DESIGN & PREP

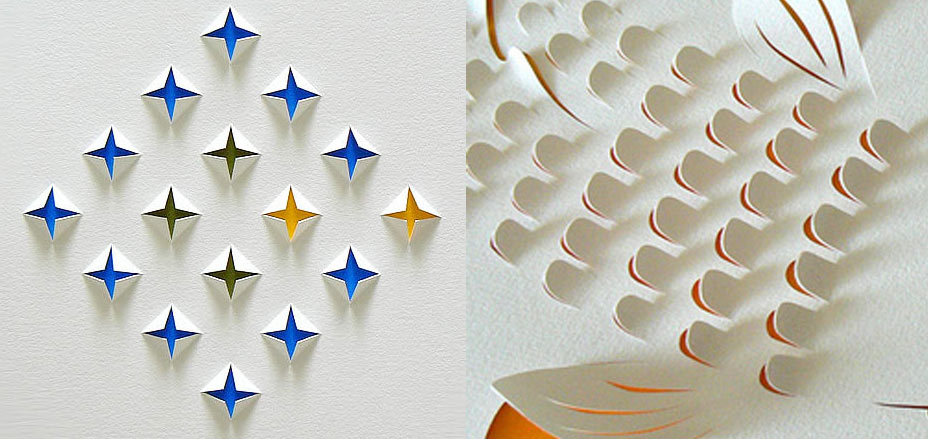

For this week I wanted to realise a simple design inspired by this artwork by Lisa Rodden.

The idea was to prepare the 2d textile through lasercutting, so that it could be laid precisely over the milled surface. The raised surface of the foam would then force the textile to remain open while vacuing, creating these open features that can let light through.

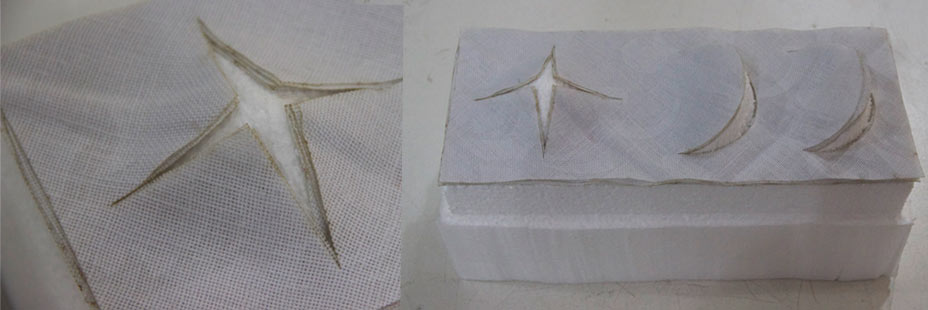

I lasercut 2 different types of linen textiles on the Trotech and I used the settings for thick paper. The first textile was weaved with such fine threads in the vertical dircetion that it disassembled as soon as I took it out of the lasercutter. Also, it would never have survived the impact with the sticky epoxy and the spatula. So I looked for a textile with a stronger weave, still slightly loose to allow the epoxy to penetrate well between the weaves.

I cut 4 layers of material, 2 ortogonal and -45 and at +45 degrees, to give more strenght to the structure.

Settings used for Trotech lasercutter:

Speed:1

Power:20

MILLING

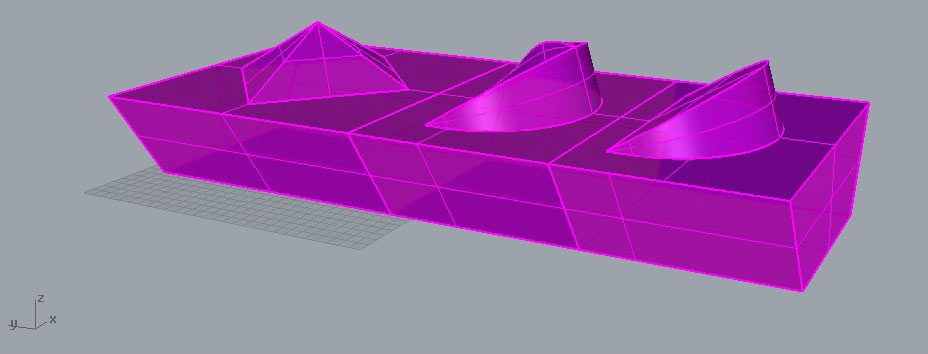

Strategies:

- Pocketing(2 cm depth) with 12mm ball nose

- Horizontal Roughing with 12mm ball nose

- Parallel Finishing with 6 mm ball nose

- Profiling with 12mm ball nose (to later cut the shape with hot wire

I made a test to check which shape would work better for this task.

I prepared the foam by cutting a 20/25 cm thick scrap of polystirene.

The first strategy was then used to level the surface for the following steps. I fixed the foam piece to the CNC table with clamps and pieces of wood for better stability.

COMPOSITE PREP

- Lay the textiles on a plastic layer

- Cover the 3d mold with the perforated bleeder layer

- Prepare the epoxy (which comes in 2 parts, 2:1 Epoxy:Hardener, 25 mins before hardening)

- Mix well the compounds in an homogeneous liquid

- Brush the material over the textile layers

- Lay textile layers onto surface

- cover with breather layer

- cover with bleeder layer

- cover with plastic layer

- place in the vacuum for 6 hours

RESULT & PROBLEMS

- The vacuum machine produces such a high pressure that it levelled my 3d features and smoothed the corners of the foam.

- I should mill again the same surface with wood to maintain the sharpness of the features

FILES DOWNLOAD LINK

HOME | ABOUT | WORK | CONTACT

Francesca Perona © 2015

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License

Original open source HTML and CSS files

Second HTML and CSS source

Francesca Perona © 2015

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License

Original open source HTML and CSS files

Second HTML and CSS source