Week 05

3D scanning and printing

For this week, I have three assignments:

1. Design and 3D print an object (small, few cm) that could not be made subtractively

For the first one, I decide to use Rhino as a practice to recovery my Rhino skill, since I haven't been using it for years, and recently decided Sketchup is not enough for my need. The object I'm going to make is one of the parts of a new open source 3D scanner, Ciclop, a line laser holder. The reason to ramake it is because the original file is for lasers with diameter of 8mm, and the line lasers I have in my possession are 12mm in Diameter.

2. 3D scan an object (and optionally print it)

Since I don't believe my Ciclop 3D scanner won't be build in time, I'm still going use a Kinect as a 3D scanner to scan myself with a software called Skanect.

3. Building a 3D scanner

For me, after trying 3D scanning with Kinect, I decide to also build a 3D scanner that can scan small objects, because the poor performance of Kinect when scan anything smaller than 30cm high. As mentioned above, the 3D scanner I'm going to build is Ciclop, a newly open sourced 3D scanner that use two line laser and a webcam to scan small objects on a turntable. Since everything is open source and I just learned how to mill PCB, I'm even going to make the PCB from scratch. This will probably take more than a week, but I will come back here to update the progress.

Laser holder stl file.

Idelarm stl file.

3D scaned stl file of me.

3D scaned ply file of me.

