Week 04

Electronics production (Feb 18)

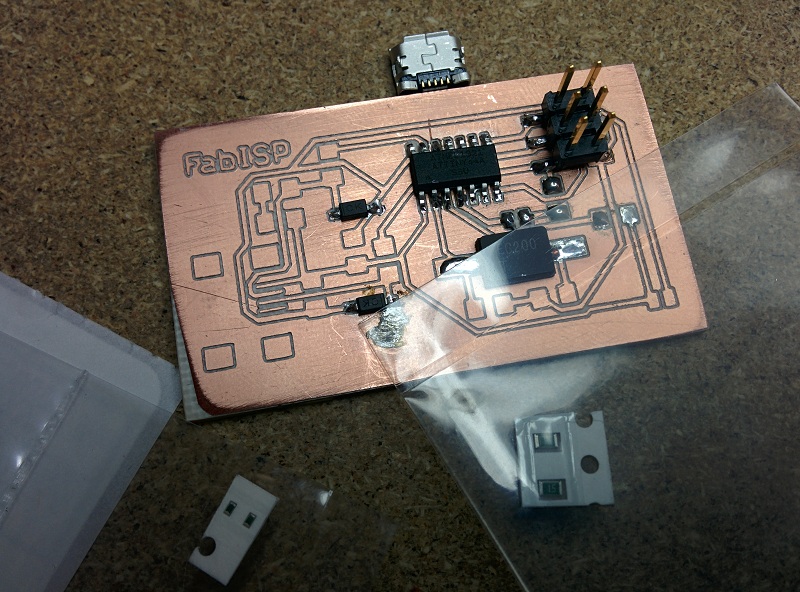

This week, we are instruct to make the FabISP in-circuit programmer from the given file of pcb drawing. The recommended way is to use Fab Module to do the compuer side of work (CAD/CAM). However I decided to go the other rout, since I had a bit experience with Fab Module already, and would like to try a more hobbyist friendly way of making PCB.

For "hobbyist friendly", I refer to using a more commenly avaliable hobbyist CNC machine, instead of Roland MODELA milling machine, which usually cost over USD 2000 at least. For this reason, I will be using a Shapeoko 2 CNC, which is only USD 1000, and are comparable if not more capable tha MODELA in my honest opinion.

On the software side, there are two different routs I'm going to try. Even though Shapeoko 2 uses grbl arduino shueld as g-code interpreter, there is a web-based CAM/CAD program called "Easel" (www.easel.com ), that can provide a one stop solution from basic drawing to control the CNC without user touching any g-code files just like Fab Modules. And the second rout is the more traditional using a CAM program to generate g-code files, and using a host program to send the g-code files to grbl shiled.

Fab ISP dxf File.

Fab ISP svg File.

