About me

Final project -

development

Final project

Weekly projects

Wk 6 Electronics

Design (Mar 4)

Assignment:

• redraw the echo

hello-world board, add (at least) a button and LED

(with current-limiting resistor)

• check the design rules, and make it

• extra credit: simulate its operation

Resources

and useful guides

Good tutorial on this week's

assignment can be found on the 2015 archive - click

here

Assignment:

Redraw the 'Echo Hello-world' Printed Circuit

Board

Introduction

As a beginner in this field, I oriented myself to the

assignment ahead by reading through the relevant links

above. Most of the learning this week was within Eagle

(Easily

Applicable Graphical Layout Editor), which

is a Printed Circuit Board (PCB) Design Software which

provides a schematic editor, layout editor &

autorouter, all within a single interface.

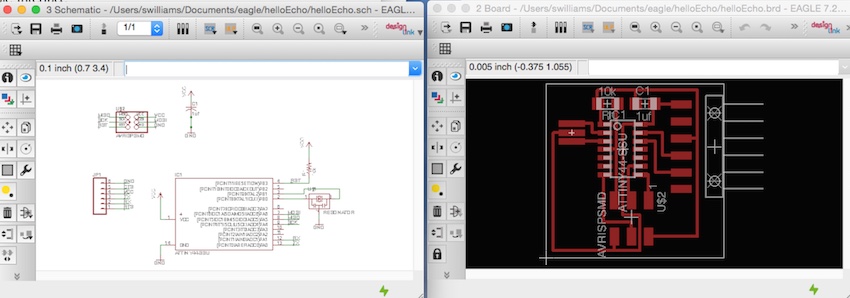

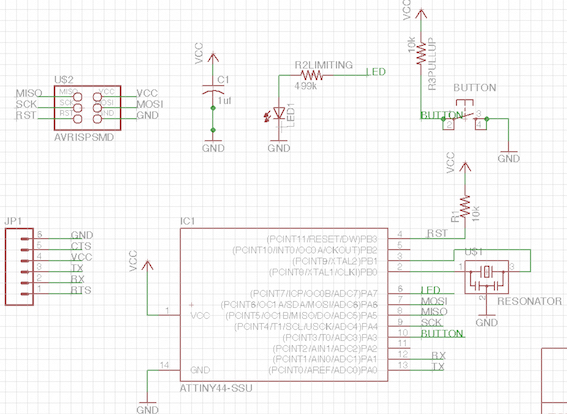

After downloading and installing all relevant software

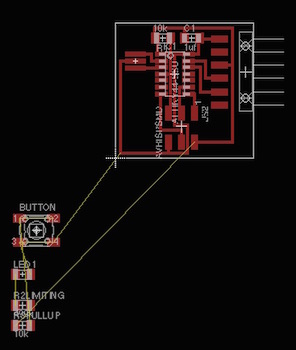

and files I opened BOTH the schematic

(.sch) and the board (.brd) files. As Eagle

updates changes made on one file in real time to the

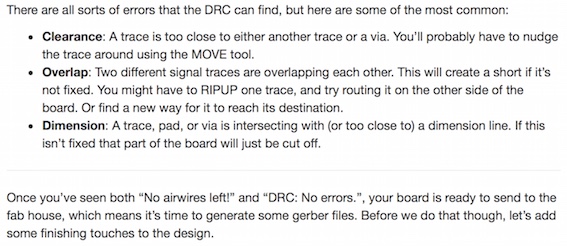

other, both must be open as you begin. The image below

shows how the files look when first opened, with some

parts already in place on the schematic (left)

and consequently also on the board (right):

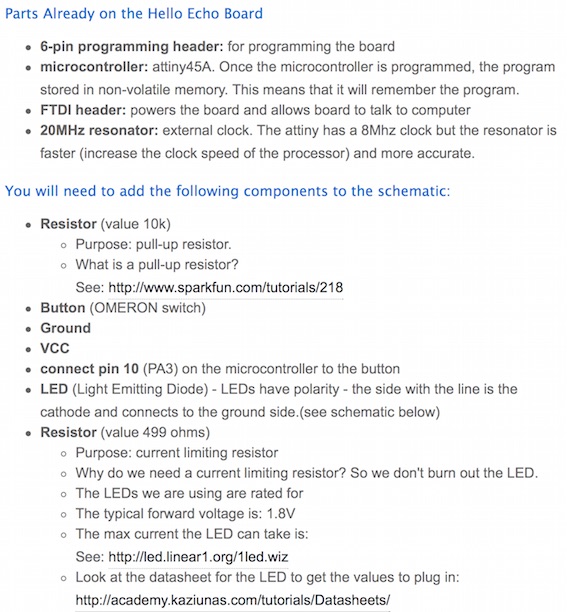

The complete component list that we were following was

as follows:

