Week 9 - Molding and Casting

Learn to design a 3D mold, machine it and cast parts from it.

Déploye Chocolate Domes

|

Mold, cast and final piece. |

The practice of this week consists of a four-step process to manufacture a three dimensional object:

1º Design the positive mold in 3D.

2º Mill the positive mold in machinable wax.

3º Make a flexible silicone negative mold from the wax positive space - Mix and pour flexible silicone in the wax mold.

4º Get a positive cast from the negative silicone mold - Fill the silicone mold with hot chocolate to make the final piece.

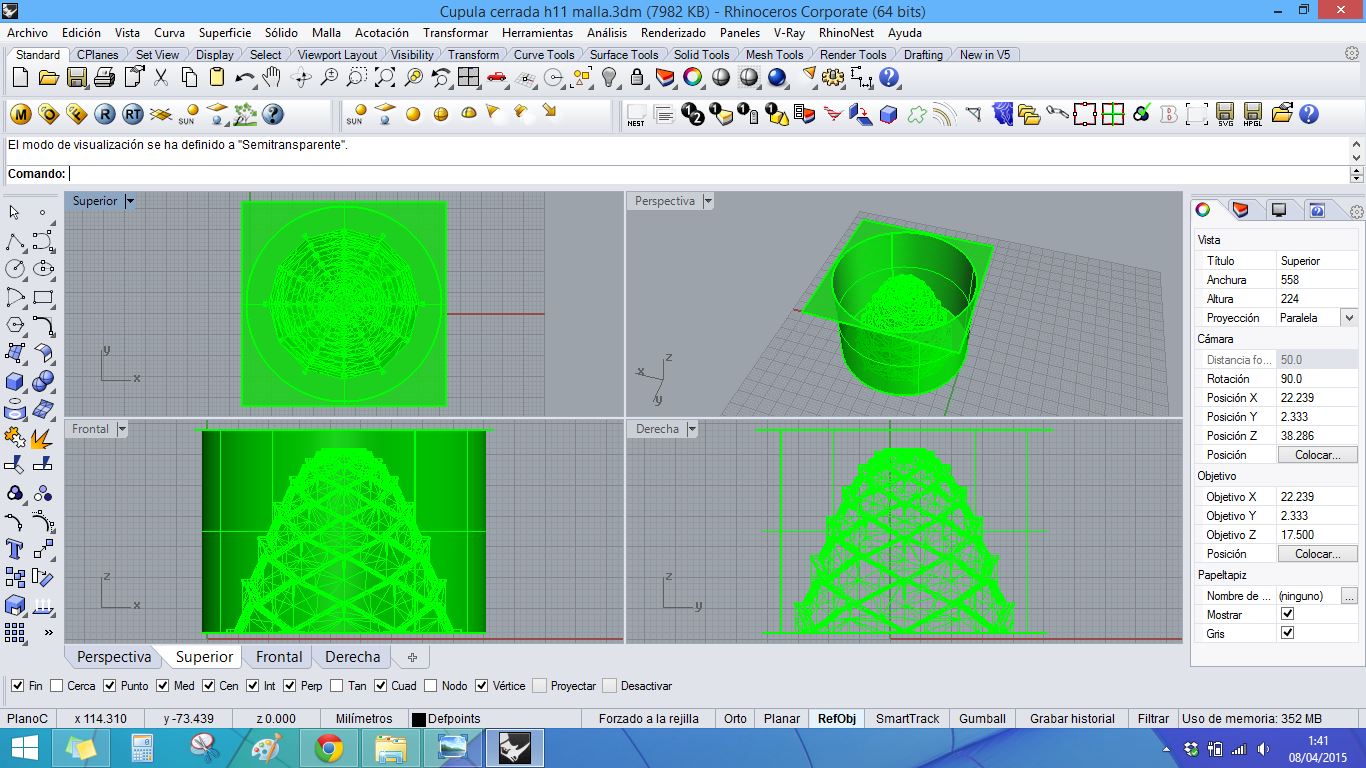

1 Design the positive mold

I decided to design a mini déploye dome.

|

1 Designing piece in Rhinoceros. |

Then I exported the file in .stl format to open it with the Fab Modules.

