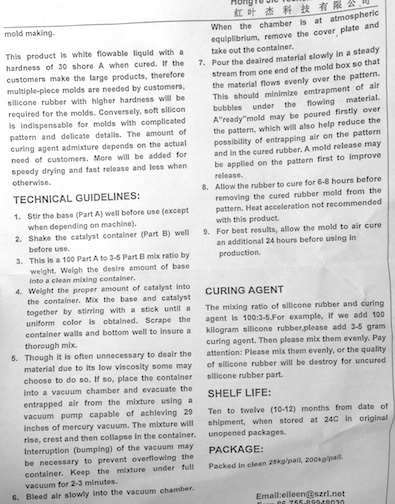

to try and

remove trapped

air bubbles

within body of

silicone:

Placed

on a vibrating

machine

(extractor motor

in this

instance on

left)

and

a vacuum

chamber (right):

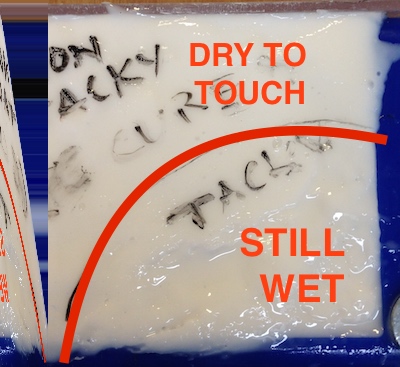

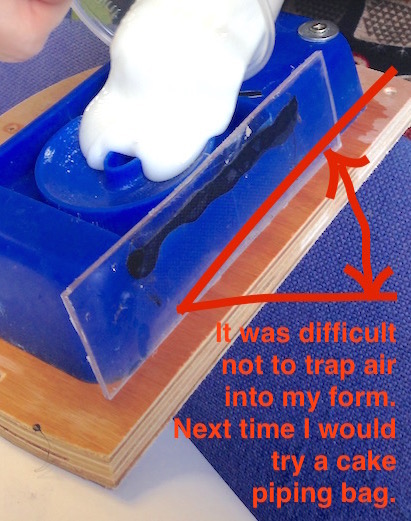

The images

below show

that some

areas that are

still very

tacky to touch

- this is a

sign that

the hardener solution

had not been

thoroughly

mixed. I remember noti

as I mixed,

noticing the

mixture

begin to

harden and

became

aware

that

'flow' time

was limited.

In

retrospect

I remember the

voice of my

tutor "when

you think it

is ready, you

probably need

to mix for

a little

longer..."

However,

if air

bubbles had

not been

trapped within

the silicon

fluid

upon pouring,

the

actual quality

of the mould

would have been

quite

good.

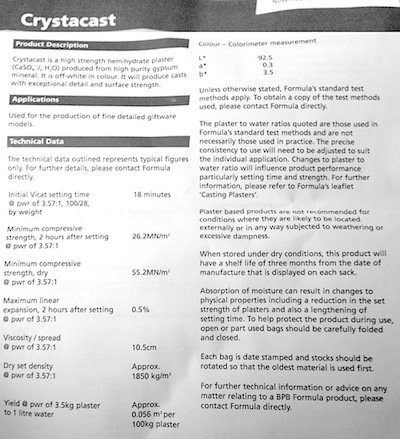

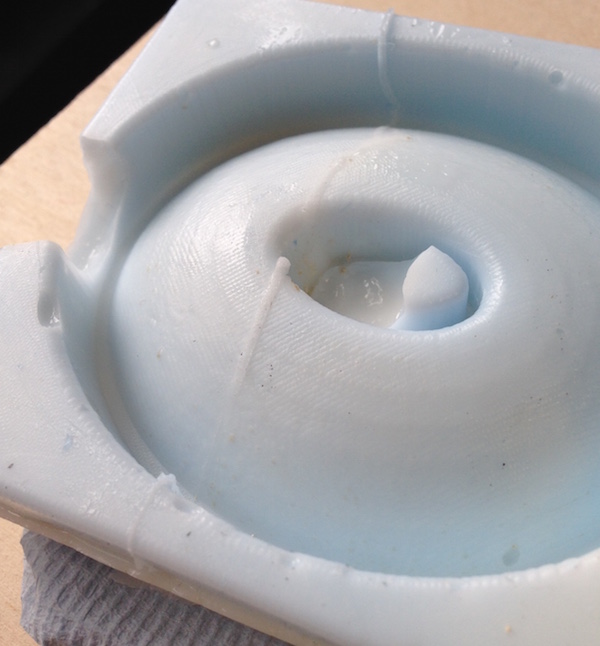

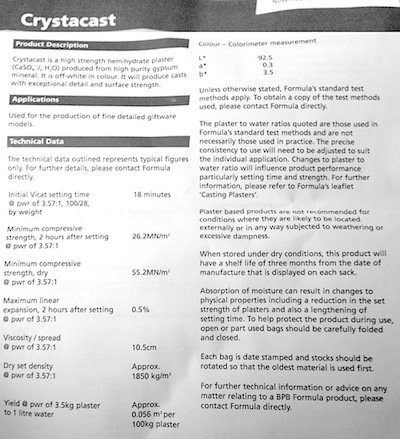

Preapartion

of Crystacast

- a product that

is similar to

Drystone (but

competitively

available in

UK market).

I

had forgotten

to

stop pouring

the plaster

into the mould

to the right

height!

Therefore I

inherited

the skirting

around the

base.

Although the

material is strong,

it

was quite easy

to shear,

I was

therfore

able to use a

strong pair of

scissors

to shear away

the unwanted edges

for my

prototype.

First

prototype of

table dish for

olives shown

below

(using grapes

which look

huge in this

scaled down

version).

Download

file