WEEK 5

05. 3D Scanning and Printing

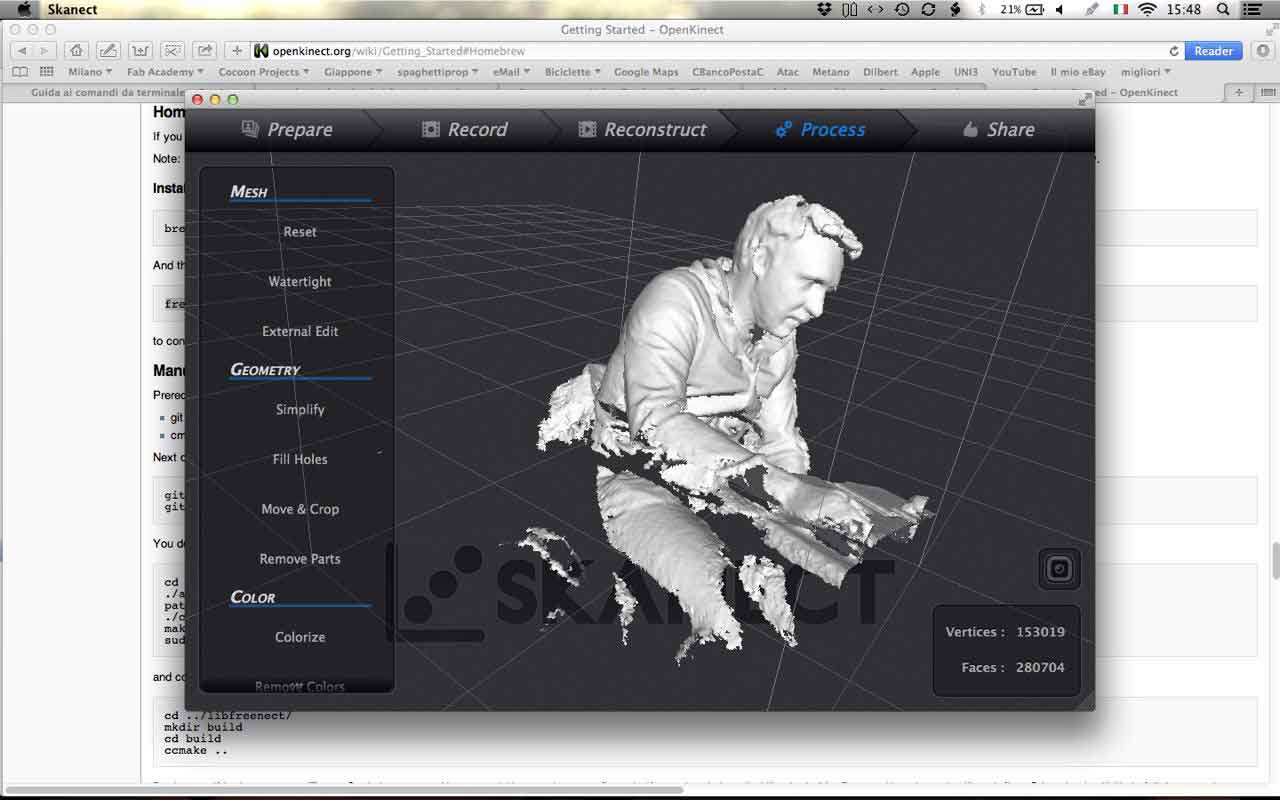

I started the exercise "playing around" with 3D scanning together with my collegues. We had an X-Box 360 Kinect which we used with Skanect software.

After the first scans we realized that to have better results we had to keep the Kinect steady and rotate the object instead of moving the scanner around, because the Kinect doesn't have any georeferentiation capability. So we clamped the Kinect to a tripod and we turn ourselves on a rotating stool.

