About me

Final project -

development

Final project

Weekly projects

Wk 8 Large Format

Machining (Mar 18)

Assignment:

• Make something big

Design

Last week,

a dear friend of mine asked me "So

what's your project this week Sal?!". When I told

her the brief was captured in three words "make

something big", she said "Any chance of a

new garden bird table?" I

thought it was a nice challenge.

I had witnessed many times, magpies and crows swooping and

stealing bird feed from the

smaller more vulnerable

garden birds on her bird

table and so I wanted my

design

to offer

some element of

protection for them.

Something that would

enable them to move

freely (due their

size) and

make

swooping

difficult for

the larger

birds, whilst

not prohibiting

the view from

the house

window.

After

an initial idea

and sketch,

I set about

cutting some

cardboard by

hand so that I

could see the

form as soon

as possible in

space.

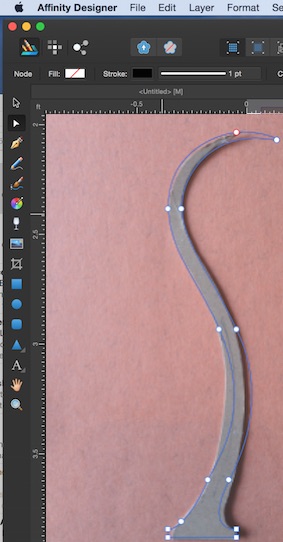

I

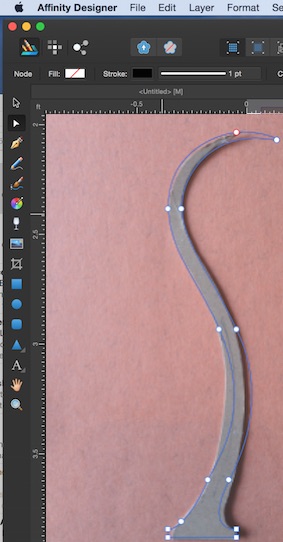

then set about

tracing the

cardboard rib

as a vector

drawing in

Affinity

Designer:

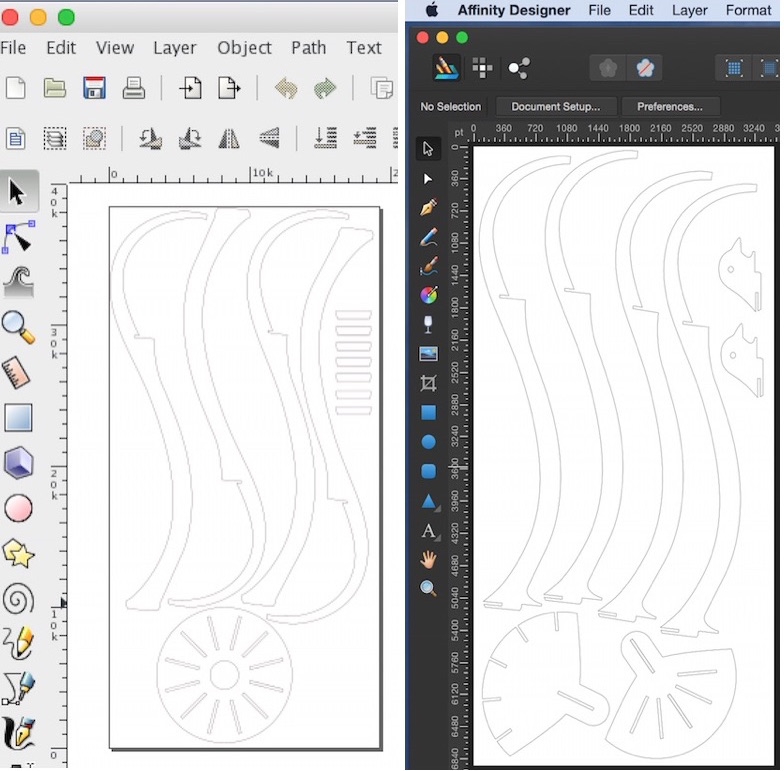

I tried to draw

the vector paths in both Affinity Designer (£39) and

Inkscape (free). As I am new to both applications, a

large part of the week was trying to create these paths

and refining design and structural detail as I went

along. Given my design was quite tall with minimal in

structural support, my tutor pointed out that a lock

joint would help to give strength.

