Week 16

mechanical design, machine design (May 20)

This is probably the week that I encounter the most problems.

First of all, we couldn't find card board that match the tutorial file, the closest card board we found easily caught on fire when laser cut, and our laser cutter is not big enough.

Therefore I design another linear stage that use 6mm material (wood or acrylic) and is small enough to be cut on a 450mm x 600mm laser cutter.

The second problem we (as the whole lab student) encoutered is the Gestalt boards we got. Three out four boards we got is not working. We didn't managed to find out the reason. But since when using the exact same steps and same PC by the same guy (me), only one board works correctly.

For the three that have problem. One will move the motor for less than a second after press the identify button, stop, and shows "could not reach virtual node". The other two have the same problem like many other fablab students, clicking the button just don't trigger any respond. (One of these two get really hot when connect to power )

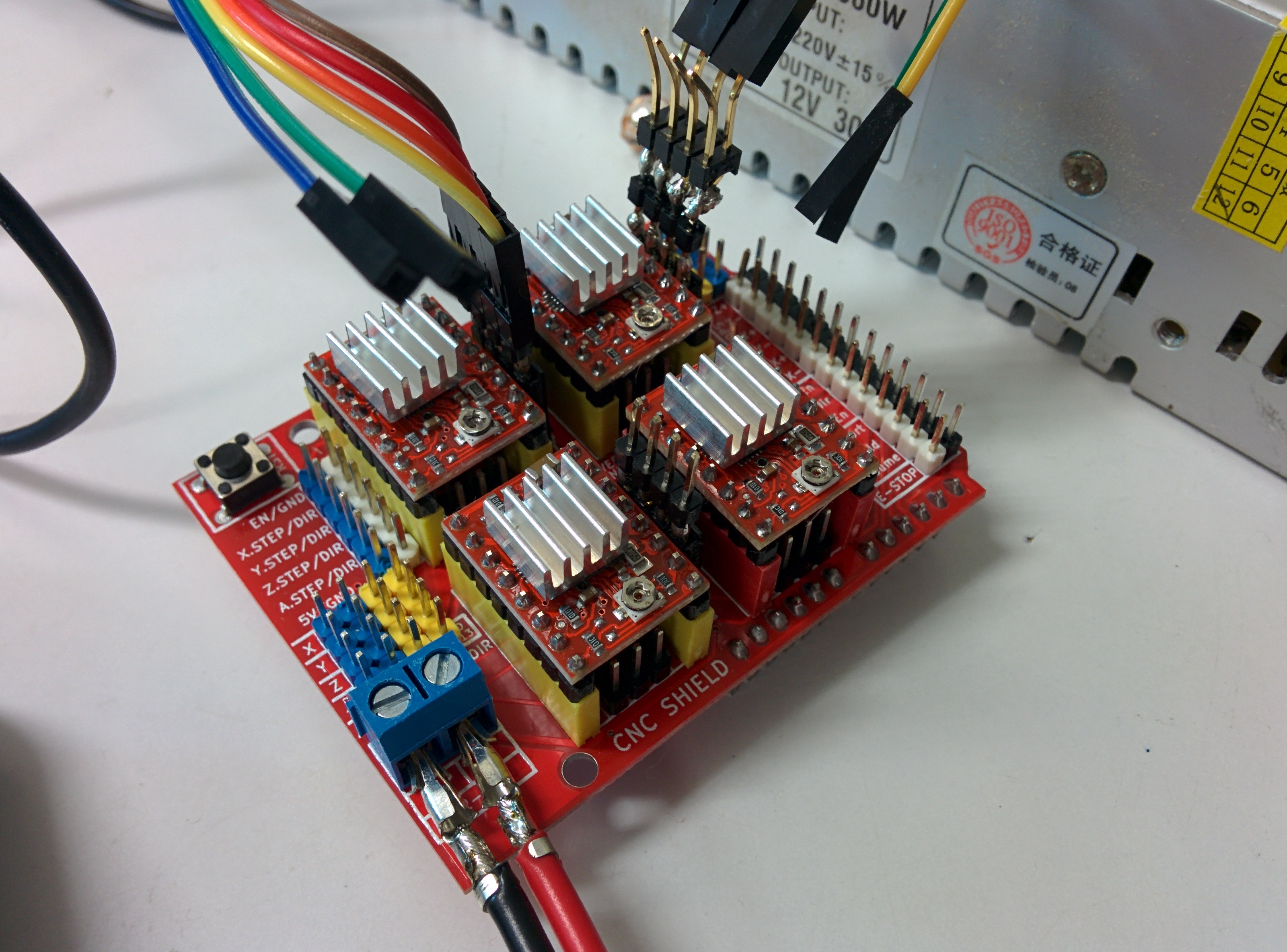

Because of the above reason, we are forced to use a more traditional approach: using an Arduino UNO running grbl with CNC shield for the machine presentation.

