About me

Final project -

development

Final project

Weekly projects

Wk 5 3D Printing and

Scanning (Feb 25)

Note:

Assignment for Week 5:

• design and 3D print an object (small, few cm)

that could not be made subtracively;

• 3D scan an object (and optionally print it)

Presented and discussed final

project development with Tomas Diez during regional

review. This was followed in the afternoon with Neil

Greshenfeld's introduction to 3D Printing and

Scanning.

Assignment: Design of an object for 3D Printing

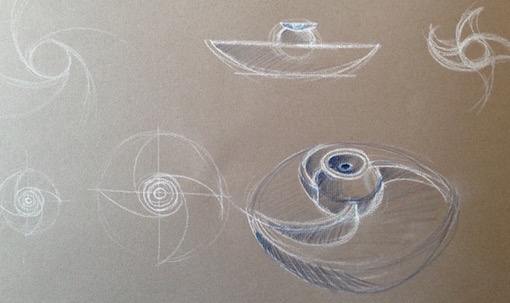

Slightly intimidated by the week ahead, I eased and

loosened my mind into the idea of 3D printing by doing a

pastel rendering of a vessel with an enclosed sphere. It

helped me consider how I might approach developing

certain forms.

However, I do not yet have the skills to create these

forms in any of the 3D software packages that I have

explored, so this is a little frustrating. Today, some

good news, I was finally able to install Solidworks onto

new windows partition on macbook (this I completed using

Bootcamp Assistant - on Mac, installing the now free

Windows 7).

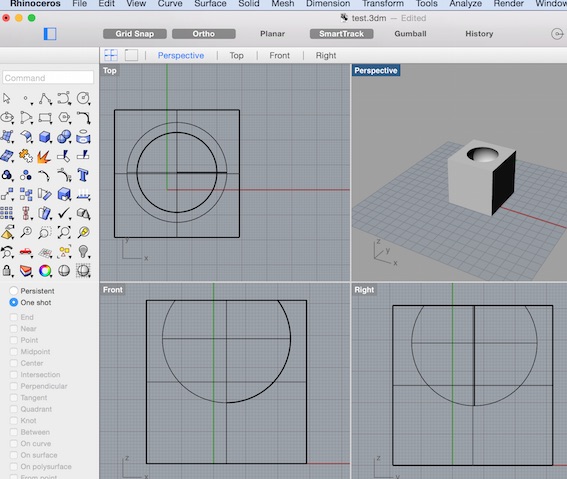

Below, I include some images of various basic 3D files

that I tried to generate - and give overall first

impressions for each, as I consider developing a form

for 3D printing.

