C o n t a c t F a c e b o o k S k y p e I n s t a g r a m P i n t e r e s t H o m e

11. Composites

Design and make a 3D mold and produce a fiber composite part in it

In thinking about what to do for this week, I decided to experiment with the idea of making a shoe composite. What interested me particularly in this idea is the multipurposed use of the fiber component in that not only does it provide some tension, but it also extends outside the composite and serves as the supporting outermost part of the shoe. With this in mind, there were a number of design issues that arose in the design of the mold. These issues have been moved to Week .14 where the mechanics of the project are discussed in detail.

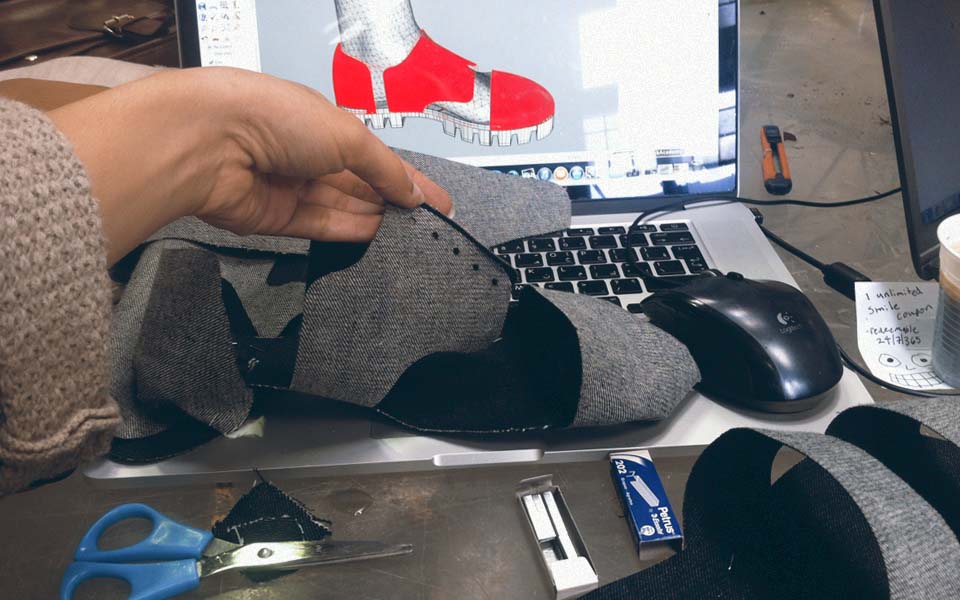

To design the mold, a 3D scan of both of my feet were taken using the Skanet software. The resulting mesh was then exported and imported into Rhino and served as the basis for the design of the mold and the fiber composite. The bottom contours of the feet meshes were then extracted and used to define the contours of the insoles of the shoes. This insole mesh was then subtracted from the insole of the 3D Rhino model designed in Week .02. The resulting shoes are the positives that are expected to come out of the mold casts. The molds for the shoe were then designed around this shape and allowed space for the extension of the fiber outside the perimeter.

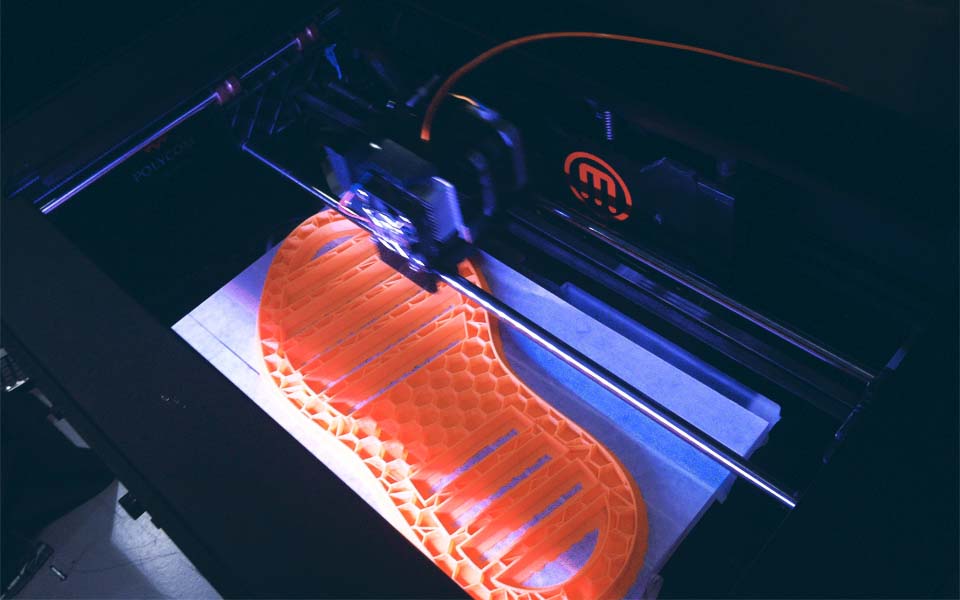

Because the resulting molds required a high resolution, which was not achievable with the 6mm Shopbot bit that was available, they were to be 3D printed using the Makerbot Replicator x2. Considering this, the thin size of the mold reflects the optimization of material.

The next step is to generate the lasercut files for the fiber component off of the 3D Rhino model and then send the file to be cut out of denim fabric. With both the molds and fiber component designed and fabricated, the composite is ready to be cast. Instead of using resin for the cast, the material was replaced with Smooth-On PMC 770 Urethane Rubber which will provide a more comfortable experience for the shoe wearer.

To cast one shoe, the following steps were taken:

1. Mix the Smooth-On PMC 770 Urethane Rubber well in a 1:2 ratio. The pot life for this mixture is 15 minutes.

2. The insole mold will be the bottom of the two-part mold. Fill this mold with the rubber to the brim.

3. Carefully position the lasercut denim fabric onto the mold composite. Lift and wrap the mold so that the fabric wraps under, around and tucks into the rubber cast.

4. Position the mold for the outersole on top of the bottom cast using the tabs to align the molds.

5. Using clamps, a straight surface and a sturdy flat block of wood, clamp down the two molds together.

6. Pour the remaining mix into the perforations of the outsole mold until it reaches the brim.

Update: Once it was decided that I would continue with this project for the final, I realized that there are several ways to improve this process. The 3D printed molds were redesigned to work universally with any outer fabric design for the shoe and to allow for an easy extraction of the composite. Another issue is that the fiber composite needs to have perforations in order for the two rubber casts to have a stronger bond. On the edges of the fabric, its clear that because they are independent, they have a tendancy to split from the rubber. Also, because of the difficulty of wrapping the fabric around the mold during the casting process, the fabric was modified with tabs marking where the outermost fabric pieces would be sewn to.

Download the corresponding files here.