5. 3D Scanning and Printing

Design and 3D print and object that could not be made subtractively, 3D scan an object

|

|

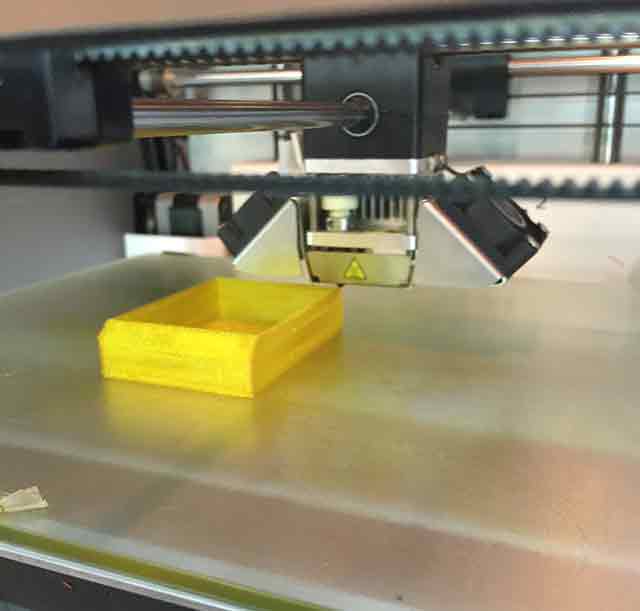

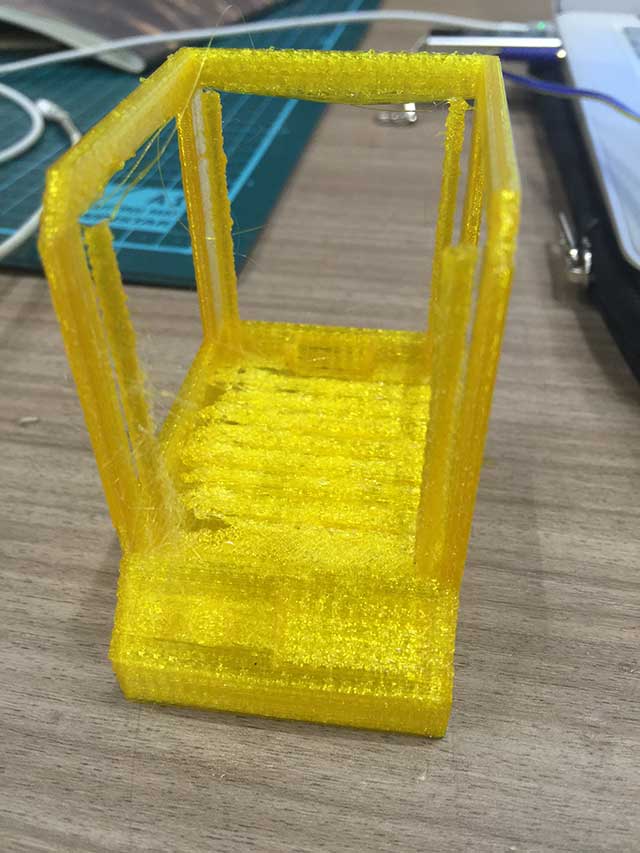

Starting the bottom layer |

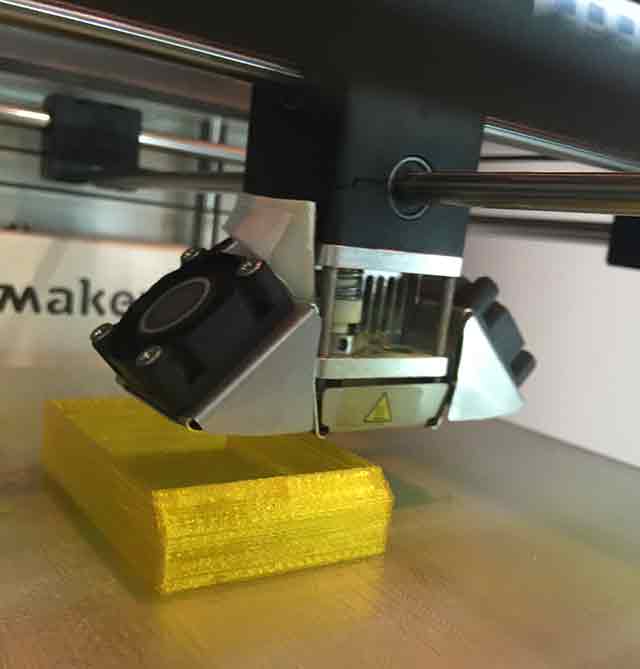

Side view of angle section(front panel) |

|

|

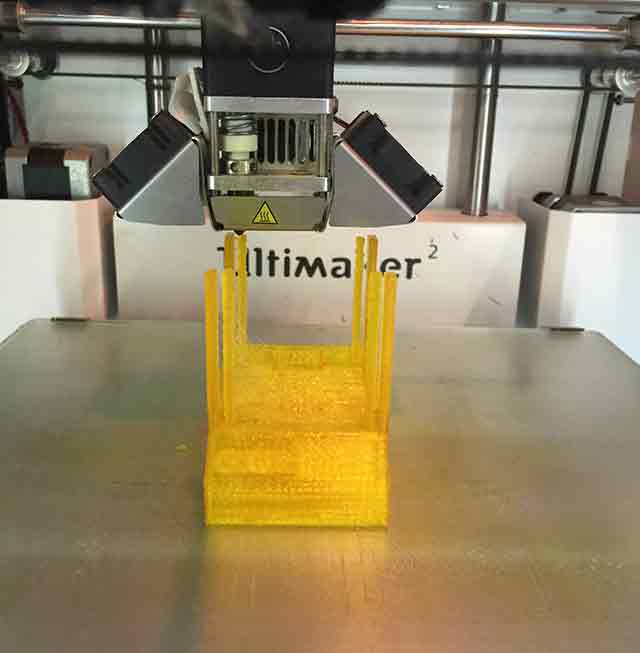

FRONT VIEW OF OUTPUT |

CLOSE VIEW OF OUTPUT |

|

|

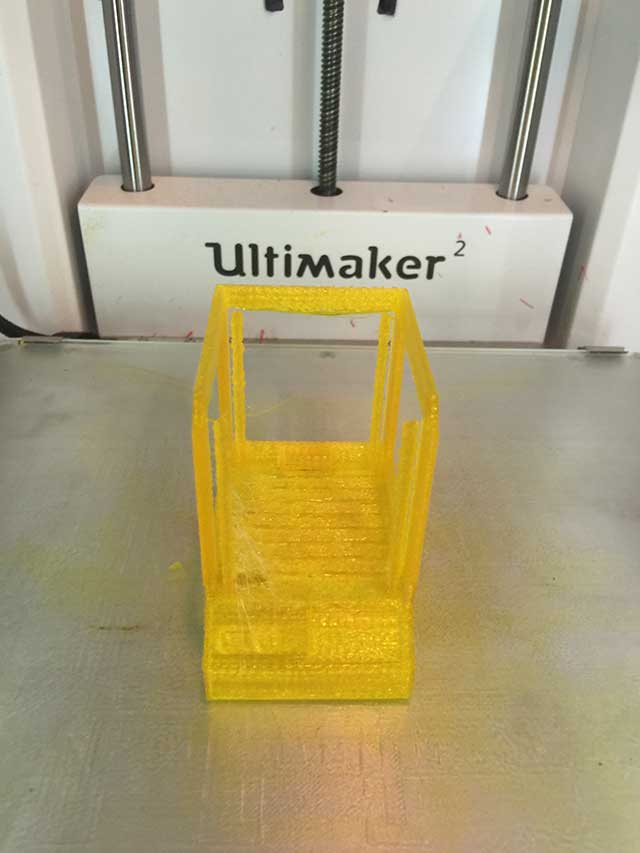

FINISHED 3D PRINTING |

CLOSER VIEW OF 3D PRINT |

I exported my design from 123D design of my final project ‘MYM’ which is an entertainment box. I tried to use without supporters.

with layer height 0.2 mm, print speed 80 mm/s, shell thickess of 20% I used the machine ‘Ultimaker’ which was very well maintained in FabLab Seoul at the moment. For addition I learned how to print and change settings for Makerbot 3D printers and XYZ printers.