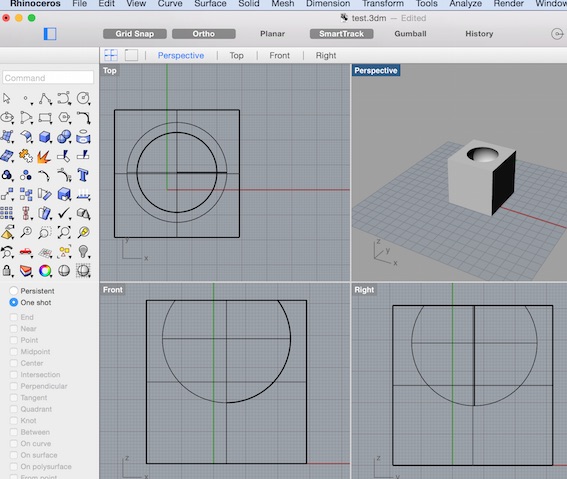

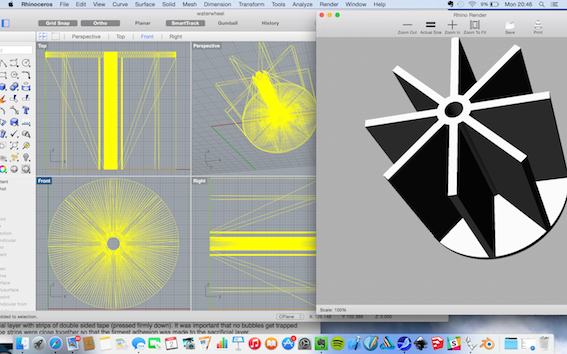

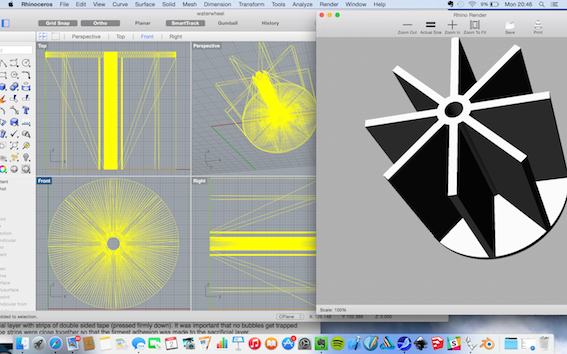

Rhino

Comments: Overall I feel that if I perservered I

could get to enjoy working with Rhino. It seems

reasonably easy to generate simple and basic forms, and

to merge them together. However, as a beginner what I

found difficult is how to control these components in

space in relation to each other. The Grasshopper plug in

is not currently avalable on Mac.