Making of the Stage

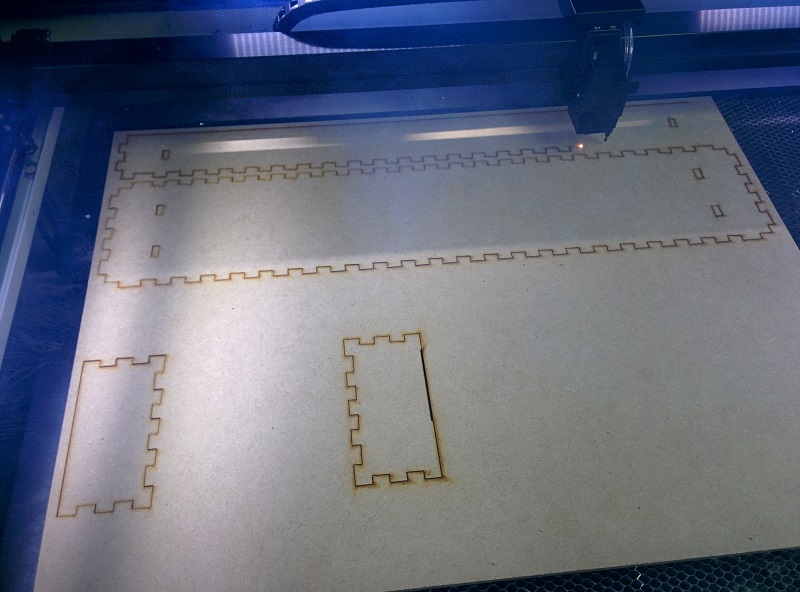

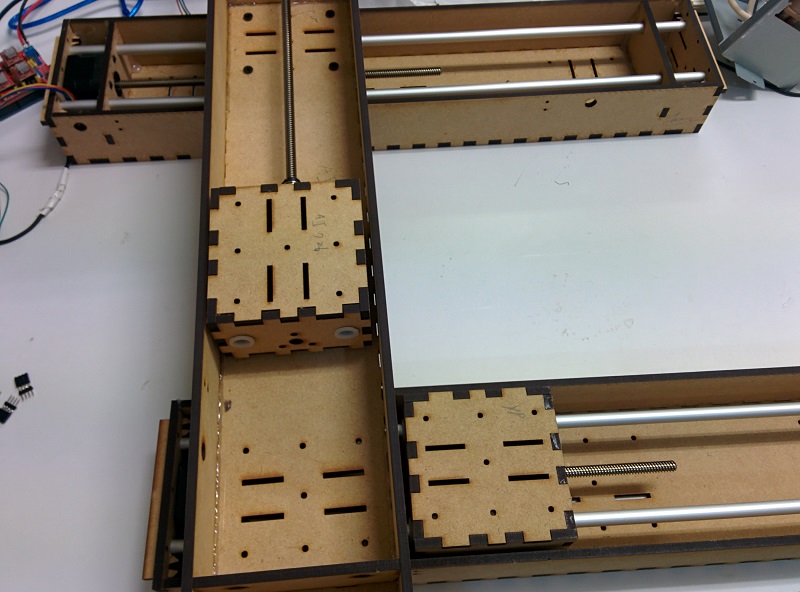

Small enough to be cut on a 450mm x 600mm laser cutting area.

Small enough to be cut on a 450mm x 600mm laser cutting area.

