About me

Final project -

development

Final project

Weekly projects

Wk3 Computer-aided

design (Feb 11)

Note:

At beginning of this week, I was finally able

to upgrade my laptop so that I could install more

applications. I am now running Mac OS 10.10

(Yosemite), so I'm now trying to get familiar with

the new system, trackpad and gesture control. It

has been noted that for CAD it is easier to use a

mouse!

Tuned in to regional reviews to

learn from others process or at least the ones that

transmitted well. This was followed in the afternoon

with Neil Greshenfeld's

introduction to computer controlled cutting

tools.

Links of interest:

XY axis CNC : http://corexy.com

Nice website on parametric design: www.parametriccamp.com/en/what-is-parametric-design

DM gave demo on simple laser cut process from

Inkscape. This helped me to see the workflow required

from vector to pdf to lasermachine (Epilogue).

Thursday

Upgraded laptop

Installed Inkscape/X11

Installed Rhino

Installed Affinity Designer. This is not open source

but a very serious and powerful competitior to

Illustrator, at a fraction of price, and very

intuitive.

Read some guides to laser cutting, eg http://www.cutlasercut.com/resources/drawing-guidelines

Friday

Followed Rhino

and Grasshopper webinar at 4pm.

Unfortunately Grasshopper not yet installable on Mac.

Watched Affinity

Designer tutorials.

The ease of use, power and intuitive interface of this

programme really appealed to me. The tutorials are very

clear and easy to follow. A very elaborate and

customisable guide system is also a very powerful

drawing aid. The cloning, step and repeat feature is

great and the zoom appears infinitesimally powerful. I

used affinity and inkscape to create artwork for lasercutting.

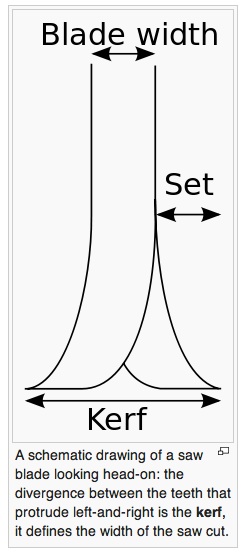

KERF TEST

It's often

tempting to want to jump straight to printing, but

persevering with producing the Kerf test was of

critical importance in Week 3. Traditionally, the

term 'kerf' defines the width of the saw cut (in

woodwork). This is shown clearly in the diagram

below (courtesy of wikipedia). Taking this 'waste

line' into account at the CAD vector drawing stage

is key, especially in push fit construction, where a

very close fit is necessary to achieve good

structural strength. In lasercutting, the high

temperature of the laser means that some materials

burn away more easily on the cutting line, so the

kerfing allowance needs to be varied ( ie cardboard

will burn more than wood, therefore any slots for

push fitting joints need to allow fr this. It has

also been noted that making sure the Vector drawing

is editable for future correction is also a very

important point to bare in mind!

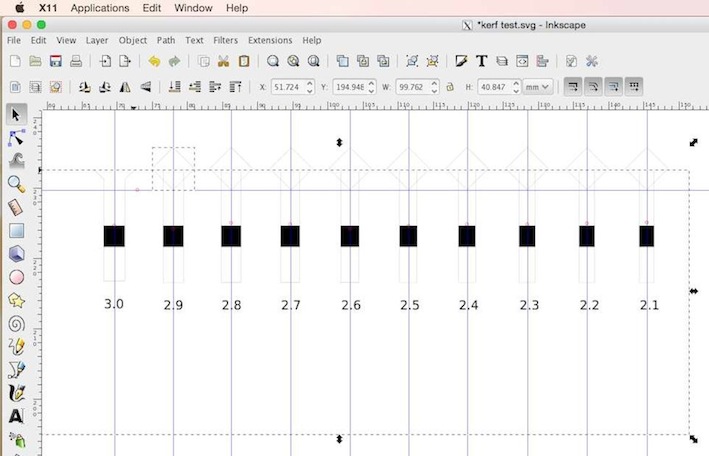

I produced

a kerf test to demonstrate what allowance should

be given to 3mm cardboard for push fit

construction, relative to the conditions of the

machine tool (Epilogue) in our lab.

