{ Fab Academy 2015 : Koichi Shiraishi }

{ Home } { Final project } { Class } { Fab Academy }

- Week 12: Composites -

Weekly Assignment

- design and make a 3D mold (~ft2), and produce a fiber composite part in it

1: Concept

I tried to make “Taiyaki” by FRP. Challenging point is using sponge within layer.

About "Taiyaki"

“Teriyaki” is a japanese sweets what a fish‐shaped pancake filled with bean jam. It bakes with a mould imitated fish.

2: Making test piece

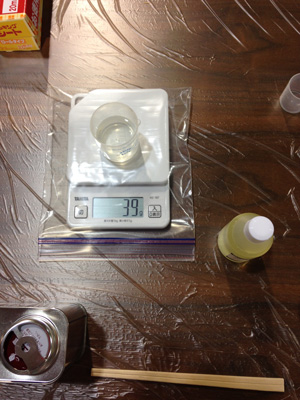

I used a epoxy resin in this time.

To scale a hardener with extreme care.

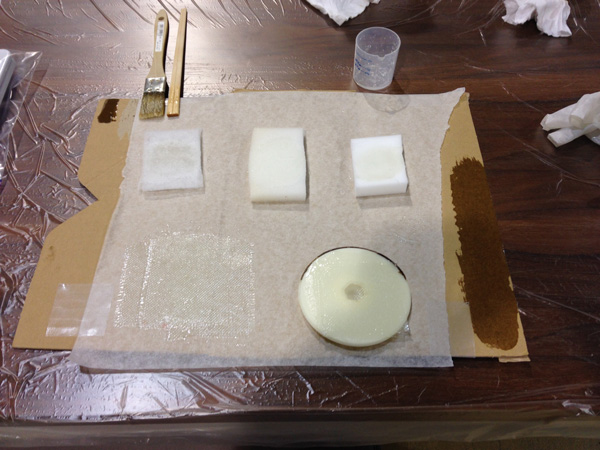

I apply a wax for easing form removal.

To use a brush to apply a resin.

Results

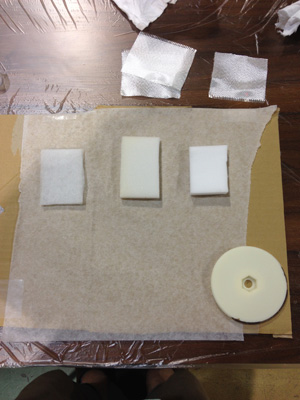

1: sponge(urethane foam)

it takes many resin. Hardening has no problem.

2: Sponge(melamine)

Almost the same results of urethane foam. It turned yellow little bit.

3: Glass cloth

I check strength three case.(1 ply to 3 ply) I decided 2 ply in this case.

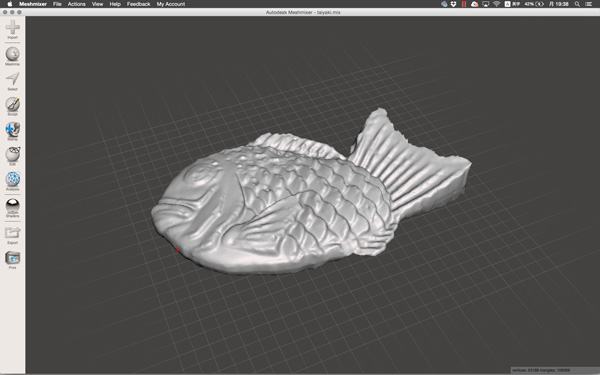

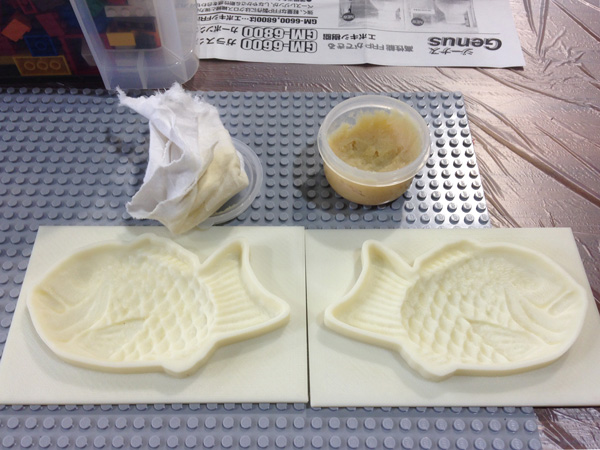

3: Scaning and Modeling

To scan a “teriyaki”. and print.

