Assignment Week15

Interface and application programming

This week’s assignment is "propose a final project that integrates the range of units covered:”.

I answered below questions.

What will it do?

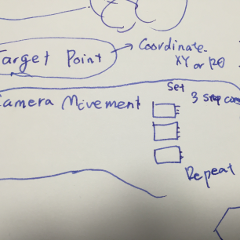

I will make Robotic cinema camera. It can move and shoot a movie, following simple camera work what I order.

If I turn on power, Robot starts movement. This camera can be set shot direction.

Robot moves and keeps direction of shooting object.

This is my laf sketch.

Who's done what beforehand?

I found lower product. It can follow-up a moving object in automatic.

This project is very interesting and similar with my project.

But my project don't have automatic tracking function. For shoot a movie, this function is not enough. Because, movie is expression. It can’t by machine.

Technique of layout of screen is very deep.

So, If we shooting cinema, camera should be moved by human intention.

What materials and components will be required?

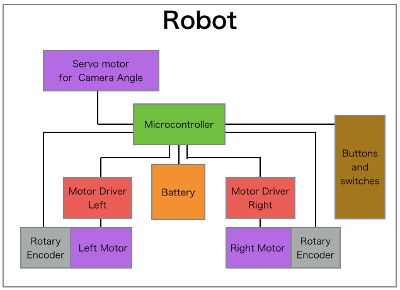

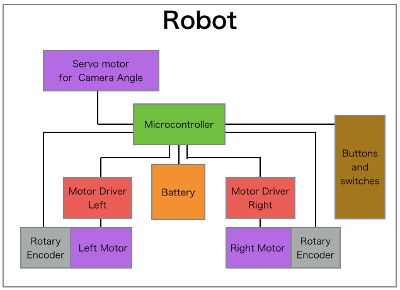

>Electronics

Geared DC motor for move machine and camera.

Micro computer for calculate machine’s movement

Rotary encoder for detect machine’s speed

LED for indicate condition

>Mechanic

MDF T=5.5mm

acrylic T=3-5mm

PLA for 3D print

Gear box for Toy

Parts for tire

Where will they come from?

>Electronics

Geared DC motor : DIY ceter

Micro computer : My FabLab

Rotary encoder : Internet shop "Akizuki

LED : My FabLab

>Mechanic

MDF T=2.5mm : DIY ceter

acrylic T=3-5mm : DIY ceter

PLA for 3D print : My FabLab

Gear box for Toy : DIY ceter

Tire parts : DIY ceter

How much will it cost?

>Electronics

Geared DC motor : 1500JPY x3

Micro computer :500JPY x2

Rotary encoder : 500JPY x2

LED : 50JPY*4

>Mechanic

MDF T=2.5mm : 1000JPY x2

acrylic T=3-5mm : 1000JPY

PLA for 3D print : 1000JPY

Gear box for Toy : 800JPY x2

Tire parts : 500JPY

What parts and systems will be made?

Micro computer drives two Geard DC motors that connected two tires.

Rotary encoder detect rotation of tires. It connect to Micro computer.

What processes will be used?

Making body : Computer-controlled machining

MakingPCB : embedded programming

MakingMotorDirver : Output devices

Making Shaft holder : 3D printing

What tasks need to be completed?

Making rotary encoders.

Makign body and tires.

Making running distance detect system by rotary encorders.

Making velocity control system of DC motor.

What questions need to be answered?

How to detect running distance?

How to design control terminal?

What is the schedule?

5/24 : Making rotary encoders

5/25 - 5/31 : Making dirve circuit

6/1 - 6/7 : Making body and tires.debugging.

How will it be evaluated?

It can move following my order.

It can start movement following my power switch.

Projects can be separate or joint, but need to show individual mastery of all of the skills

Skills what is used this project is 2D-CAD, 3D-CAD, electronics design, output device control.

I found lower product. It can follow-up a moving object in automatic.

This project is very interesting and similar with my project.

But my project don't have automatic tracking function. For shoot a movie, this function is not enough. Because, movie is expression. It can’t by machine.

Technique of layout of screen is very deep.

So, If we shooting cinema, camera should be moved by human intention.

Micro computer for calculate machine’s movement

Rotary encoder for detect machine’s speed

LED for indicate condition

acrylic T=3-5mm

PLA for 3D print

Gear box for Toy

Parts for tire

Micro computer : My FabLab

Rotary encoder : Internet shop "Akizuki

LED : My FabLab

acrylic T=3-5mm : DIY ceter

PLA for 3D print : My FabLab

Gear box for Toy : DIY ceter

Tire parts : DIY ceter

Micro computer :500JPY x2

Rotary encoder : 500JPY x2

LED : 50JPY*4

acrylic T=3-5mm : 1000JPY

PLA for 3D print : 1000JPY

Gear box for Toy : 800JPY x2

Tire parts : 500JPY

Rotary encoder detect rotation of tires. It connect to Micro computer.

MakingPCB : embedded programming

MakingMotorDirver : Output devices

Making Shaft holder : 3D printing

Makign body and tires.

Making running distance detect system by rotary encorders.

Making velocity control system of DC motor.

How to design control terminal?

5/25 - 5/31 : Making dirve circuit

6/1 - 6/7 : Making body and tires.debugging.

It can start movement following my power switch.