Affinity has some very powerful and sophisticated tools

for recognising geometrical relationships and snap-to

tools. Moving to Inkscape after Affinity feels like a

downgrade, then again, Inkscape is free.

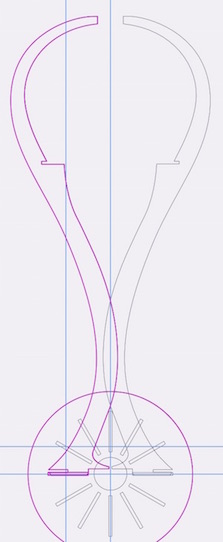

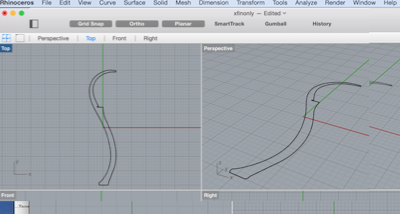

If I had more

fluidity in 3D CAD I would have definitely tried to

progress further using Rhino than I managed to do.

A 3D model of the design in space would certainly help

me identify any potential design flaws. I imported the

rib into Rhino to see the structure in space and

be able to more easily slice and select 'planes'

for intersecting pieces, but in the time available

I was not able to progress quickly enough, so

I focussed on preparing the form in 2D to create a pdf

for the Shopbot Milling Machine.

HEALTH and SAFETY

Health and Safety is the most important aspect of

working with the Shopbot machine. The tool itself is

surprisingly unguarded and moves across X Y Z axis, so

its critical to be mindful at all times.

When handling materials, gloves should be worn

to protect from splintering. Goggles must be

worn to protect eyes from the possibility of loose

pieces flying off the bed, or worse, the tool itself

shattering. The milling action creates a deafening

noise compounded by an extractor fan, so ear

defenders are also must. Although we do have an

extraction fan in the lab, I could feel the irritation

of the dust particles so I also chose to wear a mask.

I am under there

somewhere.

I am under there

somewhere.

Setting up

and preparation for Milling

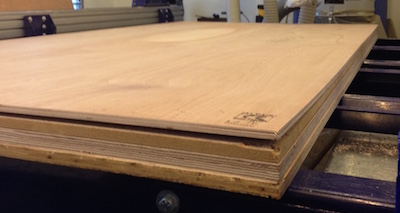

The material I had chosen to

work with was 12mm ply. In actual fact the material

varied between 11.0 and 11.4 and this had to be

accounted for in the dimensions of all joints; an

average of 11.2mm was applied. The Computer

Numerically Controlled (CNC) Machine that we had at

our lab was a ShopBot machine. The software used to

create the toolpaths was Partworks.

Once the material was placed on the bed, it became

apparent that one corner of the piece was slighlty

warped. This made clear the importance of laying the

material as flat and sound to the bed as possible, so

7 points were chosen to screw the material solidly to

the bed. I had to refer to the layout of the design to

ascertain where to best place the screws - ie, in the

waste sections and where they would be most effective,

considering any weak areas and those prone to

vibration.

The machine was now ready to have the X, Y and Z

axis 'zeroed' (- the origin offset is never used in

Partworks) .

The machine was powered on and the tool column could

now be moved by left-right on the PC keyboard to bring

the middle of the tool bit to the origin of the bed /

material. Finding the X and Y axis is straight forward

and done by eye alignment along the length of the

material.

To determine an accurate zero for the Z axis and to

avoid damaging the material (which is soft relative to

the powered drill bit), the Z axis zero origin is

detemined by use of a metal plate of a certain depth

(known and previously calibrated in Partworks), which

is placed solidly on the material (away from the

edges) and under the drill bit (choose a clean

undamaged area). A metal clip is attached onto drill -

this establishes an open electrical circuit. Upon

selection of Z-zero on the PC control panel, the tool

tip automatically travels down and detects the right

contact with the metal plate (closing the electrical

circuit - check for green light in the control panel).

This process completes the Z-zeroing

Checking and amending the toolpath in PartWorks

(ready to mill)

Partworks (the software

that controls the shopbot) is where final checks

and refinements are made to the pathwork before

calcualting the final toolpaths to mill.