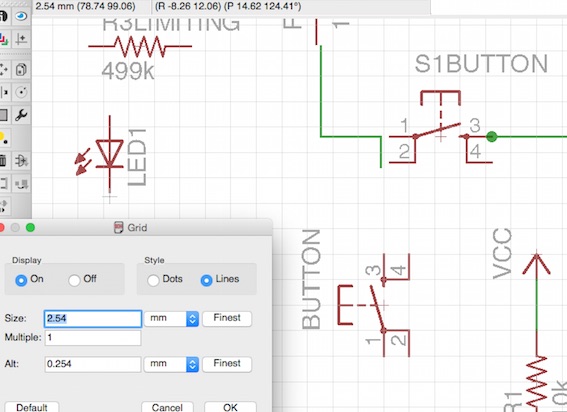

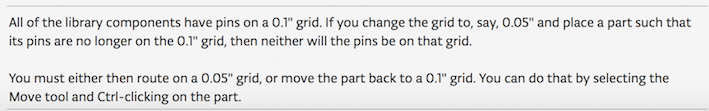

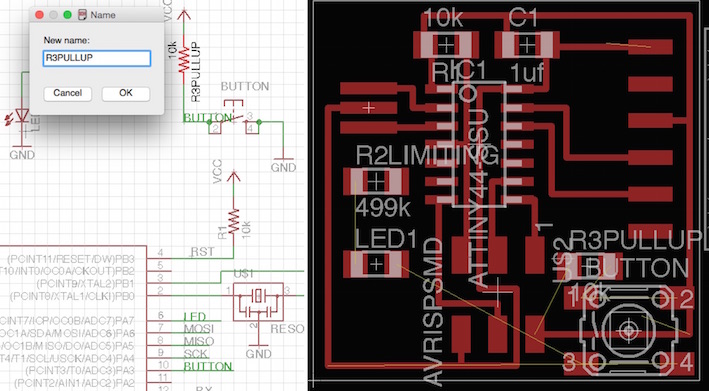

Everything was going fine until I remembered that I

had seen a grid underlay on one of the

tutorials and thought that it could be a useful 'snap

to' support. I went about finding and turning on the

grid. I changed the grid unit to a nice rounded metric

number. Now, I started adding all the components from

the relevant libraries in turn.

HOWEVER

If you look closely, you will

notice, that the switch button that I added in the top

right hand of the image above - "S1BUTTON" - did not

snap to the grid as had all the other parts already

placed (on opening). As explained below:

Therefore I

had to delete all newly added parts, change the units

back to the default settings and re-add all the

necessary parts from the libraries. This fixed the

alignment problem - see scematic below. SO DO NOT

CHANGE GRID UNITS!

Frequently

used technical terms

Airwire:

Unrouted connection on a board, displayed as thin

yellow line in the unrouted layer (= rubber band).

Design Rule Check (DRC):

EAGLE can identify the violation of certain Design

Rules (e.g. if two different tracks overlap or are

too close) with the DRC.

Electrical Rule Check (ERC):

EAGLE can identify the violation of certain

electrical rules (e.g. if two outputs are connected)

with the ERC. It also checks the consistency of the

schematic and the layout.

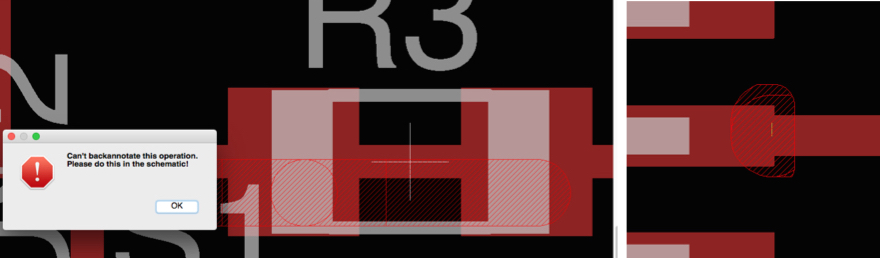

Forward&Back Annotation:

Transforms all the actions one makes in a schematic

online into the lay- out (and with limitations from

layout into schematic). Both files are consistent

all the time.

