About me

Final project -

development

Final project

Weekly projects

Wk 12 Composites (Apr

22)

Assignment:

• Design and

make a 3D mould, and produce a fibre composite

part in it

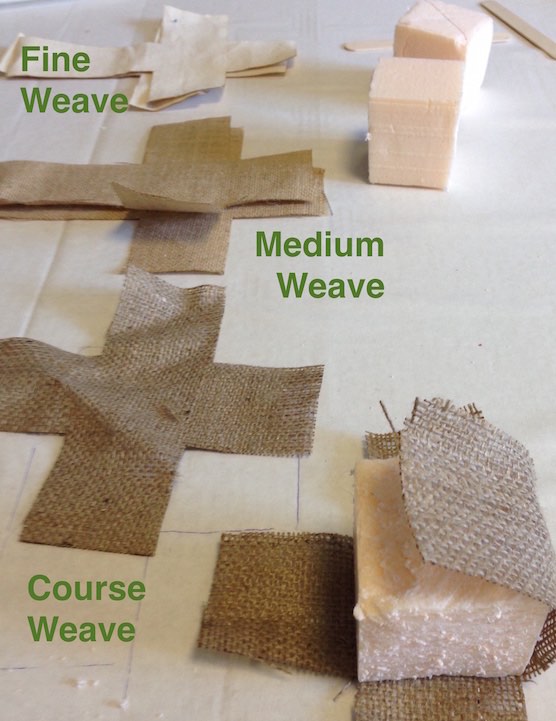

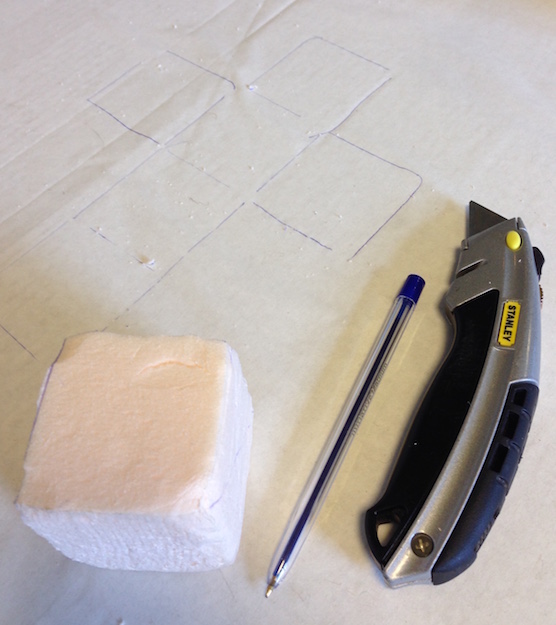

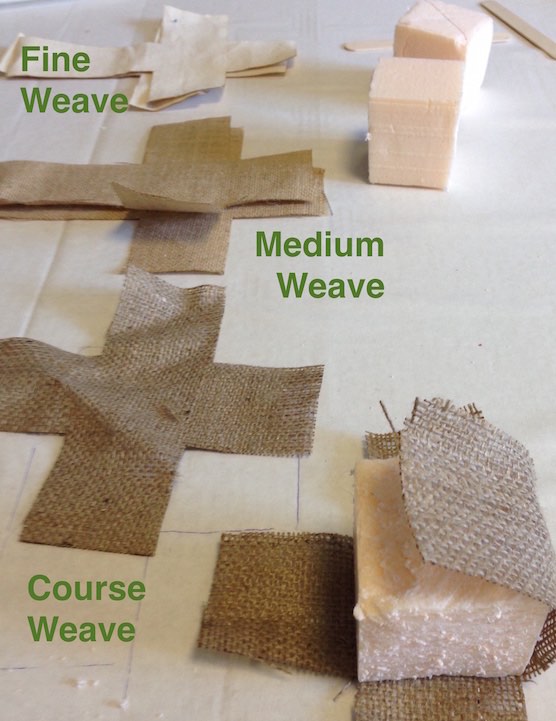

Testpieces

For efficiency and so that we could all share

in the learning, we made some test pieces as a

group. A simple foam cube was suggested as a

standard shape around which to impregnate and wrap

three different weave densities with Epoxy Resin.

