|

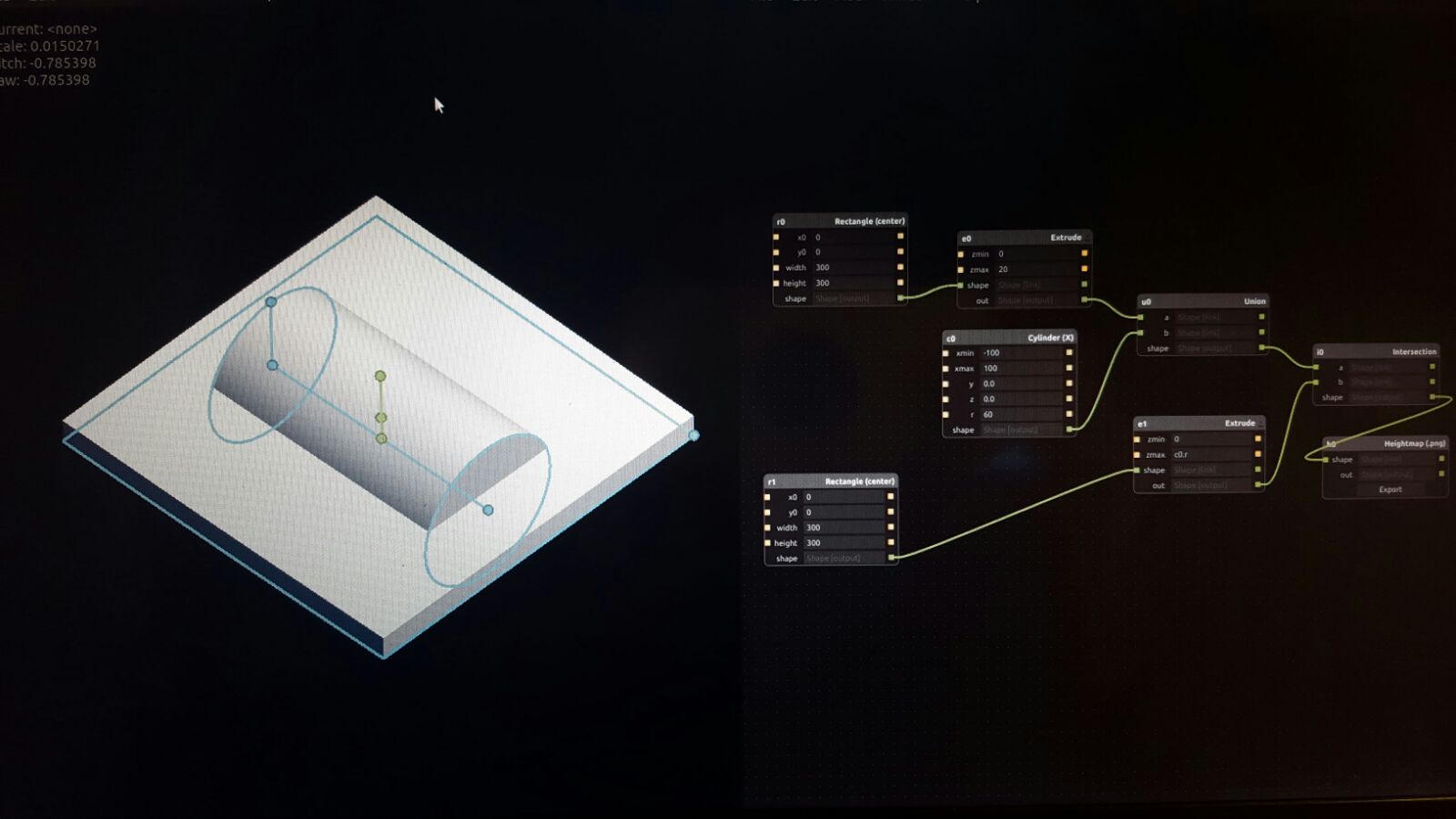

Before proceding for making composites i need to design mold. That would hold the material together to form solid output. For this mold

to be form. Mr.fransisco suggestted me to use Antimony 3D desining software to design 3D mold. Antimony is a special type of Computer-Aided

Design software. With this tool you can program your 3d model, instead of the standard click and drag interface suggested by my instructor Mr.

Francisco. This software is a computer-aided design (CAD) tool from a parallel universe in which CAD software evolved from Lisp machines rather

than drafting

For this i have used antimony software. I enjoyed design on it. Also enjoyed mathematical boolean. I feel it is easy than blender Becoz in

antimony we have to mension dimension and used looping to make design

|

Antimony mold design and nodes |

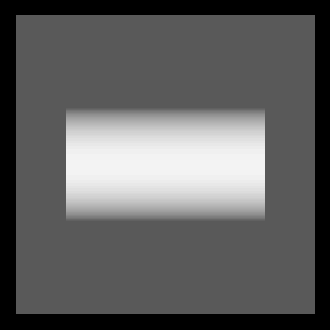

So I made 3D design in antimony.