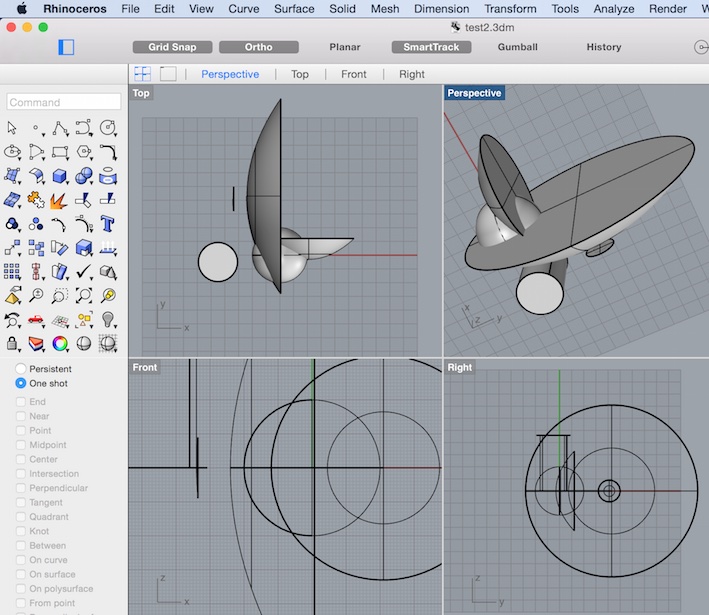

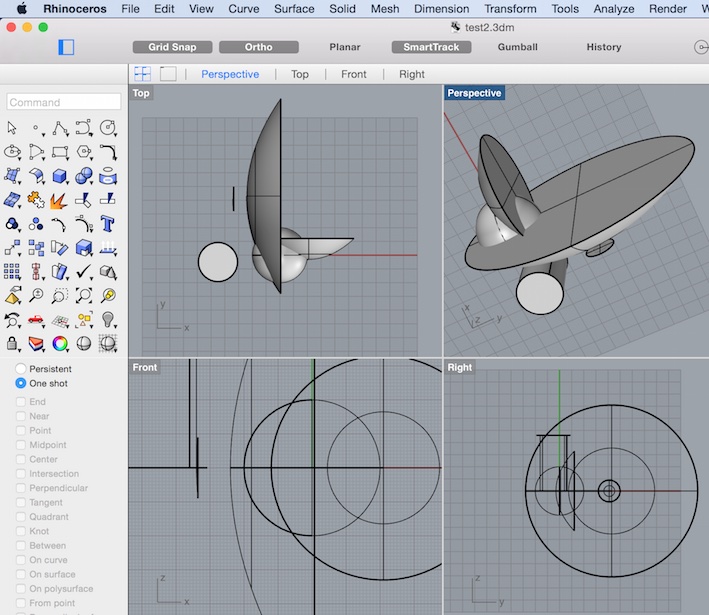

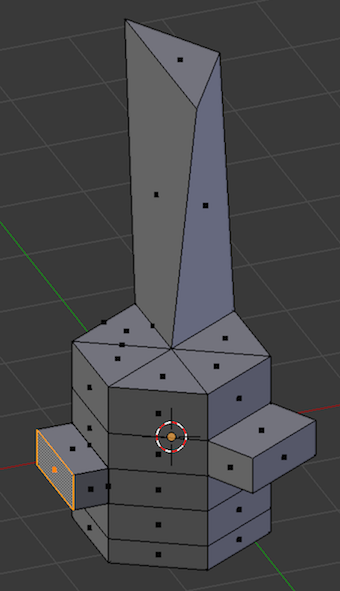

Blender

Comments: Although I did not have more than a few

hours trying Blender, I could see how this software was

very powerful and had an effective graphic interface. I

liked the 'dots on planes' feature from which you can

pull controlled fragments out of the basic form you

start with. This might be an application that really

supports a creative and visual workflow, less technical

in approach and more potential to explore forms. Its an

interesting way of thinking. It also makes apparent how

architecture has been able to evolve in the way it has

over the last few decades. Here I refer in particular to

the torsion the computation is able to make.

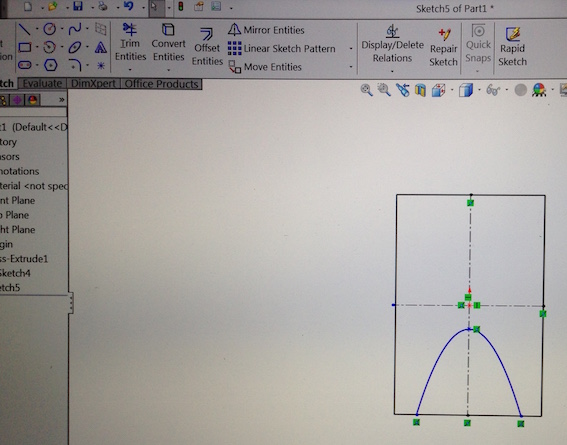

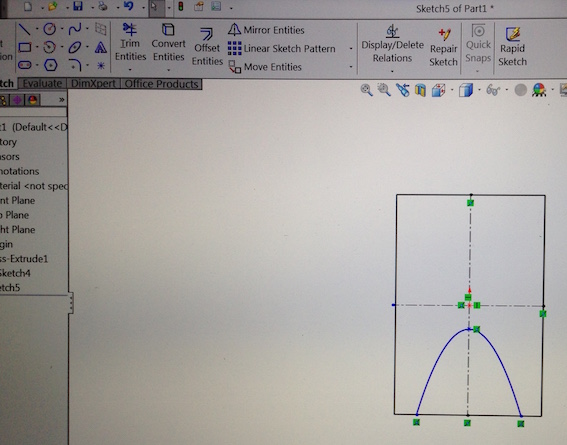

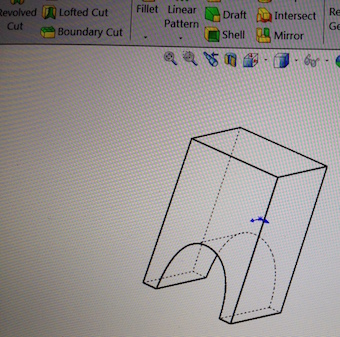

Solidworks

Comments: I had quite a lot of anticipation and

expectation in finally getting to have a go with

Solidworks. I was a quite surprised to see an unrefined

graphic user intercace, it looked so 'Windows' - very

clunk and click. However, in performance terms, it did

not take long to see how much control there was over

each element of the form-generating process. I was very

impressed, although it might work better with a

technical geometric approach.

Following a demo from our mentor, I could see that

Solidworks had an effective and powerful capability to

generate a drawing / 3D model. In Solidworks, you can go

back and edit changes at every level of the the

dimensions, this was my first true experience of

parametric design. I therefore decided to choose

Solidworks over Rhino and Blender to generate the form

for my 3D design assignment.