3D modeling for final project

: middle piece done by looking at the reference of Robert Garitart from Fab Academy 2014.

with the radius of 7.5 it’s waiting for the steel rod to be in charge of core XY movement.

: Top pieces are going to holding the servo and therefore must be getting an exact distance of motor size.

: bearing was later on going to be use as essential part for controlling movement.

: I have tried diffrent kind of printers and this kind of guided me into how to treat material and how the software program is run

3D Printer I’ve tried

XYZ printing company : Davinci 1.0

Very good indeed, even with slower speed I think because it's working inside like a chamber system the extruder get steady heat and therefore get good result. The only bad point i found was It took a lot of time for slicing. Then, I realized that it was caused by my stl files that have several faces or internal edges that is very hard to be recognized by the program

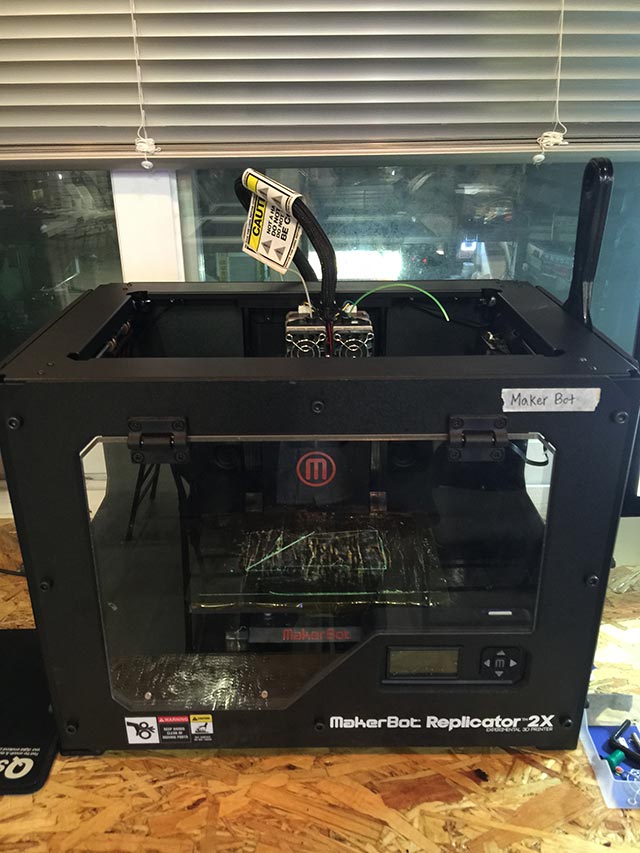

Makerbot : Replicator 2X ( only one extruder, left extruder always not in good shape)

: This printer only could build small parts such as rings or bearings. any more than that size the raft seems to be unstablized and makes a whole mess.

Ultimaker : Seems alright with most of the efforts but without watching carefully at the printer sometimes lead to a disaster with filament stucking and extruder not working properly

Almond : The heating bed system for Almond is not very well with our Fab Lab as the heating temperature of the board only goes up to 90.