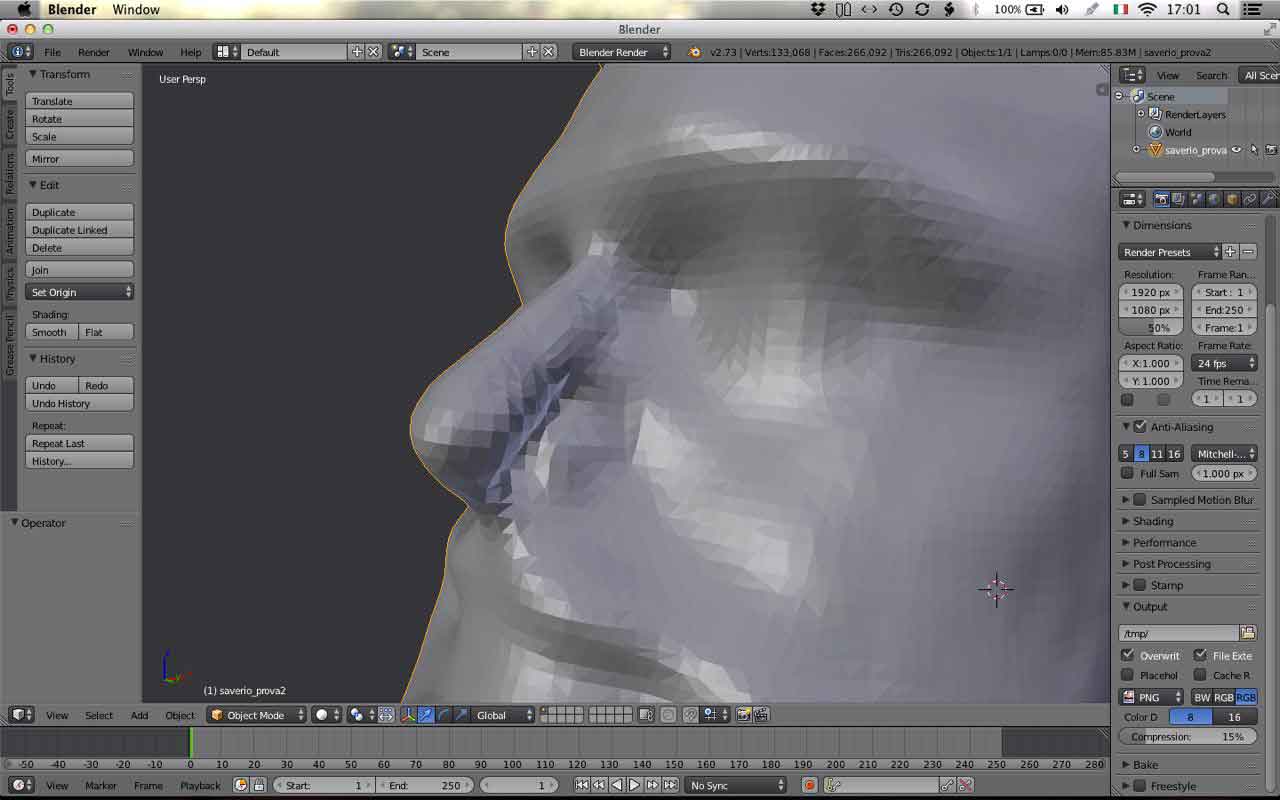

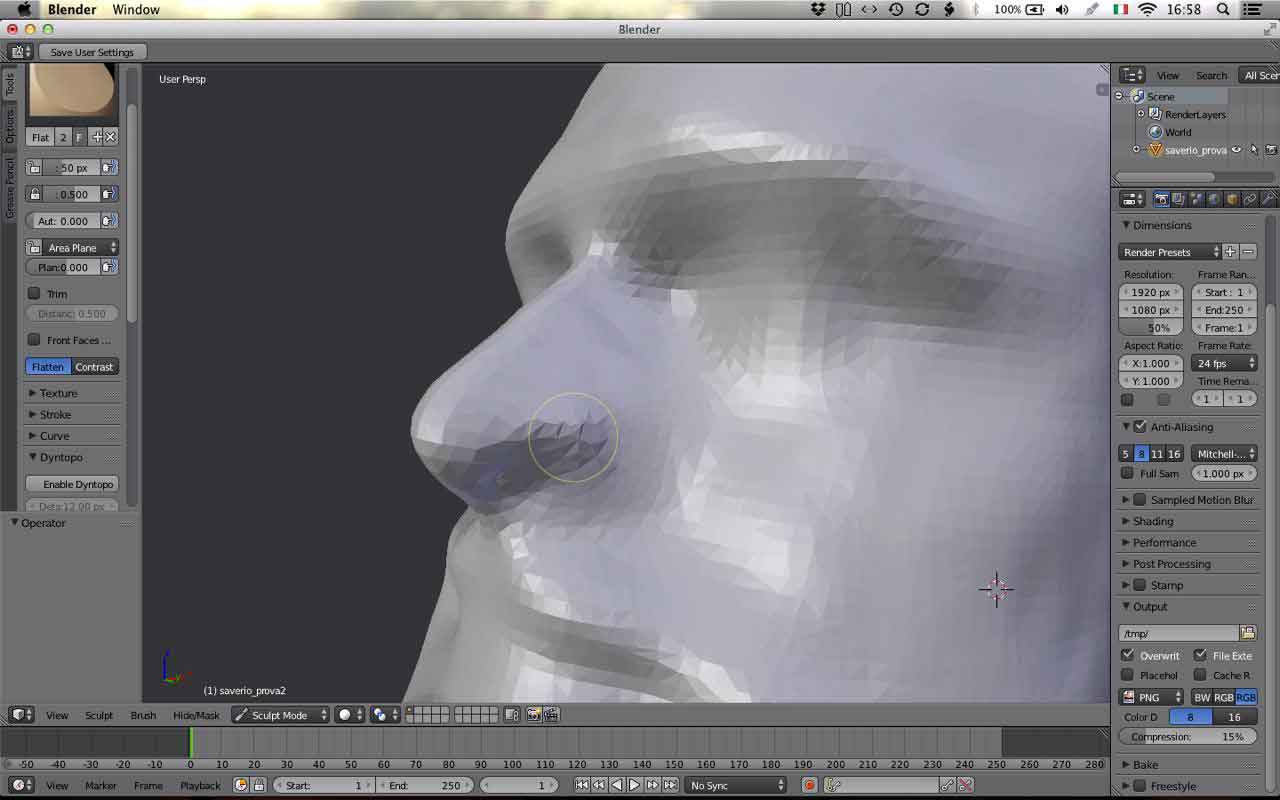

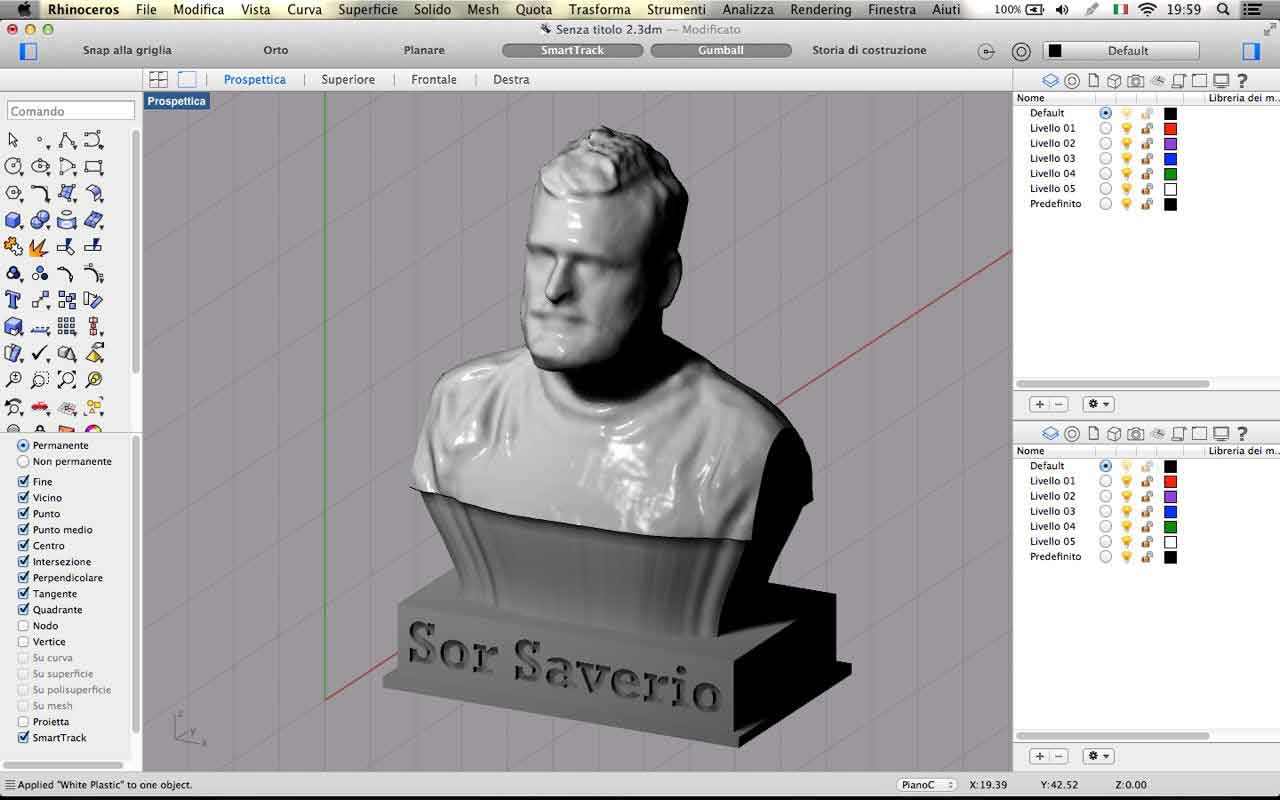

Scans came out much better, but we had some problems with holes in the model. I exported the model as a .obj file and put it into blender