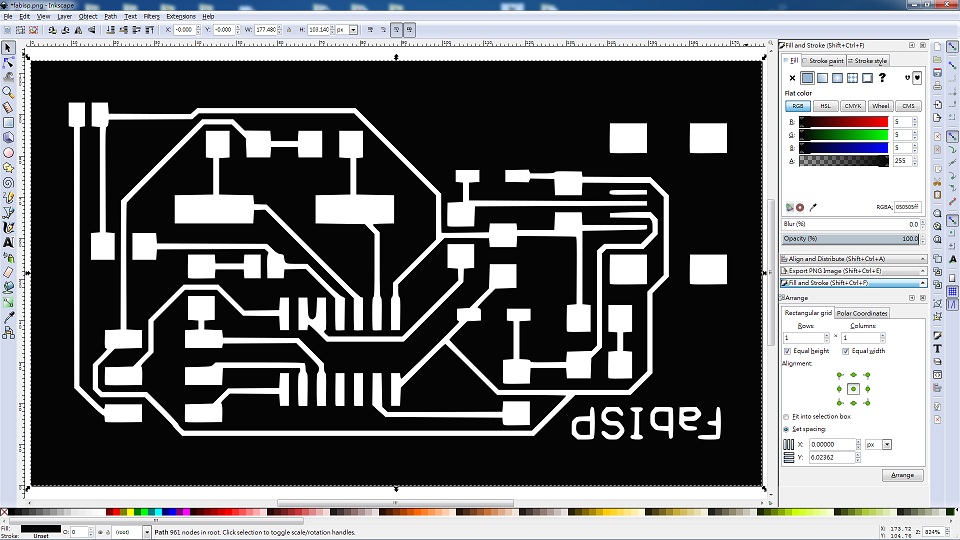

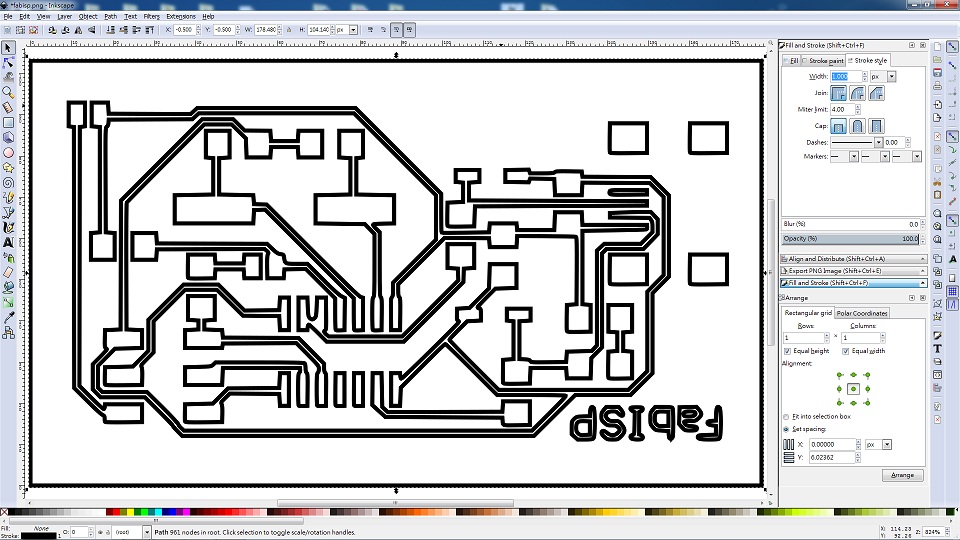

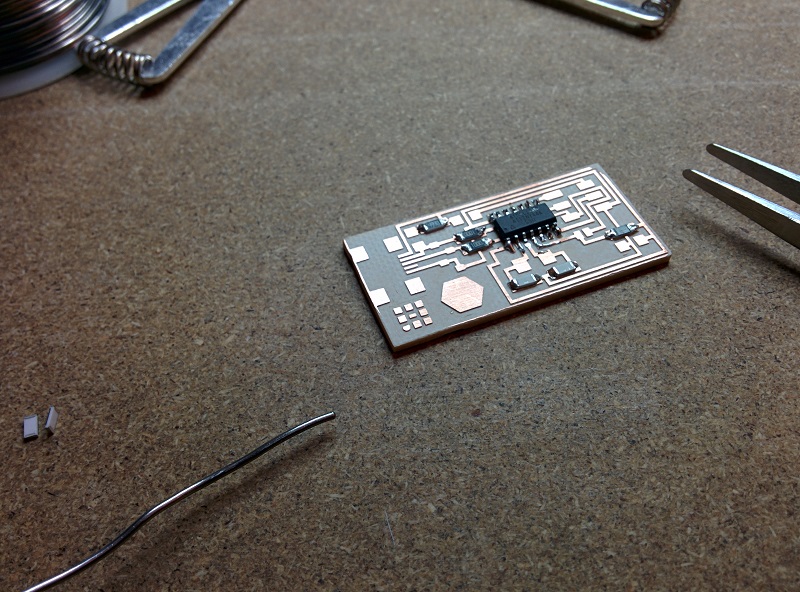

For testing purpose, I also make one SVG files with only "stroke" of the pcb, and without "fill". I'm curious how fast can I save on milling time, and how much harder will it make soldering become. (Normally, all the black area on the picture above will have to be milled out. With only stroke, the CNC only need to mill out the deperation line, whcih should cut down the milling time significantly. )