3D Scanning

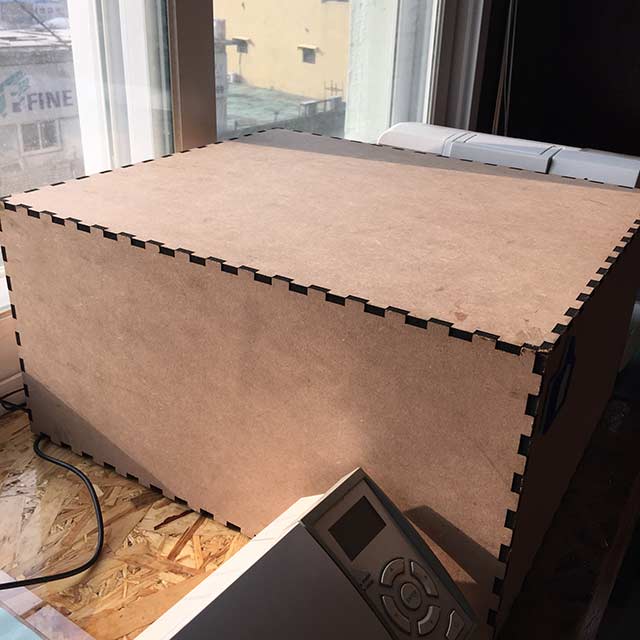

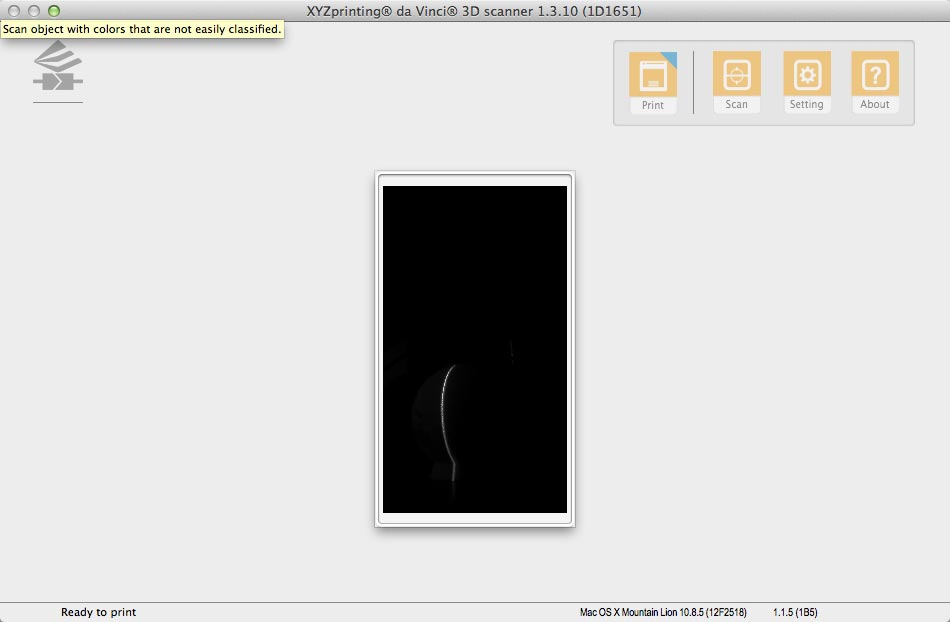

It was pity that one of our kinect the 3D scanner was not in good shape to be used and I had to use the second option which is ‘Makerbot Digitizer’ the thing about the 3D scanner is that It’s not quite getting the image that I want and there are too many variables that make variation in object surfaces. In FabLab Seoul, we use laser-cut box made out of MDF to cover light for the moveject. As for doing this we don’t get blurry image behind |

