First Project Proposal

I am going to create an

Context: mushroom grow-kits

In recent years there have been numerous start-ups selling mushroom cultivation kits. A grow-kit is a container (usually a plastic pag inside of a cardboard box) filled with a substrate (coffee refuse is a popular one) and inoculated with mushroom mycelium (most commenly a variety of oyster mushrooms, Pleurotus spp.). Once inoculated, after about 3 to 4 weeks, the substrate is fully colonized and ready to be sold. The consumer now only has to make or open holes in the bag and add water, and a week later mushrooms will begin to grow. A single kit may produce up to a kilo of mushrooms in seperate flushes before the mycelium has exploited the substrate and dies back. Once the kit no longer produces mushrooms, it becomes waste and is discarded of.

Continuity: repeating the cycle

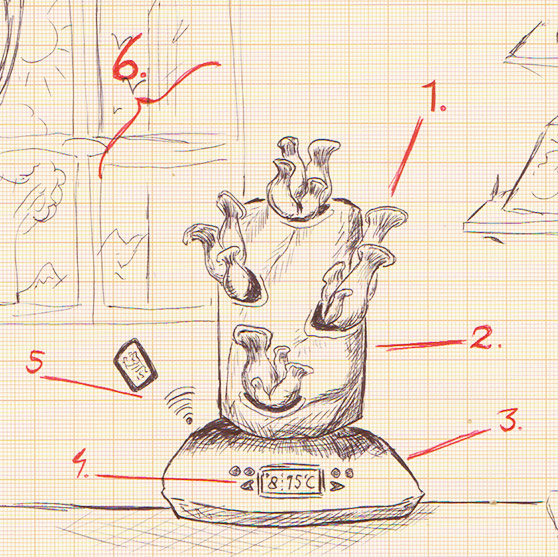

My idea for this project arose on new years day of this year. During Christmas I was mentally preparing to make grow-kits using spent grains from a local brewery (Edge Brewing) in Barcelona. However, I did not like the idea that mushroom-enthusaists buying these kits would get a few flushes of mushrooms, then throw the kit away, and not really learn much about mushroom cultivation. Besides that, I had made a design that would be too expensive and time-costly (and too awesome) for a disposable kit. And so the idea came to convert this idea into a mushroom growing appliance that would teach the consumer about the basics of cultivating mushrooms, while making it as easy and as fun as possible to do so. Here is a sketch of the idea:

- 1. The appliance is used for growing mushrooms. In this example King Oysters (Pleurotus eryngii) are shown.

- 2. The container should have a volume of about 3 litres, and has fruiting holes that can be opened and closed at the appropriate moment in the mushroom life cycle. The material it is made of has to be resistant of temperatures of up to 120 degrees centigrade in order to be sterilized and/or pasteurized, and has to be resistant to bleach. The container is a permanent feature of the appliance, only the contents are changed for each mushroom cultivation cycle.

- 3. The conainer is mounted to a base element that contains the electronics and is plugged into a power socket.

- 4. The base element contains at least a temperature control unit and has programmable features. An LCD display shows the chosen program and the current temperature of the substrate in the container. A sensor inside the container detects the temperature, and a heating element responds to the sensor according to the chosen temperature program. The sketch shows an example of "p8:15C" (could be program="8; Pleurotus eryngii" fruiting phase="15 degrees centigrade")

- 5. Optional (not absolutely required) features include humidity sensor and correction, oxigen sensor, pH sensor and wifi connection to an app on a mobile device to choose a program and keep track of the conditions.

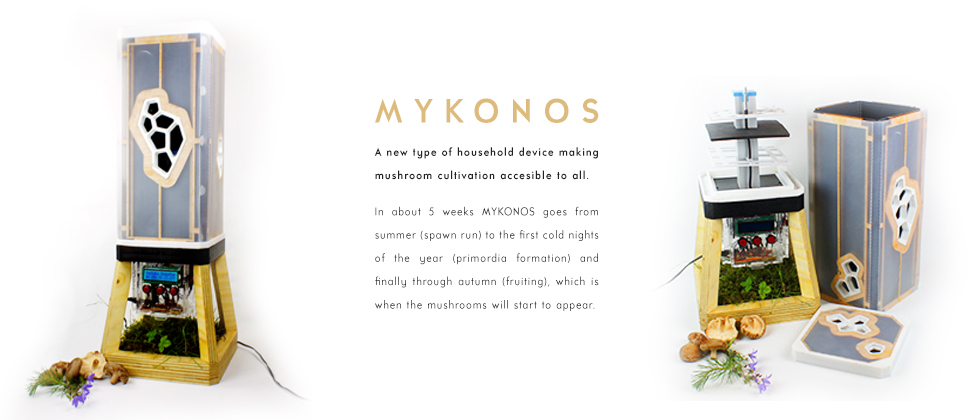

- 6. The appliance is made in such a way that it fits on a kitchen surface, is visually attractive enough to do so. It has to make mushroom cultivation fun, easy and accesible for anybody who want to grow mushrooms with a minimum amount of effort.