Composites

April 22, 2015

Assignment:

Design and make a 3D mold and produce a fiber composite part in it.

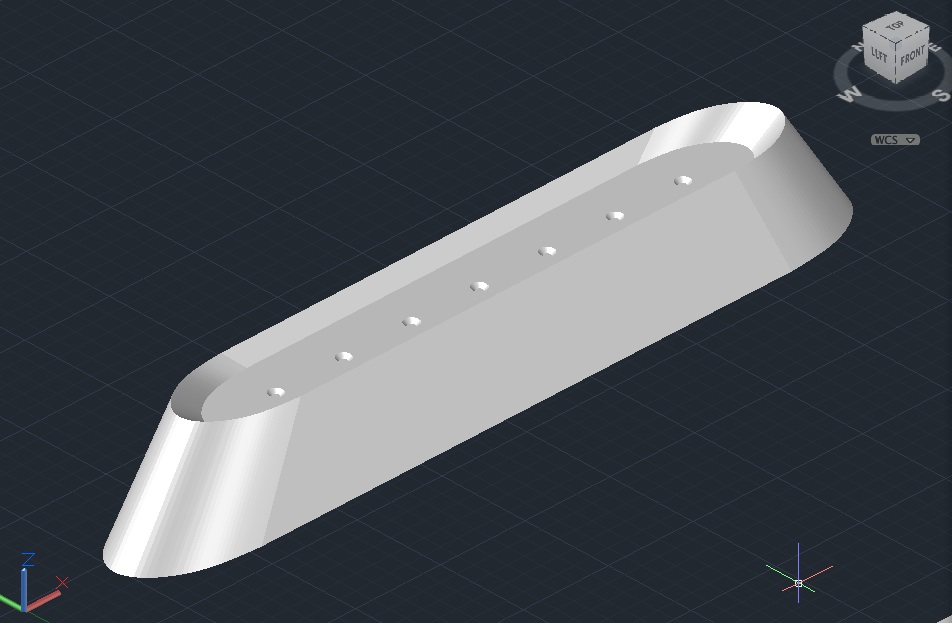

This week, I will create a long and narrow hanging lamp shade for a table.

3D modeling of design:

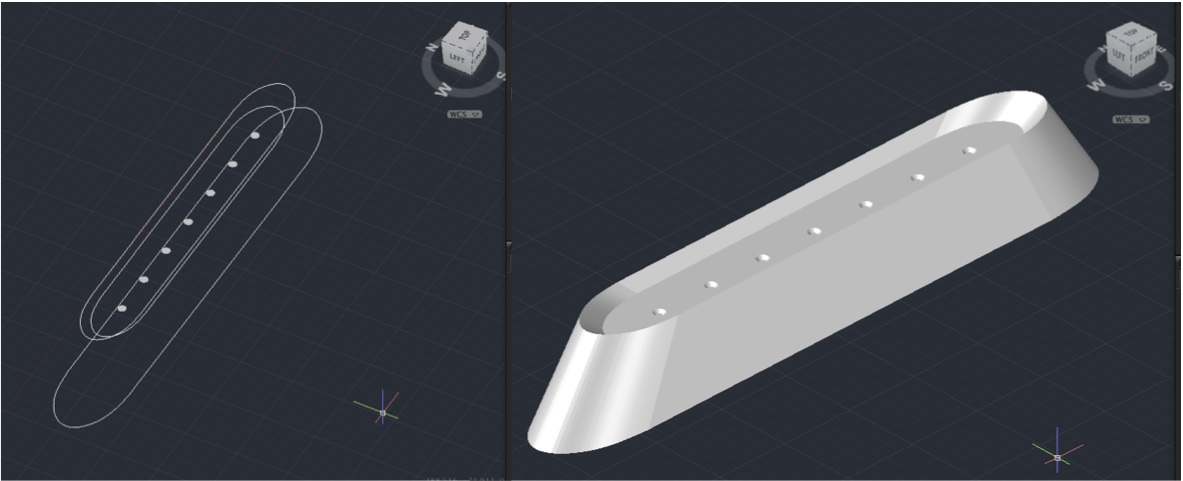

CNC's Tool path:

I will make the mold out of foam in layers in order to create more volume.