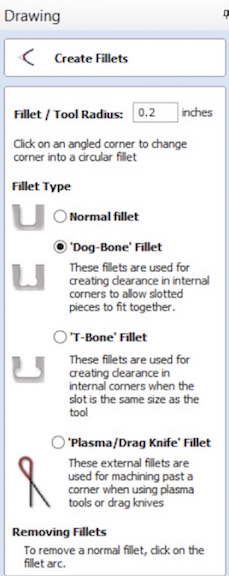

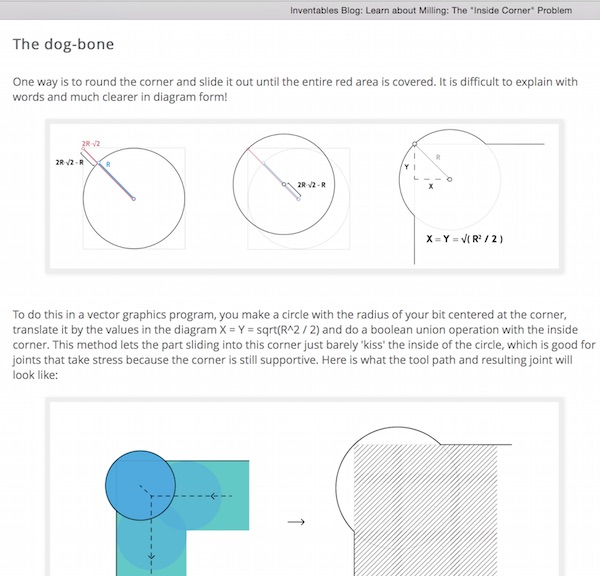

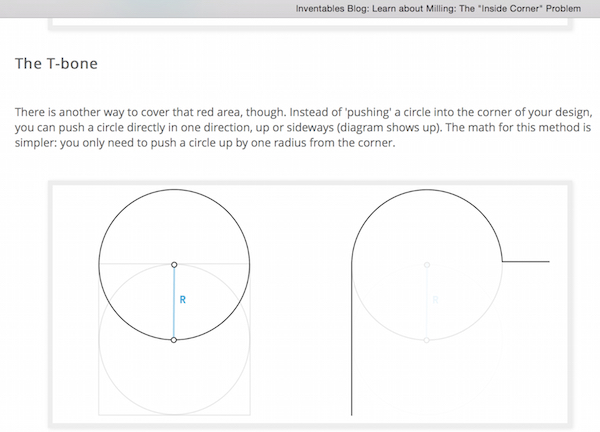

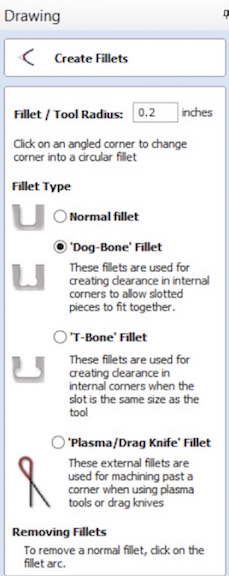

Dog and T-Bone fillets

Most joints are square in form. However a milling

tool is circular. The

'Dog-Bone' and 'T-Bone' fillets allow

toolpaths to mill into corners of slots and

grooves, allowing mating parts to fit flush.

This also allows the limiting radius of the

cutter to be removed from the bottom of slots.

This ensures the strongest possible engagment and

fit. Choice depends on the

needs of the design and whether the joint

can be visible or needs to be hidden for

aesthetic reasons.

When I transferred my pdf file to

Partworks, all the vector lines were closed as

required, which is good. However there was quite a bit

of work to do. For example,

we found duplicate line work which needed to be

deleted. Also, in some places, the click-on-path

feature in PartWorks to assign a dogbone fillet in

a corner would not work in every position. In some

places, new traces had to be drawn over existing

lines and then the fillets would work. In some

cases, by reducing the radius of the cutter in the

dogbone settings, the fillet would also work, as

the software would not allow the fillet to extend

beyond the width of the slot.

In future I would choose to go through

this process outside the shopbot PC environment to

make sure it was truly ready to mill.

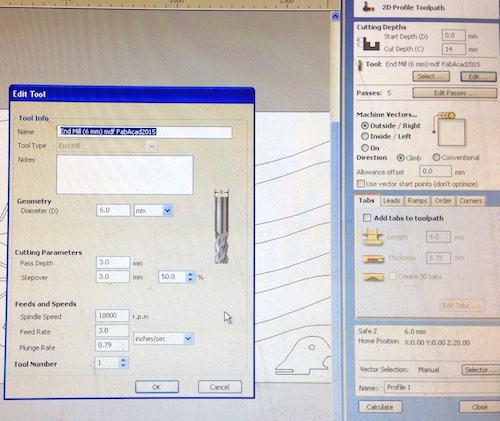

Toolpath set up

There are 3 toolpaths to choose from. Profile,

Pocket (for scooping out) and Drilling.