to work the holes I had on the left of my nose, top of the head and bottom of the chin.

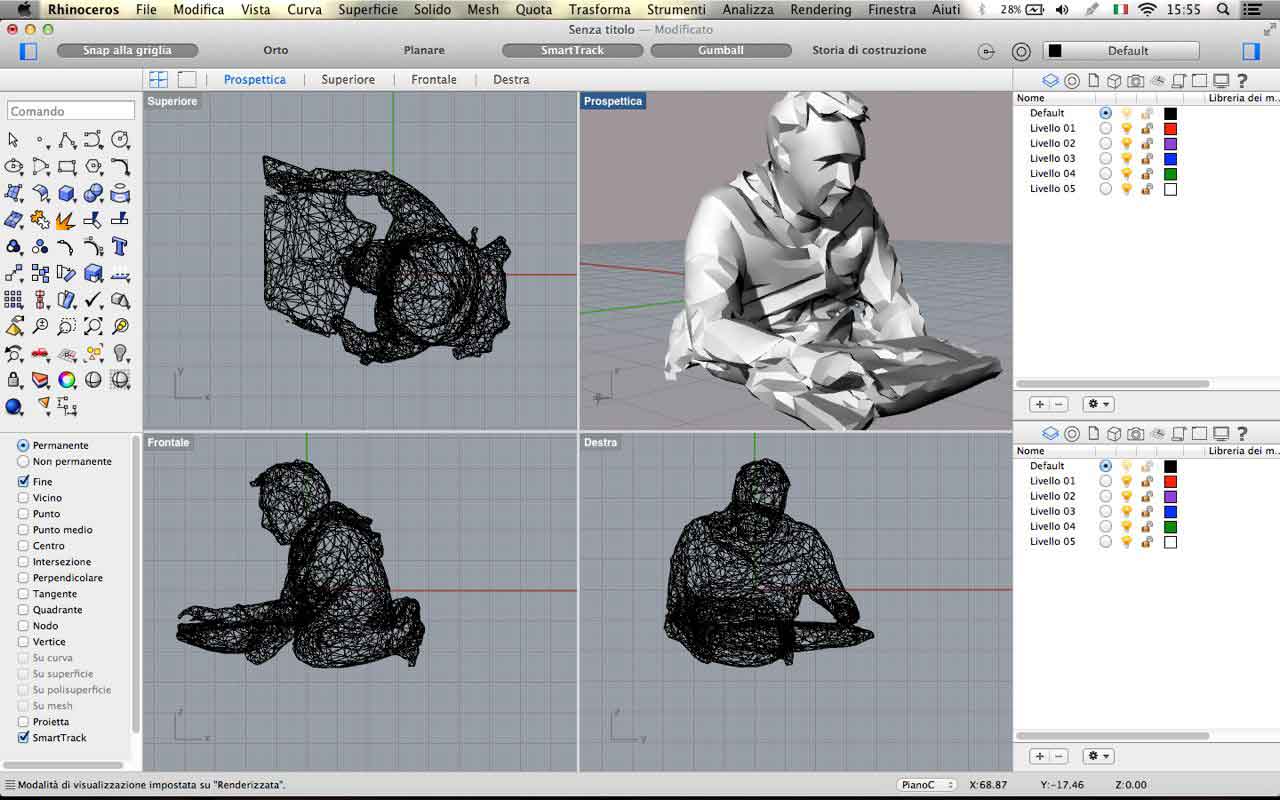

Then I moved to Rhino where I refinished the shape and added a base with my name to the bust. I plan to 3D print it as well.