Export file and save as png file for

|

|

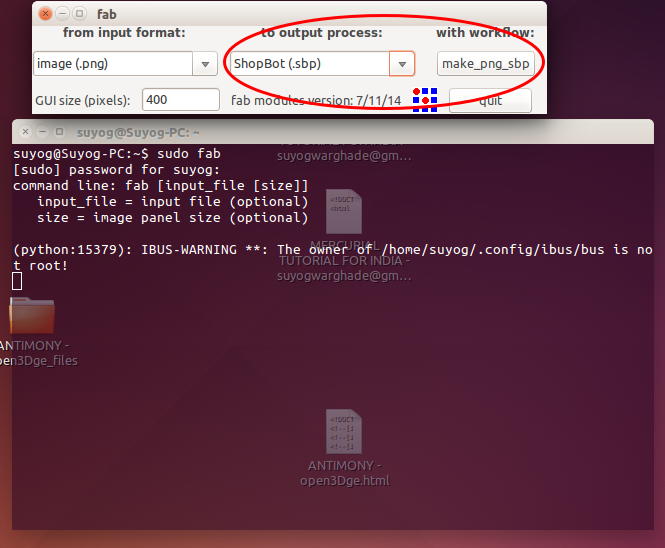

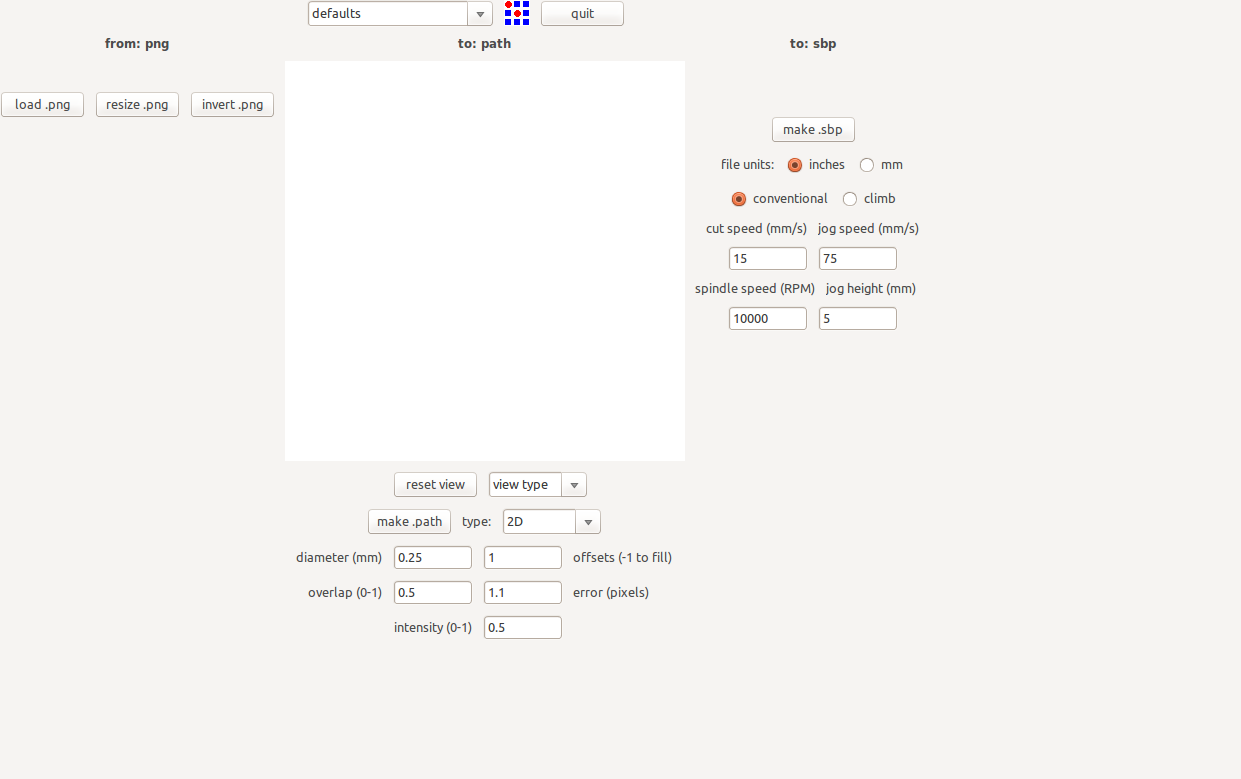

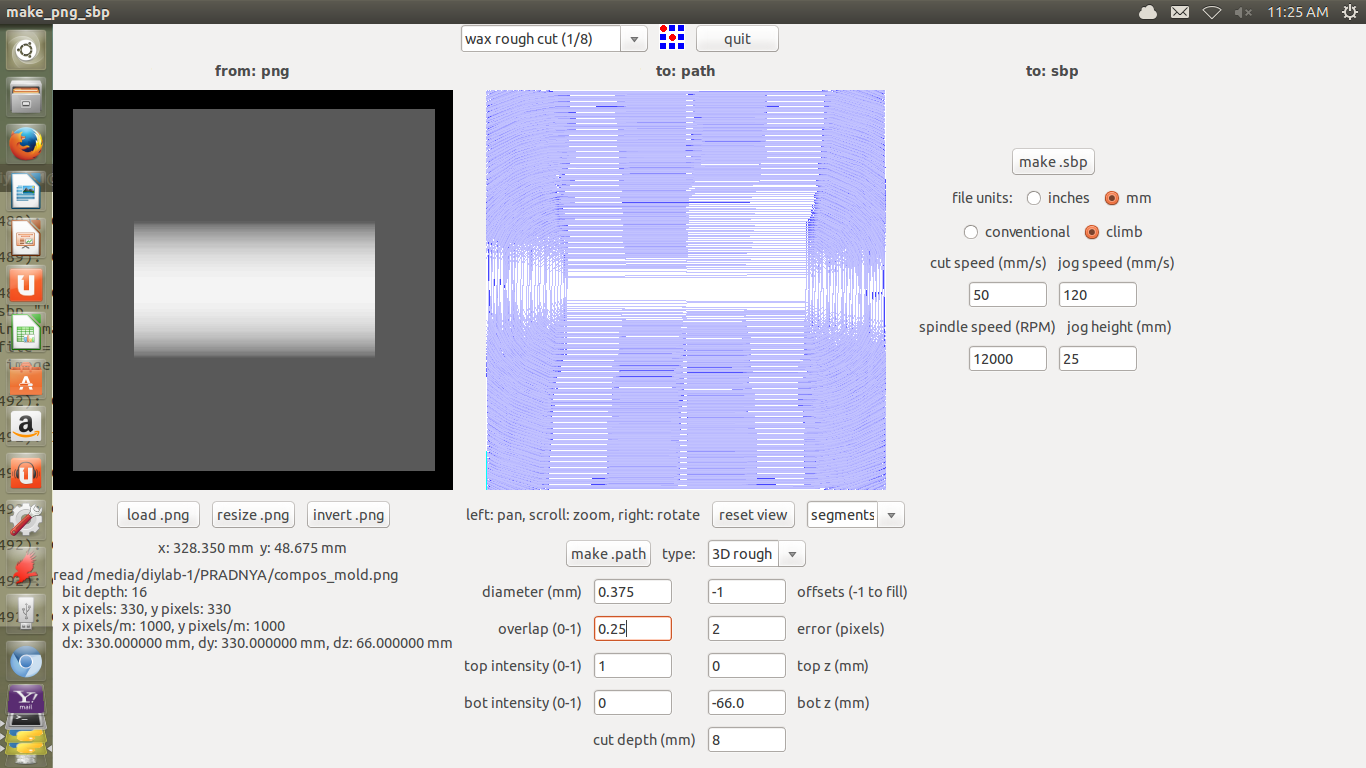

To engrave this mold on wood I have to used shop bot. I used fab modules to generate make file for shopbot.I used the following setting in fab

module

|

|

|

I set the parameter as shown in screen shot.

|

Downloade make file and png image

Our lab has no ShopBot machine. So I cant make the mold on ShopBot. I have used the shopbot as I work on shopbot

during computer controll machining week In CEOP fab Lab

So alternatively I have to form handmade mold. Which I made using wood and plastic bottle.

|

So I made the mold now I have to make actual composite material using rise husk,glue by wheet and treads. For some strength I would hydro stone

First of all I covared mold by plastic transparant tape so that coposites will not stick to it. Then made mixture of rise husk and wheet glue

and littel amount of hydro stone then pour the mixture on mold equally. Wheet glue is sticky and husk will stick with it. hydro stone will give

little hardness.

First step was only base now I have to made bonding using treads.So I placed treads on mixture to give extra hardness pour hydrostone on that treads

|

> > |

Now it needs time to get dry. I have to wait for couple of hours

Its was taking to much time to get dry. I left it for 8 to 9 hours. I thought it is enough to get dry.

I seen the mold it didnt get proper bonding. Wood powder should be used instead of rise husk. Already I have lost time in this week for

3D desining antimony. I will try with wood powder next time

>

>