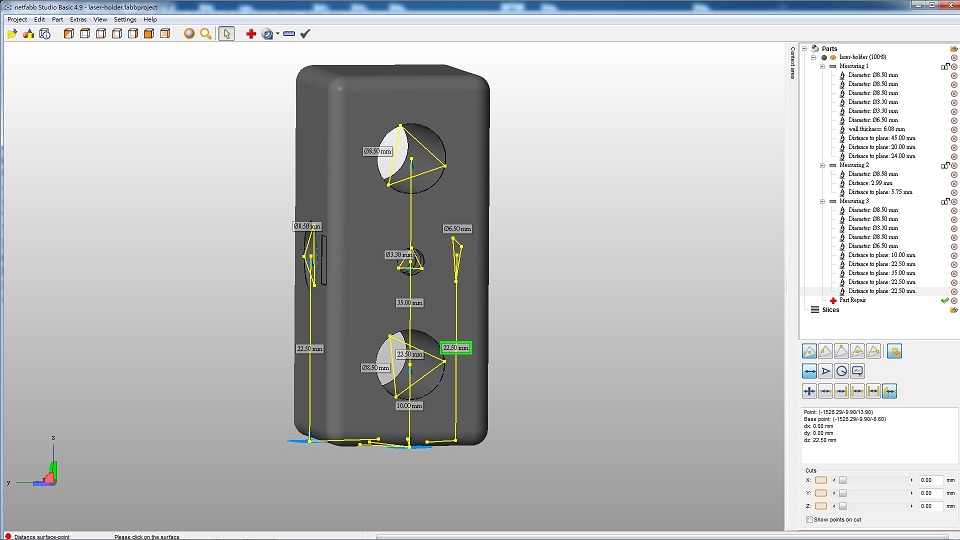

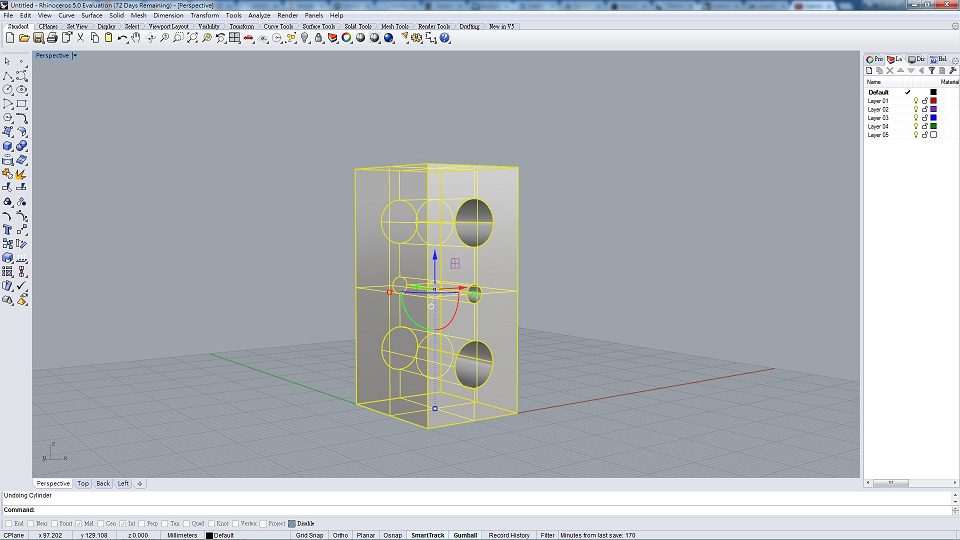

Using the dimentions I measured in Netfabb, I start drawing the part with a different sized laser holding hole.

Using the dimentions I measured in Netfabb, I start drawing the part with a different sized laser holding hole.

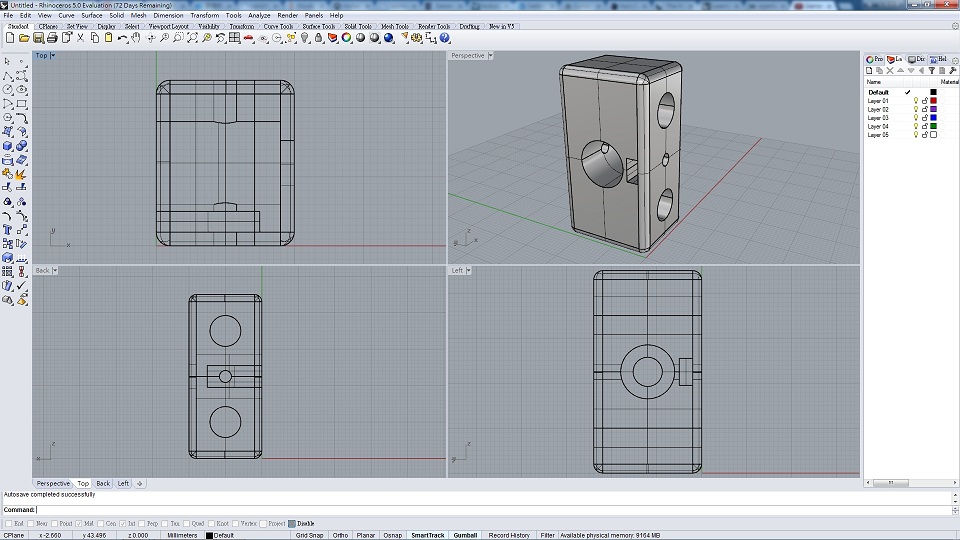

Fillet is one of the functions Sketchup is lacking without plugins, yet very important for a last minut refinement.

Fillet is one of the functions Sketchup is lacking without plugins, yet very important for a last minut refinement.

And here is the new improved part with much more reinforcement, and also a tilted screw hole to compensate the flexablity of PLA.

And here is the new improved part with much more reinforcement, and also a tilted screw hole to compensate the flexablity of PLA.