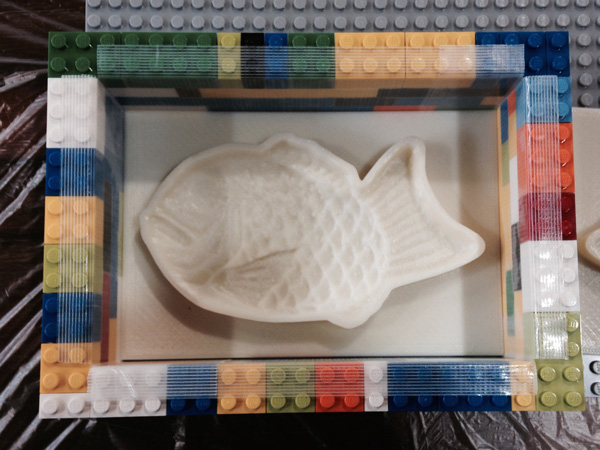

To build a frame by LEGO lest a moulds slip out of place.

Printed file

4: layup

To apply a resin to mould’s surface.

To ply clothes, and then ply a sponge.

To engage tow parts with extreme care, and the vacuum pack a mould.

Hardening whole night, after then I demold a model.

Results

This methods is not good. Casting is better than composites when a model is thickly.

Using 3D printed mould is hard to demold. Because a resin infiltrate mould.

Consequently, My “Taiyaki” came off a surface.

Second challenge

I tried to make molds for a final project part(lamp hood) by machinable wax. However It was not enough to form a block. Therefore I tried to mill a 3D printed mold coated with thin wax.

As a first process, I made a mold for mold by 3D printer. After the finished printing, I coated a 3D model with wax. The wax thickness target was about 3mm.

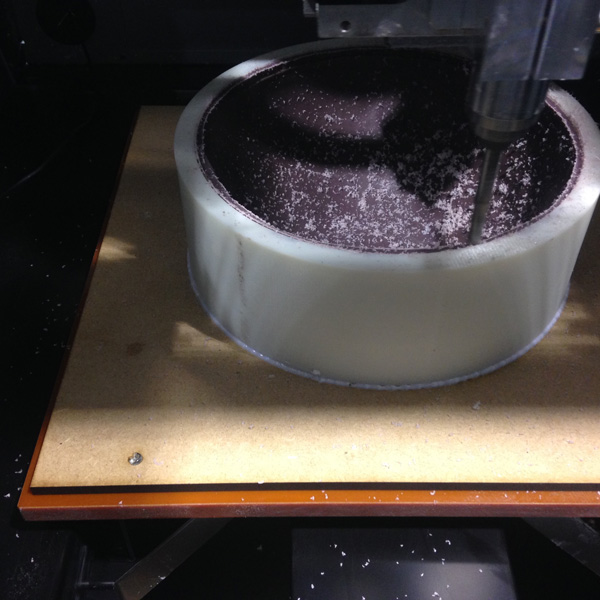

1,Milled the complex mold

I used a “MDX-40A” to mill the complex mold with “SRP player.” The working process was only finishing. (I did not appended a Roughing process.)

| Tool | Feed speed | Spindle speed | Machining time |

|---|---|---|---|

| R1.5mm ball endmill(2 flute) | 1200mm/min | 5000rpm | about 8h/part |

Milling files

Mold stl(positive)Mold stl(negative)