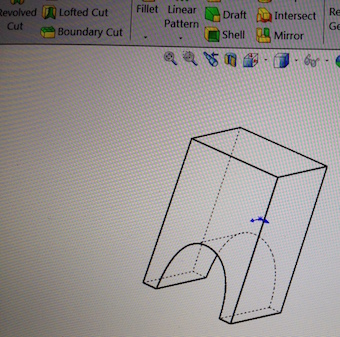

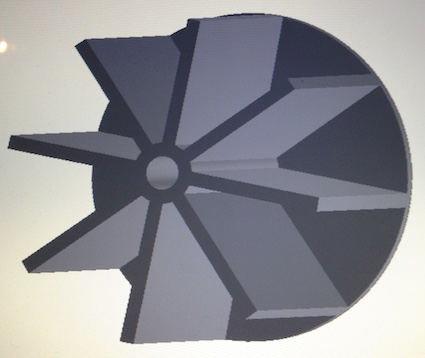

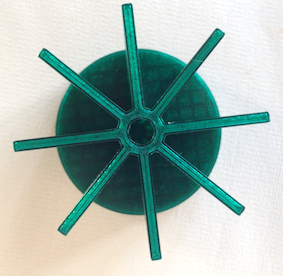

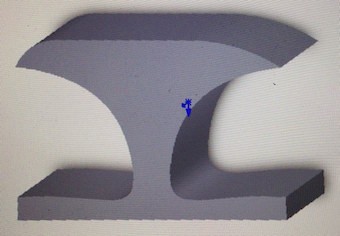

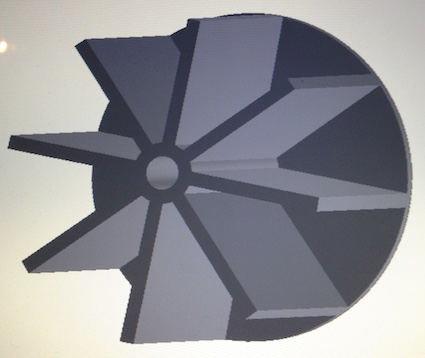

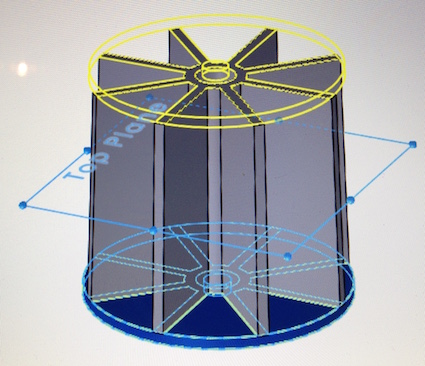

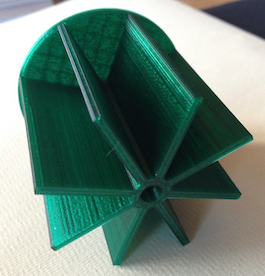

I had wanted to create a mini waterwheel that could be

placed on a spindle, or a biro, to show the power of

water. Also, this form could not easily be produced

subtractively, due to the angled fins towards the

central axis. What I found interesting was that the 3D

printer would not have been able to print this form if

it used the x-plane as a foundation plane, as it would

not have any supporting structure to undertake effective

printing paths. By simply turning the object 90 degrees

and printing on the end plane, it had all the support

structure it needed to 3D print effectivley.

Once the form was completed and all 'dead' lines had

been trimmed and cut away, solidworks was ready to

export a .stl file. This process converts the form into

of a mesh triangles. In lower end software application,

.stl files may need to undergo a error correction

process in order to ensure the file to be printed does

not have any holes (3D printing does not succesfully

compute open faces). However, in Solidworks, and in

particular with the simplicity of the form I had

generated, Nettfab error correction software was not

necessary.

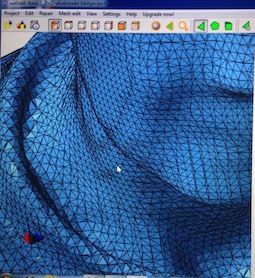

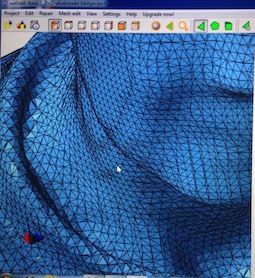

Below, the same .stl file opened in Rhino, which, after

using Solidworks did not appear to have so much control

and refinement possibility.