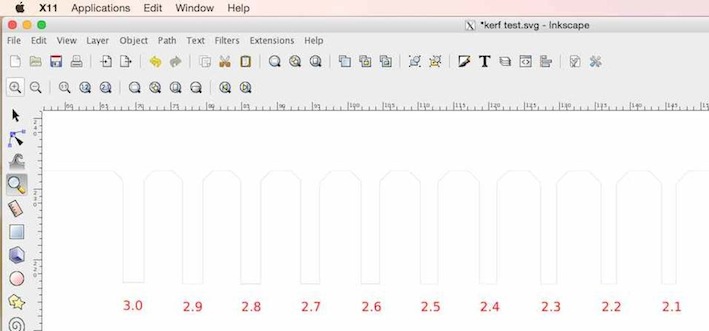

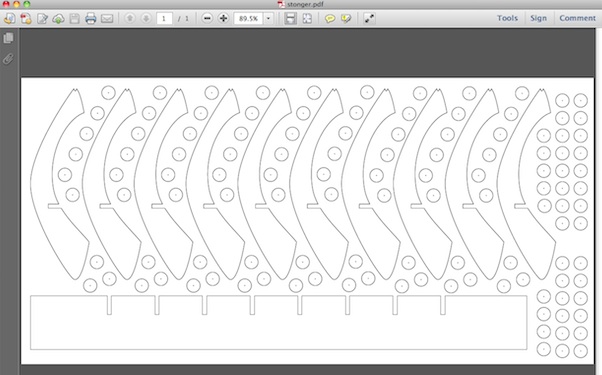

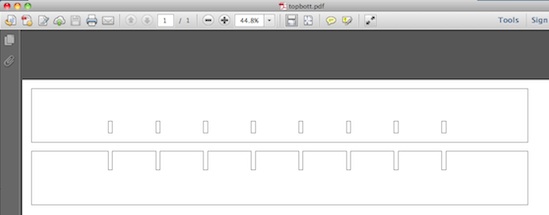

The images below show the linework for the laser

to enable push fit testing across a range of

increments (±0.1).

ALSO, as

you can see, this also includes the creation of

a CHAMFER, to aid smooth push fitting. As I

found out later on, slots without chamfers make

it very difficult to 'slide' into the joint,

making push fitting more difficult. This can

also damage and compress cardboard, thus

weakening construction and structure.

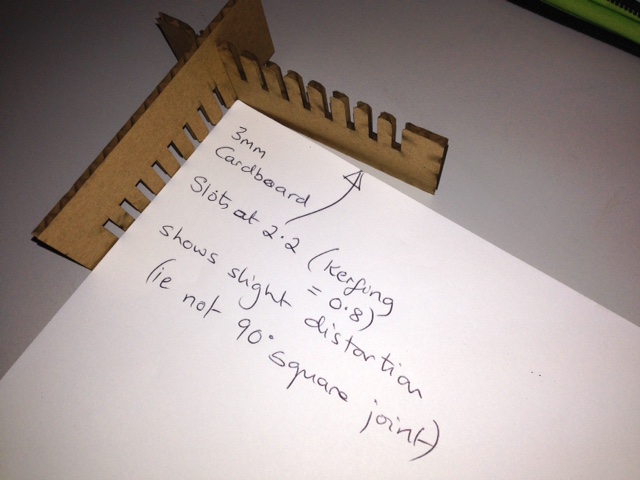

This image

below demonstrates a push fit tolerance that is TOO

TIGHT. This shows that the cardboard has distorted

beyond what should be a 90º joint.