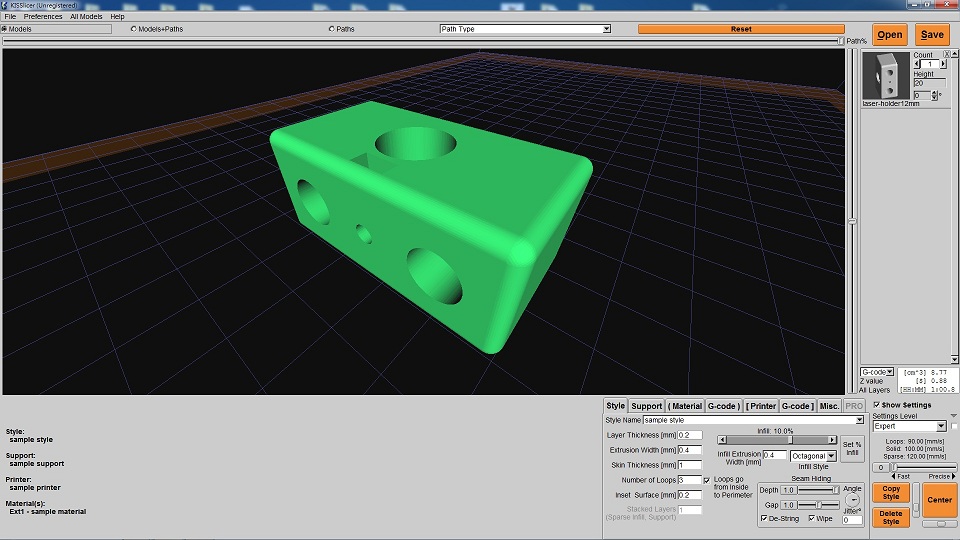

Another good thing about KISSlicer is how fast it can slice, at least much faster than slic3r :p

Another good thing about KISSlicer is how fast it can slice, at least much faster than slic3r :p

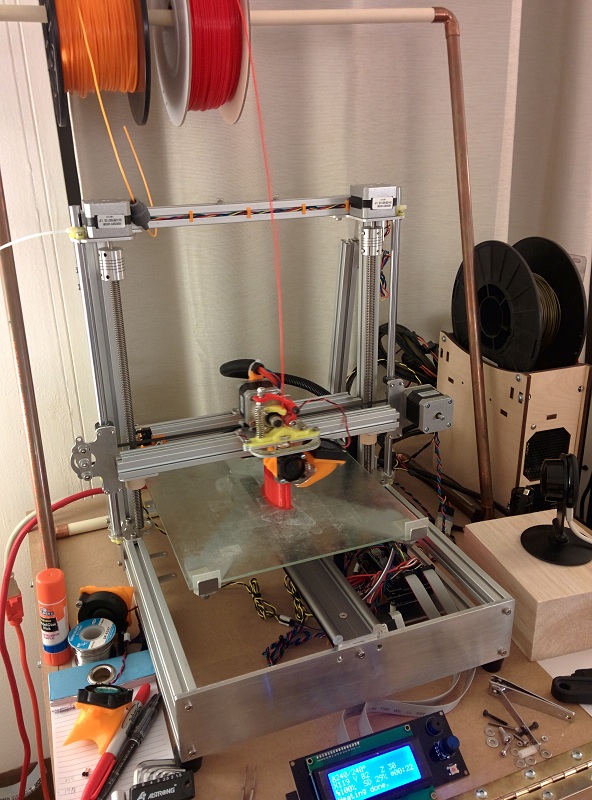

I use PLA for these parts and use glue stick for print bed adhesion.

I use PLA for these parts and use glue stick for print bed adhesion.

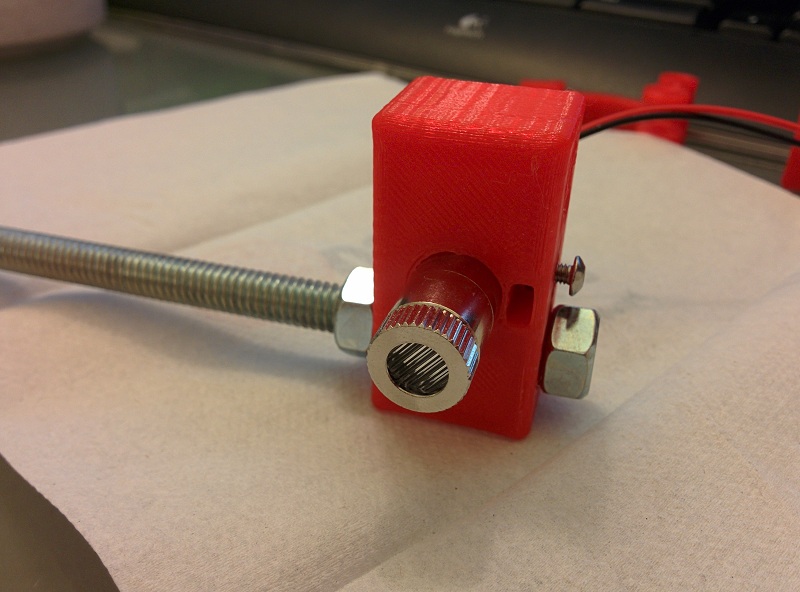

The part with both laser, holding screw, and threaded rod installed.