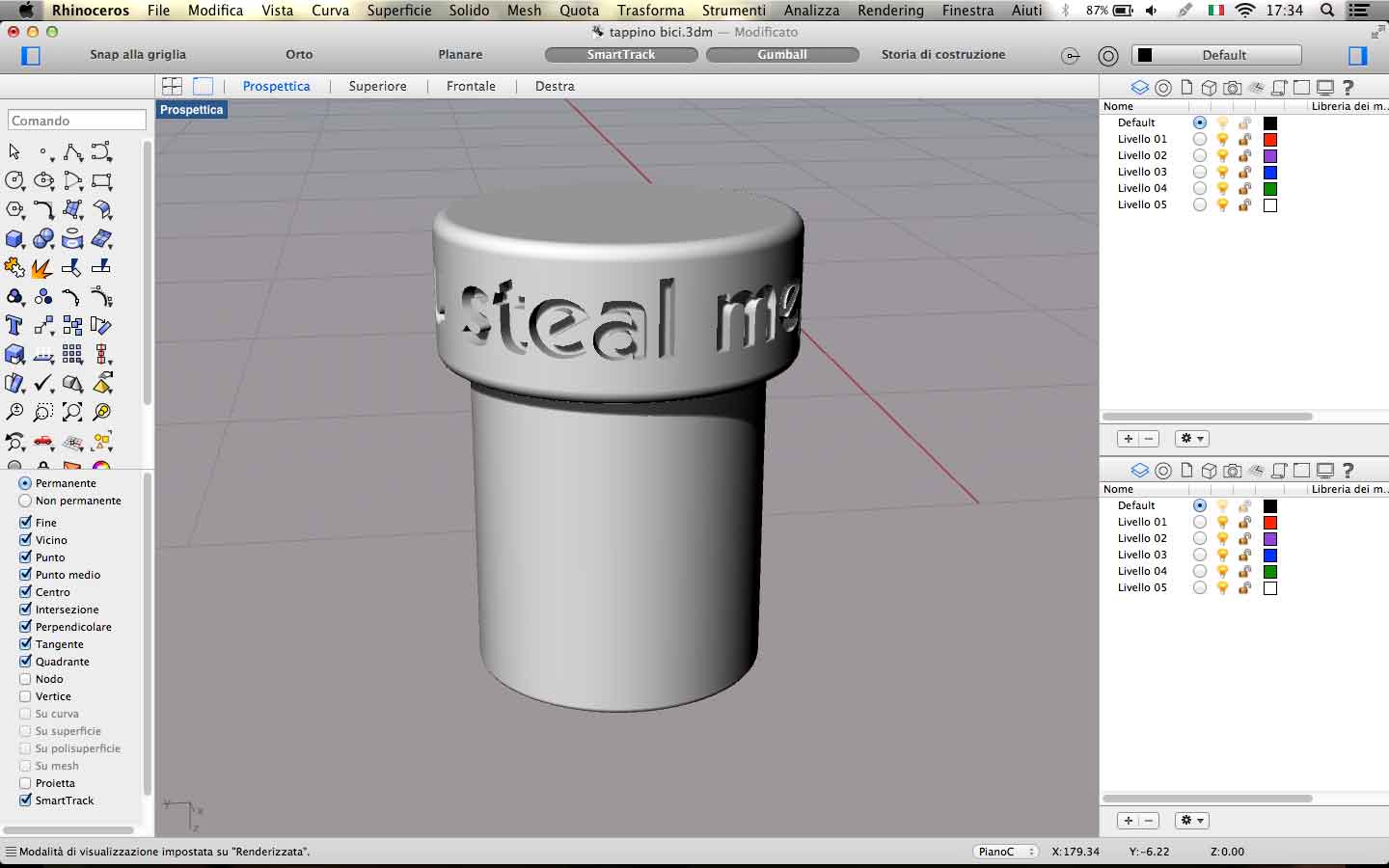

As a 3D print project I designed two caps to close my bike's handlebar's ends. I took the measure of the inner and outer diameter with a caliper and then moved to Rhino.

