Disassamble and assemble

The description of all group work is in Fab Lab Sitges web page, please

visit it to get a mountain view.

On my web page I will document only the specific task I have done. Of

course, no task was carried out completely on an individual basis because

we were always working together.

Visit group documentation here.

Francisco (Fab Lab Sitges Manager) let us work in general, just in doubt

moments he helped us.

Cable RS-485 FTDI, Fabnet, laser cut, assamble and calculating coordenates.

Content (linked):

Assignment:

Group assignment. Design a machine.

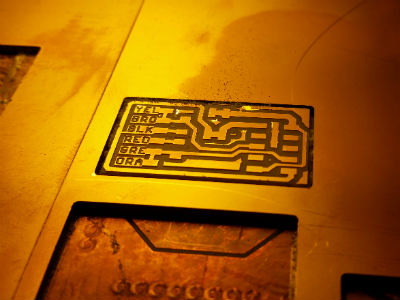

It is needed to create a FTDI, a little bit different from others. This

is a RS-485 version.

After that, it is needed to create a bridge board that adapts that cable

to FabNet (is a RS-485 bus with a few additional signals).

Download Fabnet files here

(eagle and png for milling)

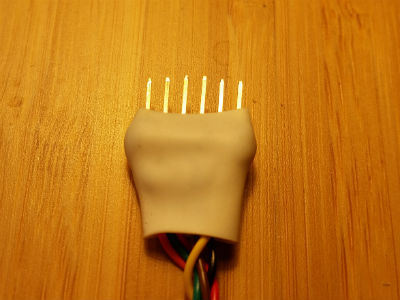

I put silicone in order to avoid short circuits between wires.

My first task in this group assignment was to create the RS-485. I downloaded all the files (eagle files), milled and soldering components on it.

Fab net schematic. You can download it on the previous section.

Fab net board. You can download it on the previous section.

Finally, we put it in action.

Assambling the light machine (well, it was a light machine at the end, but at the beginning the idea was to create a "sand writing machine").

My final project use batteries, this is the picture of the LED with my battery case. This was my first battery case, after some research I change to a compact battery for reduce weight.

This is our fantastic tool: a green led!

It is not too much now, but you can see the results on Fab Lab Sitges

web page: a light machine. It's amazing!

This picture was made with iris camera open for long time. All of us were completly still during all the movements made by light machine.

Another individual task I have made it was to calculate the light machine

coordinates. Our Fab Manager (Francisco) decided that it would be

ok if the machine does 3 turns on the vertical plane and move on horizontal

plane 20 cm (almost all the movement range).

I decided to use EXCEL and calculate the position parametrically, depending

on the angle.

How to build the coordinates. The machine have to do 3 turns in the path

of 200mm in z axis:

angle increasing every 5 degrees

x=cos(angle)

y=sin(angle)

z=200mm/(360*3turns)

Download the final coordinates here

Here it is the coordinates of one turn.

All team were working on the final adjustment. It was a complety success!