Net:

Electrical connection in a schematic.

Pad:

Through-hole pad associated with a package.

Pin:

Connection point on a schematic symbol.

Ratsnest:

Command for calculating the shortest airwires.

Signal:

Electrical connection in a board.

Supply Symbol:

Represents a supply signal in the schematic. Causes

the ERC to run special checks.

Symbol:

Schematic representation of a component, stored in a

library.

Wire:

Electrical connection in a board, or a line (since

lines are drawn with the WIRE command).

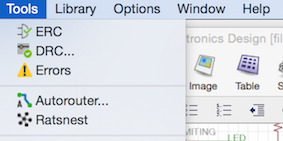

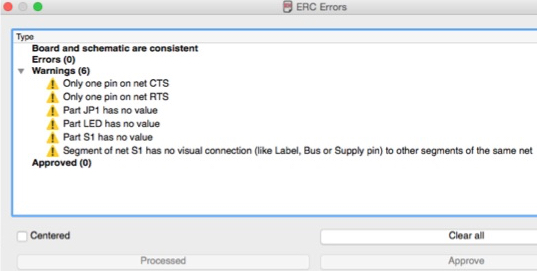

Now, with schematic completed, I could check

the board for errors using the Error tool - see below.

(ERC =

Electrical Rule Check; DRC = Design Rule Check;

Errors).

(ERC =

Electrical Rule Check; DRC = Design Rule Check;

Errors).

Some 'warnings' were shown but seeing as some of the

pins were not being utilised, I decided that these

were not problematic at this stage and proceeded.

I also had a look over the Design rules and left them

in their default settings to see how they would appear

on the board.

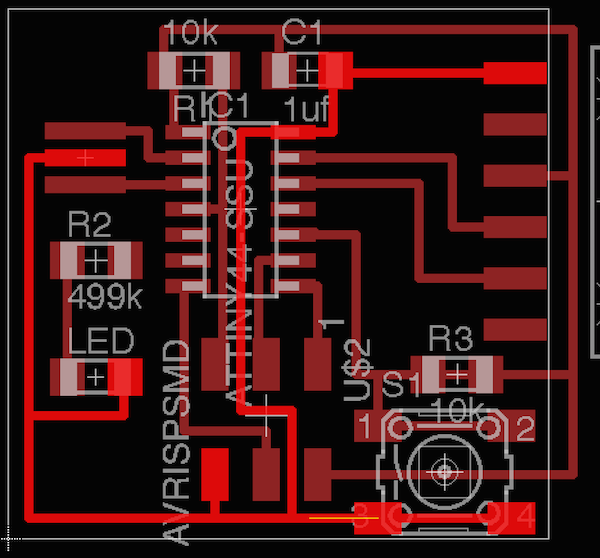

I could now switch view to work on routing the

board, on the accompanying file.

On 'switching' to view the .brd file, all the added

components get 'dumped' in a jumble in the left hand

corner - this is normal.

Also illustrated in the image above are the 'airwires'

- the unrouted connections - in thin yellow lines.

These are what Eagle displays as a guide for routing

the correct connections on the board (drawn as the

red graphic lines) based on the connections

I made in the schematic. At any time, if further

changes are required, by switching back to the

schematic, it is always possible to edit. I was

beginning to like Eagle.

I could now go about moving all the added parts into

the most efficient layout without compromising clarity

and precision of traces and connections (with support

of sample in tutorial).

When I first went to place all my added parts into

position, I noticed that I had used too much

descriptive text, which cluttered the board, therefore

I went back to edit the text in the schematic - shown

below.

It's a very satisfying feature to follow the airwires

to route the board, at least on this relativley easy

board:

Design Errors

Again, by using the error tool, some errors were

revealed as cross-hatched areas, as shown below:

I had routed across the resistor, and there was an

errant airwire showing up a faulty route. Both were

deleted and re-routed.

