Week 5

3D scanning and printing

3D Model, 3D Scan and 3D Print

This week assignment is about creating a 3D model which cannot be made subtractively and print it, and possibly 3D Scan an object and try to print it too.

Modeling a 3D object for printing

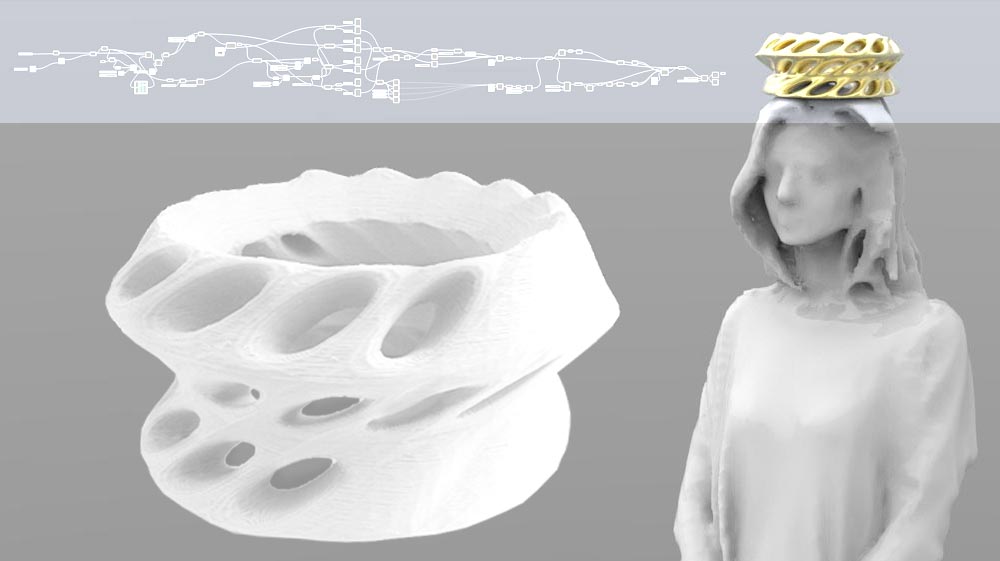

I started studying the Fab Lab Frosinone Rhino/Grasshopper Webinar and other Grasshopper tutorial about recursive design strategies.

In my idea, the simple object change form and dimention because interacts with other objects or movements; I did some modeling test to prove the correctness:

- I drew some handmade sketches to understand the starting model;

- I installed additional plugins of Rhino/Grasshopper WeaverBird;

- I started from a circle defined by radius and center point;

- I created a series of the first circle along the z axis;

- Using an attraction point and Graph Mapper I scaled in xy the circles along a Parabola;

- I transformed the curves in loft and I rotated the structure around the z axis;

- Then I created other attraction point along a circle: it attracts the normal vector of each face created;

- For this reason I subdivided the surface using a domain: when the face was out of domain range I used WeaverBird's Picture Frame;

- I constructed the internal surface using non-uniform scale and I closed the mesh;

- After I jointed each mesh and I used WeaverBird's Catmull-Clark to create the final model;

- I Baked the mesh and used UnifyMeshNormals to control it;