It was noted that the coarse weave has much more

space inter-weave to hold resin, whereas the finer

weave is tightly woven.

Epoxy Resin (Super

Sap)

Weighing the 2 parts. Ratio: 2 resin - 1

hardener

Two kinds of application were tested:

1 - by brush;

2 - thorughly pre-impregnating the fibre weaving

by gloved hand.

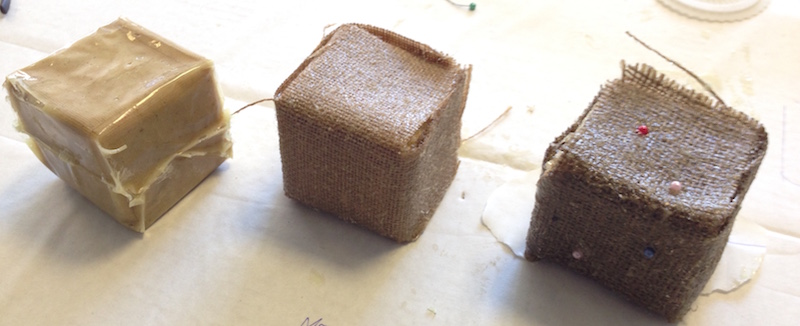

Test vaccuming of one cube:

Cured cubes:

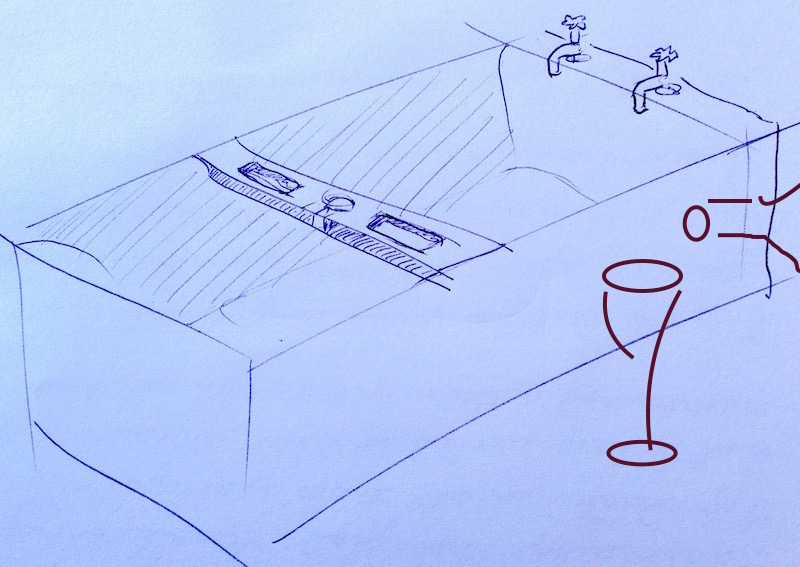

3D Design for Composite Week:

I wanted to see the strength and lightness of

a composite structure, something that was long and

put under a bit of tension.

I designed a rest to span across a 680mm bath, to

hold a few bits and pieces and a glass of wine.

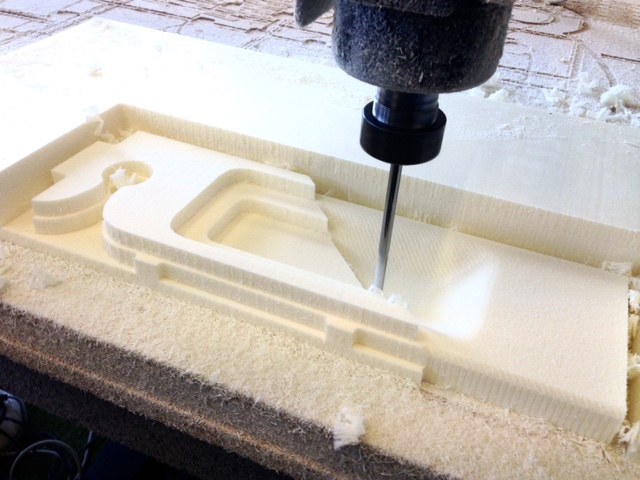

Milling the foam core on the shopbot:

Feeds and Speeds used for foam:

Flat End Mill : 1-4 inch (6mm)

Feed rate = 5 IPS (inch per

sec)

Pass rate = 1-4 inch (6mm)

Stepover = 50%

Plunge rate = 1 IPS

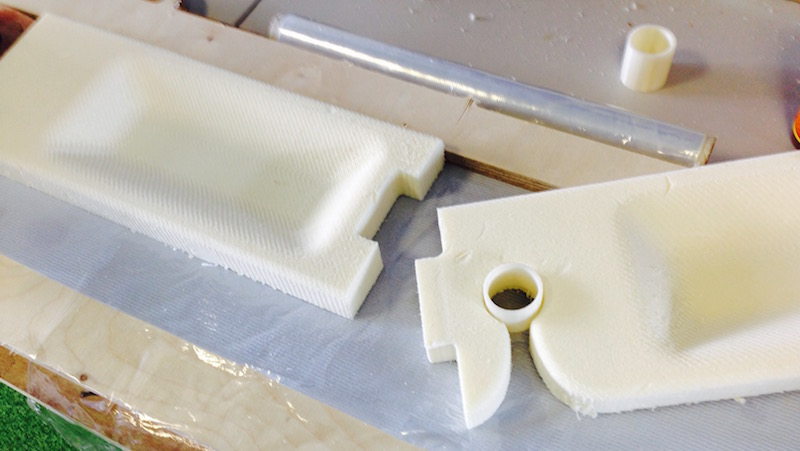

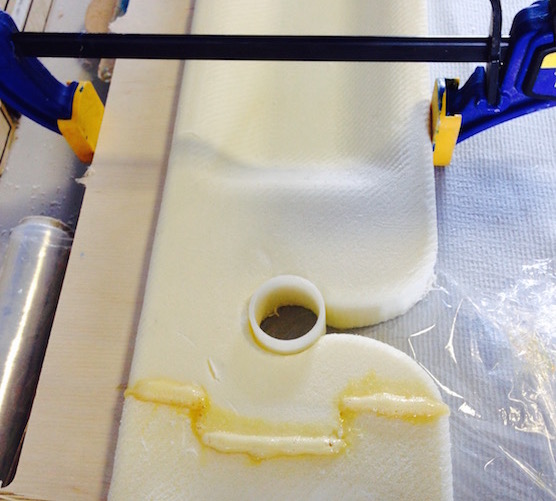

Due to foam size available, the piece had to

be milled in two parts. These would be glued

together (using Gorilla glue or similar).

A key has been in included to help locate and give

best strength back into the structure. The plastic

pipe section was inserted temporarily to protect a

potentially weak area whilst setting up the jig

and glueing the two pieces together.

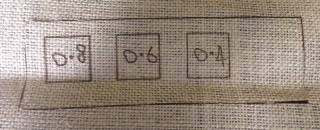

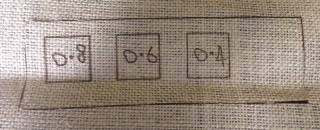

Test

engraving the jute on the lasercutter

to help with cutting the material at

the right places and to help "lay

flow"

In the

test piece above, I have charred the weave

with the laser. I had intened to use this

to provide a guide for me as to where to

best cut the jute to get the best lay of

the material to the form.

The lines engraved below are the lines

supplied with the solidworks vector lines.

This took time to engrave. In future I

would create a simplified line guide for

key cutting points for creating darts,

folds, etc.

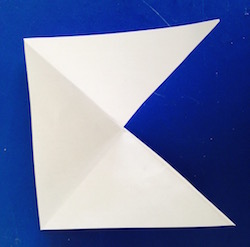

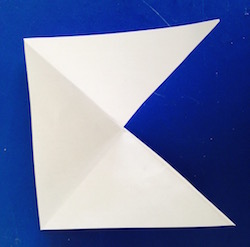

Applying the principles of darts in

clothing to try and get better form

Soaking the resin into the fabric by

hand:

At

this stage its difficult to imagine how

this could possibly work:

This is how the bathrest looked after vacuum

bagging:

Design

was created in

Solidworks,

click file

below

to download

.stl

file:

bathrestsw.stl