Here are some common errors to look out for:

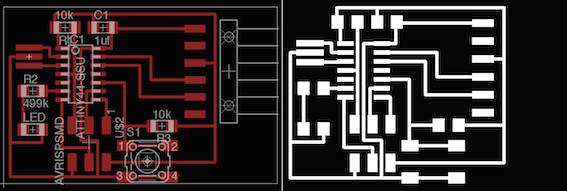

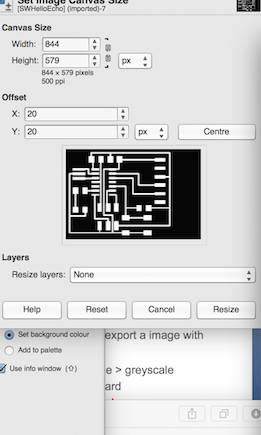

I was now ready to switching off the layers

(text, etc) on the board view to export a .png file.

This was

edited in Gimp to expand the boundary by 20 pixels

on each side to provide a good working boundary on

the PCB.

The file was duplicated in Gimp to produce a cut

out file for the Modela milling machine.

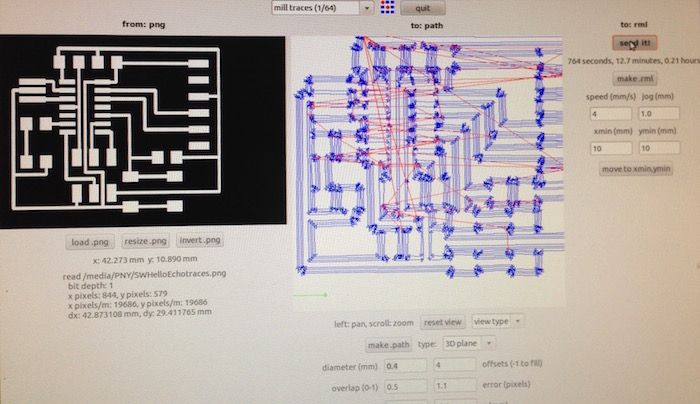

Here's a reminder of the workflow on the Modela

using the fab modules;

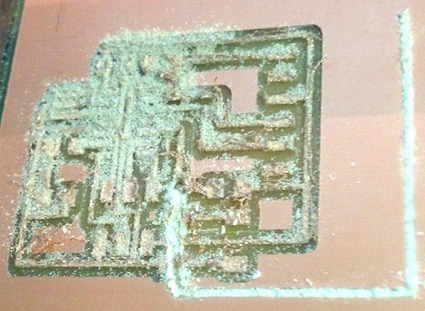

During the second milling of my board to cut it

out, there was a clear 'something

is not quite right' sound. I

interrupted the milling by pressing standby. The

mill had cut right through the middle of my board.

On closer inspection, it became clear that I had

omitted to tighten the second grub screw on the

collar. The end mill bit had not been damaged, but

the board was irrecoverable - see below.

