Conclusions

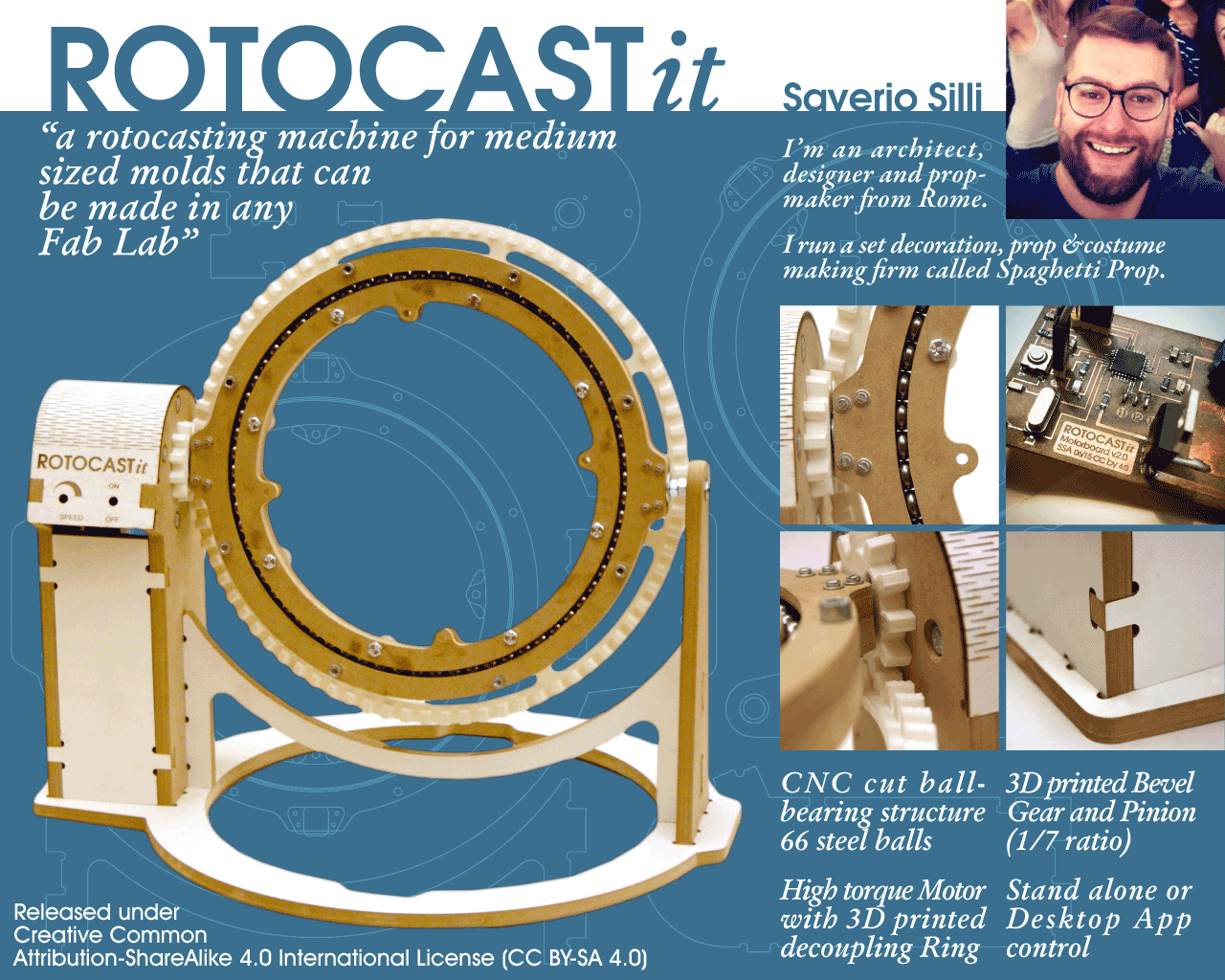

I'm very happy with the results of my project. The machine does its job very well, it is easy to make and assemble, it can be made in a standard Fab Lab and it is also good looking.