The part with both laser, holding screw, and threaded rod installed.

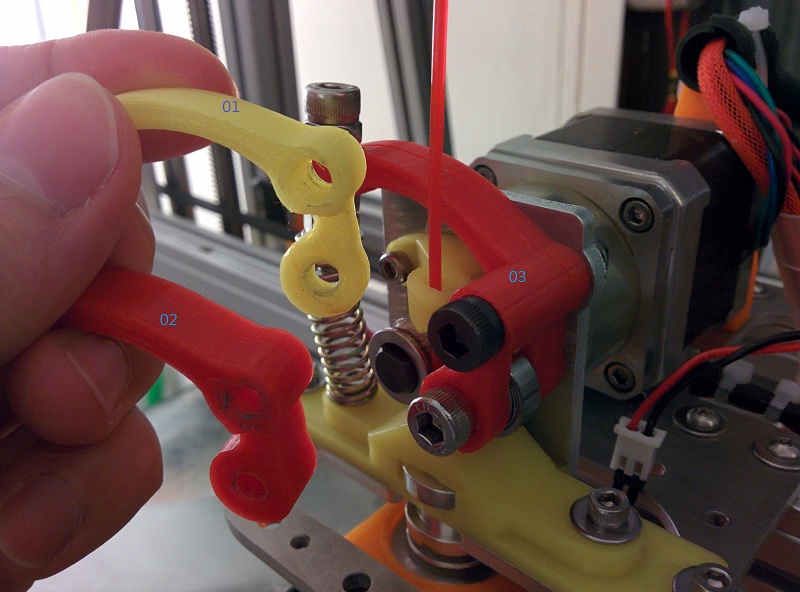

A comparision of the original part(01), the slightly modified part(02), and the final design(03) installed on the 3D printer.

A comparision of the original part(01), the slightly modified part(02), and the final design(03) installed on the 3D printer.

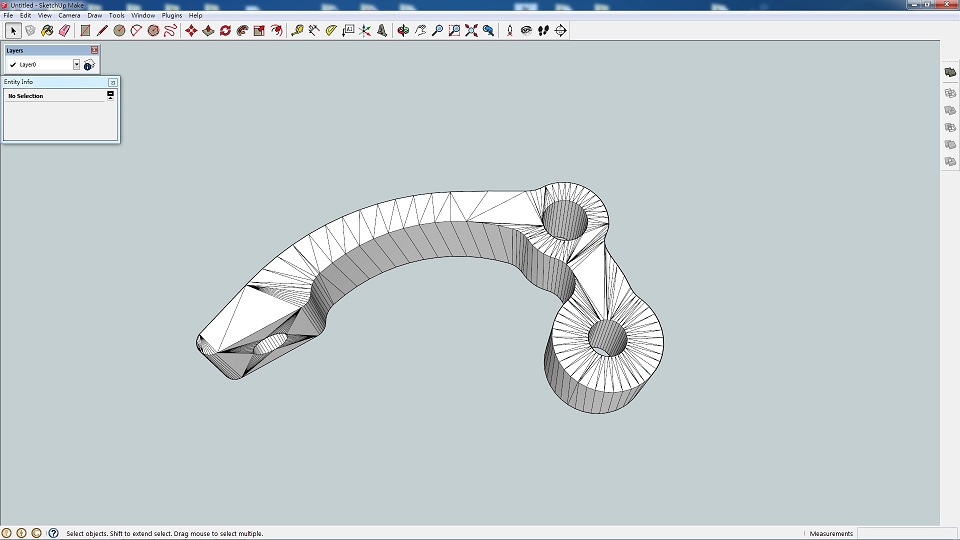

The result is ok, with only broken on the flat of my hat.

The result is ok, with only broken on the flat of my hat.

Right not I'm happy just to not make the model worse...

Right not I'm happy just to not make the model worse...