I chose 'Profile' toolpath; outside; climb. Tool was

going to be 6mm downcutting tool, which would give the

best finish in this set up. Settings are cpatured in

screen grab below:

Depth of cut passes were edited, taking

into account the depth of the material, and the amount

of passes calculated by Partworks. This is optimised so

that the best finish is obtained on the last pass of the

mill, ie it gives best result when the tool has

around 50% of its pass in the material to be cut and 50%

of the tool passing through the sacrificial layer.

This helps to avoid tearing on the last pass.

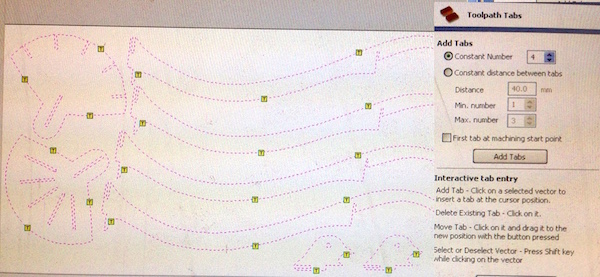

Adding tabs

In order to keep the material being cut to remain

stable and safe under the power of a 18,000rpm end mill,

tabs are added to the toolpath. The terminology is

misleading, because, in fact the reverse is happening;

'adding a tab' means that the end mill toolpath skips a

few layers (around 4mm sq area) in the toolpath, leaving

a link to the main body of the material so that it does

not fly off.

Example of a tab

Example of a tab

Tabs can be placed evenly distributed around the pieces

being cut, and in particular where there may be

increased weakeness, risk to fly off or potential

tendency to vibrate and cause damage to the finish.

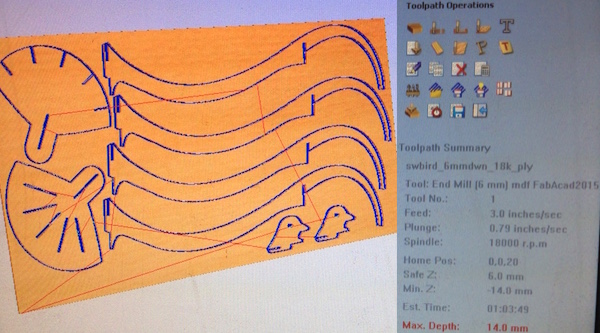

Toolpath summary:

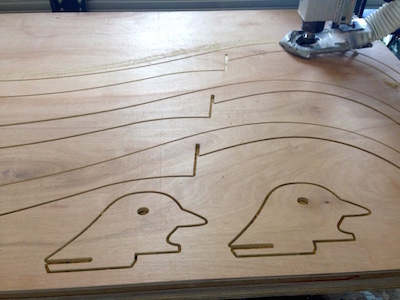

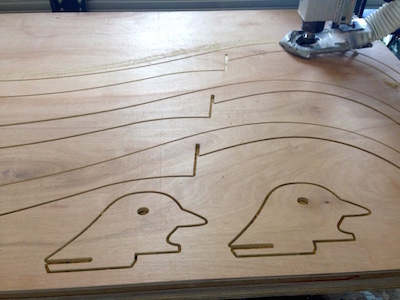

Mill cutting the plywood

I was very happy

with the quality of the cutting, it was clean and

sharp.

However there was still an hours worth of sanding to

do around all the freshly cut edges.

The photo above

shows the detail of the locking joint used, that would

give further strength to the design, as well as

clearance from the ground. The bottom edge

of this piece would provide a third foot to lift the

table off the ground (as three contact points gives

the greatest stability). Before, leaving the

lab, I tested the joints to ensure that the tolerances

of the assembly were workable. There was good firm and

solid engagment in the clearance between the pieces.

However,

as I did not want to put any unneccesary stress or

torsion on the structure (in transit in my car), I took

the flat pack, carefully protected and packed, to my

friends garden to assemble in situ.

To help ease the joints together, I used grease

in the form of lipbalm smeared on the edges. This

definitely helped the assembly push-fitting process

and reduced the stresses so that any fragile joints

could be protected from fracture.

View 360 degree movie here

Download design file here

I am under there somewhere.

Example of a tab