For testing purpose, I also make one SVG files with only "stroke" of the pcb, and without "fill". I'm curious how fast can I save on milling time, and how much harder will it make soldering become. (Normally, all the black area on the picture above will have to be milled out. With only stroke, the CNC only need to mill out the deperation line, whcih should cut down the milling time significantly. )

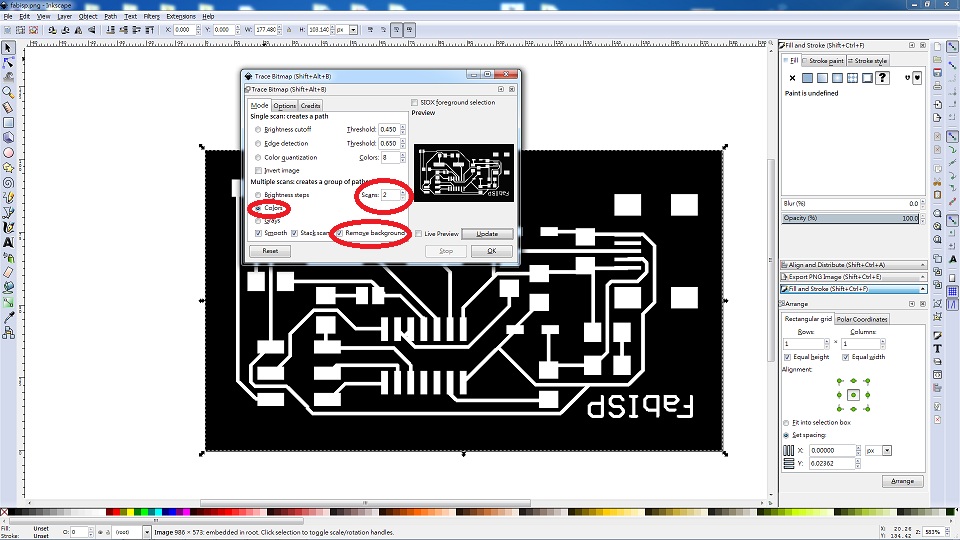

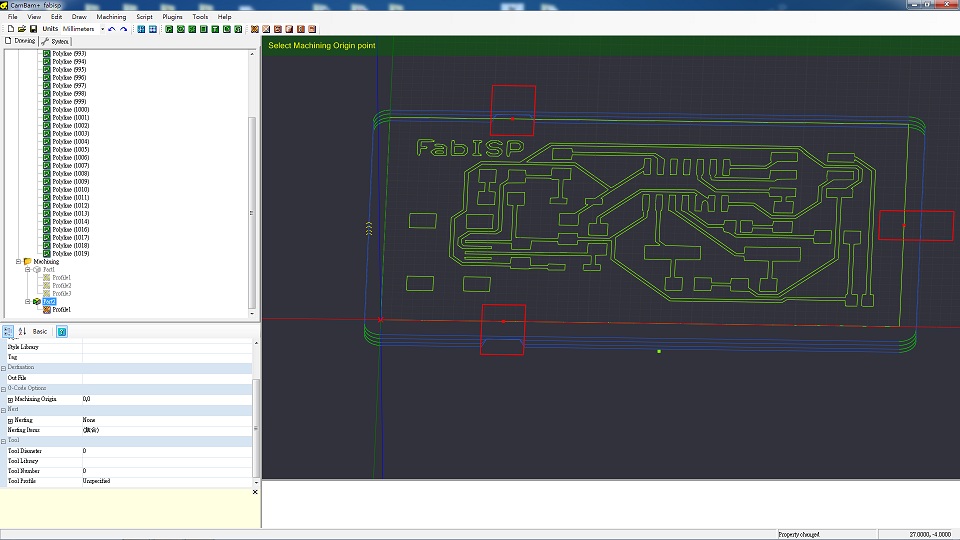

and also make sure "Remove background" is selected, or the entire face of the pcb will get milled out! (See the two big squares in the middle? yeah, don't do that...)

and also make sure "Remove background" is selected, or the entire face of the pcb will get milled out! (See the two big squares in the middle? yeah, don't do that...)