2 Mill the positive mold in machinable wax.

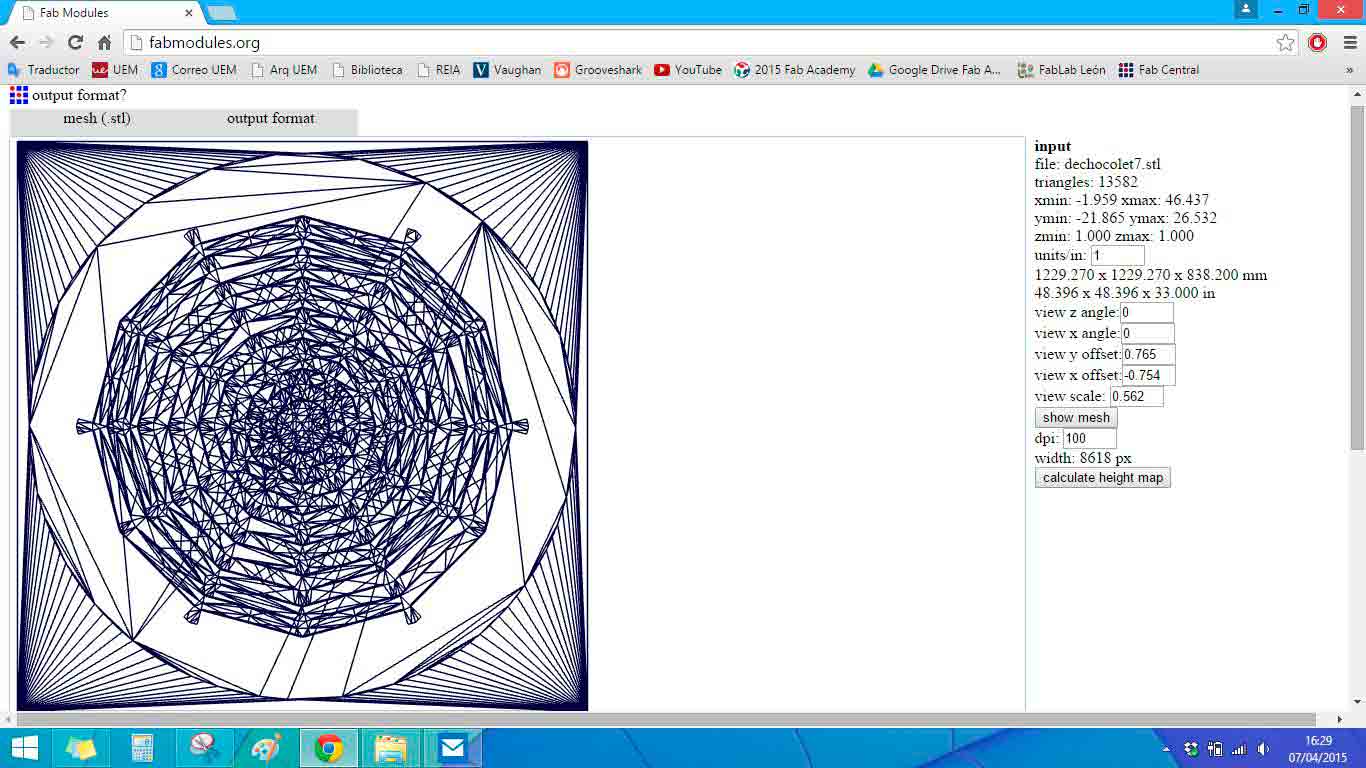

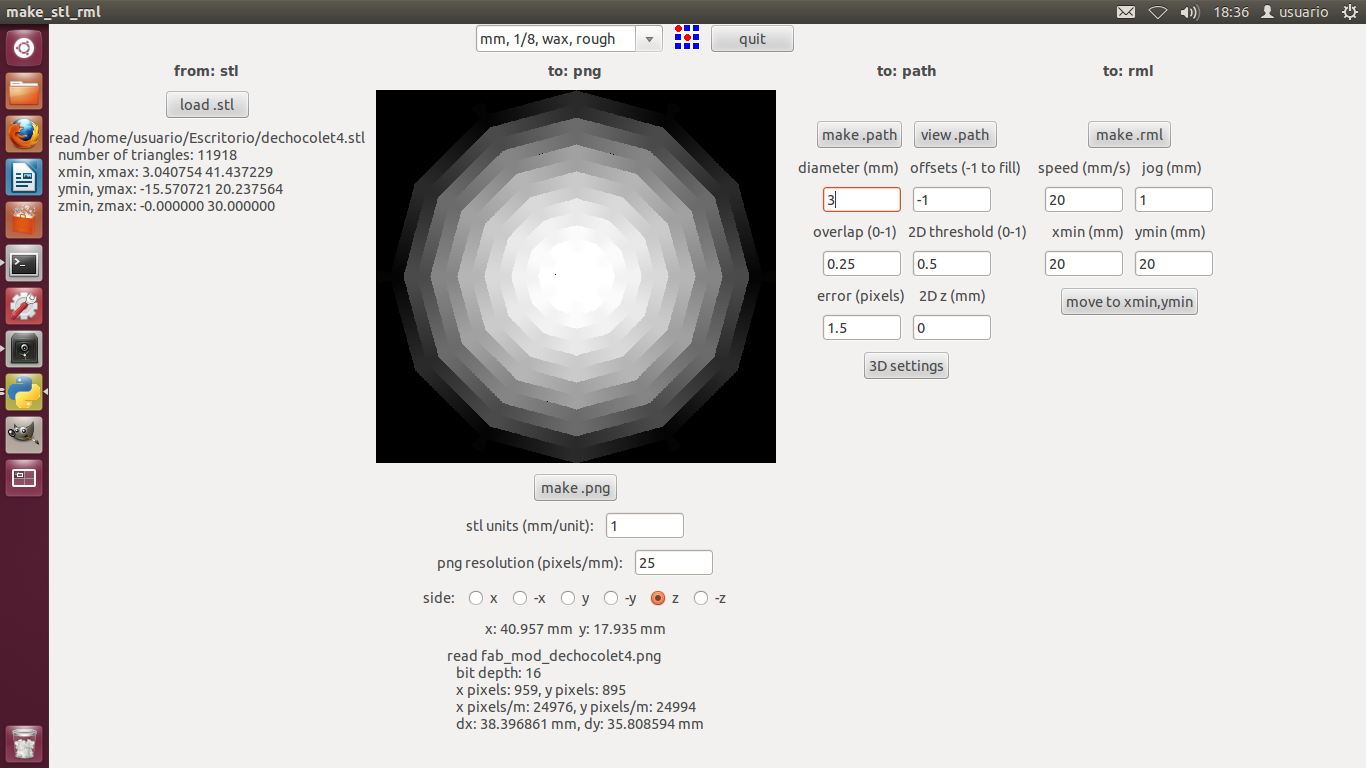

I used the Fab Modules to sen the .stl file to the Roland Modela MDX-20.

|

|

1 Opening the .stl file in HTML Fab Modules. |

2 Converting the .stl mesh in a .png draw before tracing. |

|

|

3 Milling the machinable wax. |

4 Positive wax mold. |

3 Make a flexible silicone negative mold from the wax positive space

I decided tu use the silicone for food related applications because I want to work with chocolate (Smooth-Sil 940).