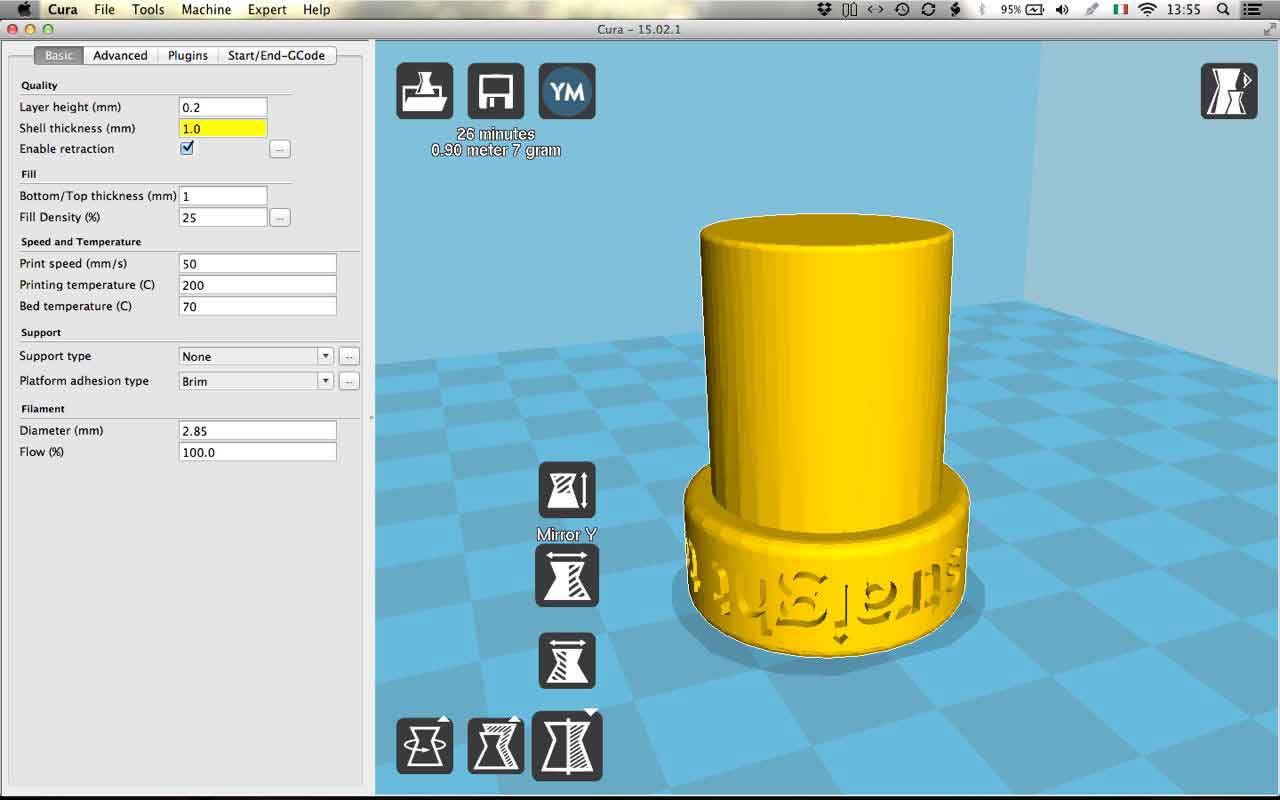

The caps have an "anti theft curse" engraved on the rim: on one cap it says "if you steal me I will" and on the other one "ride you straight to hell". I find a useful tutorial on youtube to wrap a 3D text around a cylinder.