Thank you

I really need to thank all of my classmates, Enrico Boss, Zimo The Boax, Mat Ciurnelli, Pigi Nonpusho, Daniele Sathashakit, Gianluca Owen, my instructor Massimo and all the wonderful people in Opendot, especially Il Cemma and Nicola Buccioli, for their constant help. During the months of Fab Academy we shared the same desk for 16 hours a day and we became a family where anyone would help the other even if overwhelmed by his own work. The biggest thank you goes to my Father and Mother, my family and all of my friends for loving me and believing in me always.

TESTING THE MACHINE

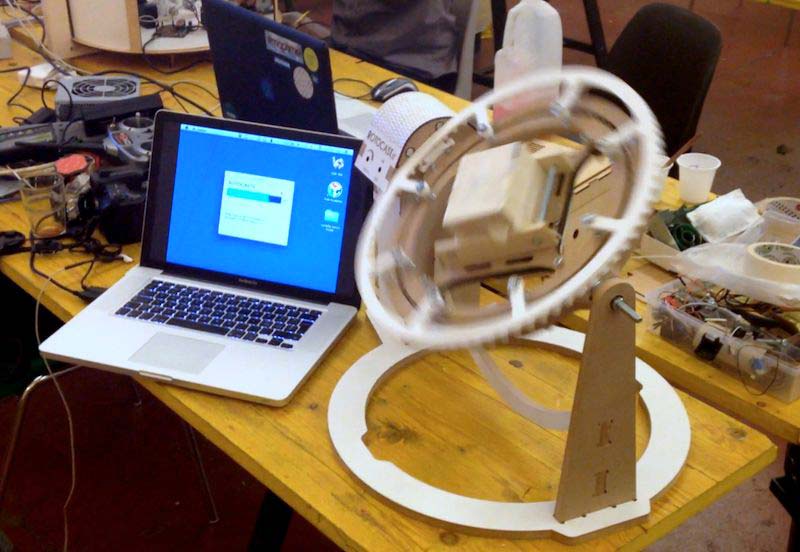

After completing the machine, I ran some tests to see if it worked properly and to find answers to the questions I figured during week 15 assignment.

Can I control the DC Motor with a desktop application?

All the electronics is working properly and the application I wrote on Processing works very well. The difference with my expectations lies in the fact that I was going to use an H-Bridge, but then used a MOSFET, losing the ability to change direction of the motor with the desktop application.

Is the Motor able to move the machine smoothly or does any part get stuck?

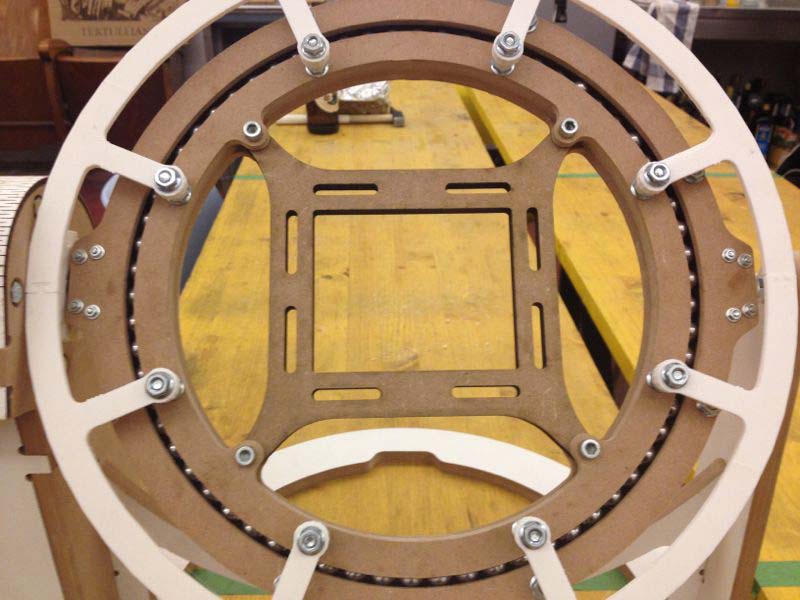

I am definitely satisfied by the structure and mechanics of the machine. The machine is easy to make and assemble, the pinion and gear action runs smoothly without issues and so does the ball-bearing system I invented.

Does a mold, loaded with resin in the machine, produce nice, hollow casts?

To answer this question i ran a simple rotomolding test. I took the mold I made in week 9, molding and casting and lasercut a support to attach it to the inner ring supports. Apparently the part came out pretty well, but, after cutting it in two pieces I discovered that the resin wasn't layed uniformly. The problem resides in the speed ratio of the two ring: while the outer ring makes one complete turn, the inner ring makes one seventh of a turn, therefore the resin spend more time in two sides of the mold than in the other four.