|

|

1 Washing the wax. |

2 Smooth silicone for food parts. |

|

|

3 Smooth Silicone for food specifications sheet. |

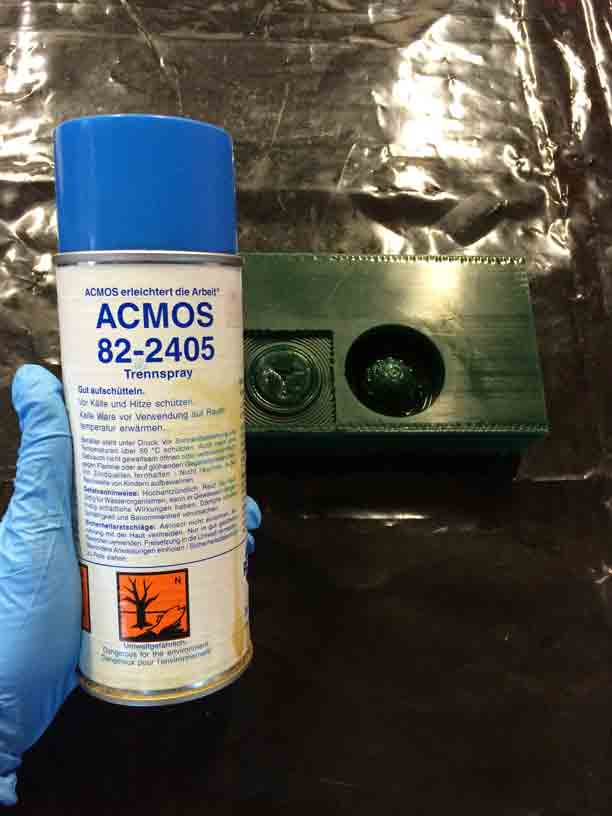

4 Spraying release agent on the wax for an easier unmold. |

|

|

5 Weighing part A (10/1). |

6 Weighing part B (1/10). |

|

|

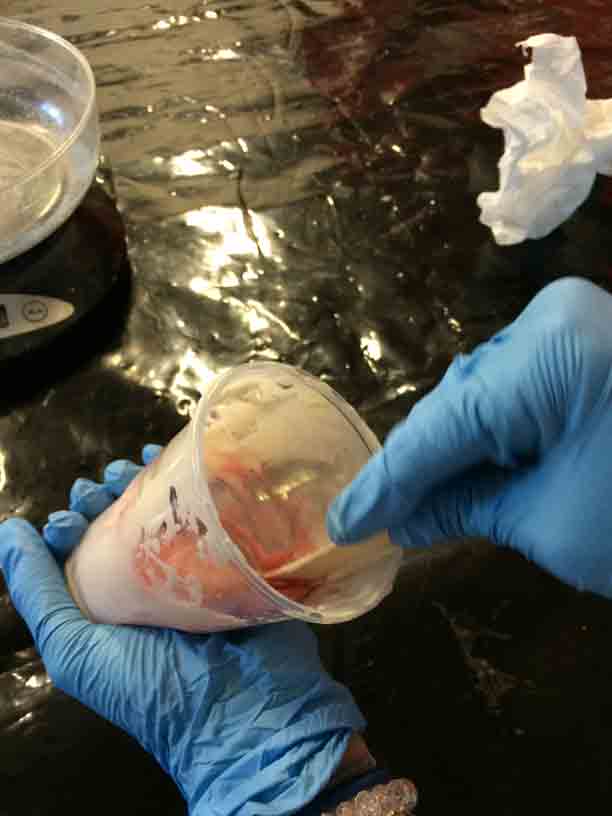

7 Mixing parts without making bubbles. |

8 Filling the wax mold with the silicone. |

|

|

9 Binding for 16 hours. |

10 Unmolding the negative silicon mold. |

4 Get a positive cast from the negative silicone mold

I decided to use white chocolate because white color shows better the geometry of the pieces and these ones are very small.

|

|

1 Washing the release agent from the silicone mold. |

2 Final negative silicone molds. |

|

|

3 Boiling water to melt chocolate. |

4 Melting chocolate. |

|

|

5 Filling silicone negative molds with chocolate. |

6 Freezing chocolate to accelerate the solidification process. |

|

|

7 Unmolding the chocolate. |

8 Resulting positive white chocolate casting. |

|

White chocolate déployé dome. |

Enjoy your white chocolate déployé domes!

FABRICIO SANTOS

FABRICIO SANTOS