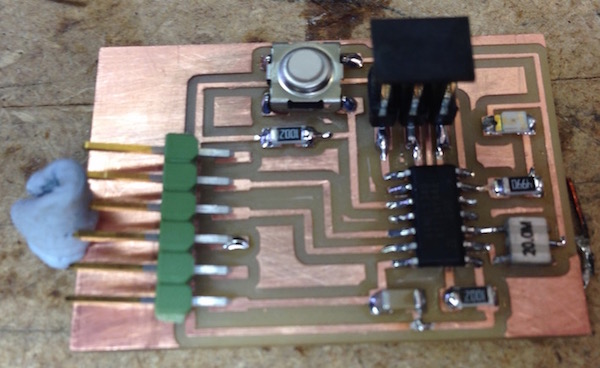

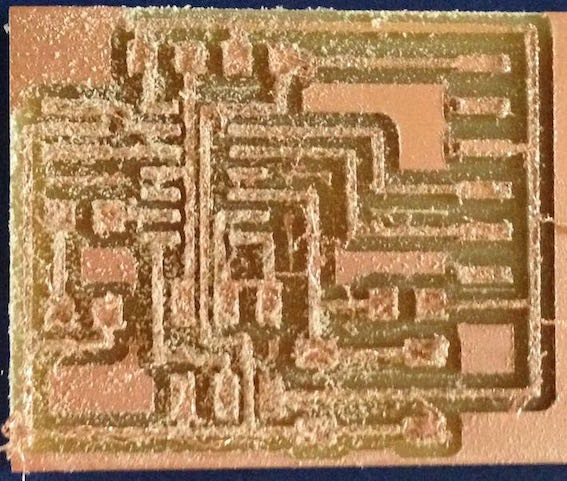

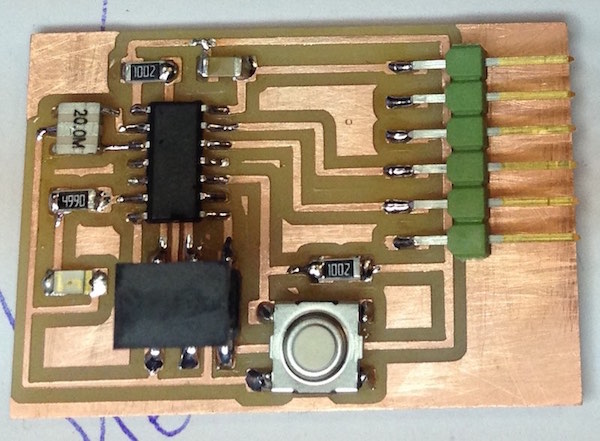

My second attempt, with both grub screws secured

on the collar, the board was milled successfully -

see below. However, this shows quite a lot of

burring around edge of each trace. This required

much more work to deburr and clean than the last

time I used the Modela 2 weeks ago, illustrating

the slow demise of the end mill. I used a ruler

edge and very fine sanding paper to deburr and

clean the board. See the cleaned up examples

further below.

Once deburred and cleaned, it was time to return

to the soldering station.

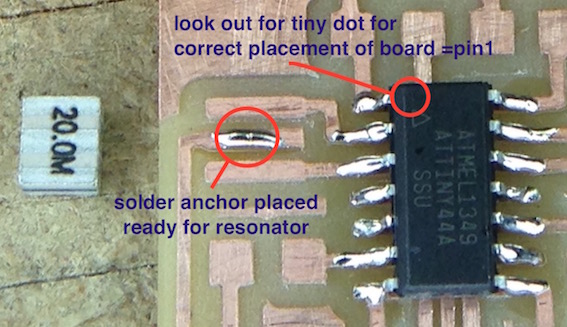

With poor eyesight, I need to make sure that I

orient components correctly. On the ATTiny

microchips there is a tiny dimple on in the black

plastic in one of the corner which reveals the

position of pin 1 - see below. Also shown below is

the anchor solder ready to recieve the resonator.

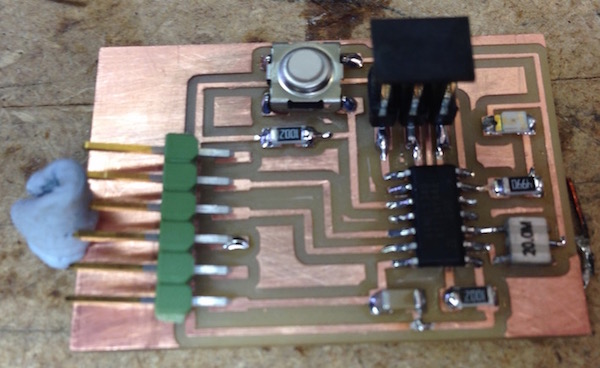

The board required an FTDI connector. This enables

connection to an FTDI cable which is a USB to

Serial (TTL level) converter which allows for a

simple way to connect TTL interface devices to

USB. This will provide a power supply to the PCB.

The FTDI connector that fab lab use, given we are

using surface mounted components, mean that the

connector had to be soldered at an angle. Once I'd

soldered an anchor in the middle of the

pads, I found it helpful to use blutack to

stabilise the component at an angle whilst I

melted the anchor solder - see below.

Soldering complete:

Testing the board and simulating its operation

- a success.

Its a bit subtle in the photo below, but trust me

when I say, "my board is blinking!" and so am I.

Happy days.

Note: the 6pin rainbow connector is connected

'away' from one chip and 'over' the other on the

other board. This is a significant configuration

and needs to be consistent, although it's possible

to do vice versa also, but not the same on both

boards. (I will try and find a way of making that

clearer in future weeks).

Download Eagle Schematic

Download Eagle Board

SWHelloEchotraces.png

SWHelloEchointerior.png

(ERC = Electrical Rule Check; DRC = Design Rule Check; Errors).