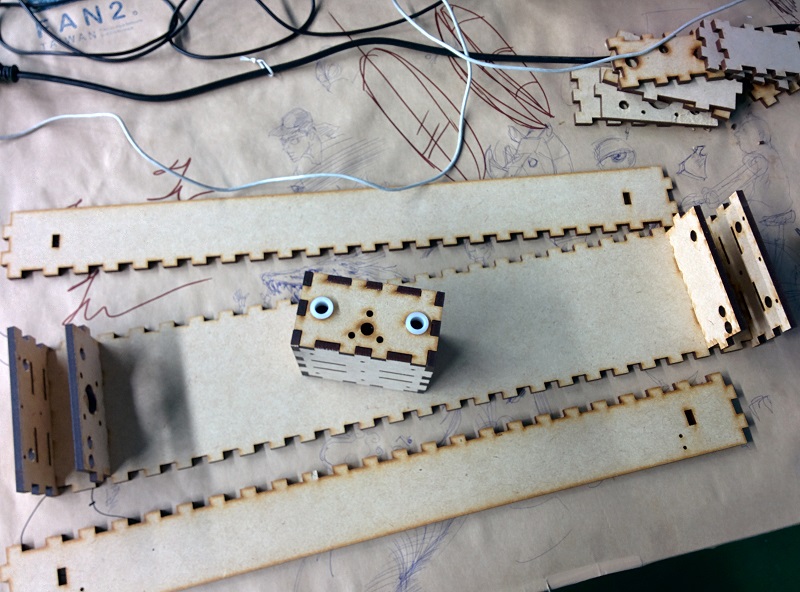

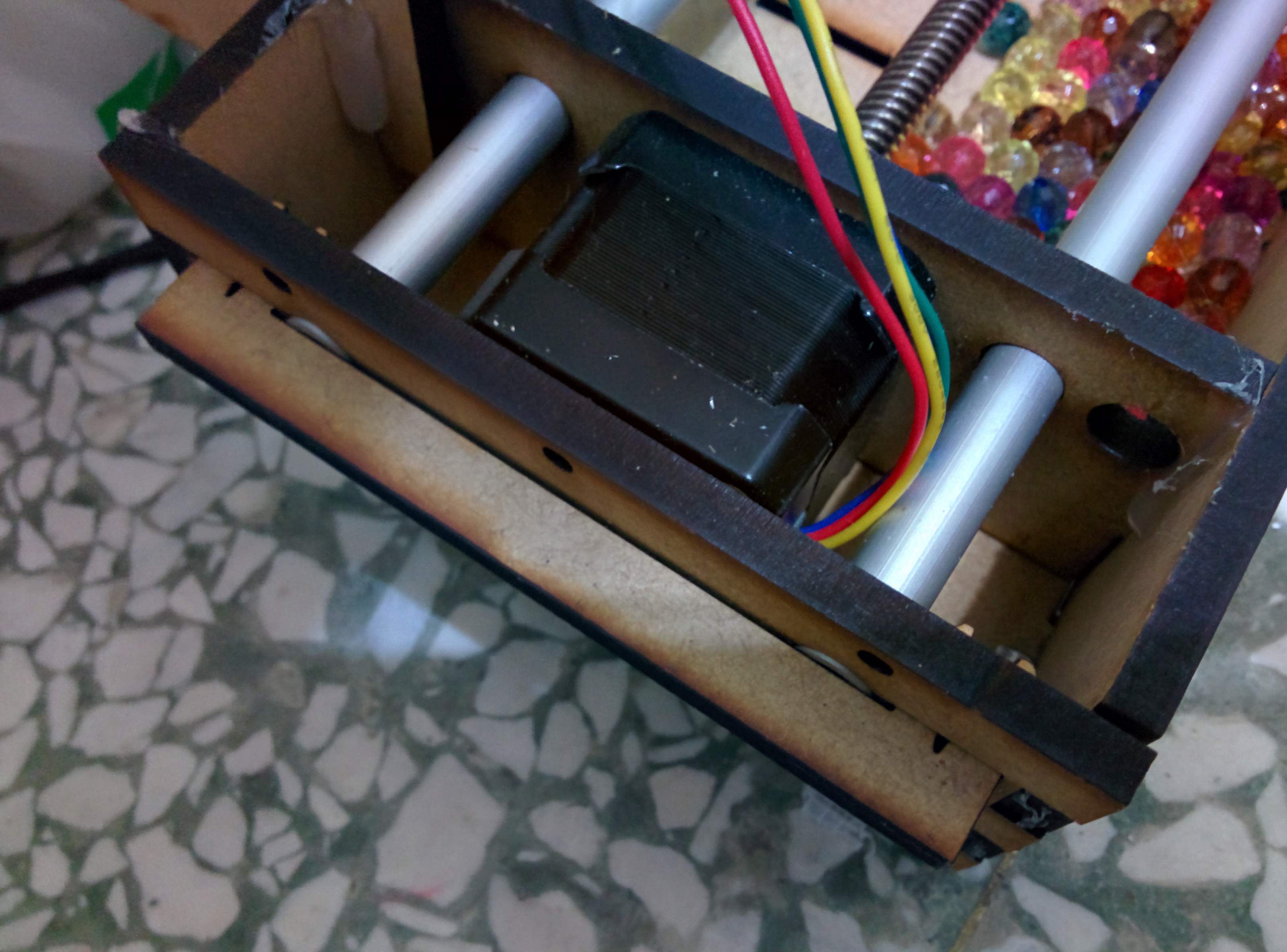

Assembling the first version of the stage, which doesn't have the screw hole pattern yet.