|

MDF COVER |

MAKERBOT DIGITIZER NOT WORKING |

|

|

XYZ SCAN INTERFACE |

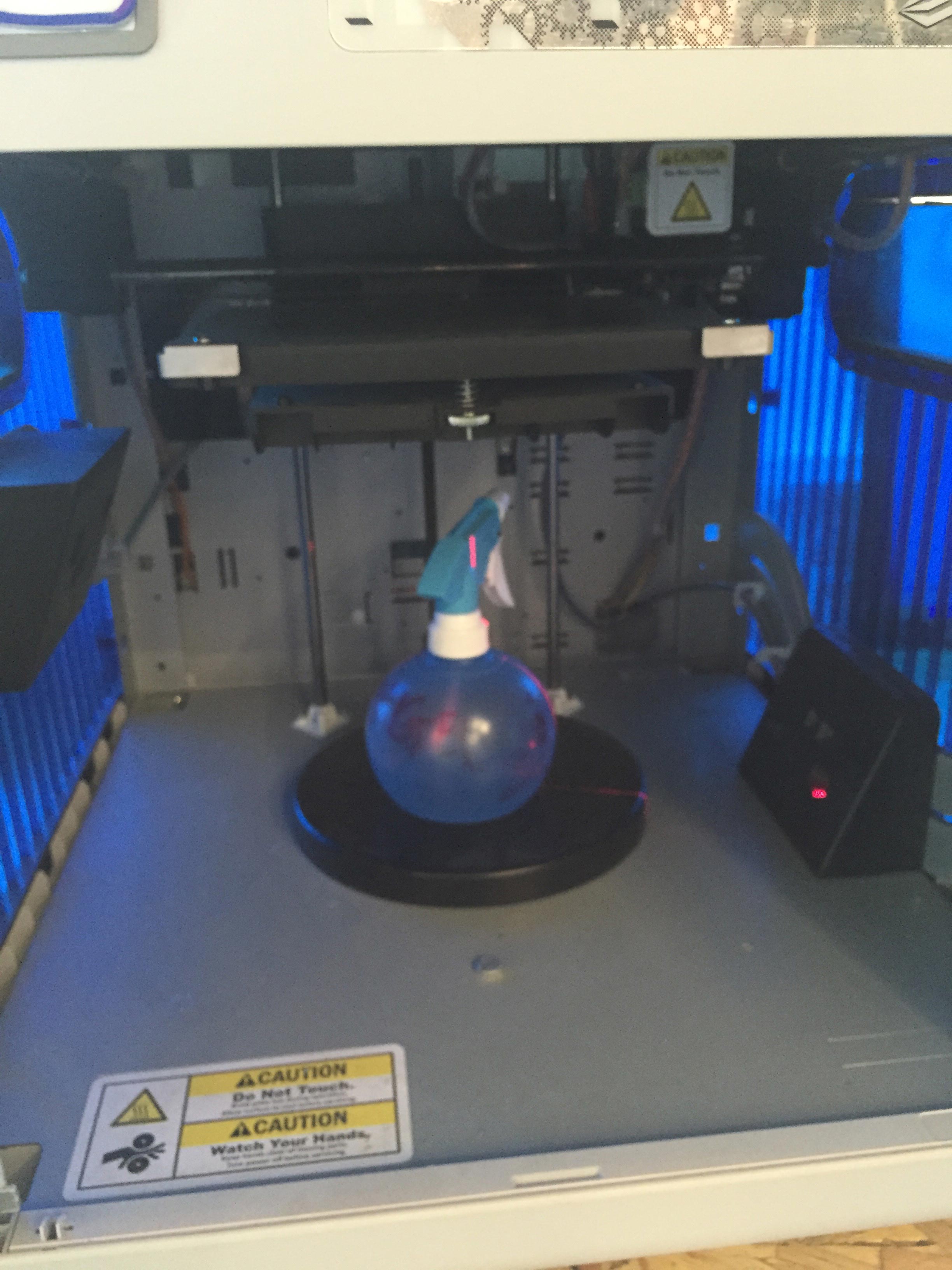

3D SCAN OBJECT ON BED |

|

|

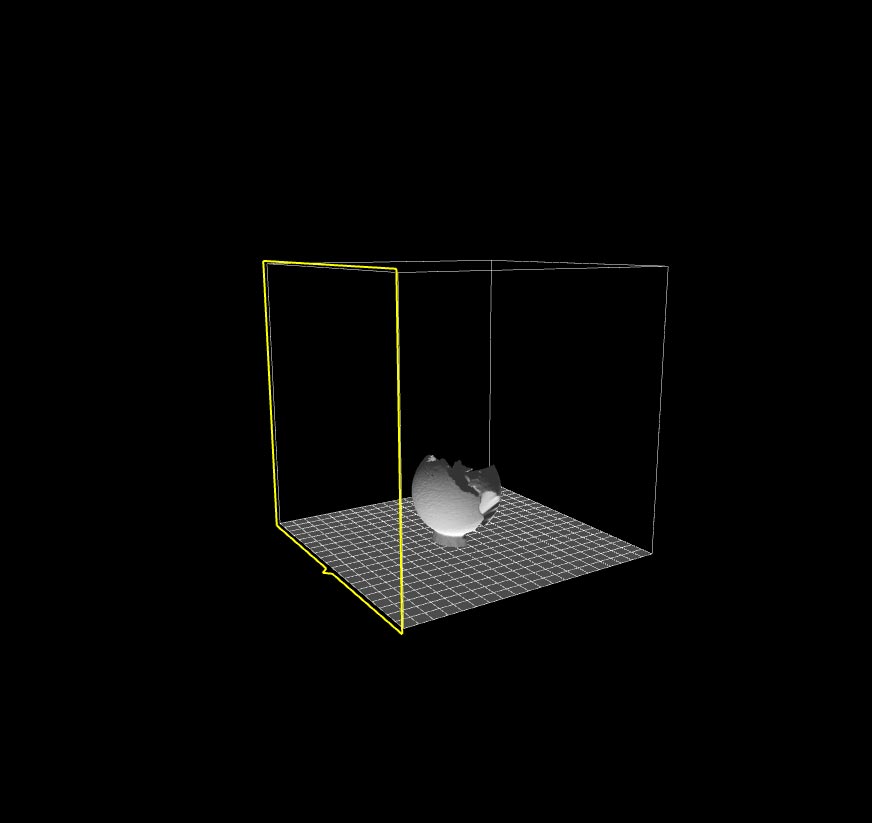

3D SCANNING OUTPUT |

GLOBE SCAN |

After serveral trial with 3D scanner I've managed to scan the file and I've noticed that the transparent object doensn't scan well. I've noticed in my stl file that only the top part of the plastic is scanned. With another scanning object (double-coloured globe) I've managed to make the outer layer of a globe and I'm quite satisfied with the work.

What i learned...

For this week assignment, I've managed to work all different kinds of machines that FabLab Seoul has, furthermore I got lucky to work and basically the whole idea of 3D printed output is that normally the infill of an object is 10~20% is more than enough and for special cases, like for my final project stepper motor gear it is printed with 50% infill so that It can withhold the torque of a stepper motor.

I used these machines ...

|

|

|

|

XYZ DAVINCHI 1.0 |

MAKERBOT REPLICATOR2X |

ULTIMAKER2 |

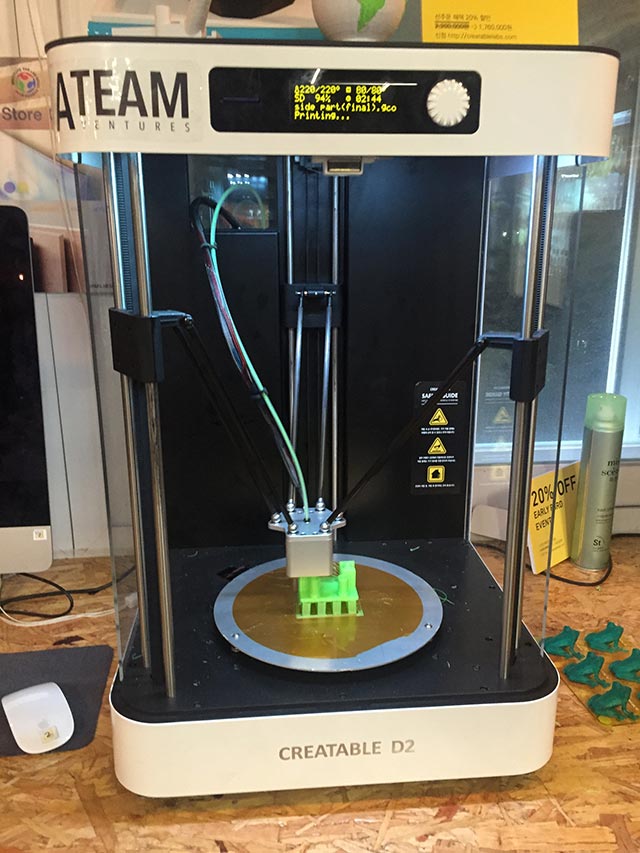

CREATABLE D2 |

Since my final project Selfie your Watie needed lots of 3D printed output as components. I've fully managed to use all the machines. The last printer which is Creatable D2 was made very recently and I've never used the DELTA ARM type printer so it was good to try with new mechanism. Other than normal axes moving type printer the DELTA-ARM type does need some setting of making sure that the extruder doesn't move fast. The printer itself is very fast along the workspace so therefore, It was normally 20m/s for me to use the DELTA-ARM type machine.