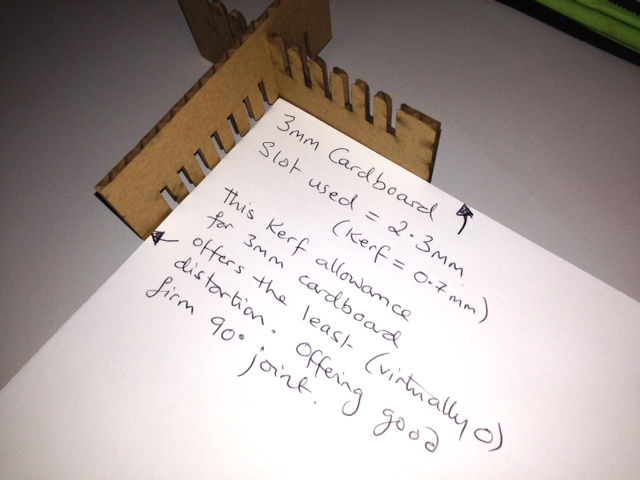

The image

below shows how the kerf test has allowed the

optimal kerf allowance without any distortion in the

joint. It also provided the firmest strucural joint.

PROJECT FOR

WEEK 3

I decided that I

would use these findings to test and explore the

strength, balance and aesthetic that I could achieve

with an organic form in cardbord. This would help

highlight considerations for structural integrity of

my indoor garden project. I wanted the design to be

light and airy - suspending plants in space.

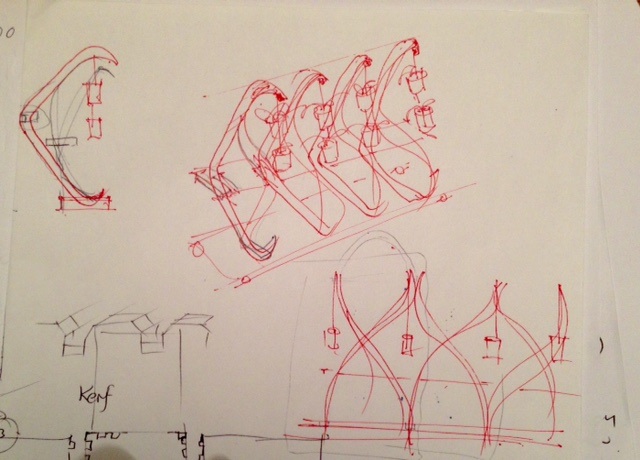

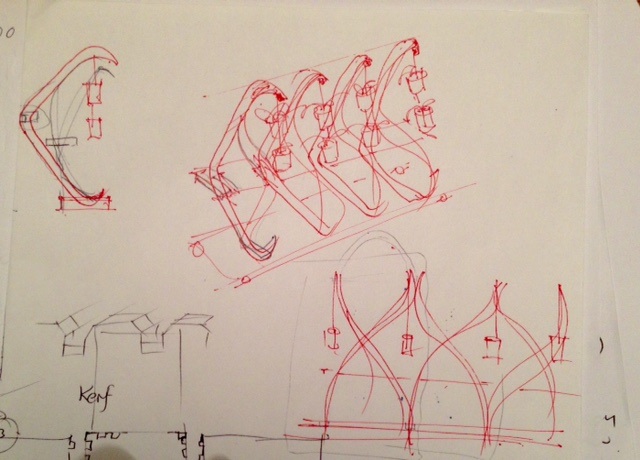

Initial

sketches for indoor garden:

Whilst I would be interested in exploring

construction of the inter-connecting 'X' form above,

I was not convinced that cardboard would be the best

material, so for the purpose of getting acquainted

with the laser cutting process, I chose to develop a

linear version.