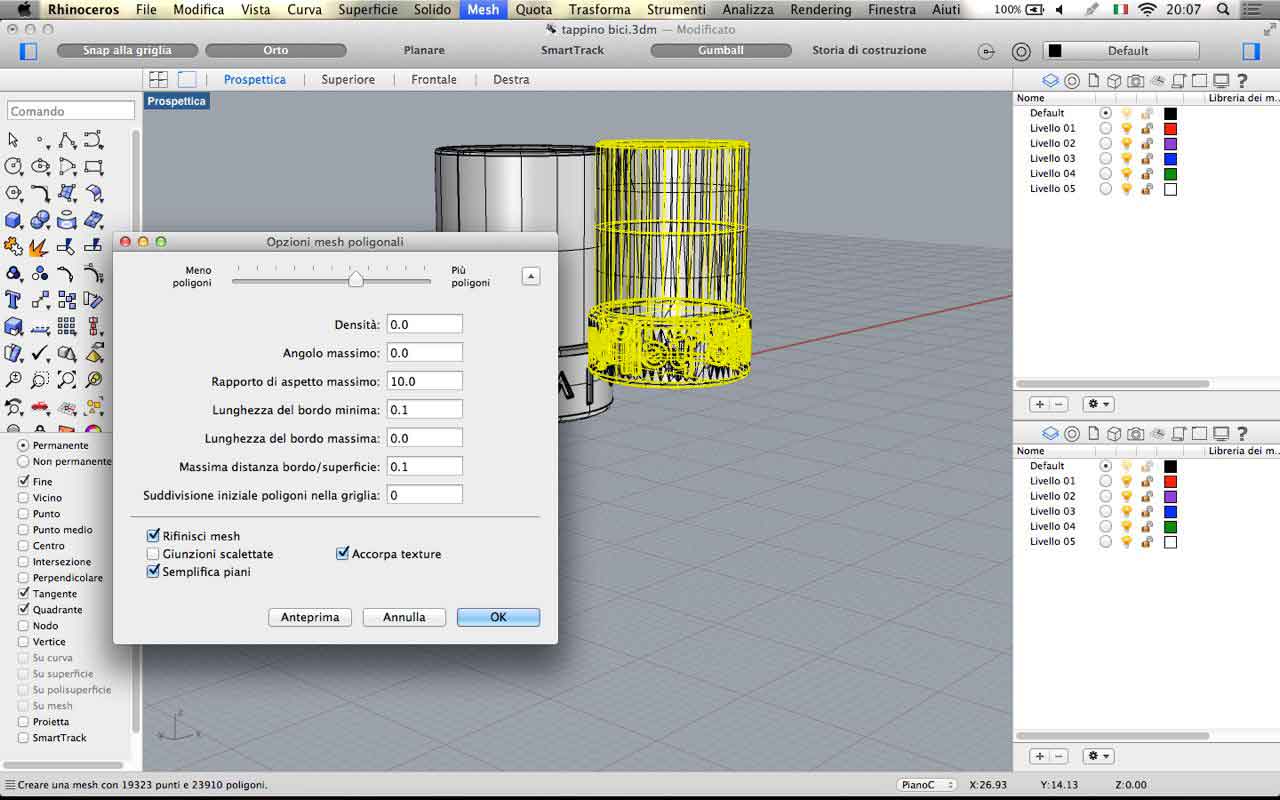

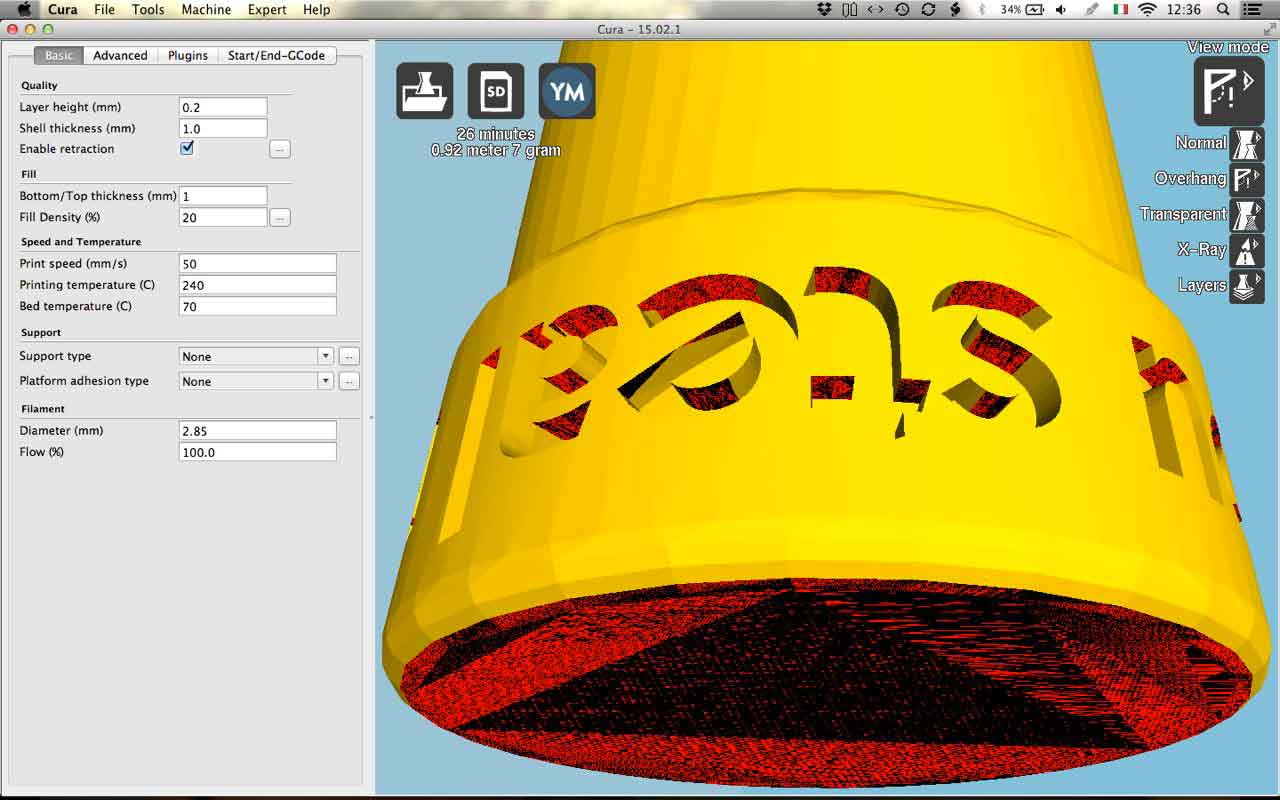

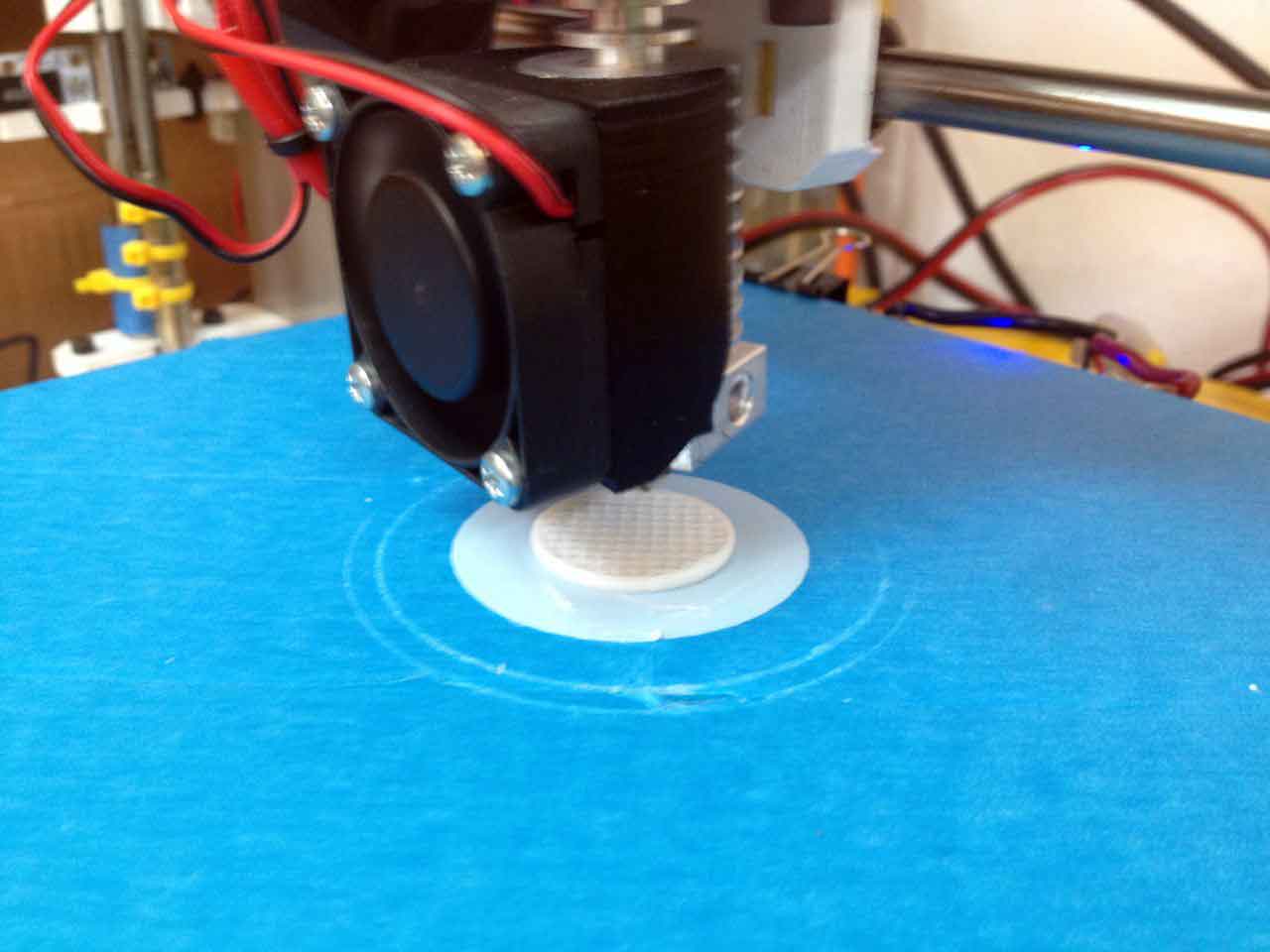

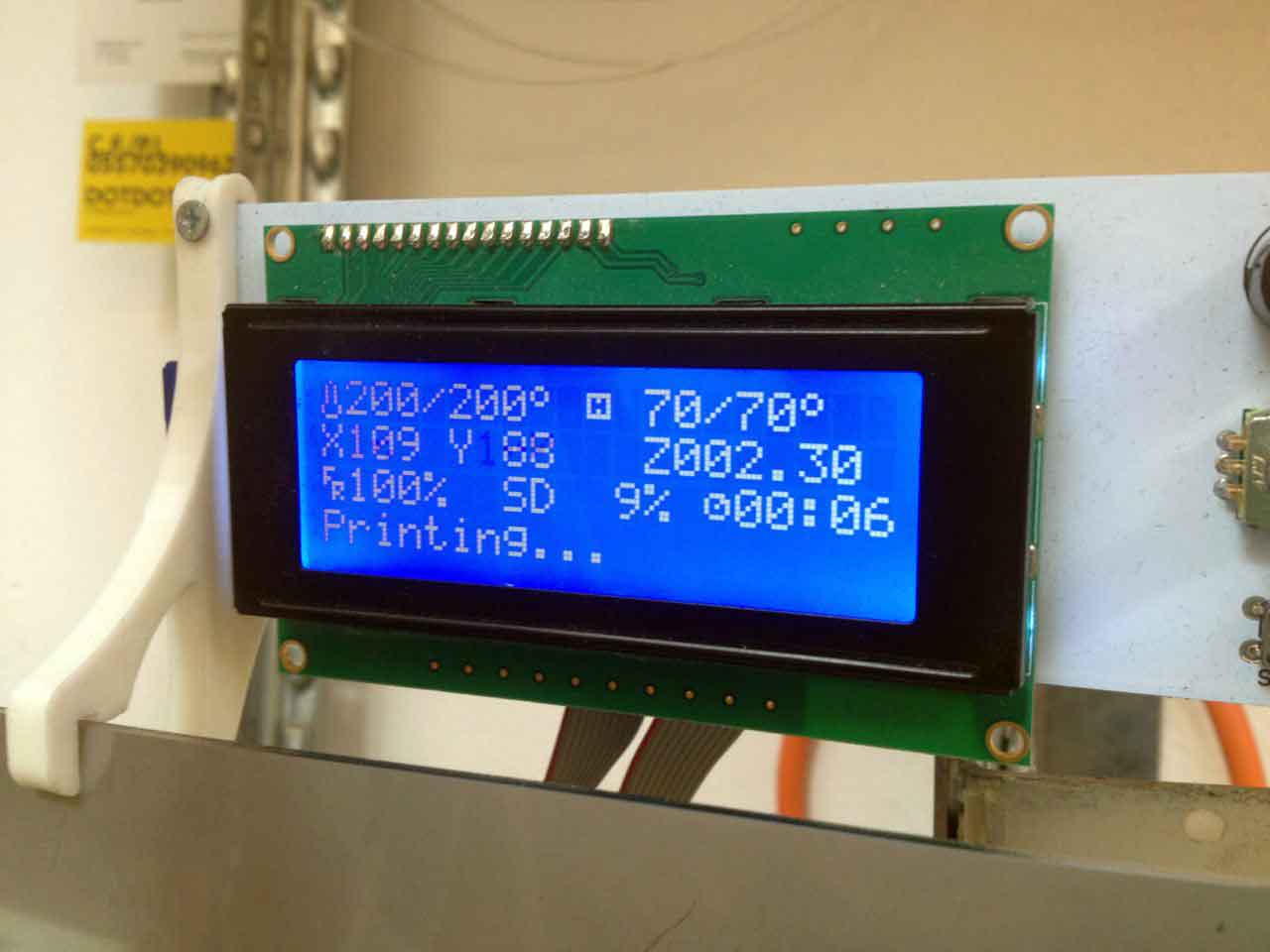

I then created the mesh on Rhino and exported as a .stl file which I opened on Cura. On cura I set some parameters for the print and send it to the printer.

While it was printing I discovered that the text was mirrored left to right, so I stopped the printer