About me

Final project -

development

Final project

Weekly projects

Wk4 Electronics

Production (Feb 18)

Note:

Assignment for Week 4 is to make a

programmable micro-controller - also known as a

FAB ISP.

Tuned in to regional reviews to

learn from others process and development. This was

followed in the afternoon with Neil

Greshenfeld's introduction to Electronic

Production.

Assignment:

Making a

programmer

For

Fab Lab tutorial, click

here.

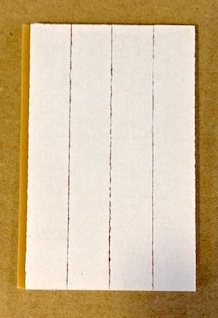

Preparation of board and sacrificial

layer

In order to get the best result (a board

milled through the copper to a consistent

degree), it is critical that the board is placed

upon a very clean surface with NO undulations

that could change the depth of milling as the

bit traces it's path. The board to be milled is

placed on a 'sacrificial layer'. (At Fab Lab

Manchester, this was a larger copper plated

board used for its engineered precision). There

was some residue of adhesive tape on this layer,

and therefore this had to be thoroughly cleaned

and brushed off with white spirit and cloth.

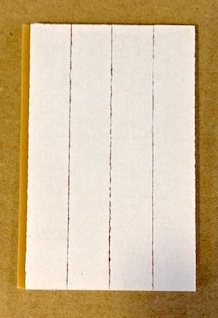

The board is adhered to the sacrificial layer

with strips of double sided tape (pressed firmly

down). It was important that no bubbles get

trapped under the tape, and also that the tape

strips were close together so that the firmest

adhesion was made to the sacrificial layer.

Pressing sticky backed copper plate firmly onto

bed at 0-0 position of sacrficial layer

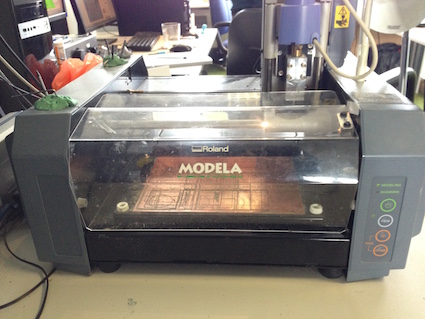

Roland Modela Milling Machine

Roland Modela Milling Machine

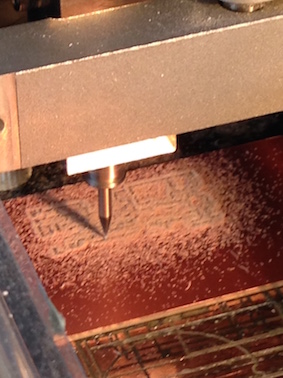

Milling

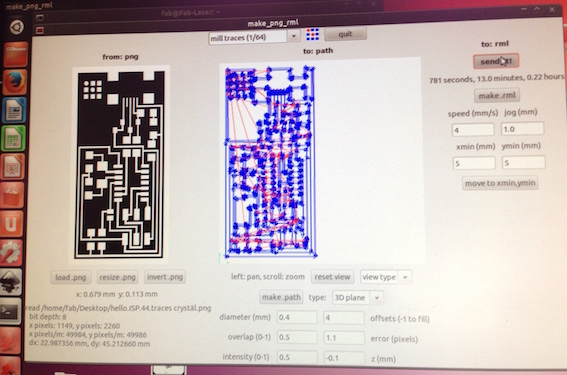

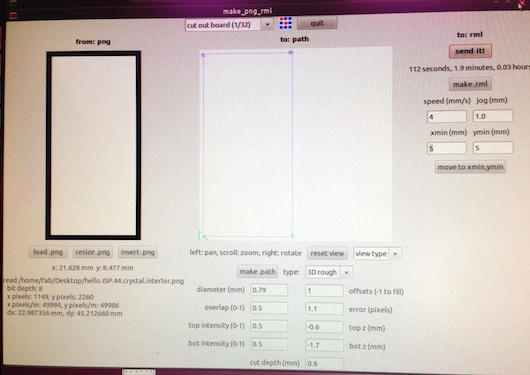

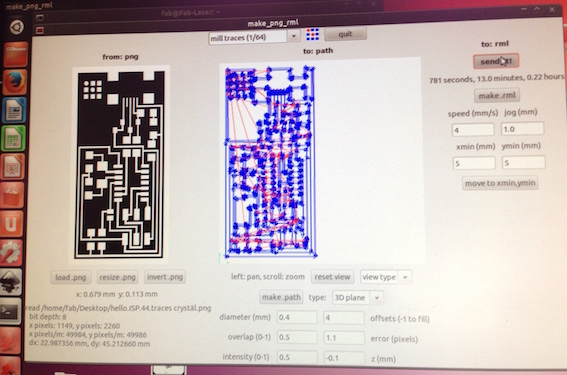

The image below shows the trace file (hello.ISP.44.cad.)

loaded

into the control panel of computer terminal (Click

here for link to files). I was using the

mill trace defaults setttings for the Modela.

This used the 1/64" end mill bit.

The

end mill had to be zeroed on the x,y

and z axis of the copper plate, then

the x and y axis was given a 5 mm

clearance of corner edge as a start

position. It

is important that the end mill bit, mills

clearly through the copper plate layer of the

board to remove any possibility of connectivity

being made where it shouldn't.