Assignment : Scan an object

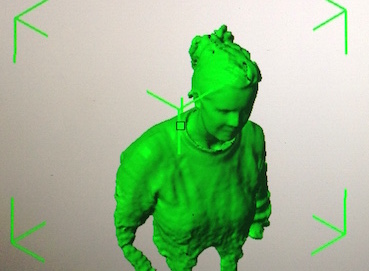

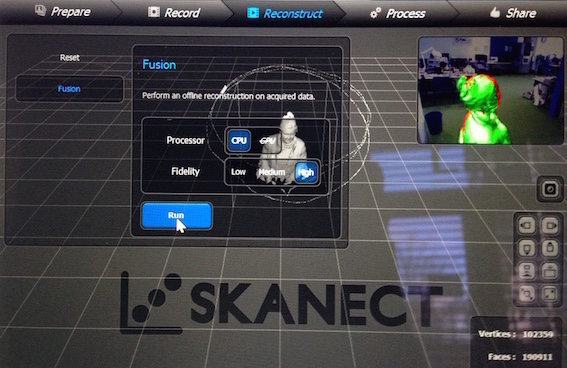

Skanect

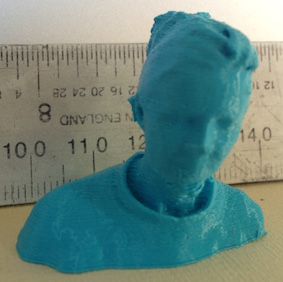

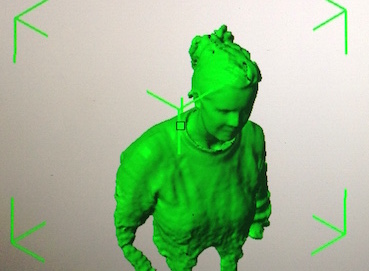

Below: using Kinect xbox360 to take a continual scan

(in series of frames/faces).

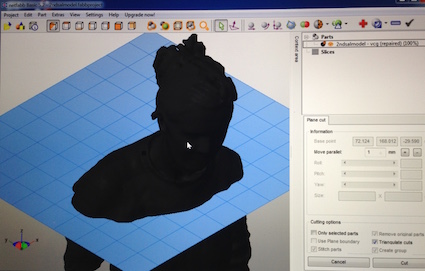

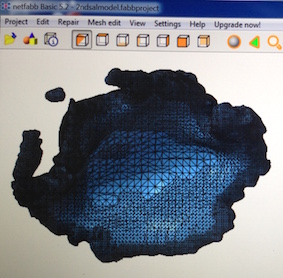

Processing the scanned data in Skanect. The file was

then exported as an .stl file, which triangluates the

form (cover form the traingles).

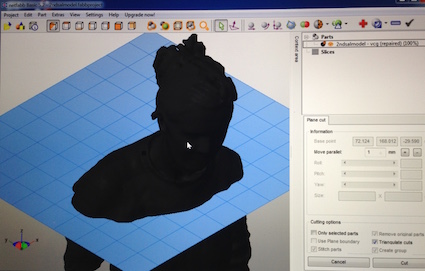

File (.stl) opened in Nettfab to correct and repair. I

checked the 'actions' for my file and no errors were

shown, therefore the object was being seen as a

watertight form with an inside and an outside (this is

critical for the 3D printing file). The form was trimmed

along the x plane and ready to be exported (as .stl) for

print.

Conistent mesh covering of triangles indicating

'watertightness'. I found that there were not any

''holes" found by the software. If they are found, they

can be repaired under the 'Actions' in the Nettfab

software.

3D Printing

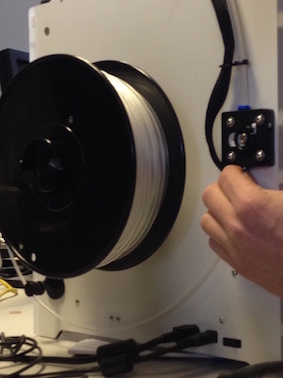

The 3D printing machine that was used was the Ultimaker 2.

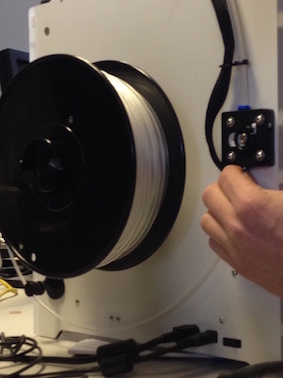

Changing the filament

The filament was changed to PLA (Poly-Lactic-Acid, a

biodegradable polymer, 2.85mm diameter, that has a low

melting point and is printable at very high speeds.

Manufacturer claim great roundness and consistency). The

new filament was placed on the reel and re-fed through

to the nozzle.

