Week 12

composites (Apr 22)

For this week, I'm going to make the top shell of my final project. The shell will house the electronic of the final project for protection.

The 3D design is done in Rhyno, which is much easier for drawing organic shape compare to Sketchup. Although also need to pay attention about broken face of the model.

CNC out the Mold

I happened to have a piece of really thick balsa wood, so I decide to give it try as a mold.

After rough cut of the mold.

After final cut of the mold.

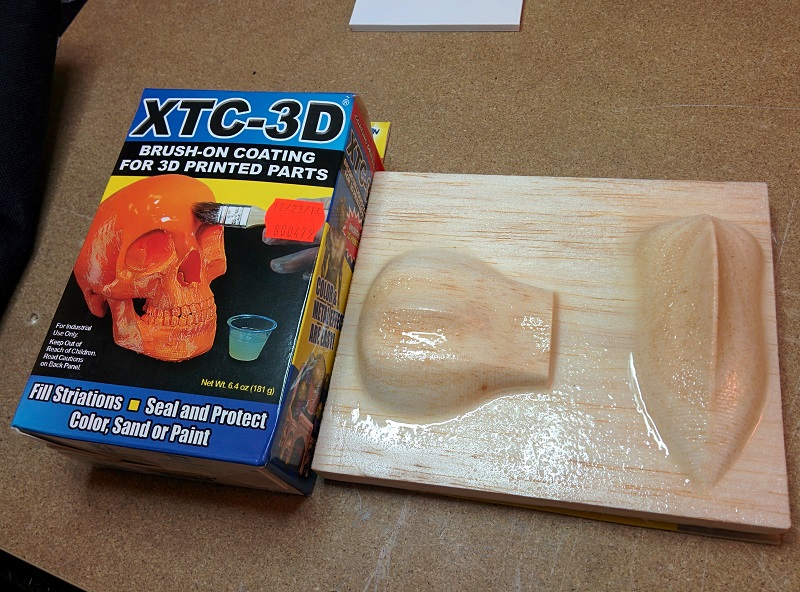

Since the wood have wood grain and CNC's lines, I decide to use XTC-3D to smooth the surface of the mold first.

It take a while to dry and harden, but the result surface is quite smooth.

For mold release, Smooth-on's Universal Mold Release is used.

Makeshift Resin Resorvoir for the vacuum pump

Instead of buying one, I decide to make a simple resin resorvoir for keeping the resin from getting into the vacuum pump.

I drill two holes to a glass buttle cap, and insert a copper pipe and a tubing through. Hot glue is used to hold both tube in place while keeping the cap air tight.

This is the set up I'm using to do the vacuum bag pressing.

The vacuum pump will pump the air out from the copper pipe, and the bottle will filter out any resin that make it's way inside the clear tube.

With the great result of oomoo, I decide to also use Smooth-On's epoxy to do the composite.

I went a little fancy and use carbon fiber for the composite.

Vacuum pumping the Mold

I use a modified bicycle pump for vacuum pumping the mold.

The bicycle have two reversed one way air valve that I made, which reverse the air direction inside the pump. It's not as strong as a real vacuum pump, but works ok for my mold, since I'm after the look more than the strengh of the shell.

Pumping the air and keeping the vacuum with a clamp on the tube.

The extra resin is clearly being squeezed out the carbon fiber and being obsorbed by the cloth layer.

I waited 24 hours and open the bag.

The bag is easily peeled off, same for the cloth and peelply.

but not the mold.....

I have to brute force the wooden mold off the caron fiber shell.

At least now I know that Universal Mold Release doesn't work on HTC-3D.

Cleaning the composite shell

The part turned out better than I though consider it's my first try with some makeshift tools.

Only the concave part have a bit too much resin.

With some trimming, the shell is ready for the final project!

As an after thought: I should have realised that carbon fiber is conductive, which makes a bad material for electronic housing, even though this didn't cause any trouble in final project.