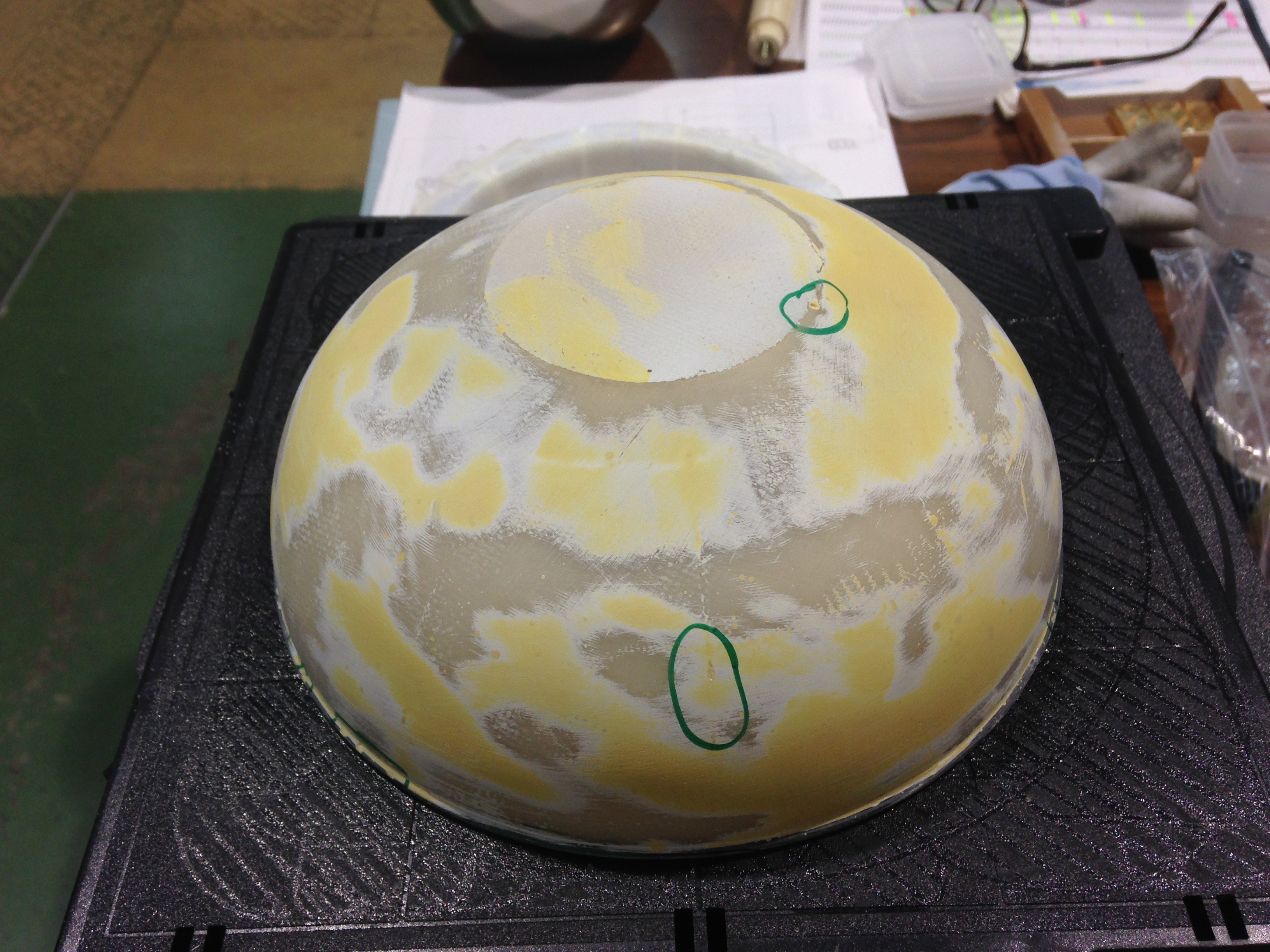

Result

he result had minor faults. The mold bare a 3D model part. Because I failed to set a origin. I decided to use it covered with parting agent.

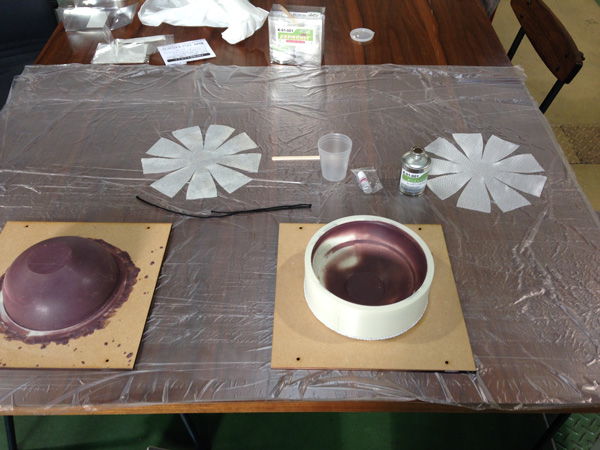

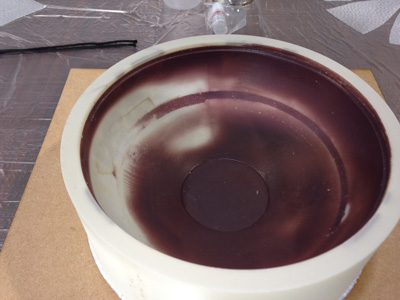

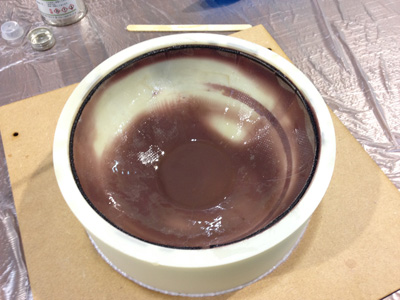

2,Laid up a FRP

I use a unsaturated polyester with glass cloth on negative mold. (2 ply) I made a divide surface program by grasshopper. After baked line I cut glass clothes by laser was set following parameters.

| Laser type | Power | Speed | Hz | passes |

|---|---|---|---|---|

| Cutting CO2 laser | 70 | 1.5 | 1000 | 1 |

trotec speedy 100 flexx CO2 laser 60W

The resin hardened quick. Because the working day was too hot temperature. Therefore I had to work without delay. I impregnated a enough resin. After then I covered by positive mold.

3,Demould

I broke a mold. Because baring parts clung a FRP model. I think a ABS was melted by binder of resin.

Result

It is very smoothly surface! It mixed several air. However It was not big problem.

4,Coated by a poly putty,sanded a model

I coated by a polyester putty, after several hours I sanded it. I did the process again to again.