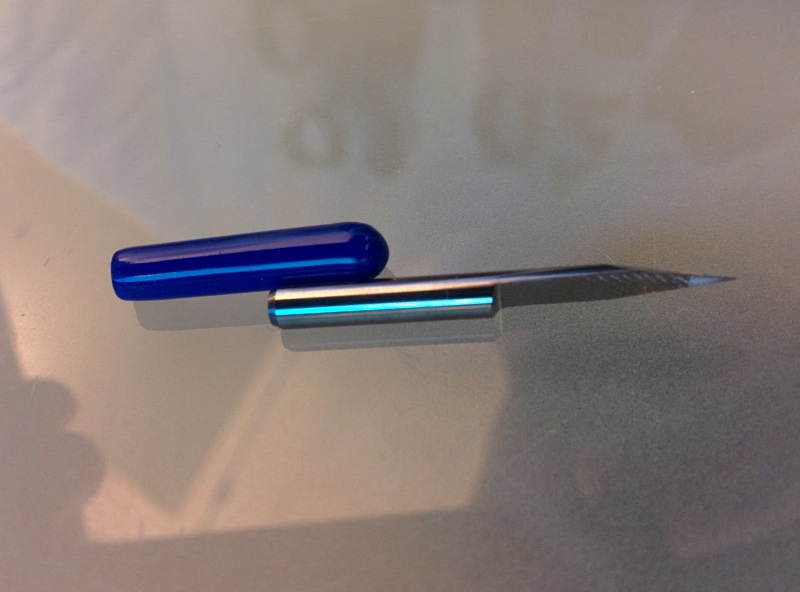

400 grid Sand paper can easily remove all the burr from the edge of the traces.

400 grid Sand paper can easily remove all the burr from the edge of the traces.

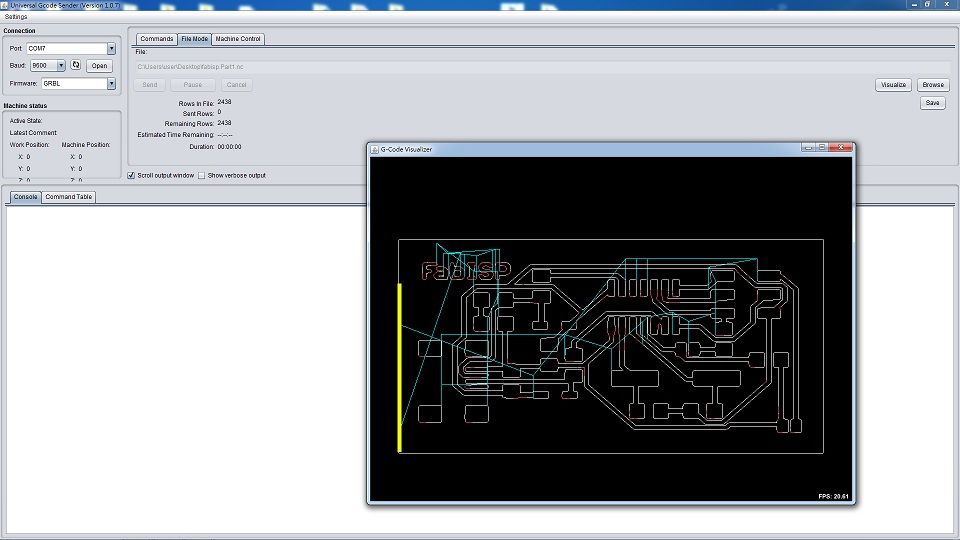

For sending the g-code files CAMBAM generated to CNC, I use Universal G-code Sender, which is really simple compaers to 3D printer's host program like Repetier-Host.