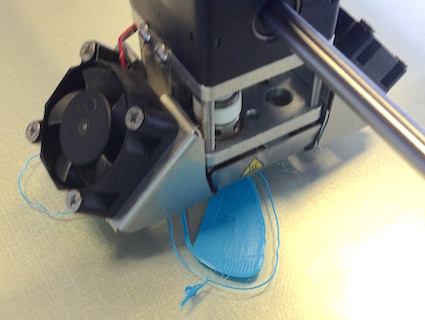

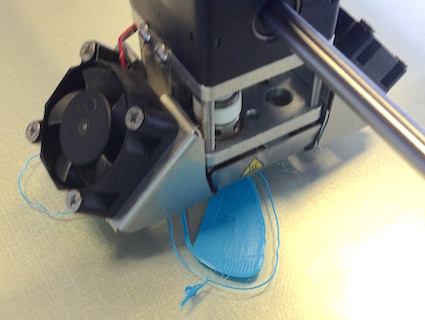

Sending to Print

File

(.stl) for the waterwheel was imported into Cura which

creates

pathways for the 3D print path on the

Ultimaker. The printer was set to print

overnight. It was noted that the software is not

accurate on times! Ultimaker takes longer than

it states.

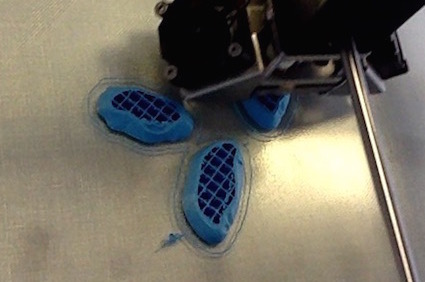

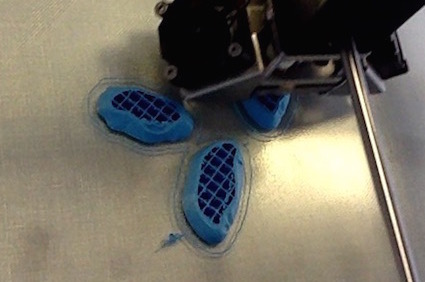

Note: It was noted that the most important

part of a 3D print is the base. If

the job does not start well, it's best to

abort and re-set. Also, where possible

you can choose to have an apparently large

solid area printed with a low FILL density,

which appears as cross-hatching inside the

scanned piece, see below.

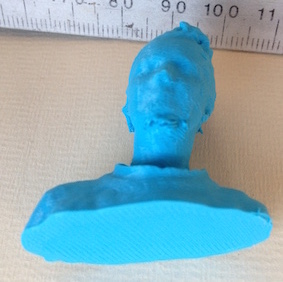

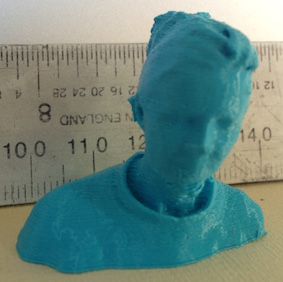

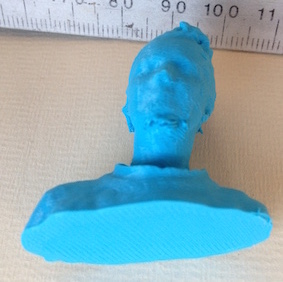

Printing from scan (route: Kinect -

Skantec - Netfabb - Cura - Ultimaker 3D

Printer):

Defect under chin area shows lack of detail

captured during scanning (the neck/jumper detail

shows up well, probably due to contrast).

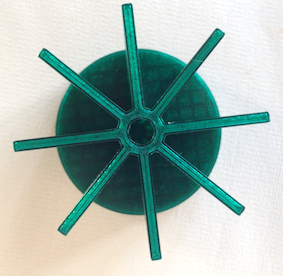

Printing 3D file created in Solidworks

(route: Soildworks - Cura - Ultimaker)

Waterwheel: I had decided to leave one side

of the design 'open-faced' so that I could see

the quality of print inside the structure. I was

very impressed with the result. It appeared to

be very sharp and consistent, with reasonably

flat surfaces (slight ridging). I understand

that the printing actually staggers along the

X-Y-Z axis; the effect of this can be seen at

this resolution and print speed.

Tolerances

The variation in print on the 2mm thick 'fins'

was between 2.06 – 2.20mm

Download larger SWmodel file here

waterwheel2.SLDPRT

test.3dm