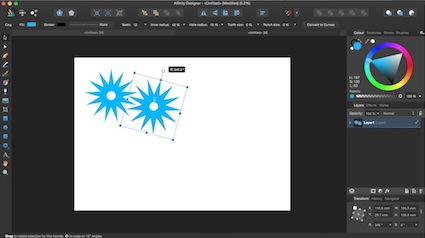

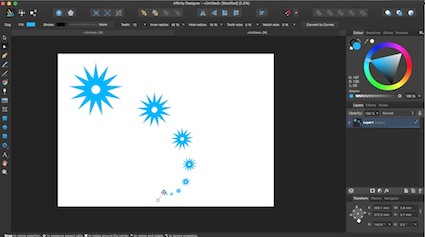

I decided to draw this using Affinty

Designer (not open source but a very good value and

intuitive 2D drawing alternative to Adobe Illustrator)

so that I could try out its cloning and use of guides.

Overall, I really

liked working with Affinity. It is the most logical

and intuitive drawing tool I have used to date. It

also has a great range of capabilities and

convertability.

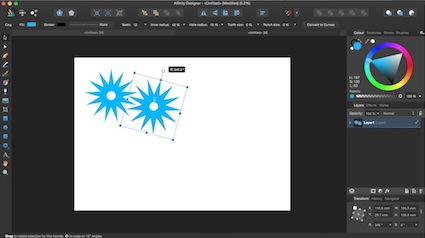

NOTE: I

will just mention here its cloning tool, repeated

into infinity would be great for

pattern work and gaming graphics. I need to do

further tests to check its editability of changing

the 'master' for global and efficient changes to

many parts, but it looks very promising. See star

repeat below.

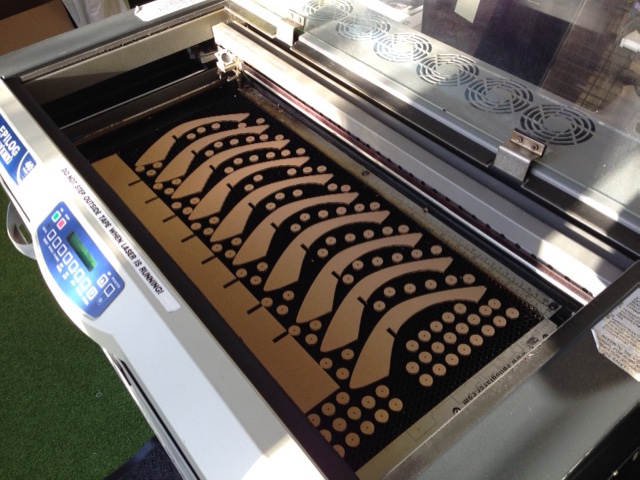

Here are

some images of the cardboard being cut on the

lasrecutter (Epilogue).

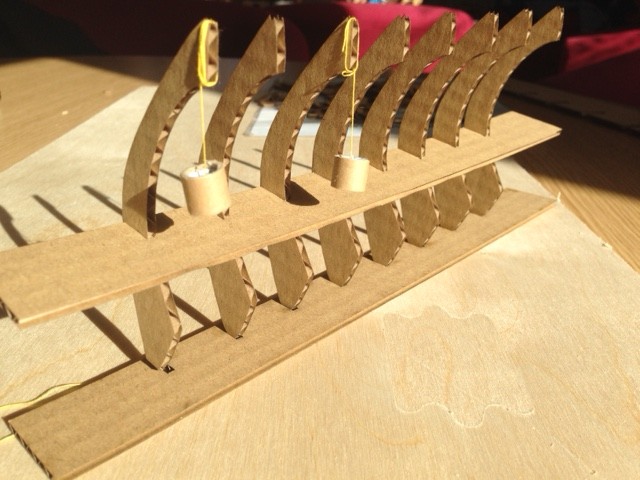

Push

fit model of structure, showing

balance, strength and proportions.

Seeing and holding the actual model in

hand (so quickly, once artwork

created) was very helpful for future

development.

Download files:

Stronger2.pdf

topbott.pdf

kerftest.svg

©

Sally Williams 2015