For sending the g-code files CAMBAM generated to CNC, I use Universal G-code Sender, which is really simple compaers to 3D printer's host program like Repetier-Host.

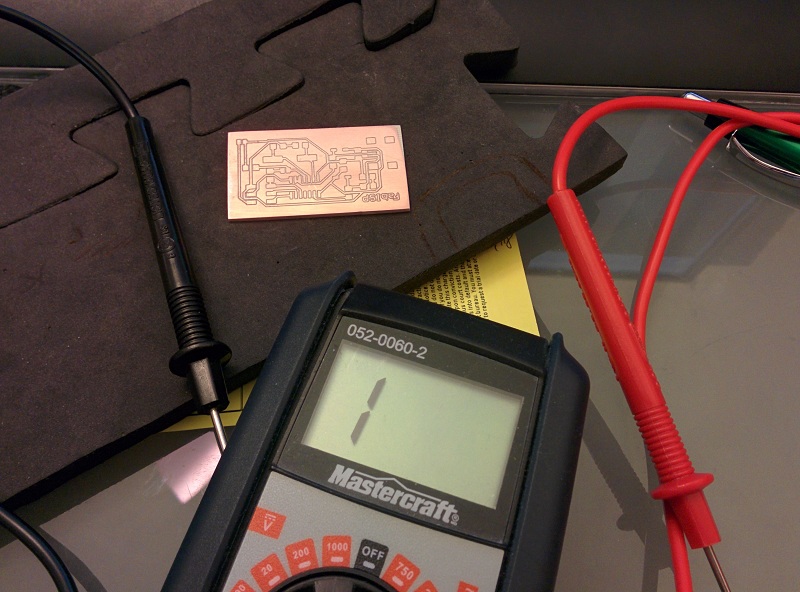

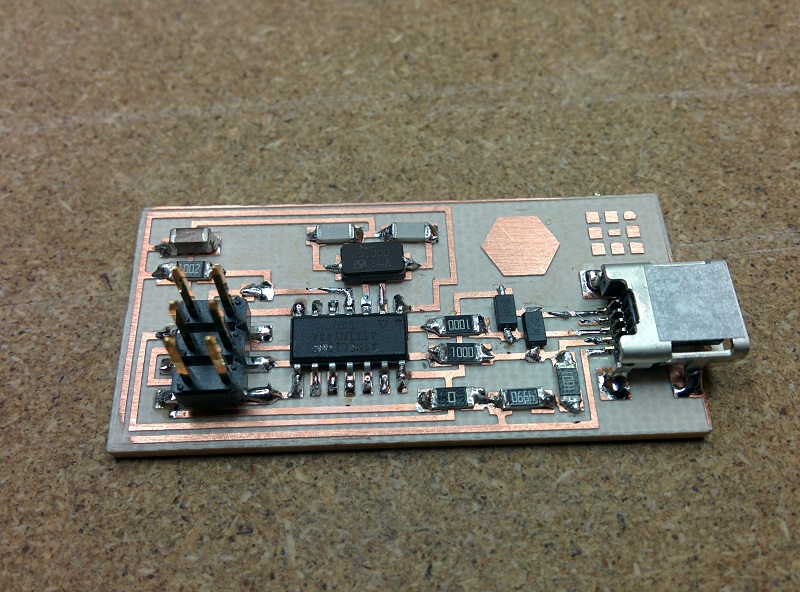

Start putting on solder and solder the component by hand,

Start putting on solder and solder the component by hand,

It's so much easier to solder without unused copper everywhere.

It's so much easier to solder without unused copper everywhere.