and came back to Cura to mirror the file on the x axis and export the g-code again. In the lab there were other students with the same problem, but we didn't investigate to see if the issue was cura or printer related.

Success! I made a fitting test on the bike handlebar and it goes smoothly into it. I have added a 0.3 mm to the diameter of the cylinder to give it a strong fit, to make sure it stays where they are.

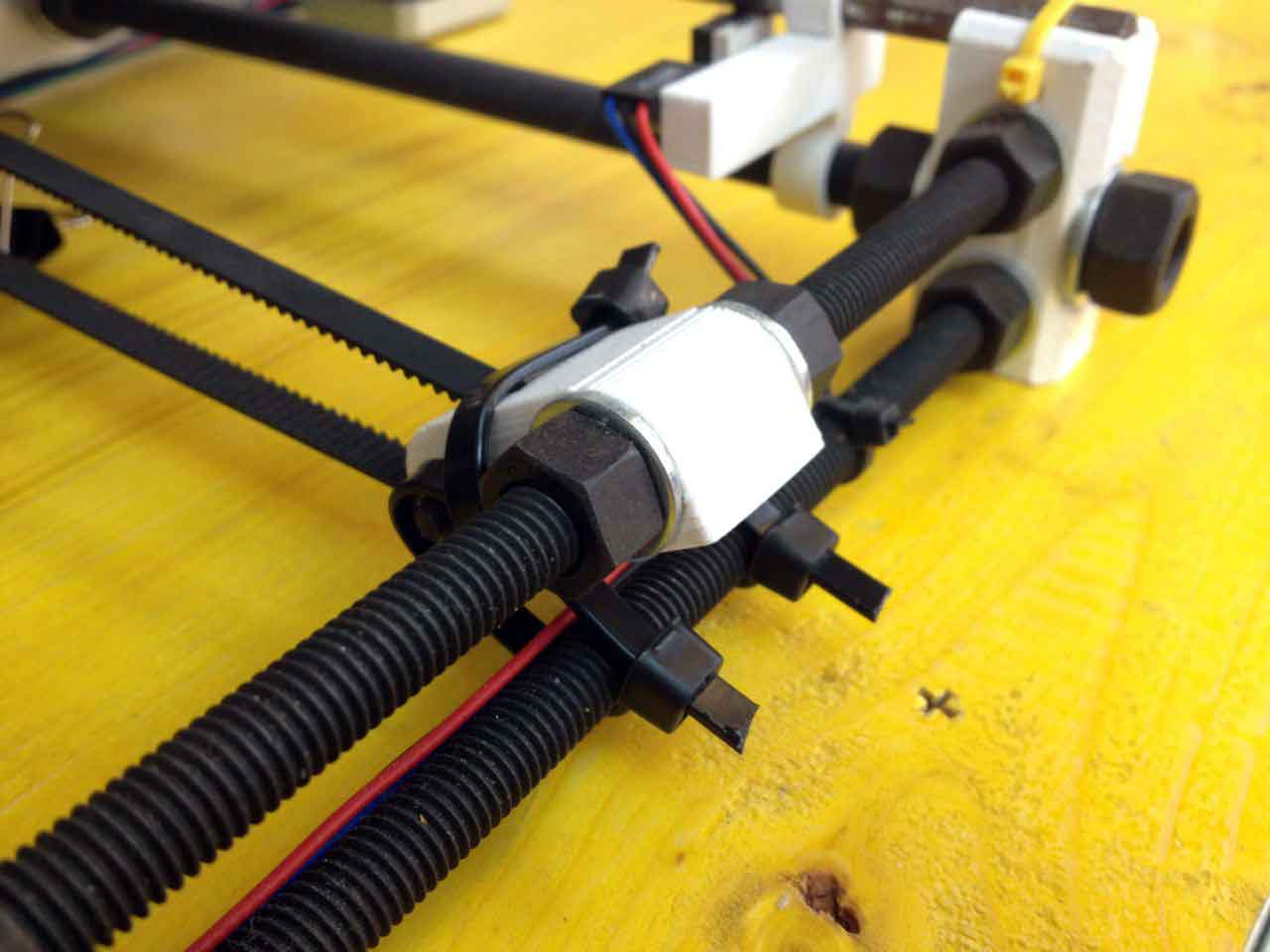

At the end I wanted to print the little bust I made from my scan, but the print was a total fail! We discovered that the y axis belt was very loose and the printer gradually lost a lot of steps on it. We fixed the problem tightening the belt pivot with "strategically placed" plastic ties. The fix was effective, and the result is pretty good.

STL files of the caps and my bust are available here: