Assignment Week3

Computer-Controlled Cutting

This week's final project is "design, make, and document a press-fit construction kit"

My snap fit is ,coffee draper holder.

I was inspired this stuff.

I like drip coffee making by hand. It is meditation time for me.

But I don’t like wash own dish, cup, and coffee dripper

likethis.

Design

First, I have sketched on the notebook and decide some dimensions of stuff.

I designed base parts and pillar parts by my hand.

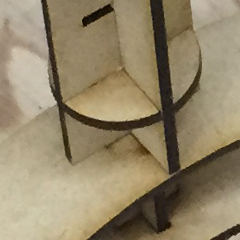

Base parts is constructed of 2 base plates that like “C” shape, and base plate connector that constructed of 2 parts.

Pillar part is constructed of one main spine parts, 2 sub spine parts, and many rib parts.

Using Inkscape

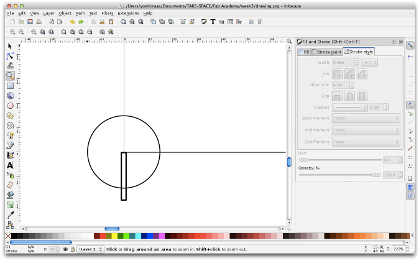

Next, I used inkscape and drew rectangle and circle.

Inkscape have shape command that can draw circles and rectangles and “convert selected object to path”command.

If shape data convert to path data we can change more detail of shape data.

And input each other nodes place.

Circle and rectangle

When i make press-fit part of each other parts, I use rectangle and "menu bar> path> difference “ commands.

Then, parts data and rectangle make cutout for press-fit.

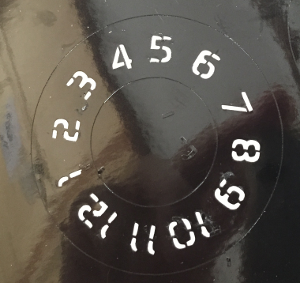

When I need to copy shapes, "menu bar>clone” command. This command can clone shapes along line or circle.

There are complete data. eps and svg.

Laser-Cutting

Next I prepare laser cutter.

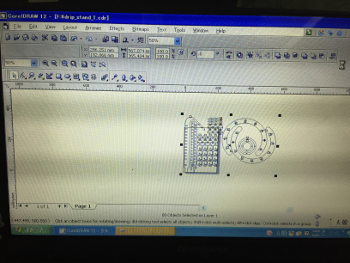

laser cutter system is the set of laser cutter and PC. PC software “corel draw" can manipulate laser cutter.

when I move Inkscape data that I want to cut, I need to convert data format .svg to .eps.

I save .eps data in USB memory, and read in corel draw.

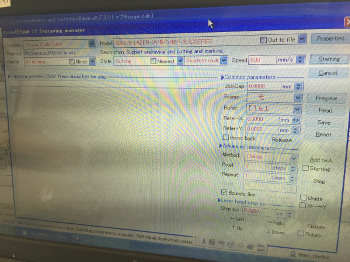

next, select data that want to cut, and crick “cut” button. Then appear “cutting-layout window”.

Cutting-layout window can set start point of cut material, and moving speed.

At manipulate panel of laser cutter , we can set laser power.

Laser power and laser speed is key parameter. This parameter need to be set for each other kind of materials.

Laser cutter setting

MDF size : T2.5Feed : 9mm/sec

Power : 32%

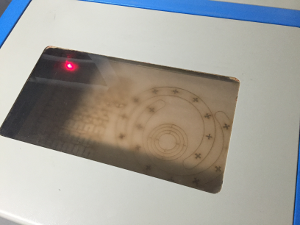

Cutting

Laser lighting is very dangerous.So we must wear safety goggle for Laser.

Done. Let's construct.

complete!

Taste is so so. Because, water fall speed was very fast, so coffee powder hadn’t been steamed.

UPDATE!! : Using vinyl cutter

I used vinyl cutter for Final Project.