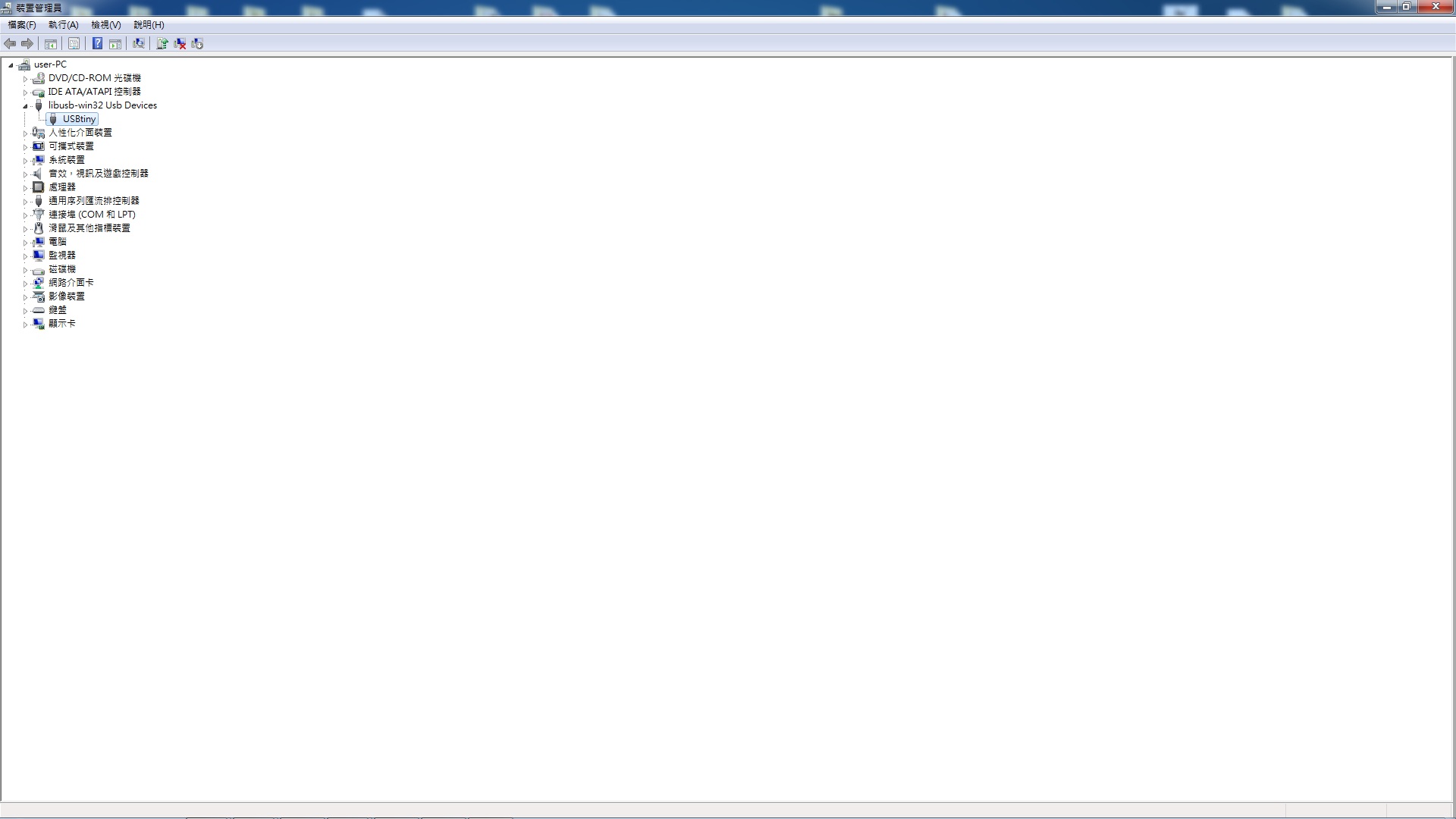

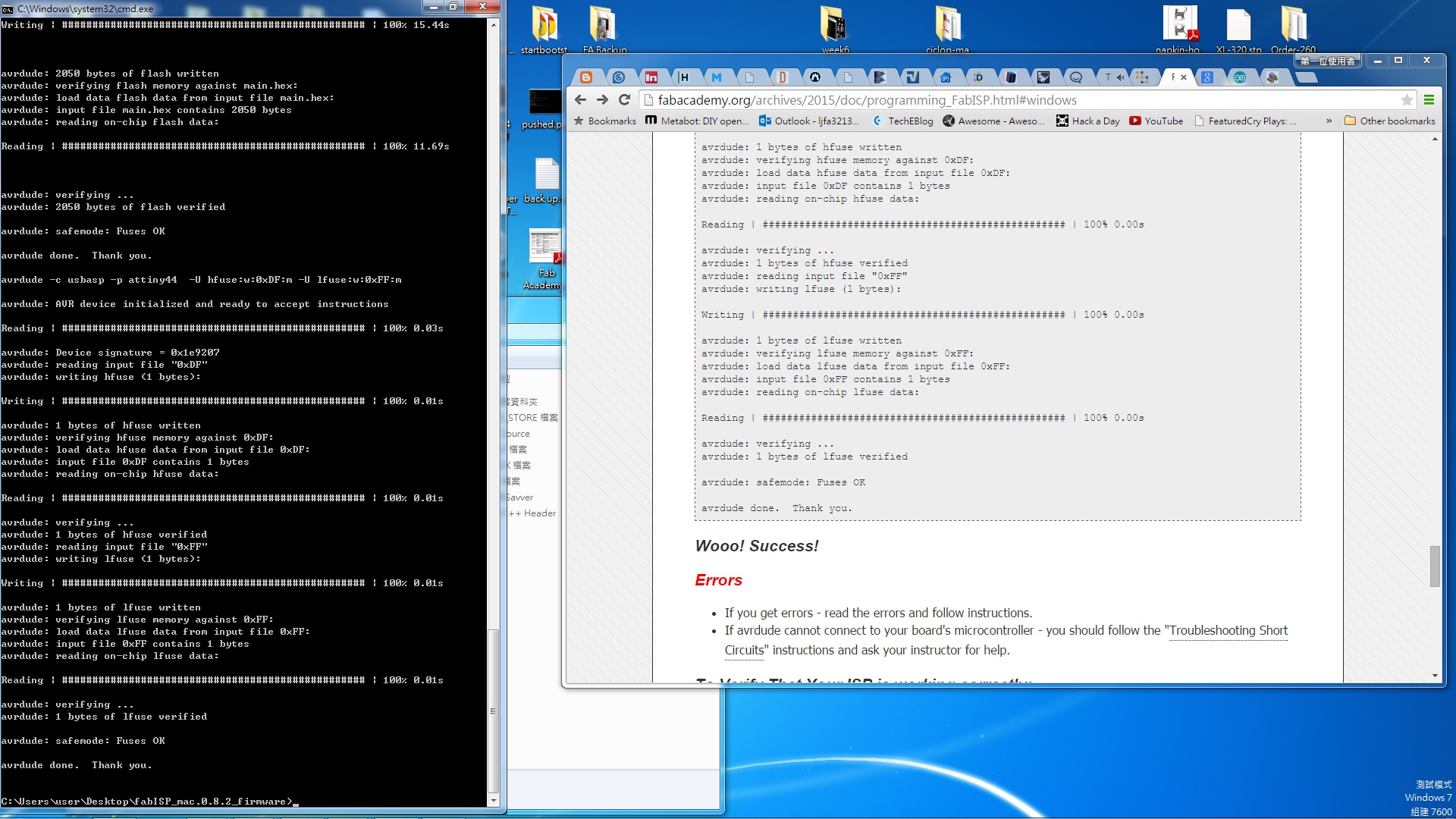

Instead shows up as FabISP, mine shows up as USBtiny in the control pannel.

However, since it works flowlessly when programing my hello world board, it's probably just Windows trying to get attention :p

Instead shows up as FabISP, mine shows up as USBtiny in the control pannel.

However, since it works flowlessly when programing my hello world board, it's probably just Windows trying to get attention :p