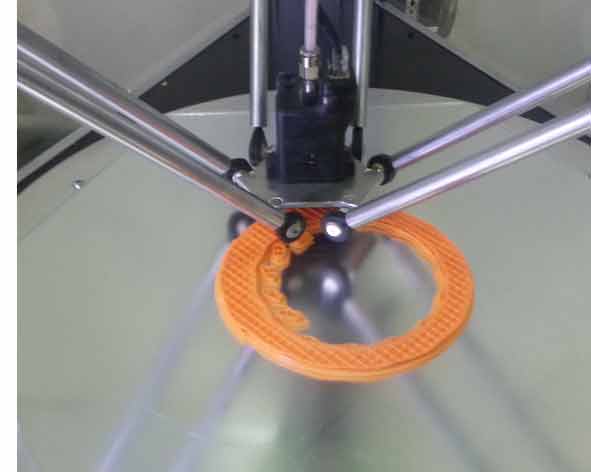

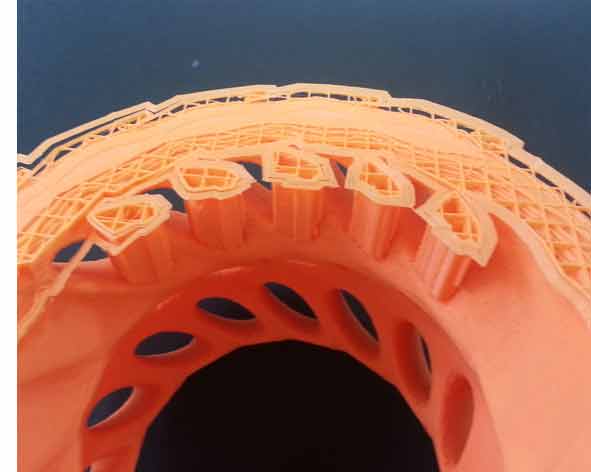

3D Printing the objects

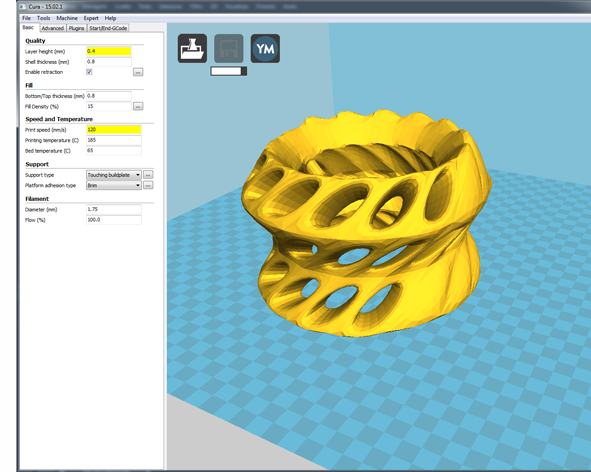

I moved the objects (file .stl) into the Cura software provided with the Ultimaker and prepared the G-code for printing it.

Parameters to print the object

- QUALITY -

LAYER HEIGHT (mm): 0,4

SHEEL THICKNESS (mm): 0,8

- FILL -

BOTTOM/TOP THICKNESS (mm): 0,8

FILL DENSITY (%): 15

- SPEED AND TEMPERATURE -

PRINT SPEED (mm/s): 120

PRINTING TEMPERATURE (°C): 185

BED TEMPERATURE (°C): 0,8

- SUPPORT -

SUPPORT TYPE : TOUCHING BUILDPLATE

PLATFORM ADHESION TYPE : BRIM

- FILAMENT -

FILAMENT DIAMETER (mm) : 1,75

FILAMENT FLOW (%) : 100

- MACHINE -

MACHINE NOZZLE SIZE (mm) : 0,4

- RETRACTION -

RETRACTION SPEED (mm/S) : 40

RETRACTION DISTANCE (mm) : 4,5

- QUALITY (Advanced) -

INITIAL LAYER THICKNESS (mm) : 0,2

INITIAL LAYER LINE WIDTH (%) : 100

- SPEED (advanced) -

TRAVEL SPEED (mm/s): 150

BOTTOM LAYER SPEED (mm/s): 20

3D Scanning objects

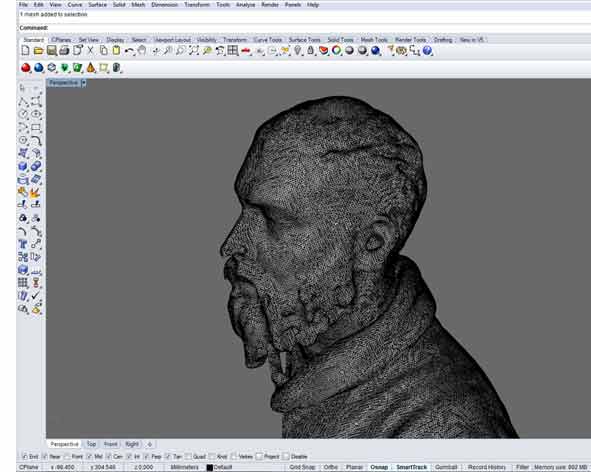

For 3D scanning I approached the task using the Sense 3D Scanner. I started defining what I had to scanned: person or an object. In my case I scanned myself and a colleague. To understand the different settings I had scanned my head and her body. I had to redo many times the scanning because I lost the center position or the correct distance. Then I moved the scan in Rhino (.ply) to fix the mesh and and finish the process.

Download Files

3d Model:

Scanning:

Programs: Rhinoceros, Grasshopper, Software Sense.

Machinery: Delta Wasp 40 70, Sense 3d Scanner.