Assembling the first version of the stage, which doesn't have the screw hole pattern yet.

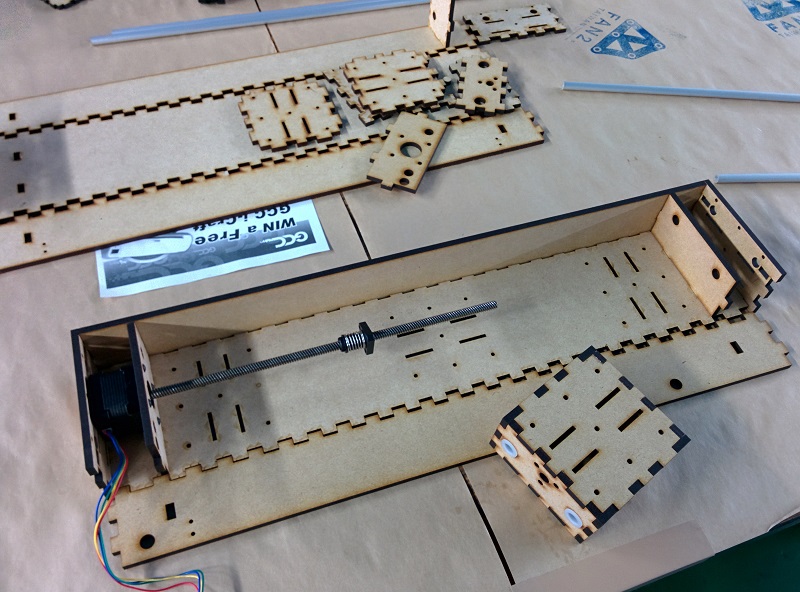

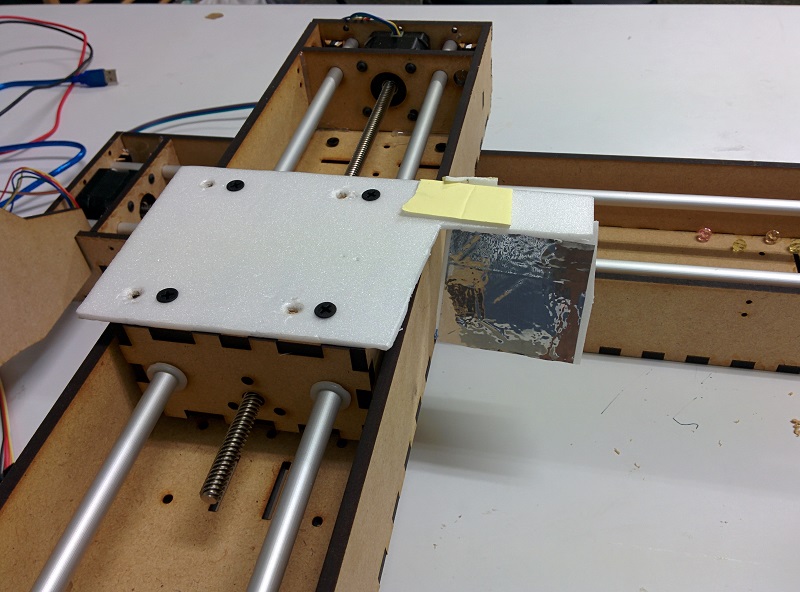

Almost finish assembled secondversion of the stage.