Remaining tasks

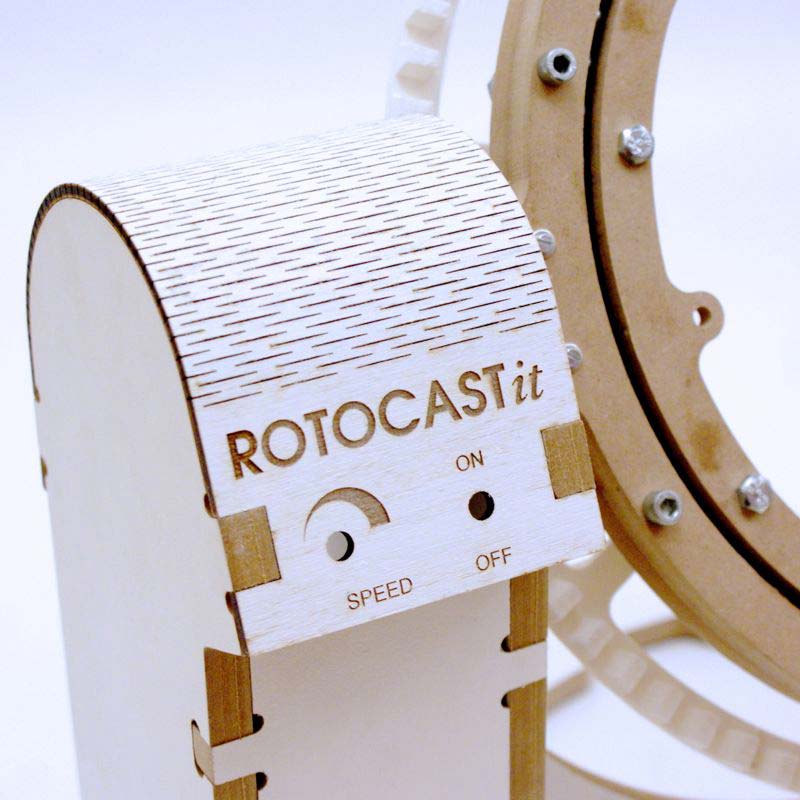

One thing I didn't have time to complete is the stand alone controls, to operate the machine without a desktop app. In the control panel there are already the housings for a potentiometer to control speed and an On/Off button.

What questions need to be resolved

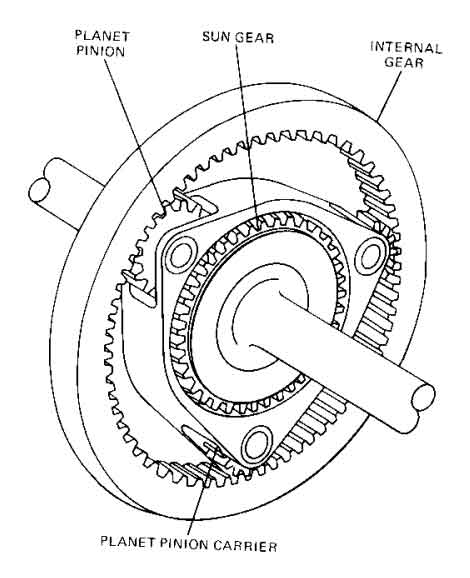

I'll need to figure out a way to reduce the speed ratio between the two ring. To have good casts with a uniform thickness the ratio will need to drop to at least 1/3. I already figured out how to do this, and I'm studying a way to make the pinion work like a Planetary Gear, so that it would move instead of stay fixed, therefore speeding up the inner ring.

As soon as this issue is fixed I would like to sell some machine, eventually trying to open a kickstarter for it, as I described in week 17 assignment

What have I learned

I learned a bunch of things in the process of making this project. Surely the biggest thing is how to design and control an electronic device, as that was the first time ever doing something like this. I'm also very happy with how I managed my time, I never had to rush or give up a feature because I ran out of time.

3D Files, Cut and Mill Plans, Board Designs, Bill of Materials

All the sources to make the machine can be found here. Everything is released under the Creative Commons Attribution-ShareAlike 4.0 International License.