Assignment Week12

Composites

This week’s assignment is "Design and make a 3D mold (~ft2), and produce a fiber composite part in it”.

I tried to make motorcycle fuel tank that made with FRP.

Making 3D mold

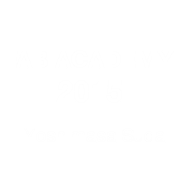

First I make 3D data of tank using Rhinoceros.

Tank's shape has flat surface and curved surface.

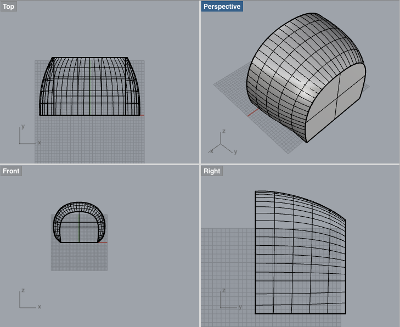

Next, I put cuboid block data over tank's shape.

And, make female die's shape using boolean subtraction command of Rhinoceros.

Female die's data can download here.

Next, I challenged to make the "female die" that be made with MDF.

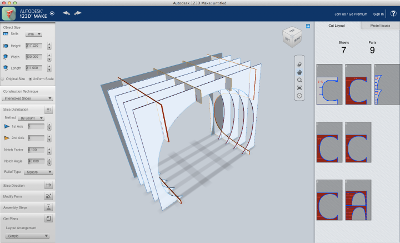

I used "123D Make" This software can translate 3D data to Press-fit construction.

We can download it here.

.

I import female die data and setting information.

Laser cutter setting

MDF size : T2.5Feed : 10mm/sec

Power : 30%

It can download here.

.

Press-fit construction have many many chinks. So I infill it with clay and stick aluminum sheets inside of female die.

Make FRP Parts

I make FRP parts using my mold.

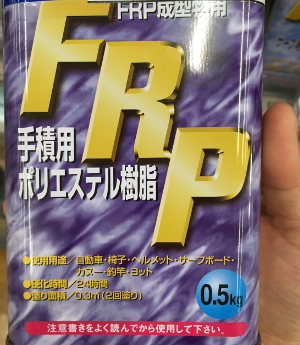

FRP made by 2 kind of synthetic resin and glass fiber sheet.

Grass fiber

2. Mix 2 synthetic resin liquid as fixed rate.

I used polyester resin, and curative agent.

5. Break female die, and scratch clay and aluminum sheets.

Complete!!