Almost finish assembled secondversion of the stage.

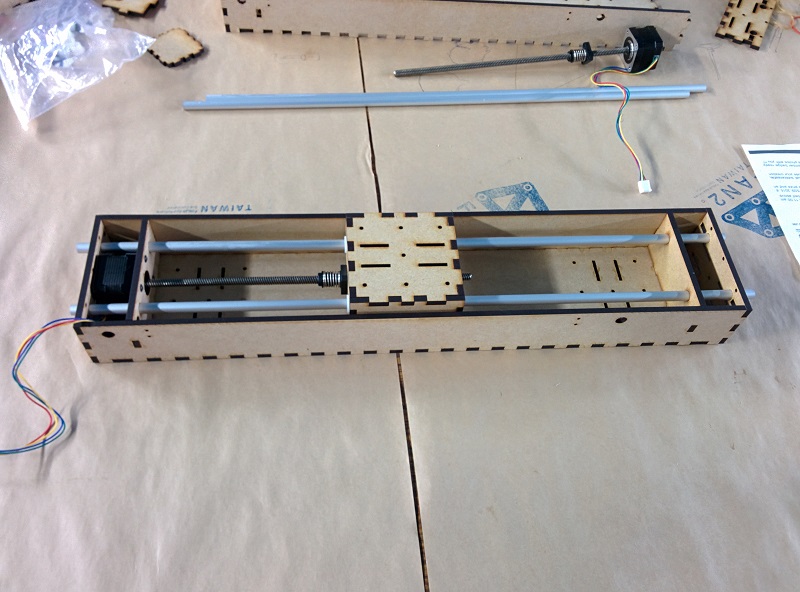

Finished linear stage, notice the longer aluminum smooth rod, which will be cut and retain in the next step.

Finished linear stage, notice the longer aluminum smooth rod, which will be cut and retain in the next step.

After cutting the aluminum rod into size, the retaining clip can be snap in and keep the rod in place.

Other than the broken boards, I managed to get Gestalt working without much problem.

A video showing the only working Gestalt board moving the linear stage.Machine Building

We orginally desided to build a automatic sand drawing zen garden using glass sand, and have a laser shoot into the glass sand to creat an lighted zen garden.

However we couldn't find anywhere that sell small enough quantity of glass sand, the least amout is 25 kg......

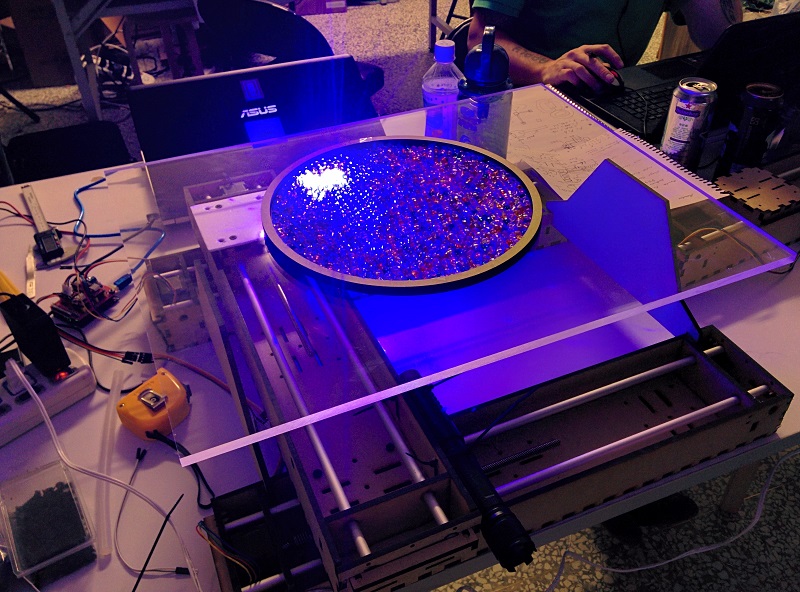

In the end, we use clear plastic beeds instead, and have the stages move the laser to shine into the plate of beeds to creat a cool light show on the roof.