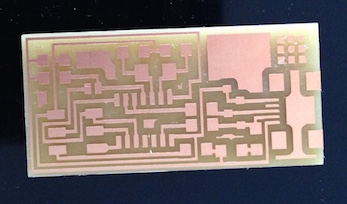

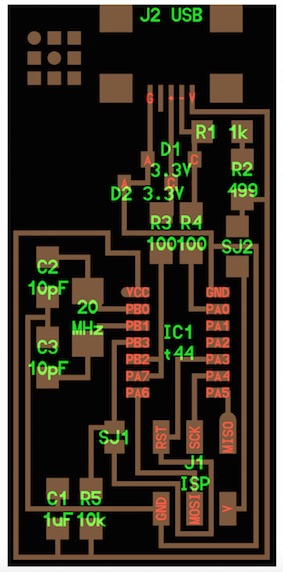

Once the trace path was milled successfully, the

'cut out trace' path was loaded in the control

panel. This would cut out the boundary of

the board

from the rest of the copper plate

stock to

it's working size. The end mill bit used for

cutting out on the Modela was 1/32"

Cut out trace

path

Cut out trace

path

Milled and cut out board

Milled and cut out board

The board was deburred (from any splices of

copper around the edging, and from any unclean

milling). The board was then washed with a

sponge to clean and degrease (from natural oils

on fingers)

Soldering

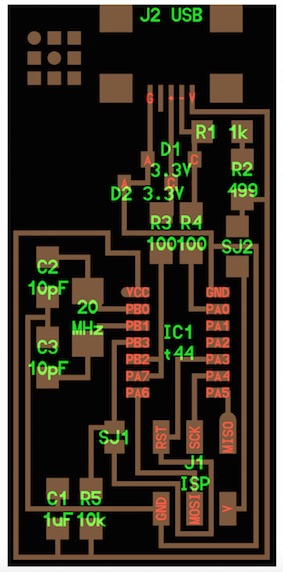

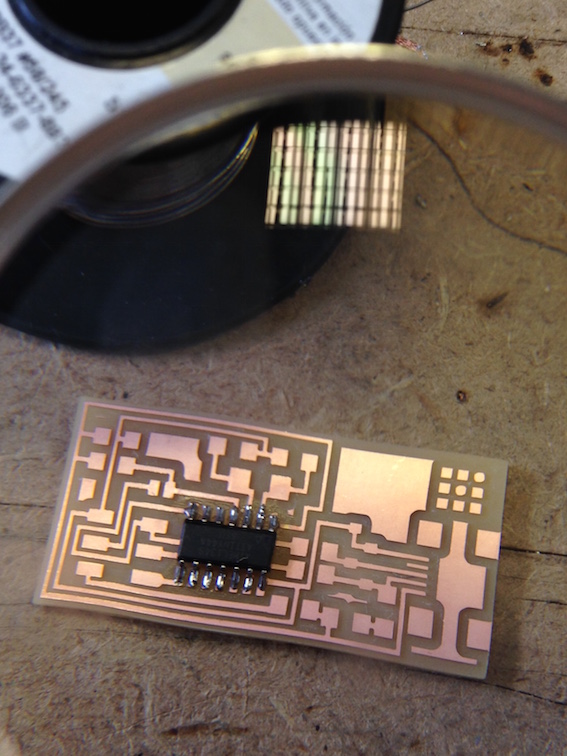

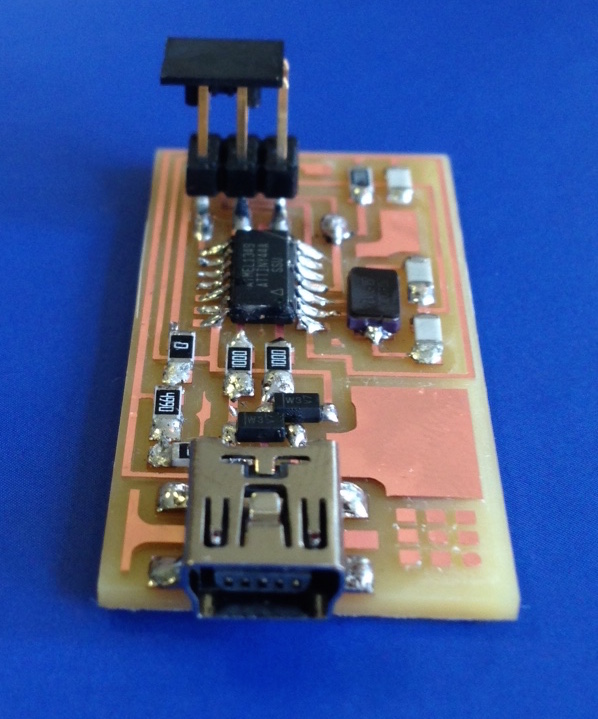

Following the schematic drawing to solder all

the components onto the board. I enjoyed this

process, although a magniying glass was

critical!

At the soldering station with my crown jewels,

with

soldering iron (300 - 350 degrees),

solder reel, tweezers,

copper cleaning braid tray, magnifier and

extracting fan at hand. The copper cleaning

braid and solder sucker were there in case it

was necessary to remove solder when errors were

made.

Just a little but proud at this point! (that's

why the image is a little on the large size).

Fab ISP

Fab ISP

I tested some of the connections with a multi

meter. The multimeter will show whether there is

a voltage being picked up between two points.

The multimeter proved the board to be clear of

any shorting faults and ready for the smoke test

and then programming.

For this sequence I successfully followed the

'smoke test' on the tutorial here

- plugging the FabISP into my laptop via the

mini USB cable. I did NOT get an error message

on my computer 'drawing too much power' so this

further supported that the board was clear of

any 'short circuiting'. Quite a relief.

I downloaded Crosspack and Xcode to enable the

programming of the microcontroller. I then

followed the tutorial here

to

program the board.

The board was programmed succesfully!

Once

programmed, the 0 ohm resistor and solder bridge

were removed with the use of the solder removing

tool.

The board is now ready for use over the

following weeks at Fab Lab.

Roland Modela Milling Machine

Cut out trace path

Milled and cut out board

Fab ISP