Assembly of the layers:

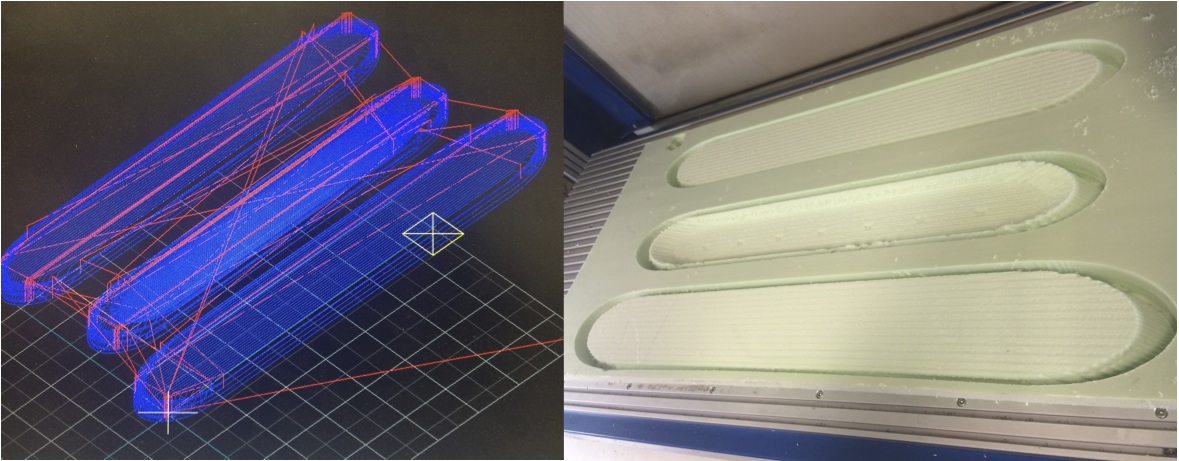

Since the finished product was too rough, I had to sand it by hand:

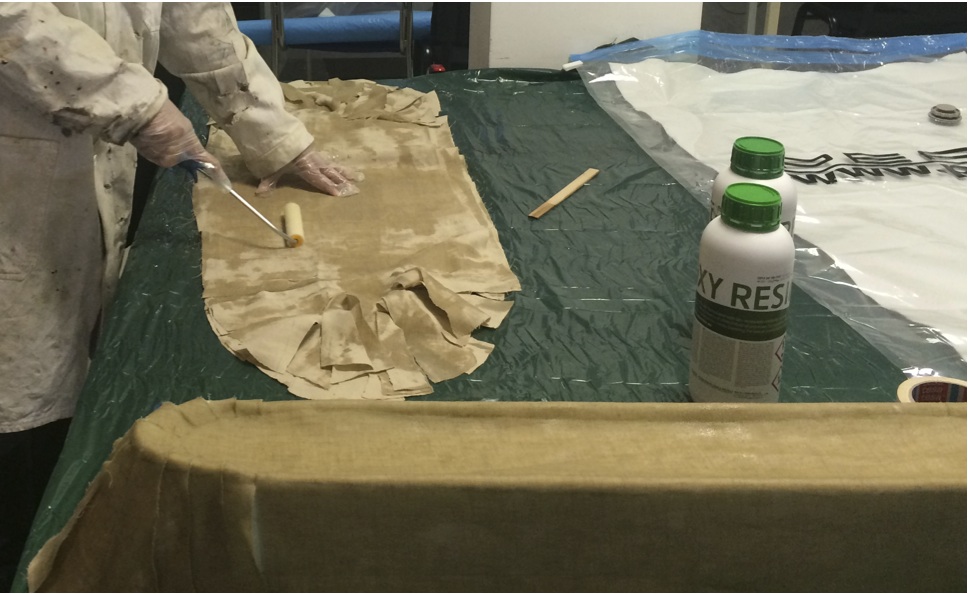

I then proceeded to cut the "fibers" of my composite to its required shape:

I mixed the epoxy following the Resin's vs Epoxy's manufacturer's ratio:

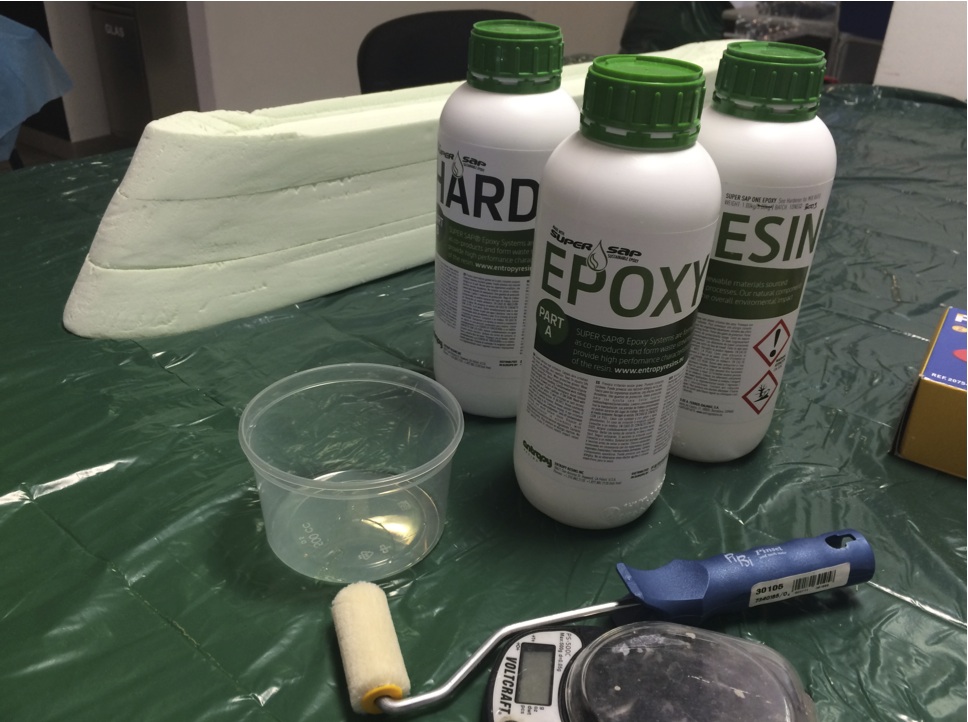

Then I soaked the "fibers" with the resin and laid 4 layers on the mold:

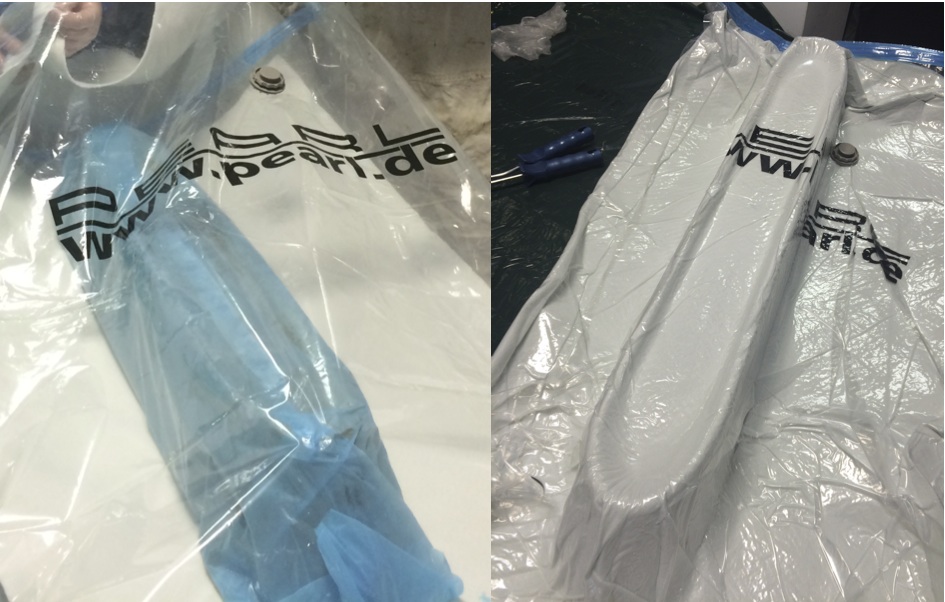

Then, I placed it inside a vacuumed bag for 24hours to harden:

Finished product after hardening:

It will not de-mold easily, I may need to disintegrate the mold with acetone:

Here is the link to my Composite Design File:

Composite Design File