Because of the pre-designed screw hole patterns, putting the stages together is a simple matter of screw in a few screw to connect them.

Super easy laser reflector that was broken and fixed twice....

The laser is mount on the side because of the length. ALso the pretty beeds~

The laser is mount on the side because of the length. ALso the pretty beeds~

This shows the path laser need to go through before shine through the beeds.

This shows the path laser need to go through before shine through the beeds.

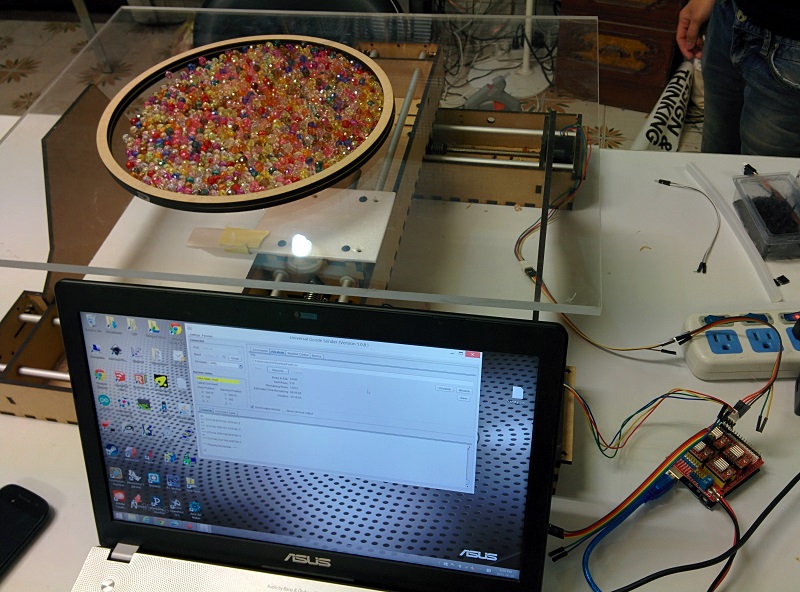

As I mentioned above, we use CNC shield and grbl to control the machine.

On the PC side, I use Cambam to generate G-code, and use Universal G-code Sender to send the g-code to the CNC shield.

On the PC side, I use Cambam to generate G-code, and use Universal G-code Sender to send the g-code to the CNC shield.

Laser shining through the plate of glass beed from below.

Laser shining through the plate of glass beed from below.

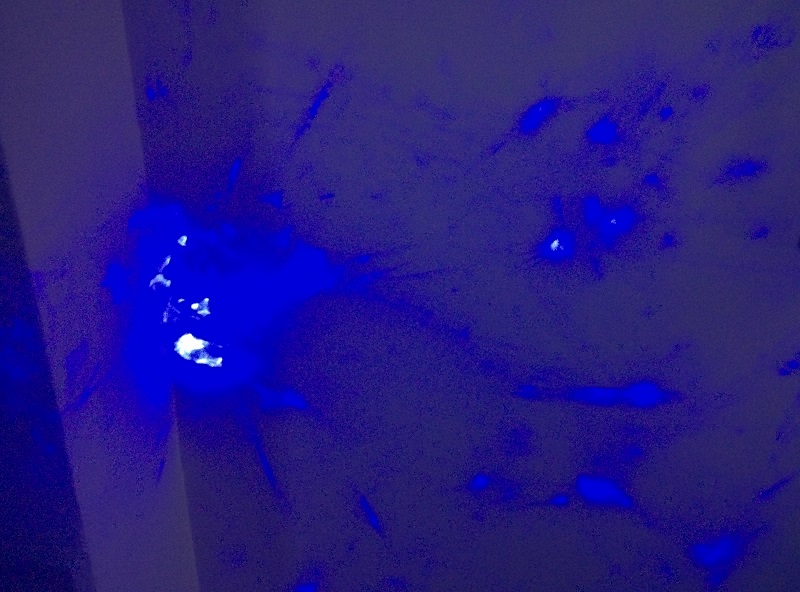

Apparently, camera doesn't like laser, this photo doesn't do the light show justice at all! The light pattern is like water reflection of sun light and change shape in a really soothing pattern.

Apparently, camera doesn't like laser, this photo doesn't do the light show justice at all! The light pattern is like water reflection of sun light and change shape in a really soothing pattern.